FW

Gopinath Bala, CEO and Technical Director, SAF, and Regina Brückner, CEO, Brückner. © Brückner Textile Technologies

Gopinath Bala, CEO and Technical Director, SAF, and Regina Brückner, CEO, Brückner. © Brückner Textile Technologies

A state of the art Brückner multi-purpose coating line for technical textiles has been successfully commissioned and is operating since the beginning of 2018 at Sri Venkatalakshmi Spinners (SVS) in Udumalpet, a textile town about 70 km from Coimbatore City, in the South of India. SVS was established in 1980 and now focuses primarily on the spinning of different yarn qualities, the manufacturing of various types of fabrics by weaving, circular knitting and warp knitting, and the manufacturing of various coated materials and technical textiles.

SVS strives to maintain its environmental sustainability efforts by generating its own electric power through grid-connected wind mill and it is currently working on a large-scale LT photovoltaic power generator project. After a careful consideration of today’s business, the change in the technological environment and its capability, SVS has established a modern coating infrastructure to become an integrated value-added manufacturer of technical textile products.

The company started its technical textiles production in December 2017 under the name of SVS Advanced Fabrics – (SAF). The project is one of the most modern and advanced production units in India. The company currently mainly specialises in high-tech preparation for digital printing, automotive fabrics, functional textiles for sports and leisure, as well as fabrics for architectural purposes.

Panoramic view of the state-of-the-art technical textile plant at SVS Advanced Fabrics (SAF) with the multi-purpose Brückner coating line. © Brückner Textile Technologies

SAF has partnered with Brückner Textile Technologies to ensure that the machine will be customised exactly to the company’s needs. Brückner’s local partner, Voltas (Textile Machinery Division) supports the customer with the troubleshooting and spare parts supply. The modern Brückner coating line is equipped with the best in class heat consistency, environmentally friendly heated with LPG fuel.

An integrated Zimmer, Austria coating head with a high precision magnet roller coating head and a screen coating and printing facility, ensures in combination with a Mahlo (Germany) QMS weight measurement system that the coated products (mainly preparation for printing) always meet the specifications consistently at high levels, the company says.

“SVS choose Brückner because it was the clear leader and a strong knowledge partner with a very long history of experience in the technical textiles industry,” explained Gopinath Bala, CEO and Technical Director.

“Brückner had adopted to technical textiles and started providing machinery to the industry way back when Europe started its ventures in technical textiles. SAF is a new company venturing into technical textiles, having a strong knowledge partner in various spectrum of products and processes to support us was the main reason for us to choose to partner with Brückner. Additionally, Brückner’s equipment is of a very high quality, precisely engineered, low-maintenance and consumes the lowest energy levels.”

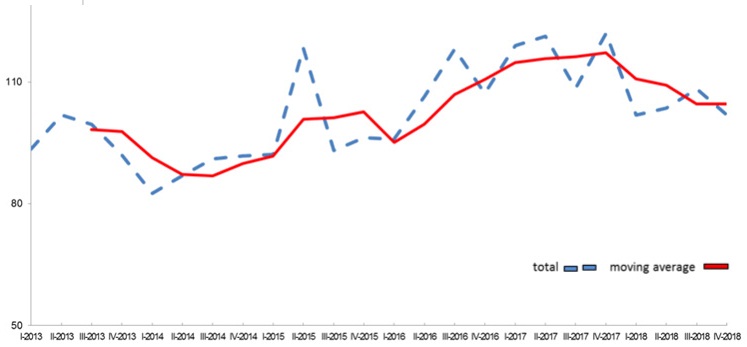

The orders index for textile machinery for the period ranging from October to December 2018, as compiled by ACIMIT, the Association of Italian Textile Machinery Manufacturers, fell compared to the same period for 2017. The index value stood at 101.9 points (basis: 2015 =100).

Orders gathered by Italian machinery builders were thus negative both in Italy and abroad. On the domestic front, the index stood at an absolute value of 148 points, that is, fully 12% less than the same period for October to December 2017. However, foreign markets were even further down at -16%, with the index standing at an absolute value of 98.1 points.

ACIMIT president Alessandro Zucchi commented, “The evolution of the domestic market reflects an overall sense of uncertainty that has accompanied the new national budget legislation, not to mention the comparison with a record fourth quarter for 2017.” Zucchi added that, “On foreign markets, our machinery manufacturers are having to face geopolitical situations that have considerably slowed investments. Turkey, Iran, and even China, all primary markets for our sector, have recorded a drop in demand for textile machinery, for a variety of reasons.”

“Based on preliminary results elaborated by our Association,” concludes ACIMIT’s president, “2018 closed with a downswing both in terms of foreign sales and total production. The overall sentiment for 2019 isn’t very positive either, but the entire sector is putting its trust in ITMA, the primary trade fair for the entire world textile machinery industry, held every four years. This year, the fair will be held in Barcelona

"As per Sanjay Kumar Jain, Chairman, CITI, India’s cotton yarn and fabric exports are struggling due to the duty disadvantage faced by exporters in major markets. There has been continuous decline in cotton yarn and fabric exports from 2013-14 to 2017-18. India’s export of cotton yarn declined 25 per cent from $4,570 million in 2013-14 to $3,443 million in 2017-18. Fabric exports, during the same period, declined 7 per cent from $4,941 million to $4,598 million. China, the largest importer of cotton yarn has shifted focus from India to Vietnam, Indonesia as these countries offer duty free access, while Indian yarn carries a 3.5 import duty."

As per Sanjay Kumar Jain, Chairman, CITI, India’s cotton yarn and fabric exports are struggling due to the duty disadvantage faced by exporters in major markets. There has been continuous decline in cotton yarn and fabric exports from 2013-14 to 2017-18. India’s export of cotton yarn declined 25 per cent from $4,570 million in 2013-14 to $3,443 million in 2017-18. Fabric exports, during the same period, declined 7 per cent from $4,941 million to $4,598 million.

As per Sanjay Kumar Jain, Chairman, CITI, India’s cotton yarn and fabric exports are struggling due to the duty disadvantage faced by exporters in major markets. There has been continuous decline in cotton yarn and fabric exports from 2013-14 to 2017-18. India’s export of cotton yarn declined 25 per cent from $4,570 million in 2013-14 to $3,443 million in 2017-18. Fabric exports, during the same period, declined 7 per cent from $4,941 million to $4,598 million.

China, the largest importer of cotton yarn has shifted focus from India to Vietnam, Indonesia as these countries offer duty free access, while Indian yarn carries a 3.5 import duty. There has been a decline in India’s cotton yarn exports to China by 48 per cent from 2013-17 while exports from Vietnam and Indonesia have increased at a remarkable rate of 129 per cent and 55 per cent respectively in the same period.

Raw cotton exports a loss, import duties add to woes

India’s raw cotton is exported to various markets at zero per cent duty. The country exported $1894 million worth of raw cotton in 2017-18. Export of raw cotton bales instead of value addition by converting to yarn and fabric is leading to loss of valuable foreign exchange, employment and better remuneration to farmers. Similarly, fabric exports from India are at serious disadvantage visà-vis exports from competing countries due to duty differentials in leading exports markets. Markets like EU, China, Turkey and Vietnam impose an import duty in the range of 8-12 per cent on Indian fabric while duty free access is given to countries such as Pakistan, Cambodia, Bangladesh and Cambodia.

The fall in Indian cotton yarn and fabric exports is impacting the entire value chain as there is considerable exportable surplus in the country. As per the Financial Stability Report by RBI, the stressed advanced ratio of textiles sector stood at 18.7 in September 2018.

Report by RBI, the stressed advanced ratio of textiles sector stood at 18.7 in September 2018.

Covering cotton yarn under MEIS to boost exports

Further, Jain highlighted growth in clothing stock has not led to consumption leading to a pressure on the yarn and fabric capacities. Export of garments has declined from $17.4 billion in 2016-17 to $16.7 billion in 2017-18. Jain urged the government to cover cotton yarn under MEIS which will boost India’s exports besides helping it penetrate new markets especially in Africa. Also, farmers will get better price for raw cotton. Cotton yarn is the only segment not covered under MEIS. Hence, despite abundant raw materials and second largest cotton spinning infrastructure in the world, cotton yarn exports are struggling in the absence of government support.

Increase in MEIS for fabric needed

Jain urged the government to enhance MEIS for fabric from 2 to 4 per cent on par with made ups. He said weaving sector is labor intensive like the made ups and garmenting sectors and mostly carried out in the unorganised sector especially in the rural and semi-urban areas. The sector employs women substantially. Hence, if MEIS rate for fabrics is increased from 2 to 4 per cent, exports of fabrics will increase by $1 billion per annum. He urged the government to consider the plea of textile industry and resolve the issues on an urgent basis.

Uzbekistan will deepen reforms in the textile industry to fully reprocess raw cotton domestically and increase the export potential of the country. Stimulating measures will be provided for enterprises engaged in exports of textile products.

Uzbekistan, the world's sixth largest cotton producer, produced 2.3 million tons of raw cotton in 2018. Traditionally, cotton has been Uzbekistan's most important cash crop. But in recent years the country has been taking serious steps to develop its textile industry to produce value-added products rather than exporting raw cotton.

Uzbekistan’s textile exports were up 41.4 per cent in 2018 from the previous year. The aim is to increase export volumes of textile products to $7billion a year by 2025. New cotton textile companies will receive a number of benefits and preferences. These enterprises will promote efficient and rational use of land, water and other resources, increase in yields and timely harvesting of raw cotton, and also ensure its further in-depth processing and production of products with high added value.

These production facilities will buy raw material directly from farms. So far there was no such mechanism for purchasing raw materials first hand. The country exports cotton mainly to China, Bangladesh, Korea and Russia.

Teejay, based in Sri Lanka, is a circular knitter has seen its Q2 revenue grow 25 per cent. Profit before tax was up 11 per cent and net profit increased 15 per cent over the corresponding three months of the previous year.

One of the region’s largest textile manufacturers, Teejay supplies fabrics to some of the top international brands across the world. The company is part owned by Sri Lanka’s largest apparel exporter, Brandix Lanka, which has a 33 per cent stake and Pacific Textiles of Hong Kong, which owns 28 per cent of the company.

This was the fourth consecutive quarter of revenue and net profit growth for the company in the face of stiff challenges, and was made possible by expanded capacity and a strong order book arising from the GSP facilities that it enjoys.

Although margins were impacted by raw material and utility cost increases in the second quarter, Teejay was able to improve its gross margin to 11.3 per cent from 10.2 per cent in the corresponding quarter as a result of better loading and an improved mix, with its USA and EU business units increasing sales volumes. The plan is to expand in India in the second half of the financial year.

The trials and changes presently facing supply chains may have spurred attendance at Sourcing at MAGIC in Las Vegas last week. One feature of the latest show was a virtual reality experience dubbed X-Ray Fashion. It’s a film made by an Italian director [Francesco Carrozzini] that takes you into various places impacted by fast fashion.

As a part of the sustainability focused immersive experience produced by Vulcan Productions, attendees could remove their shoes and virtually traverse rivers in Bangladesh and other areas that have taken a hit at the hands of the fashion industry.

Waterless denim was a major feature at the show too, with companies like Jeanologia showcasing nanotechnology and advancements in waterless and laser finishing for jeans. Levi’s has also been a major player in the area of saving water in denim processing, with its Water

Beyond sustainability and water saving, tariffs, trade and Made in China 2025 were other big focuses at Sourcing. The show floor featured micro factories showcasing technologies like a body scanner from Tukatech that can make 3-D fit models from a series of measurements derived from scanning the body, and a CAD system that creates the style in a 3-D format to bypass physical sample making, saving time and costs..

Pakistan Textile Exporters Association (PTEA) lauded the government’s move for liquidation of outstanding refunds through promissory notes but expressed concern over long outstanding liquidity under textile policy incentive schemes. It also demanded supplementary grant for payment of incentives under textile policies 2009-14 and 2014-19

The association claimed that inadequate liquidation of refunds would result in failure of getting desired results as huge amounts of exporters were still stuck against textile policy incentive scheme. The association says, exporters’ claims of Rs 10,300 million were outstanding against export finance markup support, Rs 1,500 million against Markup Rate Support, Rs 19,405 million against Technology Up-gradation Fund, Rs 434 million against Reimbursement of EOBI & Social Security contribution of women and handicapped employees of textile industry whereas Rs 2500 million were outstanding against Drawback of Taxes & Levies (DLTL) 2009-11.

Moreover, Rs 10 billion were outstanding on account of income tax; whereas Rs 10 billion was pending against income tax credit u/s 65B & 65E. With huge shortage of funds, textile industry was unable to tap its potential in accordance with capacity.

For the nine month period Nandan Denim’s capacity utilisation stood at 63 per cent. Gross margin stood at 30.2 per cent and declined by 199 bps due to lower sale realisation and relatively higher price of key raw materials such cotton, power etc.

Employee expenses and other operating expenses marginally increased by 3.2 per cent and 3.3 per cent respectively. Ebitda margin was 10.7 per cent. The temporary oversupply, aggression in pricing and higher credit period which the industry is facing impacted the volumes, realisation and profitability of the company.

Net finance cost declined by 52.8 per cent. Nandan Denim is India’s largest denim fabric manufacturer. From a year-on-year perspective, Nandan has completed capacity expansions at the denim fabric, shirting fabric, and yarn manufacturing units.

The company’s fabric manufacturing capacity is 110 million meters per annum. Going forward, emphasis will be laid on fashion denim fabrics to target better realizations compared to regular denim material.

A combination of higher sales volumes and value added products is likely to fuel top-line growth in the coming fiscals. Denim fabric contributes 80 to 90 per cent to Nandan’s annual turnover. Nandan is gradually steering the business towards the value added denim category.

The late Robert H. Chapman, III, who served as Chairman, Chief Executive Officer, and Treasurer of Inman Mills in Spartanburg, S.C., received the 17th Oscar Johnston Lifetime Achievement Award. He was honored at the National Cotton Council’s 2019 annual meeting held in San Antonio, Texas.

The award was presented by outgoing NCC Chairman Ron Craft to Ellis Fisher, a son-in-law of Chapman who serves as Inman Mills’ vice president and general counsel and who accepted the award on behalf of Chapman’s family.

Along with his service at NCTO, Chapman served the NCC as a manufacturer delegate from 1999-2017, a Board member from 2005-2017 and as an advisor in 2016. He was a member of the NCC’s 1989 Cotton Leadership Class. A graduate of the University of the South, where he majored in economics, Chapman also earned degrees from the Institute of Textile Technology and Harvard Business School. In 1976, he joined Inman Mills, a company founded by his great-great uncle, James A. Chapman in 1901.

As per representatives of the Vietnam National Textile and Garment Group (Vinatex), the country’s garment and textile industry aims to achieve an export turnover of $40 billion this year. The group advocates that in order to achieve this goal, garment and textile companies should prepare specific solutions for each market scenario and closely collaborate with fiber and fabric firms to together overcome difficulties as well as market fluctuations.

This year, positive sign is expected from the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) with two potential markets: Canada and Australia. If market scenario is good, the EU market in the last six months of this year will add about $1 billion to garment and textile exports. Therefore, Vietnam’s garment and textile industry will be able to maintain steady export to main markets and achieve its export target of $40 billion this year.