FW

Bangladesh’s apparel manufacturers say vested interests are working hard to create unrest in its garment industry and this is part of a conspiracy to blacken the reputation of the industry. Siddiqur Rahman, President of Bangladesh Garment Manufacturers and Exporters Association (BGMEA) says appealed to garment workers “not to heed” to the “call of the conspirators” and that it would “harm the workers more than it would the industry.” The BGMEA chief was speaking at a programme, which was arranged at BGMEA auditorium in Dhaka, to compensate workers who died during work at various garment manufacturing factories in Bangladesh. 150 families were paid BDT 2,00,000 each, sourced from a Group Insurance fund that all BGMEA-enlisted factories have to comply with for the security of their workforce.

This was just one of the many compensation provided over a period of time to the family of deceased workers. These families are not victims of industrial disasters. The programme was also attended by Mohammed Nasir, Vice President (Finance), BGMEA, Atiqul Hassan and Ashiqur Rahman, Directors of the governing body of the trade association. Bangladesh government had also stated in the past that vested quarters are out to tarnish the image of Bangladesh’s biggest export sector the readymade garments segment. The administration too is keeping a close watch on NGOs that are working in the apparel sector, to see if they are inciting unrest in any way.

Bangladesh has posted growth in export earnings for the third consecutive month, in December, a feat credited to political stability and the rise in value of US Dollar against Taka. In the first half of the current 2017-18 fiscal year, the country earned $17.91 billion with a year-on-year rise of 7.15 per cent and crossing the target by .05 percentage points.

In December, export earnings grew over $3.35 billion with an 8.42 per cent year-on-year rise, but missed the target of $3.41 billion by 1.84 per cent. Mohammed Farashuddin, former governor of the Bangladesh Bank, stated year 2017 was good for Bangladesh in all aspects. He gave credit for the rise in export earnings to the devaluation of taka against the dollar.

The rise in exports in July and August helped Bangladesh post a 7.23 per cent growth in the first quarter of 2017-18 fiscal year, but missed the target by around 3 per cent, dragged down by a 10 per cent year-on-year slump in September. In the first half of the current financial year, readymade garment manufacturing contributed to around 82.5 per cent of total exports, with a 7.75 per cent year-on-year growth.

Bangladesh Garment Manufacturers and Exporters Association’s says exports dropped in September because factories were closed for eight to 10 days during the Eid-ul-Azha. Exports in the last financial year amounted to $34.59 billion, which was 3.39 per cent more than the previous year, but against a target of $37 billion.

"The McKinsey Global Fashion Index estimates the global fashion industry sales to grow by 3.5 to 4.5 per cent in 2018. But this growth is not spread evenly across all regions or segments. Economic growth is shifting from mature regions in the West to emerging markets in the South and East. As per the McKinsey FashionScope, by 2018 over half of apparel and footwear sales will originate outside of Europe and North America. Rapidly growing cities in emerging markets are particularly important growth centres for the fashion industry."

The McKinsey Global Fashion Index estimates the global fashion industry sales to grow by 3.5 to 4.5 per cent in 2018. But this growth is not spread evenly across all regions or segments. Economic growth is shifting from mature regions in the West to emerging markets in the South and East. As per the McKinsey FashionScope, by 2018 over half of apparel and footwear sales will originate outside of Europe and North America. Rapidly growing cities in emerging markets are particularly important growth centres for the fashion industry.

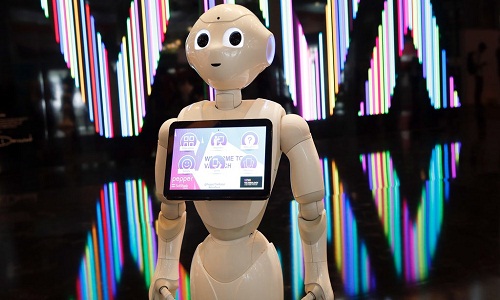

Adoption of disruptive technologies such as advanced robotics, mobile internet, advanced analytics, virtual- and augmented reality and artificial intelligence is accelerating, with the potential to disrupt entire industries, including fashion.

Online sales of apparel and footwear is projected to grow rapidly not the least in emerging markets. On average, consumers in Southeast Asia spend about eight hours a day online; from social media to video streaming and shopping amongst other things.

With information and the ease of comparison at their fingertips consumers are becoming less brand loyal: among millennials, two-thirds say they are willing to switch brands for a discount of 30 per cent or more.

Top 10 Trends: 1. Predictably unpredictable: Geopolitical turmoil, economic uncertainty and unpredictability are the new normal. 2. Globalisation reboot: A new phase of globalisation characterised by the exponential growth of cross-border bandwidth, connectivity and digital data flows will alter the global playing field and give certain players a competitive edge. 3. Asian trailblazers: Asian players will assert their power and leadership even more through pioneering innovations and global-scale investment and expansion. 4. Getting personal: Personalisation will become more important to the customer. 5. Platforms first: Consumers will increasingly look to online platforms as the first point of search, attracted by their convenience, relevance and breadth of offering. 6. Mobile obsessed: With an overabundance of mobile payment solutions already available globally, consumers will expect fashion companies to cater to increasingly convenient mobile transactions. 7. AI gets real: Leading innovators will reveal the possibilities of artificial intelligence across all parts of the fashion value chain, blurring the line between technology and creativity. 8. Sustainability credibility: More fashion brands will plan for recyclability and genuine ethical upgrades. 9. Off-price deception: As Europe and Asia get hooked on the myth of an off-price ‘panacea,’ the fashion industry could be put at risk of margin erosion. 10. Startup thinking: A growing number of fashion companies will aim to emulate the qualities of startups such as agility, collaboration and openness along with new ways of working, new kinds of partnerships and new investment models.

US company Boardriders, which owns the Quicksilver brand, is acquiring Australian rival Billabong, merging two major names in sportswear. The combination of Boardriders and Billabong will create the world's leading action sports company.

Both companies, which are well-established in the world of skiing, surfing and skateboarding, will together have 630 retail stores in 28 countries and over 7,000 retail customers in 110 countries. Boardriders is controlled by the Oaktree Capital investment firm, which already owns 19 per cent of Billabong.

Under the deal it will buy the remaining shares of Billabong at one Australian dollar per share, a premium of 28 per cent over the stock price on November 30 when the buyout bid was unveiled. Billabong's board members unanimously recommended the deal to shareholders and the firm's shares were 2.60 per cent higher at 98.5 Australian cents (77 US cents) in afternoon trade in Sydney.

US denim imports overall fell in October 2017, and the market share map continues to shift. Total imports of denim trousers across categories were down 2.51 per cent for the period, putting the market at $2.94 billion in value, with the men’s and boy’s category dipping more than triple the less than 1 per cent decline in women’s and girl’s.

China remains the United States’ largest supplier of denim trousers, though its share continues to slip. The Asian powerhouse commanded 25 per cent of market share across the categories as of October with $738.9 million worth of exports to the US, though that number is down nearly 12 per cent year-over-year.

Mexico ranks the second largest supplier of denim trousers to the US, delivering $666.4 million worth of product a 22.6 per cent share of the market. Bangladesh is currently the third largest supplier of denim trousers to the U.S., and it’s share of the market, which currently stands at 14.1 per cent seems to be continuously on an upswing. The country exported $416 million worth of denim trousers to the U.S. in the year to October.

Rounding off the United States’ top suppliers of denim trousers, in order of import value and market share, are Pakistan, Vietnam, Egypt, Nicaragua, Indonesia, Cambodia and Lesotho. The US imported $1.84 billion worth of men’s and boy’s denim trousers in the year to October, accounting for 62 per cent of total denim trouser imports. In men’s category, Mexico was the top supplier, though the $703.9 million worth of products it shipped to the US came in nearly 9 per cent lower than the prior year period. Bangladesh and China followed as the No. 2 and No. 3 suppliers in men’s and boy’s.

According to a recent report in the Guardian, evidence of worker confinement has been found in the supply chain of luxury fashion retailer Hugo Boss.

One of the company’s suppliers in southern India, Best Corporation, has been accused of several transgressions, including: refusing to allow its female workers to leave its factory on their own free will; banning workers from having cell phones or only permitting telephone calls under managers’ supervision; and the denial of independent inspections by local labor and human rights organizations.

Hugo Boss acknowledged that forced labor was a concern within its supplier base. In that report, the company says it knew of no instances of grievances filed related to human rights violations – but Hugo Boss did not report any third-party human rights reviews, either. The problems Hugo Boss and other fashion companies have confronted in India have long been a drag on the reputation of the country’s garment sector. NGO, India Committee of the Netherlands, reported a year ago that various forms of human rights abuses at factories, including forced labor and child slavery, were found in over 90 per cent of spinning mills across the country’s southern region. The majority of these people were teenage girls and women between the ages of 14 and 18; and anywhere from 10 to 20 per cent of them were younger than 14. Of the almost 750 mills surveyed, a standard working week was over 60 hours long. In addition, only 39 of those mills paid the locally mandated minimum wage and only 10 of them had any trade union presence.

Cotton production recovery continues in 2017/18 with a projected 11 per cent growth due to increased area to touch 25.4 million tons. Following the sharp drop in production in 2015/16, the 2016/17 production recovered 7 per cent to 23 million tons. Production in the USA for the current season is expected to increase 25 per cent to 4.7 million tons, a 930,000 and increase. India remains the world’s largest producer with 2017/18 production expected to be 6.2 million tons with 8.7 per cent growth. The second largest producer, China’s, production is projected at 5.2 million tons with a 7.1 per cent increase. Pakistan’s production projections for 2017/18 is 11.5 per cent increase to 1.9 million tons. Production increase in Turkey is estimated to grow 18 per cent to 829,000 tons. Other major cotton producing countries are expected to have positive growth attributed to increased area and yields.

From the season low of 77 cents per pound at the start of season, prices are at a season high at the end of this calendar year up to 88 cents per pound. The current season average of 80 cents per pound is lower than the 2016/17 average of 83 cents per pound. With a lower international price from the previous season and the rising price of competing fibres, global consumption is expected to grow. International cotton prices have continued to move upward over the last few months as the season has been underway.

After stagnating in 2016/17, global cotton demand is expected to increase 3 per cent in 2017/18 to 25.2 million tons. Chinese mill use is expected to remain stable at 8.1 million tons, while India and Pakistan are expected to increase 3 per cent and 4 per cent respectively. Consumption in Vietnam is expected to grow 12 per cent to 1.3 million tons. Moderate growth of 2-3 per cent is expected for other major consuming countries of Bangladesh, Turkey and the United States.

As the fair and the potential in the Asian market continue to gain prominence in the global industry, Yarn Expo Spring 2018 is ready to once again create an effective sales and sourcing platform for the industry. Held from March 14 to 16th of the National Exhibition and Convention Center, this year’s fair is expecting over 450 exhibitors (2016: 393) to take part. A full spectrum of quality yarn and fibre products, such as natural and blended yarns, man-made fibres and yarns as well as the fair’s rising star specialty yarns will be featured to accommodate all kinds of sourcing needs.

With Yarn Expo Spring 2018, four other textile trade fairs are held concurrently in the same venue that is Intertextile Shanghai Apparel Fabrics Spring Edition, Intertextile Shanghai Home Textiles – Spring Edition, PH Value and the China International Fashion Fair (CHIC).

Jack & Jones, the men’s apparel brand, a division of Denmark-based Bestseller, is launching two jeans that contain recycled post-consumer cotton in its effort to ensure sustainable denim. The jeans are to be included in the brands “never out of stock range.” The brand says jeans will contain the highest possible amount of recycled post-consumer cotton to reach a high level of quality. The remaining cotton will be sourced as either ‘better cotton’ or organic cotton.

The sustainable jeans project is in support of Jack & Jones’ Low Impact Denim initiative which includes the use of laser and ozone technologies. This is a part of the brand’s mission to accelerate a circular fashion system. As a strategic partner of the Global Fashion Agenda, a Copenhagen-based industry group dedicated to transforming the way fashion is consumed/produced, Bestseller is rolling out three action points on post-consumer waste.

Besides increasing its use of recycled textile fibre by 2020, all Bestsellers designers and buyers will have completed a training module on circular fashion design. The company will also offer and promote a used garment collection channel to consumers in selected markets along with partners. The action points are in reply to Global Fashion Agenda’s call to action unveiled at the Copenhagen Fashion Summit in 2017. The group called on fashion brands and retailers to sign a commitment to speed up its efforts to create a circular fashion eco-system by increasing the volume of used garments collected and resold as well as by increasing the share of garments made from recycled post-consumer textile fibre.

Dorte Rye, Bestseller’s Sustainability Manager, explained that the action points are key to a more circular system, however, they cannot stand alone. “The coming years ahead both Bestseller and the entire industry as such must learn together and be very innovative to take on the challenge on creating a more circular system for fashion.”

Inditex is gaining traction in Asia. According to the brand’s latest results, the region saw some of the group's biggest openings in the last financial year, and continues to be its second largest global market after Europe.

Last year, the continent accounted for almost a quarter of all global sales of the Spanish group. According to Inditex CEO Pablo Isla, the company plans to continue investing heavily in Asia. In 2012, Asia accounted for just 19 per cent of the retail giant’s revenue, rising to 23.9 per cent at the end of 2016. Meanwhile, other regions have remained relatively unchanged, except for Spain, which decreased its share from 20.7 per cent of all sales in 2012 to 16.9 per cent last year.

Over the last five years, Inditex has been particularly focused on growing both its physical store estate and expanding its online presence – a dual strategy that has been replicated across the Asian territory. In 2017, Zara opened an online store in India, joining the brand’s presence in Singapore, Malaysia, Thailand and Vietnam. But China is where the brand is most widespread, with a total of more than 620 stores.

Some 2017 milestones for Inditex included the opening of a 3,200-sq. mt. Zara flagship in Shenzhen, China; and similar launches in Mumbai, India; Nagoya, Japan; and Hanoi, Vietnam. Shenzhen also saw the opening of a Massimo Dutti flagship, while Bershka’s brand image was revamped in Tokyo. Meanwhile, Pull&Bear launched in Vietnam, where Pablo Isla eyes the launch of more brands following the arrival of Stradivarius in Ho Chi Minh, Massimo Dutti and Pull&Bear.

But for Inditex, Asia is not just an attractive retail market. The company has almost a thousand suppliers and more than 2,734 factories in the region, with Asian workers accounting for 10 per cent of the group’s total number of employees.