FW

All Pakistan Textile Mills Association (APTMA) has demanded imposition of 10 per cent regulatory duty on the import of yarns and fabrics to support the domestic trade. The association has written to the ministry of finance seeking the imposition on these two products.

According to the numbers quoted by APTMA, during the last fiscal year 2014-15, yarns (chapter 54-55) and fabrics (chapter 54-55) amounting to Rs 92.217 billion were imported compared to Rs 63.416 billion in FY13. A large quantity of yarns and fabrics is being imported from India, capturing the share of domestic market. Therefore, APTMA demands regulatory duty on the import of yeans and fabrics to protect the domestic industry and trade, it said.

Import data of the Federal Bureau of Statistics (FBS) revealed that import of yarns and fabrics have increased in quantity by 37 per cent and 56 per cent, respectively from 2012-13 to 2014-15. According to the Chairman APTMA, surge in import of yarns and fabrics in Pakistan is adversely affecting the domestic industry resulting in closures of mills producing yarns and fabrics meant for domestic consumption.

www.aptma.org.pk

A garment exposition is being held in Bangladesh, January 13 to 16, 2016.The fair paves the way for the display of readymade garment-related equipment. This is a garment accessories, packaging and related machinery trade show. It is being attended by representatives from the global machinery, fabrics, yarns and accessories industries. Several products and services are being displayed. These fall in the area of garments, accessories, packing, garment accessories and garment equipment. Among the exhibits are corrugated cartons, stickers, hang-tags, barcodes, sewing threads, tapes.

Bangladesh has quality products, plus a large skilled workforce, and the country hopes to overtake China and become the number one sourcing destination.

A good number of European Union premium buyers are sourcing products from Bangladesh, shifting their focus from China.

A big Bangladesh readymade garment manufacturer imported 3500 pieces of machinery last year. These manufacturers are on a capacity expansion drive to meet the higher demands for products.

Bangladesh is expected to remain lucrative as a readymade garment source for at least the next 10 years. The trend of inflow of work orders is higher than that of previous years as buyers are satisfied with the ongoing safety progress.

Bangladesh has set a target of 50 billion dollars in export of readymade garments by 2021.

The international conference on denim, Intexcon will be held on February 19 and 20, 2016 at Ravi Matthai Auditorium, IIM in Ahmedabad, following the theme of ‘A democracy in Fashion’.

The industry experts participating in the conference will deliberate upon topics like ‘Indian Economy and Textile Industry’, ‘Denim - The Blue-eyed segment of the T&A Sector’, and ‘Jeans - The prime mover of the Denim Industry’. Some of the recent International exhibitions have confirmed renewed thrust to denims by taking into considerations the fashion, trends beyond cotton, enhanced use of stretch yarns, super stretch, knitted denims, re-entry of pure and dark blues, indigo shirting’s and tops, coated and functional denims, recycled products and finally sustainability.

To deliberate upon ‘Whither Denims’, Diagonal Consulting (India) will be organising a global summit on “Denims – A Democracy in Fashion”. International denim and jeans players, value chain experts, leading brand makers and retailers, researchers, designers, trade channels, policy makers, and others are expected to participate in the event.

The conference will be chaired by PR Roy, and will be supported by iNDEXTb Industrial Extension Bureau, a government of Guajarat Organisation.

www.intexcon.in

Archroma, a global leader in colour and specialty chemicals has appointed a Sustainability Officer for its textile specialties business and released its list of products compliant with the new version 1.1 of its list of Zero Discharge of Hazardous Chemicals (ZDHC) Manufacturing Restricted Substance List (MRSL) published in December 2015.

James Carnahan, who joined from the BASF textile chemicals business acquired by Archroma in July 2014, has been appointed as Global Sustainability Manager, Textile Specialties, and will be responsible to further intensify the business focus on more sustainable solutions. Carnahan has more than 30 years of experience in textile chemicals in application development and marketing and sales in South Africa, Italy, Germany, China and Singapore. In his last role with BASF, he was responsible for portfolio strategy development and implementation, with focus on developing sustainable solutions to support the textile value chain in this direction.

On this new appointment, Thomas Winkler, President Textile Specialties at Archroma said, “Everyone at Archroma is committed to continuously challenge the status quo in the deep belief that we can make our industry sustainable. We have been looking for the right sustainability specialist and, when we met James Carnahan, we realized he shared our belief and had been acting upon it during his past tenure.”

Archroma had published its list of ZDHC MRSL-compliant colorants and chemicals for textile and apparel for the first time in July 2014, shortly after the first version of the ZDHC MRSL was released. The list features a full range of colorants and chemicals for colours and functional effects, and process chemicals, covering fibres to finishing. The new list released now required no changes since the company was already adhering to standards.

www.archroma.com

American Apparel has got a $300-million buyout offer from an investor group interestingly backed by the company’s former chief executive Dov Charney, who was ousted after a series of sexual harassment cases against him.

Private equity firms Hagan Capital Group and Silver Creek Capital Partners in a joint statement said that their offer of $300 million for the troubled retailer included $90 million of new equity and a $40 million term loan. The enterprise value of the deal is above the valuation of $180 million-$270 million. If the deal gets through, the company would be able to address the bankruptcy pressure and will also see Charney rejoining as the CEO of American Apparel.

The company operated 218 stores in 19 countries and became popular for its advertisement campaigns depicting over-the-top sexual imagery. Meanwhile, a hearing on the bankruptcy application will be conducted on January 20, 2016 to confirm the bankruptcy plan. Under the bankruptcy plan, American Apparel said it has secured $40 million in additional capital, in addition to the $40 million of new capital previously committed by lenders.

www.americanapparel.net

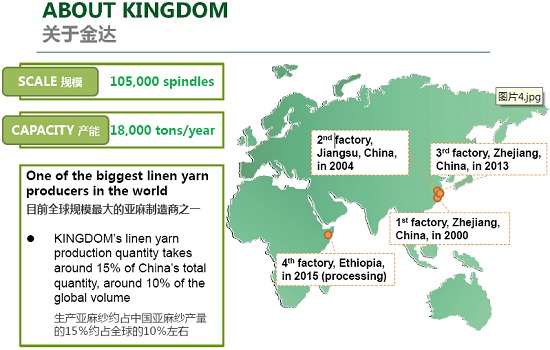

“Kingdom right now has total installed spindles over 100,000, with an annual capacity more than 18,000 tons of wet spun linen yarn, one of the largest linen yarn spinning abilities in the world. Now Kingdom shares 15 per cent in China's domestic linen yarn market and 10 per cent of the global market.Kingdom shares around 50 per cent of the whole export of linen yarn from China to the high-end markets such as Italy, Japan, Korea and other countries in EU.” exclaims Ren."

Kingdom, a leading China-based linen fibre producer, organised a ‘Mumbai Day’ on January 7, 2016 to meet existing clients and establish a network with new clients. Ren Weiming, Chairman of the Board, Kingdom Holdings China inaugurated the session that also focused on the origin and growth of luxury fibre linen and its growth, and its emergence in the Indian market.

China’s Kingdom in India

The event organised in association with Sundaram TexVentures, saw around more than 60 select industry professionals interact and network over common interest. Stalwarts including Ramesh Poddar from Siyarams, Virendra Arora and R Mishra- D Décor, Rajendra Agrawal- Donear, Yogesh Mittal- Kottex, Surat, Vijay Puniyani and Gulshan Kumar- Vardhaman, Sunil Patil and Vishal Shah-Arvind Mills, Ashok Ramdham from Mafatlal, Balachander were some of the attendees. The audience included around 45 customers from various parts of India Mumbai, Delhi, Tamil Nadu, Surat, Ahmedabad and Ichhalkaranji attended the program.

Mumbai Day was also graced by Jean Claude Lambert, President of Teillage De Lin Du Vert Galant, which is an excellent flax enterprise in France, who spoke about ‘The Growth of Flax in Europe’.

Talking about Kingdom’s expertise in linen, Ren said the company has more than 30 years of history, and started its linen business 16 years ago. “Kingdom people are dedicated in linen business with our enduring passion for pure linen. We constantly invest in advanced linen spinning technology to provide best quality of linen yarn in the world.”

Renowned linen manufacturer-exporter

Kingdom Holdings that started as a silk spinning and weaving company for first 17 years, in 1999 moved to spinning linen, sighting growing opportunities in the segment. Kingdom procures all of their scutched flax fibre from best of the Scutching mills in France.

Kingdom has three linen spinning mills, located in the two most developed textile centres in China: Zhejiang and Jiangsu provinces and is in the process of developing the fourth one in Ethiopia. “Kingdom right now has total installed spindles over 100,000, with an annual capacity more than 18,000 tons of wet spun linen yarn, one of the largest linen yarn spinning abilities in the world. Now Kingdom shares 15 per cent in China's domestic linen yarn market and 10 per cent of the global market,” exclaims Ren.

Kingdom shares around 50 per cent of the whole export of linen yarn from China to the high-end markets such as Italy, Japan, Korea and other countries in EU. In addition, Kingdom has also established strategic cooperation relations with Siemens (China) Co in the energy saving, environmental protection, fine management, information system, and automation.

Emergence of linen in the India market

Linen is one of the most popular textile products in the international market. While Europe continues to be the traditional consumption market for linen, demand in other countries like China, India and Japan is growing fast, which has brought a new momentum and opportunity for the linen industry. “India has become one of the fastest growing markets of linen consumption in the world. Kingdom is one of the most active linen yarn suppliers in India. We want to provide better quality linen yarn, to meet the continuous upgrading demand in the Indian market. With our third spinning mill put into running, we will have sufficient capacity to meet the quantitative demand in India. India will be one of Kingdom’s major markets in the future,” explains Ren.

“My association with Kingdom Holdings started in the year of 2009, when I first met Marc from Kingdom in Shanghai. At that time the consumption of linen yarn in India was at a very nascent stage but I had a definite idea that it was going to grow very fast. I explained the future potential of linen yarns in India market and that’s was how this business association started,” avers Manish Mehta, Managing Director, Sundaram TexVentures.

Kingdom associated with Manish Mehta as their exclusive agents in the year 2009 for promotion and selling of their wet spun linen yarn in India and later other neighbouring countries like Pakistan, Bangladesh, Sri Lanka were added to this exclusive arrangement. “We started with a mere 300MT sales in the year 2009¬-2010. And over the past six years with the continued support of our esteemed customers in India, volumes have grown gradually and consistently. In this calendar year 2015, we have achieved a sales of 2,400MT of Kingdom’s linen yarns in India alone which is around 20 per cent of the total 12,000 MT yarn shipped from China to India during this period,” informed Mehta.

www.kingdom-china.com

Bangladesh wants India to lift countervailing duty (CVD) on goods coming from Bangladesh. CVDs are tariffs levied on imported goods to offset subsidies made to producers of goods in the exporting country. The duties are meant to level the playing field between domestic and foreign manufacturers of the same product. Bangladeshi businesses have been facing challenges in exporting to India due to the CVD.

Currently the highest rate of CVD on Bangladesh’s products destined to India is 20 per cent. Garments, Bangladesh’s main export item, have been facing 12.5 per cent CVD since April 2013. The duty reduced the competitiveness of Bangladesh’s products in India and caused exports to fall. This is after India allowed duty-free entry to all products from Bangladesh except 25 alcoholic and beverage items in November 2012.

With CVD, Bangladesh’s exports to India declined 19 per cent year-on-year in fiscal 2013-14, mainly due to a slowdown in shipment of garment items. Bangladesh’s exports to India have not increased despite measures to reduce the huge trade gap between the two neighbors. Major impediments are a lack of product diversification in Bangladesh, non-tariff barriers, and inadequate banking facility along the border areas of the two countries.

Bangladesh mainly imports basic commodities from India like rice, cotton, onion, fabric, chemical products and dye, limestone, cattle, electricity, machinery and pulses.

Cotton futures extended their rebound after the US raised above 9m bales its forecast for the top in world stocks this season, as it downgraded Chinese and Pakistani harvests to multi-year lows. Cotton futures for March closed 0.1per cent higher at 61.41 cents a pound in late deals in New York, achieving their first back-to-back winning sessions of 2016.

The increase followed the downgrade by the US Department of Agriculture, in its much-watched monthly Wasde report on world crop supply and demand, of 1.5m bales to 102.9m bales its forecast for world stocks at the close of 2015-16. The cut to stocks expectations reflected weakened estimates for output both in China, now seen tumbling by 6.20m bales to a 15-year low of 23.8m bales after a subsidy rejig, and in Pakistan.

The Pakistan crop was downgraded by 800,000 bales to a 17-year low of 7.20m bales, with falling arrivals of cotton at gins indicating "more extensive whitefly damage than previously expected", the USDA said, adding, "Yields are reported at record low levels due to widespread whitefly and cotton leaf curl virus infestations with continued reports of significantly poor productivity across the major cotton growing provinces Punjab and Sindh.”

The USDA also trimmed its estimate for domestic output last year by 88,000 bales to 12.8m bales, thanks to a small yield downgrade, but reduced its estimate for domestic consumption too, citing data on spinning activity up to November. US inventories at the close of 2015-16 were pegged at 3.10m bales, an upgrade of 100,000 bales, but a figure in line with market expectations.

www.usda.gov

With a strong increase in the number of exhibitors and all indications suggesting that the new furnishing season will be a good one, Heimtextil starts today in Frankfurt. The globally-leading trade fair for home and contract textiles will present the world’s largest range of textile products, trends and new products until January 15, 2016. Top players in the international industry will present their wares in the newly extended exhibition space comprising 20 different hall levels.

Among the 2,866 exhibitors are an increased number of European companies. Some firms that are returning after a year or several years’ break or coming to Heimtextil for the first time are also fuelling the growth in the number of exhibitors. ‘The high demand consolidates our position as the most important meeting place for the industry and proves that our positioning of Heimtextil is the right one’, says Detlef Braun, CEO of Messe Frankfurt. He also suggests that this reflects the current positive mood in the industry: ‘The increase in European exhibitors comprises mainly exhibitors from Italy, the Netherlands and Belgium, as well as Turkey. The number of exhibitors from Brazil and the USA has also grown.

It is not just the number of home textile exhibitors that has grown in 2016, but also the exhibition space. This is due in part to the expanded range of décor and upholstery materials on offer. The product segments “window” and “upholstery” have been expanded at Heimtextil 2016 on account of the huge demand. The brand companies returning to Heimtextil in 2016 include Enzo Degli, Luilor, TEXAO, Marzotto Lab, Ratti Spa and Pozzi Arturo from Italy, as well as Libeco-Lagae, Verbatex and Annabel Textiles from Belgium and Penelope from Turkey.

Another highlight of Heimtextil is the “digital print” area. Digital printing is one of the most important growth segments in the industry. This is also reflected in the newly expanded exhibition space at Heimtextil 2016. Global top companies such as Epson, Hewlett Packard and Kornit will present their digital printing innovations on a surface area of over 1000 square metres. The event has also strengthened its offer in the segment of mattresses, bedding and bed systems. Renowned new exhibitors and returning companies present new products related to sleeping. The product “bed” incorporates an expanded offer comprising the segments bed linen, bedding, covers, decorative pillows and mattresses.

In order to continue strengthening the “green” textile market and act as a point of orientation and trailblazer, Heimtextil offers sustainable companies a forum, puts resource-saving products in the spotlight and invites visitors to take part in an accompanying event programme. In the “Green Village”, the expert centre for sustainability, visitors have the opportunity to talk to certifiers and quality seal awarders and get professional advice. The sustainability expert Max Gilgenmann will take interested trade fair guests on a “Green Tour” around Heimtextil and to selected exhibitors, thereby giving them an insight into the current developments in the green segment.

In line with key theme “Well-Being 4.0”, visitors to the Heimtextil “Theme Park” will experience the latest developments in the world of textile design. Every year, the Trendtable panel made up of international players in the industry evaluates the most important general trends and supplies furnishers, designers, product developers and creative teams with valuable orientation as well as reliable trend statements. These are showcased in the “Theme Park”.

www.messefrankfurt.com

Optitex, a provider of integrated 2-D CAD and 3-D digital product solutions for the textile industry, has joined the IEEE Standards Association Initiative to collaborate, research and build technology standards for 3D body processing.

As consumers seek more personalised shopping experiences, brands are seeking to incorporate 3-D scanning, modeling and visualisation into their businesses to further enhance their customer’s experience. This includes creating customised, tailor fitted garments, but also better products with improved 3-D capabilities.

Optitex, as an innovative thought leader in the future of 3-D and fashion, has joined the initiative to help create standards to implement these technologies into the fashion industry. Such standards will include privacy, communication, quality specifications, and sharing protocols.

According to Optitex, in a fast-fashion market, it’s all about getting the best products out for the consumer needs, as quickly as possible.

www.optitex.com