China’s textile industry has turned to water conservation measures. There is a cap on water use and tough new controls on polluting industries. The textile dyeing and finishing industry is taking action in key areas, including adoption of upgraded technologies and a requirement for advanced water efficiency and wastewater reuse.

Progressive, innovative textile mills are embracing regulatory changes – using it as a means to separate their business from less reputable operators. As a first step, they are halving water and energy use by adopting dye innovations and process improvements. Promising innovations and developments are helping mills make dramatic savings without requiring investment in new plant or equipment. They are using eco-friendly dyes which compared to commodity dyes help mills reduce water consumption by up to 50 per cent.

Other simple changes like fixing leaks, installing sensors and water meters, and collecting the monsoon rains, can also pay big dividends. Stricter regulatory enforcement and growing consumer concerns mean that pollution will no longer pay in China and factories that are unable or unwilling to invest to meet the stringent new standards will no longer be viable. Environmental issues are now global, and few brands can afford to compromise their standards in the face of calls for greater supply chain transparency.

China gets tough on saving water

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

CMAI FAB Show 2024 wraps up successfully, boosting textile industry

The Fabrics, Accessories & Beyond Show 2024 (FAB Show 2024), organized by the Clothing Manufacturers Association of India (CMAI), concluded... Read more

US retail sales on the rise, but fashion sector growth murky

American consumers are opening their wallets again, with retail sales experiencing a modest uptick in recent months. According to the... Read more

The Fast Fashion Conundrum: Profits soaring, sustainability stalling

The story of Shein's soaring profits in 2023 presents a fascinating paradox. While a growing number of consumers, particularly millennials... Read more

Wall Street and the Seduction of Sexy Calvin Klein Ads: Hype or performance boos…

The recent Calvin Klein campaign featuring Jeremy Allen White in his skivvies has set the fashion world abuzz. But can... Read more

Looming Iran-Israel conflict threatens to unravel global apparel trade

The already fragile global garment industry faces fresh challenges as tensions escalate between Iran and Israel. This adds another layer... Read more

Fabric Stock Services: A rising trend but not a replacement

The fashion industry is notorious for waste. Unsold garments and excess fabric often end up in landfills. Fabric stock services... Read more

CMAI’s FAB Show 2024 inaugurated with industry giants

The 4th edition of the Fabrics Accessories & Beyond Show 2024 (FAB Show), hosted by the Clothing Manufacturers Association of... Read more

Asian Apparel Exports: A tale of four tigers, one lagging behind

The apparel industry in Asia presents a fascinating picture of contrasting fortunes. While Bangladesh, Vietnam, and Sri Lanka have seen... Read more

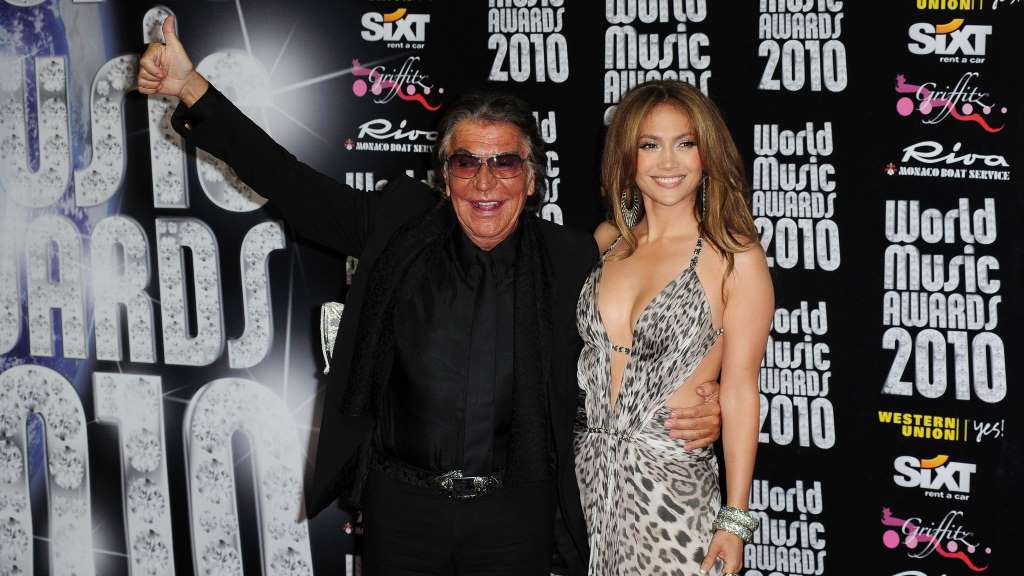

Roberto Cavalli: A legacy of bold prints and unbridled glamour

Roberto Cavalli, the iconic Italian designer who passed away on April 12, 2024, leaves behind a rich legacy. Cavalli was... Read more

Candiani & Madh unveil first regenerative cotton jeans

In a move towards sustainable fashion, Swedish denim brand Madh has partnered with Italian producer Candiani Denim to introduce the... Read more