The just concluded annual Global Fibre Conference in Dornbirn put forth a complex picture of the synthetic fibre industry. While the conference highlighted overcapacity and the economic fallout of current trade policies, it also showcased promising technical advancements in recycling and biobased fibres, hinting at a future shaped by innovation and sustainability.

A glut of synthetic fibres and economic disruptions

The opening session, dedicated to strategic issues, delivered a sobering assessment of the global market. Overcapacity in synthetic fibres remains a massive problem, with polyester (PIF) and nylon (NIF) production exceeding demand by almost 52 per cent and 29 per cent, respectively. Analysts say, at current growth rates, it would take until 2050 to absorb the existing capacity, suggesting that a sustained increase in prices is highly unlikely.

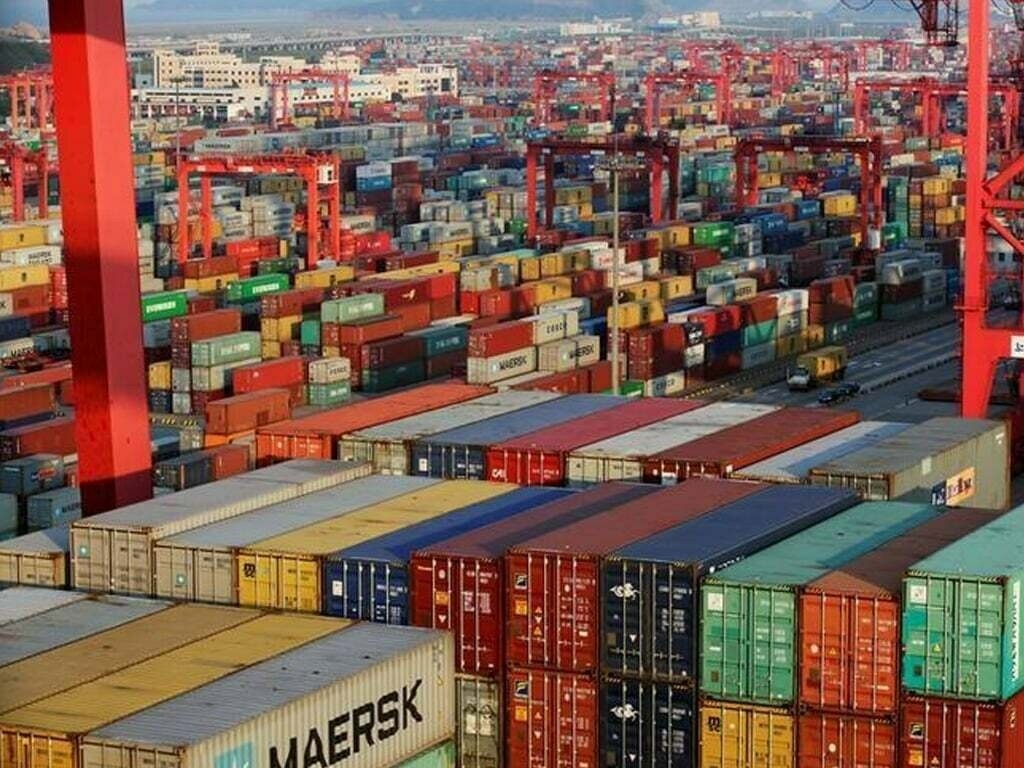

Adding to the market's woes, current US tariff policies are guaranteed to cause price hikes, particularly for American consumers, while also leading to widespread disruptions and supply chain shifts. For example, a recent Crisil Ratings analysis revealed Indian home textile manufacturers are bracing for a 5-10 per cent decline in revenue and a drop in operating profits due to the 50 per cent US tariff imposed on August 27.

The conference also raised concerns about global climate policies, with Prof Radermacher an expert, noting that the current approach of concentrating decarbonization efforts in industrialized nations is both costly and ineffective, underscoring a fundamental disconnect between environmentalism and sustainability.

Recycling vs. biobased, a race to scale

The technical sessions provided a more optimistic outlook, focusing on cutting-edge research in recycling and biobased fibres. Many players showcased their technical progress across all textile-to-textile recycling methods, mechanical, thermo-mechanical, chemical, and enzymatic. However, some hurdles remain before these technologies can achieve industrial scale. Challenges include a lack of sustained demand, an inability to compete on cost with virgin fibres, questions about total process yield, and a lack of common feedstock and recyclate standards.

A particularly hot topic was the future of bottle-to-fibre recycling. While it has been a common practice, the conference highlighted that it is now under pressure. The packaging industry, which uses one-third of global PET, is failing to meet its own recycling targets, creating competition for recycled PET (rPET). This competition, combined with the fact that two-thirds of all PET goes to fibre production, suggests that relying on bottles as a feedstock is not a sustainable, long-term solution. The textile industry will need to establish its own circular supply chain based on its own waste.

In contrast, biosynthetics emerged as a strong contender for a faster path to market. These "drop-in" solutions can be integrated into existing manufacturing processes, bypassing many of the challenges plaguing recycling, such as high capital expenditure and quality issues. They also boast of superior Life Cycle Assessment (LCA) values, particularly when compared to chemical recycling.

The conference focused on biobased textiles, including man-made cellulosics (MMCFs), which are highly versatile and use renewable feedstock. There was also a notable presence from the cotton and wool industries, challenging outdated myths about their environmental footprints. Overall, a major takeaway was the need to ensure that the inevitable volume growth of global fibre production is not exclusively absorbed by synthetics.

Innovations and future

Beyond the main sessions, the conference covered other critical topics, including microplastics (or fibre shedding), safe chemicals management, and new innovations for protection and defense markets. The diversity of topics and the opportunity for one-on-one discussions highlighted the event's role as a vital hub for industry knowledge.

The conference also celebrated the next generation of innovators, with a special shout-out to Ing Leonie Beek, was awarded the prestigious Paul Schlack Prize for her groundbreaking research on oil-absorbing biomimetic textiles. Beek, a researcher at the Institute of Textile Technology (ITA) at RWTH Aachen University, developed a "Bionic Oil Adsorber" (BOA) that can separate oil from water without external energy or chemicals, a technology inspired by the water fern Salvinia molesta. (Source: Dornbirn GFC, SciProfiles)

To sum up the Dornbirn Global Fibre Conference remains the premier venue for understanding the current state of the fibre industry and anticipating which innovations will be market-ready in the near future. While some presentations are highly technical, they are always framed within the context of market trends and sound industry logic, making it an essential event for anyone in the textile sector.