FW

"As Industry 4.0 is slowly making its place in manufacturing, retail diaspora too needs to catch up as it’s not an advantage, it’s a dire necessity. Today, digital transformation is not about speed and reduced time to market, it’s about efficiency, earlier validation, creating better products and, more importantly, the ability to focus on creativity and innovation. In short, there is a need for digital solution that will disrupt the entire supply chain. With shoppers turning towards online channels, brands and retailers are in the process of stepping-up their game in order to provide the goods. Added to that, ‘see now, buy now’ concept is forcing brands and retailers around the globe to not only adapt to a new digital reality, but also push towards an even more innovative environment that will allow them to compete in their market without wasting valuable resources."

As Industry 4.0 is slowly making its place in manufacturing, retail diaspora too needs to catch up as it’s not an advantage, it’s a dire necessity. Today, digital transformation is not about speed and reduced time to market, it’s about efficiency, earlier validation, creating better products and, more importantly, the ability to focus on creativity and innovation. In short, there is a need for digital solution that will disrupt the entire supply chain. With shoppers turning towards online channels, brands and retailers are in the process of stepping-up their game in order to provide the goods. Added to that, ‘see now, buy now’ concept is forcing brands and retailers around the globe to not only adapt to a new digital reality, but also push towards an even more innovative environment that will allow them to compete in their market without wasting valuable resources.

As Industry 4.0 is slowly making its place in manufacturing, retail diaspora too needs to catch up as it’s not an advantage, it’s a dire necessity. Today, digital transformation is not about speed and reduced time to market, it’s about efficiency, earlier validation, creating better products and, more importantly, the ability to focus on creativity and innovation. In short, there is a need for digital solution that will disrupt the entire supply chain. With shoppers turning towards online channels, brands and retailers are in the process of stepping-up their game in order to provide the goods. Added to that, ‘see now, buy now’ concept is forcing brands and retailers around the globe to not only adapt to a new digital reality, but also push towards an even more innovative environment that will allow them to compete in their market without wasting valuable resources.

3D technology at the back of everything

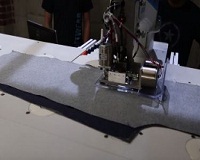

The real digital disruption started with the 3D technology as it has a 95 per cent accuracy rate and can enable the production of a digital sample that is similar in appearance to what a physical sample would look like. Photorealistic rendering, advanced fabric and texture properties, along with the ability to easily embed rigid parts such as buttons and trims, can allow decision makers to see how a garment will act and look without needing to create a physical sample. A recent study revealed apparel industry spends approximately $7 billion per year on samples alone. An extremely high financial cost in addition to the aspect of pure waste, which could easily be reduced by 75 per cent using 3D technology. The ability to finalize prototypes within hours instead of weeks, review collections within weeks instead of months, and change colours and graphics at a push of a button is revolutionising the way garments are being produced. Moreover, the way the entire supply chain functions.

similar in appearance to what a physical sample would look like. Photorealistic rendering, advanced fabric and texture properties, along with the ability to easily embed rigid parts such as buttons and trims, can allow decision makers to see how a garment will act and look without needing to create a physical sample. A recent study revealed apparel industry spends approximately $7 billion per year on samples alone. An extremely high financial cost in addition to the aspect of pure waste, which could easily be reduced by 75 per cent using 3D technology. The ability to finalize prototypes within hours instead of weeks, review collections within weeks instead of months, and change colours and graphics at a push of a button is revolutionising the way garments are being produced. Moreover, the way the entire supply chain functions.

3D technology was integrated through advanced plug-ins into existing tools such as in the case of Adobe Illustrator, whose 3D plug-in allows designers the freedom to validate and customize garments in 3D without abandoning the reliable graphics editor. Today, designers can visualize 3D garments with accurate proportion and scaling, customise the garment’s fabric, texture, print patterns and graphic placement without waiting for a printed sample, all by using a 3D plug-in that runs in the native design environment on a PC or a Mac. The use of technology led to reduced waste both of time and fabric as 3D technology enables brands to cut development time in half and reduce the use of physical samples by nearly 50 per cent, which further resulted in the massive reduction in ecological damages.

Newer dimensions of growth

Emerging technologies such as artificial intelligence, virtual reality and augmented reality are fast dominating the online sphere and personalise content for every single user. The fashion playing field is now more global than ever before. The only way to fully optimize the supply chain and focus on creativity, is by going digital.

Morocco Style will be held from March 28 to 31, 2019. This is an opportunity for fashion, textile, accessories, ready-to-wear professionals like importers, exporters, manufacturers and distributors to weave B2B relationships in this sector which is in constant evolution.

Exhibits will include textiles, leather clothing, nightwear, shoes, bags, cosmetics, yarn, wool, knitted fabric, women’s and men’s clothing, denim, lingerie, sportswear, children’s clothing, accessories and more.

The four day fair will be attended by over 350 exhibitors from Morocco, Turkey, China, Pakistan, Taiwan, Portugal and Germany. It is also expected to have 15,000 trade visitors from Morocco and 32 other countries. These include: West Africa, North Africa, the Middle East, the Gulf and Europe.

This platform enables national and international companies from different industrial sectors to show and promote their skills, to meet partners and to discover the new trends and techniques of the sector.

Morocco Style also contributes to the development of Moroccan expertise in the textile sector by consolidating Morocco's competitiveness and making Morocco an international reference point and an African regional hub of the sector. The 2017 edition was attended by over 300 exhibitors who presented the latest trends in fashion and textiles. Moroccan fabric imports are exempt from tax. This accelerates the export of ready-to-wear.

The United Arab Emirates (UAE) was India’s second largest apparel market after the US in 2017. However, imports from India dipped drastically by 59.26 per cent during the first half of 2018. India’s shared dwindled both in knits and woven categories significantly. Knitted apparels export witnessed a massive fall of 60.73 per cent. Woven garments declined by 57.36 per cent.

The declining trend is certainly a worry for India, since the UAE contributes 20.14 per cent to Indian’s apparel export in value terms. It’s pertinent that for the first four months of fiscal ’18, there was a 17.8 per cent growth in garment exports to the UAE. The otherwise top destination, United States, saw only a 1.5 per cent growth in Indian shipments.

Falling exports can be attributed to many reasons. The UAE’s overall textile and apparel imports have been declining for three years. The five per cent VAT as well as an increase in fuel and electricity prices following the crash of oil prices in the international market has hit the country negatively. The ongoing recession in the UAE is hurting consumer spending badly. Changing consumer shopping pattern is impacting retail business, pushing buyers to cut import orders.

China’s surplus with the US has risen to a record while its overall export growth has slowed. With further large-scale US tariff measures, Chinese exporters will be hit hard and China’s GDP growth rate in 2019 is likely to be dented. If the US keeps ramping up its tariff measures against China, the export sector will face a long, hard road ahead despite government measures to mitigate the impact.

The US has threatened to impose higher tariffs on Chinese imports. While the immediate impact of the trade tension may be limited, the effect on economic confidence may be larger. Chinese exporters are feeling the pain as trade tensions between the world’s two biggest economies worsen.

China has announced measures to support some exporters targeted by the barrage of higher duties. Export rebate rates will be raised for 397 goods, ranging from lubricants to children’s books, meaning that firms shipping such products abroad will pay less value-added tax.

Export growth could decelerate to five to ten per cent over the next few months, then slowing more next year on high base, trade tension and a broad slowdown of the global economy. In the event of an all-out trade war, China could be hit harder by a change in market sentiment than a direct impact from tariffs.

Leaders of Bangladesh Garment Manufacturers and Exporters Association (BGMEA) and Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA) have urged the government to give tax or cash incentives as the wage of the workers would be raised.

The leaders claimed any increase in the workers’ wages on top of the amount suggested by the owners’ representative to the wage board would be a threat to the survival of the country’s readymade garment sector. BGMEA recently proposed Tk 6,360 as minimum wage. Labour rights groups are demanding Tk 16,000 as the minimum wage while workers’ representative to the wage board, Shamsunnahar Bhuiyan, a ruling party-backed labour leader, proposed Tk 12,020 as the minimum wage. BGMEA president Siddiqur Rahman will negotiate with the government to protect the interest of factory owners. He was apprehensive that the wage hike would increase cost of doing business.

Primark, in its recent trading update, has stated the brand would generate 5.5 per cent more sales than past year at constant currency 6 per cent at actual exchange rates), driven by increased selling space. But this will be offset by a 2 per cent decline in like-for-likes (LFL).

The company has stated the chain had performed well in the UK, where full-year sales are expected to be 6 per cent higher over last, and its share of clothing market has also increased significantly. The brand’s stores in Spain, Portugal and Italy also delivered strong sales growth in the year. LFL sales decreased due to a decline in northern Europe where the unseasonable weather during three periods this year led to difficult retail conditions. Despite this, sales in northern Europe were well ahead of last year driven by increased selling space.

The company’s operating margin during decline to 9.8 per cent, down from 10 per cent year-on-year, due to the adverse effect of the US dollar exchange rate on purchases. But margin in H2 will be “well ahead of the first half and last year, driven by the benefit of the weakening of the US dollar exchange rate on purchases and by better buying.”

Rights campaigners, women leaders and government officials in Bangladesh have demanded higher wages from overseas employers who wished to recruit skilled apparel workers from the nation. As per Bangladesh Overseas Employment Service Limited (BOESL), it was essential for overseas employers to double the wages of Bangladeshi garment workers as their wages had been increased in Bangladesh.

Over one lakh Bangladeshi apparel workers are employed abroad and 50per cent of them were sent by the country’s lone state owned recruiting agency BOESL. Workers employed in Jordan, Mauritius and Bahrain were paid lower wages, compelled to work overtime without any extra payments and were provided with unhealthy accommodations.

Karmojibi Nari, Director for Programme Sunzida Sultana believes that since garment workers were drawing better wages in Bangladesh, overseas employers should increase their wages by at least two times.

In Bangladesh, 67 green garment factories have already obtained LEED (Leadership in Energy and Environmental Design) certification from the US Green Building Council (USGBC) and over 300 more are waiting to be certified. The garment sector's strong green initiative was noticed in the survey of the Partnership for a Cleaner Textile (PaCT) of the International Finance Corporation. Local suppliers are also contributing by saving water, energy and environment.

Around 250 textile factories in Bangladesh have invested $39 million to save 21 billion liters of water a year. Currently, 1,700 factories run effluent treatment plants (ETPs) in their factories to save the environment. Although the factory managements of these units regularly report to the Department of Environment (DoE), they need to improve the performance of the ETPs. The DoE will start monitoring the operations of these ETPs online in 500 factories to obtain better results from the plants.

The value of Vietnam’s textile and garment exports rose 19.2 per cent in 2017 compared to 2016. However, the cost of logistics activities for textile and garment enterprises accounts for 9.1 per cent of total export turnover. Logistics costs in the country are six per cent higher than in Thailand, seven per cent more than in China, 12 per cent higher than in Malaysia and three times more than in Singapore.

Despite reasonable labor costs, Vietnam’s competitiveness has been affected by transport costs, surcharges at seaports, and limited seaport infrastructure. Regulations on fees and charges for logistics services are high, making transport costs also relatively high, accounting for between 30 and 40 per cent of the cost of products, compared to some 15 per cent in other countries.

In addition, the surcharges of shipping lines also contribute to the cost of logistics operations in the country. Expanded costs for logistics have significantly affected the garment and textile industry, which employs a large number of labourers and is hugely dependent on input importation, which results in low added value.

To address these challenges, many firms have applied technology to better manage warehousing and optimise supply chains. One of the most commonly used technologies includes backing up bills and contracts, and automatically transferring documents between firms. Logistics enterprises are working to improve their competitiveness, and consider cooperating in transport services to reduce costs for other enterprises.

Japan and China, in recent months, have undertaken strategic measures to improve their trade relations in response to trade war measures against both countries by the Trump administration. Both governments are exploring closer economic relations to offset Washington’s trade war measures.

Japan, as the third largest economy in the world, is turning to China to offset the negative impact of the more openly predatory US policy. With the economies in the region closely linked, the US tariffs on Chinese goods will also indirectly impact Japan. However, Tokyo will use whatever foothold it can gain through this apparent thaw in relations with Beijing to ensure its imperialist interests are met. Rather than working as a junior partner of the US, the Abe government is increasingly pursuing a more independent foreign policy and remilitarizing so it can back it through force of arms if necessary.

For China, opening new markets would mitigate some of the effects of US tariffs already imposed on $50 billion worth of goods and another $200 billion that Trump is now proceeding with. To mend relations with Tokyo, Beijing has toned down its anti-Japanese chauvinism and also eased tensions over its territorial dispute.