FW

American retailer BCBG is closing 120 stores.

California-based BCBG sells women’s dresses, apparel and accessories. The group is reducing its physical retail footprint after being negatively impacted by growth in online sales at its rivals.

The stores to be closed either are unprofitable or have untenable lease agreements.

BCBG is repositioning its brands and operations for the future with a focus on digital, e-commerce, selected retail locations, in-store boutiques and wholesale and licensing arrangements.

Glitzy fashion house BCBG was founded in 1989. The first boutique opened in 1992. The fashion brand has operated more than 570 boutiques worldwide, including more than 175 in the US. It has long been a favorite of red-carpet celebrities. Kate Winslet, Victoria Beckham and Alicia Keys have worn its fashions, which include cocktail dresses, handbags and other accessories. The name BCBG is short for the French expression bon chic, bon genre.

BCBG is just the latest retailer to announce plans to pare store counts in the face of increased competition from online sites. Kenneth Cole Productions, a fashion house and shoe company, announced plans in November to close almost all its shops. Macy’s recently announced plans to close 68 stores. Sears and J.C. Penney are also planning store closures.

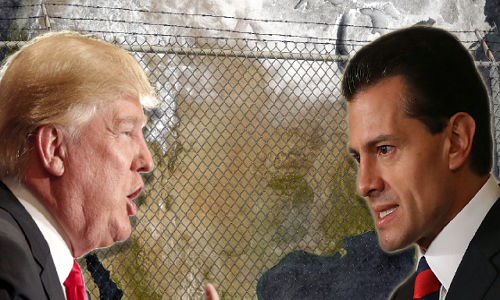

"With speculation about the US President Trump imposing 20 per cent or other duty on Mexican imports, Mexico could slap ‘mirror’ tariffs against US fabric and apparel imports. This move is slated to negatively impact cross-border manufacturers and retailers. Analysts say for the US to come out with any other compensation treaty to avoid any trade deal damages."

With speculation about the US President Trump imposing 20 per cent or other duty on Mexican imports, Mexico could slap ‘mirror’ tariffs against US fabric and apparel imports. This move is slated to negatively impact cross-border manufacturers and retailers. Analysts say for the US to come out with any other compensation treaty to avoid any trade deal damages.

This statement came at a time when Mexico is set to begin negotiating the North American Free Trade Agreement (NAFTA) by May to meet Trump’s calls for a rewrite. That said, Mexico’s economy minister Ildefonso Guajardo said in mid-January that if Trump imposes a tariff or a border adjustment tax, Mexico would pursue ‘mirror actions’. This indicates the growing tensions between the two neighboring countries, longtime allies, as Trump pursues his plan to build a wall along the border and claims Mexico will pay for it. The 20 per cent tariff or other duty proposal forms part of the plan to fund the wall. Owing to such brewing tension, a possible trade war has strained diplomatic relations and unleashed a nationalist uproar in Mexico with populist groups calling for consumers to boycott American companies including Wal-Mart, Starbucks and McDonalds.

Textile trade dynamics

The US ships roughly $6.5 billion worth of apparel and textiles to Mexico — $4 billion is fabric and $1.2 billion apparel parts. Conversely, Mexico sends back $4.5 billion worth of clothing and textiles — $3.5 billion of apparel and $1 billion of textiles.

In 2016, the textiles and apparel sector grew 5 per cent as strong local apparel sales offset a 4.3 per cent drop in US sales. Going by such a scenario, local sales could grow 7 per cent compared to 10 per cent in 2016. Amid strong anti-American sentiment, local-brand turnover could eclipse US brands for the first time in recent memory.

Many consumers could shun Walmart in lieu of Mexican archrival Coppel or choose to buy at department-store chain Liverpool’s lower-end unit Fabricas de Francia. Mexican fashion designers, long in the shadows, could win consumer hearts. This is bad news for the likes of the Axo or El Palacio de Hierro network, which have grown by bringing aspirational US brands such as Calvin Klein, Tommy Hilfiger and Abercrombie & Fitch south of the border.

Finding newer avenues

To meet the challenges, Mexican apparel producers are seeking new markets in Central America and Europe with which Mexico has a largely vague free-trade agreement. Costa Rica, Panama and Central America could be good markets to compete on price and quality but not Argentina and Brazil, because they have very strong industries and brands. In Europe, Mexican fashion jean labels Oggi and Siete Leguas could make successful forays because they have high-quality products using innovative fabrics and new washing technologies. These companies sell premium jeans to Levi’s, Wrangler and True Religion so they could also start selling in Europe. That will require even more innovation, training and other investment the industry has been slow to pursue.

Exporters in the Tirupur cluster are disappointed with the RBI’s decision to keep the repo rate unchanged at 6.25 per cent. They were expecting a reduction in interest rate, post demonetisation. A reduction is as important at this juncture to increase competitiveness at a time when export growth rate was a meager 3.54 per cent for the nine month period of this fiscal year 2016 -17.

Exporters also feel this is the right time for knitwear sector to capture the market that’s leaving China, due to an increase in cost of manufacturing. If the opportunity is missed, the market would be captured by competing countries like Bangladesh, Vietnam, Indonesia and Cambodia.

They add that growth of the apparel, leather and footwear sectors, which are labor intensive, is possible only when they get borrowings at a lower rate. Similarly, they are concerned over the lack of thrust given to adequately fund the Pradhan Mantri Rojgar Protsahan Yojana, a scheme that was envisaged during 2016-17 financial year to incentivise employers for generating employment. The sixth bi-monthly monetary policy statement for 2016-17 has maintained the repo rate at 6.25 per cent.

The recent Milano Unica held from February 1 to 3, 2017 had 427 textile companies showcasing their products, of which 300 were from Italy, 65 from elsewhere in Europe, 40 from Japan and 22 from Korea. The benchmark trade show for Italian textiles and accessories showcased collections for Spring/Summer 2018. The event marked a major comeback of companies from the Russian Federation, whose numbers went up by 34 per cent. Equally remarkable were the increase in number of buyers from Canada and a rise in companies from China as and the UK and US.

But there was a decrease in visitors from France, Japan and Turkey besides a diminished German presence. Milano Unica has been created through the tradition of five Italian exhibitions, Ideabiella, Ideacomo, Moda In, Prato Expo, Shirt Avenue. The project is held twice a year and presents the finest quality products from both Italian and European textile manufacturers. The name Milano Unica represents the three essential characteristics of the textile fair, singular, exclusive, united.

Milano Unica has changed the date of the winter show. It will be held in July instead of September. One reason for the change is the show had lost some ground in the last few years. So this decision means it will be held earlier than other textile events.

Vietnam’s exports in 2016 rose 8.6 per cent over the year before. However, 70 per cent of the export turnover belonged to foreign owned enterprises. Which meant Vietnamese enterprises contribution was modest to the export turnover. The biggest problem for Vietnam’s garment producers is that they have to import input materials. Since Vietnam’s fashion design industry is still weak, Vietnam’s products cannot attract customers. And since Vietnamese companies are involved only in outsourced work, they cannot earn big money.

The country’s enterprises face the danger of falling into the outsourcing trap of low added value if the situation does not improve. As Vietnam tries to integrate more deeply into global economy, avoiding the outsourcing trap when joining value chains will be a great challenge. The country is the world’s fifth largest garment exporter. It has maintained double-digit growth, ranging on average from 10 per cent to 36 per cent, since 2001.

However, a strong Vietnamese dong and sluggish demand from key markets damped textile exports in 2016. Garment exporters are also faced with increasingly intense competition from outsourcing hubs Cambodia and Bangladesh, which get tariff preferences in the US market. Market access for Vietnam’s clothing in the US is limited by an average tariff of about 11.1 per cent, with tariffs on some textile and apparel products nearing 30 per cent.

Lenzing has developed a new fiber based on cotton scraps and wood. Called Refibra, it is the first cellulose fiber featuring recycled material on a commercial scale. Refibra stands for Reduce, Reuse and Recycle. This fiber is made of recycled materials and promises reduced reliance on natural raw materials. The fiber is produced in tencel production process. Tencel itself is an environmentally responsible fiber of botanic origin. Because Refibra is based on the tencel fiber, which has been internationally recognized for its environmentally responsible closed loop production process, Refibra offers a deep sustainability profile that clearly contributes to circular economy.

Refibra is expected to build Lenzing’s reputation as a leader in the field of environmental fiber technology and push for new solutions in the textile industry toward a circular economy by recycling production waste.

To assure customers that the fiber, made from recycled material, is really in the textiles, Lenzing has developed a new identification system. The system makes it possible to identify Refibra in the finished textile. This is said to guarantee transparency in the overall processing chain. The Refibra fiber itself is part of the global Lenzing Branding Service and the brand is licensed once the textile has undergone a certification process.

Haryana is coming up with a new textile policy aimed at making it a global hub for textile manufacturing and a preferred investment destination. The policy is packed with fiscal incentives and contains provisions for infrastructure augmentation, setting up of textile parks and facilities for skill training. It aims at generating 50,000 new jobs by attracting investment in the textile sector to the tune of Rs 5,000 crores. It aims to boost textile exports by a compound annual growth rate of 20 per cent during 2017.

The policy proposes a capital subsidy of 10 per cent for eligible new projects of all textile enterprises across the state. It has been formulated with an eye on the cotton belt of Haryana. The state is one of the leading cotton producers in the country. This sector provides employment to about one million people and readymade garments worth two billion dollars are exported from the state annually.

The textile policy will incentivize setting up of new units and ensure growth and modernization of existing textile industry in the state. Help will be offered for setting up textile parks exclusively for garmenting units with provision of labor, housing and built-up sheds (to be provided on a lease basis) to facilitate the expansion of the garmenting industry in the state.

Planet Textiles will take place in Bangalore on May 24. This is an annual summit on environmental issues for the textile sector. This year’s event will highlight the crucial issue of textile waste, water pollution, chemical management and natural resource conservation, including energy and water use. Planet Textiles will attract companies along the entire global textile supply chain to accelerate their sustainability initiatives in order to meet the market’s demands.

Speakers will present methods for improving and managing global sustainability measures with emphasis on third party, independent certifications as important and effective business tools. Planet Textiles is the leading international event on sustainability in the textile sector because it discusses real-world practical issues and ideas on how the global supply chain can move to a more sustainable future.

This is jointly organized by Messe Frankfurt, the leading trade fair organizer, and Sustainable Apparel Coalition, an industry-wide group of leading apparel and footwear brands, retailers, manufacturers, NGOs, academic experts and the US Environmental Protection Agency that aims to reduce the environmental and social impacts of apparel, footwear and home textile products around the world. The last edition attracted over 440 industry leaders – from fiber and textile suppliers through to the world’s largest clothing brands and retailers. The first edition of Planet Textiles took place in 2009 in Hong Kong.

"Q3-2016 saw a rise in global yarn production on a quarter-on- quarter basis. Thereby, output in Asia and South America rose. However, in Europe and the US, yarn production fell. On an annual basis, global yarn production in Q3-2016 increased versus Q3-2015. Global yarn stocks climbed in Q3-2016. Yarn stocks reduced in South America while in Asia, they increased. However, year-on-year, global yarn stocks declined. Yarn orders in Europe and in South America fell quarter-on-quarter. Compared to the same quarter a year ago, yarn orders increased in South America and fell in Europe."

Q3-2016 saw a rise in global yarn production on a quarter-on- quarter basis. Thereby, output in Asia and South America rose. However, in Europe and the US, yarn production fell. On an annual basis, global yarn production in Q3-2016 increased versus Q3-2015. Global yarn stocks climbed in Q3-2016. Yarn stocks reduced in South America while in Asia, they increased. However, year-on-year, global yarn stocks declined. Yarn orders in Europe and in South America fell quarter-on-quarter. Compared to the same quarter a year ago, yarn orders increased in South America and fell in Europe.

In contrast, Europe’s fabric production decreased. Global fabric output improved moderately year-on- year in Q3-2016. Thereby, Asian and South American output climbed moderately, while it fell in Europe. In Q3-2016, worldwide fabric stocks fell quarter-on-quarter. Fabric inventories were reduced in South America and increased moderately in Asia and North America. Year-on- year, fabric stocks declined. European and South American fabric orders decreased quarter-on- quarter. On a yearly basis, South America’s fabric orders increased and Europe’s fell.

Global Projections

The global outlook for yarn and fabric signals a decline for Q1-2017. In Q3-2016, global yarn production increased by 3.4 per cent quarter-on- quarter. Thereby, Asian yarn output strengthened by 3.7 per cent quarter-on- quarter and by 2.6 per cent in South America. In Europe and North America, it fell by 13.3 per cent and 1.4 per cent, respectively. Global yarn output increased by 3.7 per cent in Q3-2016 versus Q3-2015. In Asia, yarn output improved 3.5 per cent year-on-year and in South America by 21 per cent. In Europe and North America, yarn output declined by nearly 4 per cent year-on-year and by 7.8 per cent, respectively.

Global fabric production

Fabric production went up by over 3 per cent in Q3-2016 across the world against previous quarter. While Asian and South American output grew by over 4 per cent each, European fabric production fell nearly 15 per cent quarter-on- quarter. Year-on-year, global fabric output improved moderately by 0.6 per cent in Q3-2016. Thereby, Asian production increased by 0.6 per cent and South America’s output improved by 4.7 per cent. Europe’s fabric output fell by nearly 7 per cent year-on-year.

Global yarn inventories increased in Q3-2016 by 4.8 per cent quarter-on-quarter with increases of 5.7 per cent in Asia. In contrast, in South America inventories fell by 1.4 per cent. In Q3-2016, the annual percentage change of global yarn inventories saw a dip of nearly 6 per cent. Thereby, European yarn stocks increased by 5 per cent year-on-year. Asian yarn stocks, however, fell by nearly 7 per cent annually and South American stocks diminished by 0.6 per cent.

Worldwide fabric stocks fell by 1.4 per cent quarter-on-quarter in Q3-2016. The major culprit was South America, where stocks reduced by nearly 8 per cent. In the Asia and North America fabric stocks increased moderately. On a yearly basis, global fabric inventories in Q3-2016 decreased by 5 per cent. Asia’s fabric stocks decreased by 0.4 per cent annually and South America’s inventories fell by over 16 per cent. In Europe stocks declined by over 2 per cent, while in North America they increased by 0.8 per cent year-on-year.

In Q3-2016, European yarn orders fell by 5 per cent quarter-on-quarter and by 2 per cent year-on-year. In South America, they fell by over 11 per cent quarter-on-quarter and increased by over 100 per cent year-on-year. European fabric orders in Q3-2016 fell by nearly 10 per cent quarter-on-quarter and by 11.5 per cent year-on-year. South American fabric orders in Q3-2016 fell by 3 per cent quarter-on-quarter and increased by 10 per cent year-on-year.

Uzbekistan’s cotton fiber processing volume reached 40 per cent in 2016. Now the country aims that by 2020 it will process all available capacities of cotton fiber within Uzbekistan.

Cotton yarn accounts for nearly 50 per cent of exports. The share of finished products in the total volume of production amounts to 47 per cent. In future, Uzbekistan plans to increase this figure to 65.5 per cent. Export of products with high value added will be increased along with a gradual reduction of yarn exports.

Textile complexes will be launched on the basis of a four-phase system that includes all processes, starting from processing and ending with the production of finished products. More than 27,000 new jobs will be created. About 120 new enterprises will be created and ten will be upgraded.

Allocation of credits for projects will be implemented based on a completely new mechanism. Commercial banks will co-finance the projects and open a credit line for the purchase of modern spinning, weaving and painting equipment. In projects implemented at the expense of attracted funds of commercial banks, banks or investment companies can participate with a share up to 100 per cent in the share capital of the company.