FW

The Egyptian minister of trade and industry Nevine Gamea has revealed the government plans to manufacture around 30 million cloth masks a month to meet local demands. Production of masks will begin in the next few days, with 8 million fabric masks to be manufactured in the first phase. These will be supplied to the Authority for Unified Procurement, Medical Supply and Technology Management (AUPP), who in turn will provide them to state agencies.

As per the government, this project will offer the domestic industry an opportunity to become a major centre for fabric mask manufacturing, especially in light of the increasing global demand for these types of masks. The raw materials needed for manufacturing of these masks are already available in the country.

The Micro, Small and Medium Enterprise Development Agency (MSMEDA) of the government have also prepared an inventory of small textile and garment factories that it has funded since 2015. The ministry aims to link these factories with large ones as part of the value chains in this industry, which contributes to maximizing the benefit from these production capacities and then maintaining existing labor in these factories.

S&P Global says as soon as restrictions are eased and economies open, retailers will have to rapidly transcend their selling process, their relationships with customers and also make changes to their assortment, supply chains, store bases and store configuration.

One of the biggest challenges for retailers will be to invest and fund this transformation while dealing not only with the pandemic but the accelerated digital disruption most of the sector has endured in recent years. They will have to integrate their supply chains, warehousing, distribution, and stores into a cohesive unit to offer a seamless ‘phygital’ (physical-digital) experience. At the same time, they will need to rethink their strategies aimed at differentiated shopping experiences at stores, given physical restrictions.

Retailers will also have to drastically reduce their cost base, as the pandemic will lead to higher costs and investments in cleaning, hygiene, and health and safety measures to protect employees and customers. This, coupled with physical distancing, will weigh on profitability in the near term, it added. However, the company expects these costs to gradually blend into the industry's cost structure.

Though it might take over a year for the US economy to reach pre-COVID-19 levels, apparel sales may see a quicker recovery. This can be especially estimated from the high visitor turnouts at recently opened clothing stores. As per latest data from Placer.ai, in year-over-year data comparisons, apparel sales in the US during the week of May 11 fared slightly better with apparel sales declining 71.8 per cent as against the 87 per cent decline in week ending May 4.

Though it might take over a year for the US economy to reach pre-COVID-19 levels, apparel sales may see a quicker recovery. This can be especially estimated from the high visitor turnouts at recently opened clothing stores. As per latest data from Placer.ai, in year-over-year data comparisons, apparel sales in the US during the week of May 11 fared slightly better with apparel sales declining 71.8 per cent as against the 87 per cent decline in week ending May 4.

During this period, apparel traffic in Florida improved the most. Traffic in this region improved from a decline of 87 percent year-over-year for the week of May 4 to a decline of just 55 percent for the week of May 11. A similar trend was noted in Georgia where traffic improved from a 75 per cent year-over-year decline for the week of May 4 to just 23 per cent decline a week later. A clear indication US retail economy is on recovery path. However, this revival is full of challenges, believes, Ethan Chernofsy, Marketing Vice President, Placer.ai

Financial concerns, rising inflation worry consumers

One of the challenges that the retail sector faces is financial uncertainty that consumers face today. As per Deloitte Global State of the Consumer Tracker, which polls 1,000 consumers in 15 countries, around 27 per cent consumers are anxious about making upcoming payments while 43 per cent are putting off large purchases. Around 37 per cent fear losing their jobs. According to the survey, the percentage of US consumers visiting stores also increased to 42 per cent in May as against 30 per cent in April. On the other hand, the number of online shoppers is gradually falling, particularly for apparel and electronics. The Deloitte survey reveals that while 82 per cent of Americans plan to “buy online, pickup in store” in the next four weeks, only 40 per cent plan to use this service for safety reasons, down from 48 per cent.

consumers in 15 countries, around 27 per cent consumers are anxious about making upcoming payments while 43 per cent are putting off large purchases. Around 37 per cent fear losing their jobs. According to the survey, the percentage of US consumers visiting stores also increased to 42 per cent in May as against 30 per cent in April. On the other hand, the number of online shoppers is gradually falling, particularly for apparel and electronics. The Deloitte survey reveals that while 82 per cent of Americans plan to “buy online, pickup in store” in the next four weeks, only 40 per cent plan to use this service for safety reasons, down from 48 per cent.

Though consumer confidence appears to have stabilized, they remain concerned about their financial prospects. Rising inflation rates continue to diminish their purchasing power and curtail spending. Beth Ann Bovino, Global US Chief Economist for credit ratings firm S&P, believes retail recovery in the US could stretch to 2021 and beyond and hopes businesses reopen and recall furloughed or laid-off employees by this period.

Two years to road to recovery

Politicians in the US continue to struggle in balancing public health and economic vigor. How long will it take for the economy to recover to r the level it was prior to the COVID-19 outbreak remains a topic of debate. Though analyst believe markets will eventually recover from today’s Great-Depression-esque unemployment levels, the economy to emerge out of this crisis will be different, believes David Rubenstein, Cofounder and Co-executive Chairman of private equity firm The Carlyle Group. He expects another stimulus bill or bailout from the American government next month.

Prior to the pandemic, America was expected to reelect President Trump later this year. However, now the country’s state of the economy will determine who will be the next leader. Whatever, the outcome of the election, the next elected government can’t afford to wait even for a month to restart economy. It will have to start from day one itself.

The luxury fashion industry is in the middle of a transformation as fashion designers, executives and retailers are trying to reset the fashion calendar. Earlier this month, Belgian designer Dries Van Noten and others urged designers to not only adjust the seasonality and flow of their women’s wear and menswear collections but also limit discounts at the end of the season.

The luxury fashion industry is in the middle of a transformation as fashion designers, executives and retailers are trying to reset the fashion calendar. Earlier this month, Belgian designer Dries Van Noten and others urged designers to not only adjust the seasonality and flow of their women’s wear and menswear collections but also limit discounts at the end of the season.

They also urged designers to reduce the number of clothes being manufactured, engage in less travel, make use of digital showrooms in addition to personal creative interactions, and review and adapt fashion shows.

Addressing overproduction with periodic drops of collections

Calls for change continue to gain steam within the industry though it is not clear what their outcomes might be. On one hand, luxury and high fashion brands may reduce the

collection size and simplify their business models to meet heightened consumer demands for a more sustainable future. On the other hand, they may opt for smaller drops of products on a more regular basis.

Adopting the first solution may enable them to replace their usual trend-specific creations in favor of fewer offerings. And the second solution may enable them to sell in relatively mass capacity with reduced emphasis on wasteful elements such as excessive runway shows. Though there are greater chance of brands opting for the first solution as it enables them to address the problem of overproduction of garments and accessories that plagues the fashion industry and results in discounting and/or product destruction, particularly as the latter becomes increasingly problematic for brands both socially and legally.

Opting for a more sustainable structure

At the same time, luxe brands may not completely abandon the regular drop model as it helps them to boost revenues and meet shareholder expectations. Brands like LVMH and Kering may instead, adopt a more environmentally and socially sustainable structure and align the newly-released initiatives with customers’ needs. How much of these efforts to address the inherently wasteful and unsustainable elements of the fashion industry play out, needs to be seen.

Primark plans to reopen its shops in England from June 15. Sales at its recenretly reopened stores elsewhere have been encouraging”.

Primark stores globally started closing from 11 March, leading to that £650 million-a-month lost sales figure. The company cut costs to counteract these losses and also cancelled some forward orders but the key contributors to its reduction in overheads were the government employment retention schemes across Europe.

The company has been able to reopen 112 stores recently and now plans to open all its English stores with social distancing protocols and hygiene measures in place. Unlike some other retailers that are taking a phased approach, Primark is confident that it can handle this as it's learnt a lot from its European reopenings, although it’s waiting for further guidance for the stores in Northern Ireland, Wales and Scotland and anticipates openings in late June.

By 15 June, it will also open three new stores that were originally planned for earlier debuts. They include Mons in Belgium and Gropius in Berlin, Germany that have already opened, while a store in Manchester’s Trafford Centre in the UK will open on 15 June.

Gas Jeans is launching a series of retail projects to help the brand further expand. The Italian jeans specialist has just opened its first temporary store inside Roma Termini railway station and will open a few more all over Italy in the coming months.

The plan includes four more new openings, in Turin’s Porta Nuova Station and Florence’s Santa Maria Novella in January 2021, Naples Central Station in April 2021 and Milan Central Station in July 2021.

The new Gas Rome store will be visited by a significant number of visitors as the location, hosted within a shopping mall, counted 160 million visitors in pre-Covid-19 times, including residents, and counted up to 50,000 passages during the lockdown.

Gas is also involved in reopening its stores all over Italy. In the Italian Peninsula it counts a total of 32 doors: two monobrand stores, 18 concessions and 12 outlets. It will also reopen its 27 stores in Hungary, including five in Budapest, and eight doors in Czech Republic.

Ray Kelvin, the founder of troubled fashion brand Ted Baker has backed a plan to raise £95 million to avoid seeing his majority shareholding being wiped out.

The 75p-a-share raising, advised on by Goldman Sachs and Liberum, represents a deep discount to Friday’s 153.3p closing price. The shares, down 90 per cent over the last year, fell a further 10 per cent to 137p, valuing Ted at just £62 million.

The funds will be used to cut debts and help the company through the Covid crisis, with all of its 201 stores closed until at least June 15. They would allow it to invest behind its inherent strengths, which it said were a strong brand and diverse distribution via its own shops, wholesaling and licensing, as well as its wide product ranges and wide geographical spread.

Japanese sports fashion brand Descente has decided to integrate its 47 independent ‘Young Athlete’ outlets exclusively dedicated to kidswear in major department stores and malls in South Korea with its general stores.

The Japanese company entered the Korean market in 2000 and launched the ‘Young Athlete’ brand in August 2016 and opened exclusive stores for kidswear in 2018.

But the company began facing unexpected setback last year when the anti-Japanese sentiment over Seoul and Tokyo’s conflicts led to Korean consumers’ boycott movement against Japanese goods and services.

Other Japanese fashion labels are also having a hard time in the country with a double whammy from the COVID-19 shutdowns. GU, a budget brand under Japanese fast-fashion giant Uniqlo, said recently that it would pull out all of the three offline stores, in just less than two years since it was launched in Korea in September 2018. Uniqlo also shuttered 13 outlets from February to May, bringing down the number of stores in Korea from 188 to 175 as of May 29.

Copenhagen Fashion Week, CIFF, Revolver, Dansk Fashion & Textile (DM&T) and Wear have jointly decided to postpone Copenhagen fashion events to one week later than initially planned.

The events will now be held from August 09-12. One extra day will be added to the schedule in order to make also the visit of the trade shows as smooth as possible for both brands and visitors and at the same time meet regulations.

CIFF will host its CIFF Showrooms Order Days from August 2-14, giving buyers individual access to several brands located on the first and second floor.

Revolver is planning to offer a Plug and Play solution and deliver all brands the same design of rails, tables, chairs, shelves and signs. This way, the organizers want to reduce cost to a minimum for exhibitors. Booth sizes will still vary though.

Revolver will also present new digital initiatives: One is a digital calendar system that in combination with Revolver’s registration site, shall help both the trade show and the brands to control flow and traffic and also ensure that Revolver complies with any restrictions on the amount of assembly.

Proving to be silver lining amongst the dark clouds, Facebook Inc recently announced an investment of $5.7 billion into India’s largest telecom company, Reliance Jio, instantly valuing Jio to being among the top five companies in India.

Proving to be silver lining amongst the dark clouds, Facebook Inc recently announced an investment of $5.7 billion into India’s largest telecom company, Reliance Jio, instantly valuing Jio to being among the top five companies in India.

According to the Harvard Business Review, though this deal is largely digitally driven, the year 2020 could mark an inflection point in the bilateral trade of goods between the United States and India. As Ajay Sahai, Director General and CEO of Federation of Indian Exporters believes, India being a bigger market than Vietnam or Cambodia could be a bigger draw for investors looking to move operations out of China. However, to achieve this, the country first needs to guarantee that its government will not introduce retrospective tax amendments.

A few states including Maharashtra have already ensured the functionality of their supply chains for foreign manufacturers through India’s national virus lockdown. Others like Tamil Nadu in the south and Uttar Pradesh in the north have offered concessions for those planning to move.

Mukesh Aghi, CEO, US-India Strategic Partnership Forum, a trade group India also proves to be a perfect alternative for the US as it has a large English speaking workforce,  highly skilled, the cost of labor in the country is cheap and the country is a growing market of 1.3 billion people whose disposable income is growing.

highly skilled, the cost of labor in the country is cheap and the country is a growing market of 1.3 billion people whose disposable income is growing.

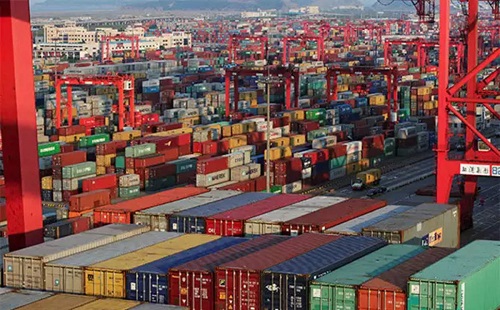

Pressure on companies to decouple from China

The Harvard Business Review report reveals COVID-19 has hit supply chains of companies in US, Canada, Europe, and Australia leading to a disruption in the flow of materials from China. The CEOs of these companies have therefore asked their supply chain teams to develop additional sources that are completely independent of China. There is also a pressure from employees in the US who are wary of traveling to China and from customers who are concerned about the safety of foods and other items from the country. Even investors are worried about the country’s over-dependence on any one country, and are increasingly pressurizing companies to rapidly decouple from China.

In a recent virtual meeting with the American Chamber of Commerce in India, Thomas Vajda, Deputy Assistant Secretary for South Asia told the Economic Times that India can quickly replace China as a favorable jurisdiction for more of industrial activities.

India emerges as the hot favorite

Besides, spices, textiles, apparel, jewelry, and handicrafts that India has been traditionally exporting to the US, it now also exports helicopter cabins like that of Marine One, which was fabricated for Lockheed Martin’s Sikorsky unit in India. Besides, NASA’s Jet Propulsion Laboratory in Pasadena, California is collaborating with the Indian Space Research Organization on the most expensive imaging satellite ever to be launched. This probe will be built and launched in India and will study hazards and global environmental change more accurately than ever before.

India also plans to export Apple iPhones built in India. According to USIBC, India can supply medical devices, energy efficient green transportation, power semiconductors, switches, and rectifiers for American needs. India already provides almost 40 percent of the generic drugs sold in the United States, produced at factories inspected and approved by the US Food and Drug Administration

Stats from India’s Ministry of Commerce shows, Indian companies already export billions of dollars each in categories like furniture, medical and surgical instruments, electrical machinery, ships and boats, vehicles, boilers, parts made of plastic, steel and aluminum, organic and inorganic chemicals and more. American companies can source these goods from their Indian corporate counterparts.

India is seeking to lure US businesses, including medical devices giant Abbott Laboratories, to relocate from China. In April this year, the government reached out to more than 1,000 companies in the US and offered them incentives to move out of China. It is currently focusing on medical equipment suppliers, food processing units, textiles, and leather and auto part makers.