FW

Nigeria is taking steps to revive the textile industry. Forex for textile traders has been banned. A gas tariff for textiles has been approved but is yet to come into full operation. Problems plaguing the Nigerian textile industry include: lack of sufficient electricity supply, counterfeiting and smuggling, among others. A major problem is cost of energy. One suggestion is to set up a textile task force to combat smuggling of textiles and fix a minimum value for textiles coming into Nigeria.

Stagnated by unchecked smuggling and dilapidated infrastructure in the mid ’80s and early ’90s the Nigerian textile industry used to have about 95 companies. The sector was one of Nigeria’s largest and oldest manufacturing sectors and rated third in Africa behind Egypt and South Africa.

Nigeria aims at producing up to 4,50,000 metric tons of cotton in three years. This is part of an effort to revive the textile and garment industry. Up to 3,00,000 farmers will be engaged to achieve this aim in 26 out of the 36 states of the country. Six thousand metric tons of cotton seed have been imported and an additional 2000 metric tons have been sourced locally. The total expected yield at the end of the current season is 3,02,440 metric tons.

Rreadymade garment exports dropped around 4.51 per cent in February 2020. COVID-19 outbreak is expected to impact exports for the next few months and has impacted sentiment in the European market — the largest for Indian exporters. Recent trends in US apparel imports have also been discouraging. For orders placed, delivery is taking much more time than usual. This is the primary reason for the fall in exports. As most countries are under lockdown, stores are shut and people don’t go out and stay at home. The drop is mainly due to weak buying and many customers’ going bankrupt or witnessing lower sales.

Indian apparel exporters expect a correction of around 100 to 150 bps in their operating profitability in fiscal ’20. This is expected to result in a moderation in debt coverage metrics. The impact is likely to be more pronounced for leveraged and smaller companies, with limited bargaining power with customers, and modest liquidity cushion.

When the outbreak started in China, initially it was looking like an opportunity for Indian exporters. This was because European customers, who were traditionally sourcing from China, started discussions with Indian exporters for new orders. But ever since the virus started spreading to Europe, things have turned upside down.

Apparel Export Promotion Council (AEPC) has issued a trade and health advisory that shares its initiatives of identified alternate sources of input suppliers to help diversify sourcing of raw materials and identified products with potential for exports in US markets. As for apparel export, China has recently offloaded products worth $4.9 billion in top nine markets. In these markets, though India has captured only $ 314.4 million.

Germany, Korea, Russian Federation, France and Netherlands are among the top markets where India couldn’t capture the offloaded space by China. While in Australia, UK and US, India captured the Chinese offloaded space by 29.9, 10.7 and 9.7 per cent, respectively.

As for raw material sourcing, India’s import of yarn, fabric and interlining from China were 46, 67 and 99 per cent respectively. Indonesia and Japan can be an option for yarn, while Egypt and Korea should explore for fabric. Out of top 10 product segments exported to the US by China, India has a potential for seven categories, while there are four such products exports to EU that India can tap. Some common products for US and EU are jerseys, pullovers, cardigans, waistcoats, women’s trousers, bib and brace overalls and men’s trousers.

E-commerce company Global Fashion Group has set targets for 2022. All top 30 brands it sells will be engaged in sustainability. Water from its warehouses will be comprehensively tracked. At least 50 per cent of all GFG waste will be recycled. There will be 100 per cent carbon mapping and science-based reduction targets will be set for the entire group. In countries that use delivery packaging, 100 per cent of these will be made from sustainable materials. Working conditions risk assessments will be completed, and high-risk providers audited.

Global Fashion Group, founded in 2011, which owns websites including The Iconic, Zalora and Dafiti, employs 12,828 people across 19 countries with 17 offices and ten fulfilment centers across four continents. Powered by best-in-class operational infrastructure, which is fashion-specific and tailored to local market needs, it is focused on creating inspiring and seamless customer experiences – from discovery to delivery. GFG is the only company offering flexible models and solutions for the digital distribution of fashion and lifestyle brands in growth markets. It gives brands unparalleled access to a market of more than a billion consumers and works together with its brand partners to offer the most relevant and curated products in an inspiring customer environment. Brand partners also benefit from GFG’s best-in-class operational capabilities and technology innovations that are locally tailored across all four of its e-commerce platforms.

India can expect a 0.5 per cent hit on economic growth this fiscal if the COVID-19 pandemic lasts longer, says Care Ratings.

The economic impact will be significant and long term if the virus continues for longer. A widening of the fiscal deficit is also feared. NPA levels in the banking sector are expected to increase. Exports and imports are likely to contract. While hospitality, tourism, aviation, auto and auto ancillary will be hit hard, pharma and healthcare will benefit from the pandemic.

If China continues to battle with the coronavirus, Indian garment manufacturers will need to look at other alternatives, including local sourcing, which in turn may increase the cost of finished goods by three per cent to five per cent. In addition to this, identifying vendors in such a short time can take a toll on lead times, quality and cost. On an average, India exports 25 million kg of cotton yarn a month to China. The garment sector in Tirupur is heavily dependent on China for sourcing accessories. The total shutdown in China has disrupted the supply chain. The sector may hurt its margins if accessories are sourced from a trader in India or from an overseas market other than China.

Fashion brands the world over are closing their stores for now in the wake of COVID-19. Urban Outfitters, the group that owns the homonymous brand, Anthropologie and Free People, has closed all of its stores in the United States, Europe, and Canada. VF Corporation owner of brands such as Vans, The North Face and Timberland is closing its stores across North America, its most successful market by revenue. Similar actions have been taken in the EMEA region and the Asia Pacific. Inditex has closed its stores in Spain. In total, the group has 1,953 points in the country, which consists of brands such as Zara, Massimo Dutti, Bershka, Stradivariusm, Oysho and Uterqüe.

Athletic apparel company Lululemon has closed all of its stores in North America and in Europe. The American company has a total of 479 stores. Fast Retailing has closed its stores in France and Spain. US-based Abercrombie will close its stores in the United States, Canada, and Europe, which amounts to 338 stores in these markets. For the brand, the United States is one of its most important markets in terms of revenue and store presence, as the company has more than half of its stores in this market.

Iluna’s smart laces are beautiful, innovative and responsible and totally made with recycled yarns even in the stretch part. The premium ingredients are recycled polyamide yarn Q-Nova by Fulgar, a fiber made with regenerated raw materials that is Global Recycled Standard (GRS) certified, and GRS certified premium stretch fiber Roica EF by Asahi Kasei that gives superior comfort and performance fit. The laces are also combined with Bluesign certified silk, to ensure a fiber production chain aimed at improving environmental performance.

Iluna started out in 1969 with the production of pre-shaped bra cups. The products which constitute the core business of the group are elastic and hard lace for underwear, corsetry, hosiery, beachwear and apparel, seamless items using Karl Mayer technology as well as microfiber fabric and tulle. Recently Iluna Lab was added, a hub of technological and stylistic innovations. Iluna’s spearheads are the Black Label series, enriched by ultrathin lace, and the GRS certified Green Label line.

Roica Advanced fit for living is a premium stretch fiber with an innovative range of smart functions to suit the modern wardrobe. Roica shapes comfort with high quality, performance and fit, adding value to everyday living for sport, activewear, intimates, fashion and career wear.

Earth Logic Action Plan urges businesses across the global fashion sector to radically transform their models in such a way that places nature ahead of short-term financial gain.

This program has been devised by a group of academics, businesses and thought leaders to help fashion firms align with planetary boundaries and address the climate and nature emergencies. The plan wants the fashion sector to reduce its use of virgin resources by 75 per cent by 2030. In order to make this transformation, the plan offers advice on changing business processes, forging new collaborations and managing the financial and social implications of growing out of growth. It also offers advice on the processes needed to maintain and upscale fashion with Earth Logic at its core, including policymaker engagement.

The fashion industry is involved in climate and nature crises. Humanity is now consuming almost twice as many natural resources as the planet can produce. Fashion is estimated to account for around ten per cent of global emissions annually – more than international shipping and aviation combined. It has also been strongly linked to deforestation and water pollution. Between 80 billion to 120 billion garments and 20 billion pairs of shoes are manufactured annually.

UK-based company Xeros Technology launched a new machine at the recently held Garment Technology Expo. “Our products enable us to improve water usage significantly,” states Mark Nichols, CEO of the company. For its future expansion into the South Asian market, the brand has collaborated with Ramsons. It further plans to foray into Africa and East Asia markets in collaboration with the company. “We are negotiating with the company for our foray into the Bangladesh, Sri Lanka and India markets,” adds Nichols.

UK-based company Xeros Technology launched a new machine at the recently held Garment Technology Expo. “Our products enable us to improve water usage significantly,” states Mark Nichols, CEO of the company. For its future expansion into the South Asian market, the brand has collaborated with Ramsons. It further plans to foray into Africa and East Asia markets in collaboration with the company. “We are negotiating with the company for our foray into the Bangladesh, Sri Lanka and India markets,” adds Nichols.

Recently, the cost of Xeros machines increased significantly. However, these costs are offset by the multifold use that these machines have. “Our machines can be used for desizing, stone washing, bleaching, cleaving of denims in one continuous cycle. You don’t have to take garments in and out of machines repeatedly. This reduces lead times considerably and customers can get more products out of the machine,” views Nichols.

A technology licensing company, Xeros follows a different business model for the apparel industry. “We have a license agreement with Sea Lion in China, according to which IFT will launch our machines into India. These machines will help our customers prevent their clothes from being damaged during the washing process. They will also improve the outcome of these clothes during the cleaning process,” claims Nichols.

According to Nichols, Ramsons will sell hundreds of Xeros machines in a year. “We plan use spray technologies for this,” notes Nichols. The company has invested a huge amount in developing this technology in collaboration with the CNA Group. “CNA embellishes our designs, while we provide engineering solutions come from our end. Our Indian partners are creative and fast. The level of cooperation between us is fantastic,” he adds.

Xeros also offers small commercial washing machines. “These reduce maintenance costs. In the beginning, our technologies met with ample resistance and we had to push really hard for their use,” Nichols avers.

India has taken to sustainability in a big way. Not only has it introduced new regulations to enforce sustainability but has also launched zero discharge rules. According to Xeros, adoption of such new technologies will help make the world sustainable. “We need to phase fossil fuel-based technologies besides revamping our consumers’ behavior. We also need to launch washing machines that identify and remove micro particles. Consumers don’t pay more though they say they will. Brands and retailers want everything at a lower cost,” adds Nichols.

There is a well-known saying in China’s textile industry to commend Shenzhou International Group quoted as “Shenzhou is to the knitting industry what Foxconn is to the electronics industry”, speaking highly of the knitting giant that has grown up synchronically with the rapid development of the whole textile industry in China over the years.

As a role model in the industry, Shenzhou is the largest employer with approximately 100,000 employees working diligently in different factories both at home and abroad where there has been an overwhelming job growth of its operations both in Cambodia and Vietnam.

The COVID-19 has an across-the-board impact, which aroused media and government concerns over the business and employment especially in the big companies because their ups and downs have a penetrating influence on the whole textile industry. According to its latest corporate report, as of Feb.28, the actual production capacity was running at 95% since its facilities were rebooted on Feb.10 in the homeland operations, and the pause before the production got restarted would soon be made up for and the finished goods delivery would be realized on time without delay.

|

| Mr. Ma Jianrong, Chairman of the Group being interviewed by media |

In fact, on the very date of Feb.10, the first lot of workers coming back to work amounted to 14,000 in number in different localities, 39% of Shenzhou’s 40,000 homestay jobs inside the country. In an on-site interview, Mr. Ma said “The workers who have come back to this production base today actually spent their holidays for Spring Festival here in Beilun District of Ningbo city without going to the other places. The employees now in Wenzhou city, Taizhou city inside our Zhejiang province or workers in Hubei province, where the novel coronavirus situation is a bit severe, are requested to stay at home temporarily. If some people from those regions are already here, we get all of them tested in a professional medical check procedure. If anyone is tested to have a body temperature rise, we send him or her to the local Center of Disease Control and Prevention, and it anyone from these places is tested to result in a normal body temperature, we persuade him or her to go back home and stay there until the situation gets better on a favorable term that it is a leave of absence (LOA )with salary and annual full-time premiums.”

|

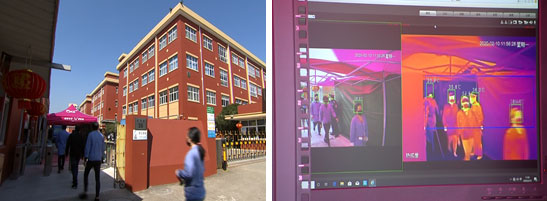

| Shenzhou’s workers come back to workplace in Beilun District, with infrared temperature measurer working on each passer-by |

Mr. Ma went on saying that every person is asked to wear face mask with operating desk a bit away from each other and to wash hands at least three or four times a day while body temperature is measured three times during working hours in addition to the entry test. Moreover, for the sake of safety, a QR code is designed and set up for each operator with quick access to the personal updated information.

At 16:oo on the afternoon ,Feb.14, a bus with over 20 workers from other provinces pulled up in front of the dormitory building, an initial step that led to a series of chartered-bus plan to carry over 17,000 workers from 14 provinces , such as Sichuan, Gansu, Yunnan, Shanxi and Shandong , on more than 700 buses to the workplaces across the country on a proximity principle where workers in different provinces are taken to the operations nearby, said Mrs. Li Saizhen, Chairwoman of Workers Union in the company.

|

| A chartered bus stops inside Shenzhou’s compound with workers returning to work |

Shenzhou International got publically listed in Hong Kong Stock Exchange in 2005 and turned out to gain market capitals amounting to HK$117.32 billion and dividend yield by 2.31%, and P/E by 22.12% on March 16,2020 according report by HKEX. The company’s business income is largely from the international sportswear and knit apparel brands, like Adidas, Nike, Uniqlo, Puma as well as Decathlon, Russell and Mizuno etc. and its advanced productions in vertically-integrated system on basis of knit fabric-dyeing, printing & finishing-garment package services make it the choicest one for the long-term supply chain partnership with those big names. The two production bases in Vietnam (fabric knitting and garment sewing) and one garment operation in Cambodia are playing important role in taking more orders to compensate for what is short of in China on merits and demerits conditions.

When the number of new infections is shrinking in China, the COVID-19 has swollen to be an international pandemic, dragging a lot of countries into an intractable chaos. The role model company is making itself an exemplary one in addressing the challenging issues that cropped up at the time when a new issue appears significantly spiny.

Contributed by Mr. ZHAO Hong

He is working for CHINA TEXTILE magazine as Editor-in-Chief in addition to being involved in a plethora of activities for the textile industry. He has worked for the Engineering Institute of Ministry of Textile Industry, and for China National Textile Council and continues to serve the industry in the capacity of Deputy Director of China Textile International Exchange Centre, V. President of China Knitting Industry Association, V. President of China Textile Magazine and its Editor-in-Chief for the English Version, Deputy Director of News Centre of China National Textile and Apparel Council (CNTAC), Deputy Director of International Trade Office, CNTAC, Deputy Director of China Textile Economic Research Centre. He was also elected once ACT Chair of Private Sector Consulting Committee of International Textile and Clothing Bureau (ITCB)