FW

The 12th edition of Shenzhen International Brand Underwear Fair (SIUF) would be held in Shenzhen, Southern China from April 19 to 21. Organized by Shenzhen Shengshi Jiuzhou Exhibition and owned by Tarsus Group, the joint trade fair SIUF, also named as China (Shenzhen) International Brand Underwear Fair & Shenzhen International Underwear OEM/Materials and Fabrics Fair has made its way to become the most influential fair in Asia.

The 2017 show will be on track to be the largest edition yet. The focus will continue to be on offering the whole supply & distribution chain of intimate apparel industry including fabrics, accessories, brands, production and solutions for intimates, swimwear, sportswear and lounge wear. Featuring 825 exhibitors and 105,600 industry visitors from 27 countries in 2016, SIUF is an important industry resource for intimate apparel professionals, distributors and retailers, suppliers, brand owners and designers of lingerie industry. Covering over 73,000sq. m. the show will be heavily supported and endorsed by official bodies: China Knitting Industrial Association, Guangdong Province Textiles Association, Shenzhen Underwear Association, HKIAIA and Taiwan Textile Federation.

Adapting the show's content to consumer trends, the 2017's edition will offer a package of activities in its three-day run, comprising distributor awards, brand awards, design contests, trend forums, brand fashion shows and the ultimate Super-model Talent Show. Covering over 650 brands, many with enlarged and upgraded booths, there will be more product launch and trends on display than ever before. Exhibitors include: Invista, Lenzing, Taubert, Muehlmeier, Penn Textile Solution, Pressless, Creora, Asahi Kasei, Toyobo, Eurojersey, Bemis Hong Kong, Bluesign as suppliers and as brand owners.

"B2B Exhibition at New Delhi & Kolkata, India by India Trade Promotion Organisation" during Feb 21-24, 2017".

The 18th edition of Tex-Styles exhibition will open doors in Delhi from February 21 to 24, 2017 at Hall No. 11, Pragati Maidan. The fair is being organized by trade promotion agency India Trade Promotion Organisation (ITPO). Following Delhi, the exhibition will also debut in Kolkata from February 26 to 28, 2017 at Milan Mela Complex. Since its inception in 1995, Tex-Styles India Fair has emerged as an ideal forum for presenting multi-faceted splendor of Indian textile industry and established itself as the leading fair of its kind in Southeast Asia.

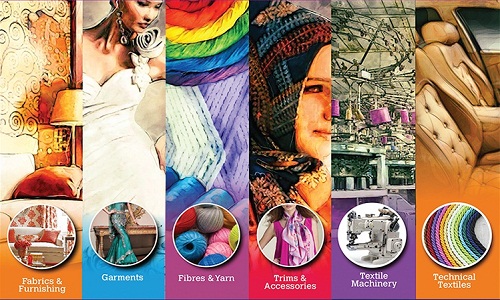

The major attractions

Tex-Styles India covers the entire gamut of products in textile industry. The display profile covers furnishings; fabrics yarns and fibres; apparel (men, women and kids apparel) - outer wear and jackets, pants, skirts, one-piece dresses, blouses, shirts, tunics, cut and sewn garments, technical textiles - nets, surgical, medical and sanitary textiles, technical & safety apparels, car seat covers, HDPE woven sacks, sports wear, upholstery, labels and laces, belts, ropes and hoses, nylon tyre cord fabric & geo-textiles; trims & accessories shawls, tussar, laces, threads and other embellishments to enhance the look and feel of the modern apparel and furnishings; technical textiles, textile gifts, textile process machinery, textile working machinery, looms and support services - CAD/CAM Systems, colour & trend forecasts, trade publications and support services for the textile & furnishing industry.

The Delhi show will have companies displaying products from woolen, silk, handlooms of North India, cotton, synthetics and rayon from West India , handloom, powerloom and silks from South India. The Kolkata edition will focus on products from the Eastern India with silk from West Bengal, Bihar and Jharkhand with different weaves, Muga and Eri silks from Northeast India, shawls from Nagaland, handloom cottons and silks from Orissa, the widespread garment export hub in West Bengal and eco-friendly jute fabric. The show offers buyers a one-stop-shop to view and source a large range of textile products of varying genres.

The USPs of the exhibition is that it offers comprehensive coverage of Indian textile industry with the best companies in each field such as cotton, silk, wool, synthetics, powerloom, jute, blended and other fibres. It is the only textile show in India which provides buyers a one-stop platform for purchase of every conceivable textile products produced by India i.e. furnishings, selected floor coverings, fabrics, garments, accessories, etc. Products displayed here are specially adapted for overseas markets and cater to the forthcoming Spring/Summer and Autumn/Winter seasons.

The range, quality and diversity of products exhibited are rarely seen elsewhere under one roof. The show assists buyers in selecting the most appropriate products. Special pavilions and facilities like Theme Pavilion, Fabric Folio Pavilion depicting the collection of swatches from all sectors of the Indian textile industry including participating firms and others are set up apart from forecasters depicting designer interpretation of trends. Tex-Styles India draws the best of participants and buyers from India.

Analysts in Pakistan believe in the absence of adequate business-friendly environment, the upcoming Rs 75 billion package for six export oriented sectors would not ensure full scale recovery of export oriented industry, say analysts. Reports say that Prime Minister Nawaz Sharif is likely to announce an incentive package for five or six export-oriented sectors to the tune of Rs 65-75 billion of which the textile sector would be the top beneficiary.

According to Zeeshan Azhar, an analyst at Foundation Securities feels, the package could go some way in making textile sector competitive internationally but core issues like uncompetitive exchange rate, higher electricity/gas prices, poor power supply, outdated technology, undiversified product base and low cotton quality will continue to hamper a full scale recovery of the sector.

The said incentives would add to the incentives already in place since the effect of Textile Policy FY14-19 and the FY17 budget. Currently, rebate on local tax varies between 1-4 per cent of Free on Board (FOB) value on 10 per cent incremental exports over last year.

This rebate could go up to 3-8 per cent of FOB value. The new tax rebate could be on 10 per cent incremental exports or be extended to full FOB value. The impact on companies' bottom line would be muted in the former case but sizable in the latter, Azhar added.

The government believes the package is necessary to encourage exporters who are struggling due to lower demand from major export markets, stable US dollar-Pakistani Rupee parity, and incentive package announced by competitors like India, Bangladesh and Vietnam. The downward trajectory in textile exports has shown some respite over the last two months but prognosis of the sector remains weak. The scope and impact of the upcoming textile package is still to be seen.

Tejidos Royo has launched its new Suave capsule collection for Spring/Summer 2018. Developed with TENCEL fiber, the Suave capsule S/S’18 includes fabrics of 100 per cent TENCEL as well as new blends with linen that for a special level of elegance and comfort. Royo draws in the past and future to the present, with its tagline: ‘Looking at the past with eyes of the future.’

Founded in 1903, Tejidos Royo has been a leader in Europe’s textile sector for more than a century. Its two production facilities in Valencia, Spain produce fabrics exported to customers in more than 30 countries. Calling denim the ‘protagonist’ of the collection, Royo’s versatility aided by TENCEL, in colors from baby blue to black and indigo in between. The collection takes its cues from three fashion trends which Royo describes as ‘Marine Soul’ inspired by nautical explorers, ship sails and sailor knots; ‘Adventure Dream’ touched by the unique romanticism of pioneering women and ‘Wild Life’ with a wild, Latin sensibility brought by tropical prints and exuberant summery color. This is another iteration of denim, where the ability of lightweight fabrics to flow contradicts their strength, something that shareholder Jose Rafael Royo attributes to the silkiness of TENCEL and its ability to work in blends.

Cotton mills across Maharashtra owe the government as much as Rs 1,700 crores. The government has recovered only Rs 73.61 crores of the Rs 1,748 crores that had been released towards share capital over the last two decades. Ironically most of the mills are under leaders from political parties.

Though 130 societies sought funding as share capital to set up the mills, 29 of them have gone for liquidation, while three have been shut down. Twenty four of them are still under construction, while only 34 of them are running. The government has failed to recover the dues due to the political patronage the mills enjoy. The mills are expected to start paying back as soon as production starts. To avoid repayment, some mills do not draw the last installment of government share. Some of them have recruited excessive manpower while in a few cases the management has paid an exorbitant price to make the business unfeasible.

The state government extends a share capital of 45 per cent to cotton mills set up on a cooperative basis by the board of directors in general categories. Given the state’s poor finances and ballooning debt, the government has now decided to review its norms for recovery of the dues.

India’s export of 100 per cent man-made fibre yarns was at 5 million kg in November. It comprised 2.28 million kg of polyester yarn, 2.15 million kg of viscose yarn and 0.59 million kg of acrylic yarn.

Exports of polyester yarn were down 9.9 per cent in value while the value of exports of viscose yarn rose 67.7 per cent during the month. Exports of acrylic yarn declined 28 per cent in November. Unit price realization was down US cents 6 a kg for polyester from a year ago and that of viscose yarn fell US cents 35 a kg. On the other hand, unit price realization of acrylic yarn grew US cents 50 a kg year-on-year basis.

Polyester spun yarns were exported to 34 countries in November aggregating $5.2 million with unit price realization averaging $2.29 a kg. On the whole, a total of 2.28 million kg was exported. Of this, 25.5 per cent was shipped by Turkey alone. Five new destinations were found for polyester yarn in November. Of this, Mexico, Dominican Republic and South Korea were the major ones.

Only 38 representatives — not a big number — from the huge global fashion industry attended a summit held at the UN Climate Change Secretariat in Bonn, to evaluate the possibility of a joint future climate action programme. The two-day agenda mainly focused on global collaboration in the fashion sector to look at methodologies to enable a significant shift towards putting together a larger, joint environmental project. Brands including Adidas, C&A, Hugo Boss, H&M and FIlippa K attended the summit along with representatives from textile manufacturers, recycling associations and fibre innovators.

Environmental targets, an online platform to open dialogue and enhance engagement with policy makers at the national and international level, were key aspects of the agenda across the two-day United Nations Framework Convention on Climate Change (UNFCCC) event.

One of the most significant aims of the initiative is to engage more organisations in these discussions. The next step will be preparation and execution of a report by the UN Climate Change Secretariat to share with stakeholders in the fashion sector. The UN hopes this report can be a catalyst in beginning a global climate action programme to integrate existing environmental initiatives within the fashion industry.

Mistra Future Fashion’s Sigrid Barnekow was the moderator for the panel discussions, along with the UNFCCCs executive secretary and manager for Strategy & Relationship: Patricia Espinosa and Niclas Svenningsen. In her role as moderator, Patricia said, “I believe we stand at a turning point in history. For the first time, humans are no longer just affected by weather cycles, we are affecting those cycles and suffering the consequences of doing so.”

Mistra was of the view that total greenhouse gas emissions from textile industry production is estimated to be 1.2 billion tonnes per year, which is believed to be more than all international flights and maritime shipping combined. Niclas highlighted the fact that to agree on such a program, all parts of the fashion system needs to be taken in consideration, “The fashion sector has a huge challenge, complex supply chains from primary producers to retail shops and fast-growing demand with limited recycling.”

Knit-Tech, a well known International brand in the International Textile Machinery Expo Industry is owned by a Tirupur-based company Hi-Tech International Trade Fair (India).

The brand’s very first expo Knit-Tech 1993, an international textile and knitting machinery expo was very successful during the UPA government. The expo created awareness and a revolution of sorts in the knitting and textile industry of South India.

After that, Hi-Tech International Trade Fair India, has been conducting a series of exhibition once every two years. It has been successful in a big way by bringing latest machinery, technologies, concepts, services from all over the world. Normally, more than 100 participants from overseas including US, Europe, Singapore have been regularly participating in all events along with their latest developments.

Knit-Tech is a reliable, strong, dynamic, established platform for overseas manufacturers of textile machinery to showcase their products to the right clients in a economical way. By this, they could promote their identity globally. As of now Knit-Tech has conducted 13 international events that attracted more than two lakh business visitors from all over India and neighbouring countries like Sri Lanka, Nepal, Bangladesh and Bhutan. These expos generated business worth $300 million.

As production in spinning mills has come to a grinding halt since demonetisation, sales of yarn in western Tamil Nadu have plummeted. As a consequence, yarn stocks are piled up in city mills most of which rely on migrant labourers who have stopped work.

With shortage of labour, owners of spinning mills are unable to run their units on a daily basis. As a consequence, the number of shifts has come down to two or one per day. With inadequate workforce, mills are unable to carry out production to the capacity. This has resulted in piling up of yarn stocks. On any given time, most big spinning mills have stocks of 15 to 30 days. Now, it has piled up to three or four months.

The loss incurred due to the fall in production has doubled. The textile industry has been facing a dull market in the past two years. Yarn exports have come down as a result of which it has been a loss of anywhere between 15 to 25 per cent as compared to the business two years ago.

The Bangladesh’s garment-making sector has rebounded so strongly following the Rana Plaza disaster that the country’s economists and labour leaders are warning it could hold back the country’s economy as a whole. Nearly four years after the Rana Plaza collapse in Dhaka where more than 1,100 garment workers were killed western clothing companies are seen buying more from Bangladeshi factories like before.

While the booming garment industry is contributing to an overall growth rate of 7 per cent, economists feel it is suppressing wages and crowding out higher value sectors. As economics professor at Dhaka University, Rashed al Mahmud Titumir says there is no diversity in the economy. Bangladesh has not been able to produce more lucrative products and there are barely any exports except readymade garments.

As per Bangladesh Garment Manufacturers and Exporters Association, in fiscal 1983-84 Bangladesh garment sales abroad was around 3.9 per cent of its total exports worth $31.6 m. By 1989-90 it rose to 32 per cent, worth $624.2 m. At the time of the Rana Plaza collapse, the country’s worst industrial disaster garment exports had reached 80 per cent or $21.5 bn. Despite the tragedy, the sector has continued to grow, hitting $28.1 bn in the last financial year and accounting for 82 per cent of total exports.

Industry representatives say continued growth is the result of unprecedented action taken in the aftermath of the disaster. In the year after the Rana Plaza incident, the number of clothing factories in Bangladesh shrank by 1,654 — 615 of which were related to the new safety measures. More than 200 foreign brands have signed up to two different safety schemes, the Bangladesh Accord on Fire and Building Safety and the Alliance for Bangladesh Worker Safety and have promised to spend tens of millions to improve factories.