FW

Cifra returns to Milano Unica with an innovative concept collection of technical and upper casual outerwear. This collection, resulting from scrupulous planning and careful development in the Research and Development department of the company based north of Milan, coming from the need to create a new versatile and essential outerwear, with a technological and sustainable soul.

A style that taps into the travel wear trend and that provides a new generation of ultra-comfortable, technical, design garments that fully represents Cifra's overall technical and stylistic heritage.

The garments are made with the patented Warp Seamless Knit technique in pre and post-consumer sustainable yarns traceable and certified to preserve true ethical value alongside the Zero Waste program for the reduction of production waste.

The new UNIC - CONCERIE ITALIANE campaign has been designed in collaboration with Spring Studios, the international agency.

The aim is primarily at end consumers, so that they can appreciate the absolute value of a product of made in Italy excellence, whose identity is grounded in its unquestionable features of naturalness, durability and creativity, within the circular economy.

To achieve this goal, the REAL LEATHER IS REAL SUSTAINABILITY campaign will be aired worldwide on the web and on social networks, using traditional channels and through specific events. Particular attention will be dedicated to places and moments where media attention will enable it to obtain a greater audience for its messages.

The new UNIC campaign aims to raise awareness of leather and its qualities, especially among the younger generations, and to get across in how many ways it has always been a shining example of the circular economy. Leather, in fact, is a by-product of the food industry which would otherwise be subject to waste disposal techniques that have a great impact on the environment. Italian leather is produced by a sector, the tanning industry, consisting of 1,200 companies located mainly in 4 regions (Veneto, Tuscany, Campania and Lombardy) and employing in the region of 18,000 people.

Italian leather is world leader in value terms, dominating the European scene with a 62% share of production volumes (22% on a global scale) and is unique in the world for its recognized sustainable approach based on tangible values of transparency and strict compliance with the most stringent regulatory constraints in terms of safety, quality, responsibility towards consumers, traceability and animal welfare.

Considering all the reasons, the Italian leather promoted by UNIC - Concerie Italiane is proudly second to none and rejects the critical perceptions that surround leather, which are the result of disinformation, hypocrisy and media manipulation.

Saurer will showcase spinning and embroidery machines at ITME Africa 2020 expo that will be held at the Swiss Pavilion in Addis Ababa, Ethiopia. To be held from February 14-16, 2020, the event will focus on economic growth, employment generation, and technology up-gradation in Ethiopia and other countries in Africa.

At the exhibition, visitors will learn more about Saurer’s extensive spinning offerings, which enable customers to process a wide range of fibers depending on their needs using ring-, worsted- and compact- or rotor-spinning technologies. Autoairo, the group’s new double-sided air-spinning machine, will also be introduced to prospective clients, according to Saurer.

Further, Saurer will also enlighten visitors about Epoca 7, its shuttle embroidery machine. Developed with over 150 years’ experience, this technology enables embroidery plant owners to embellish their fabrics according to their clients’ specifications, thus creating an array of designs ranging from traditional to haute couture. Additional attachments for the application of cords, ribbons and sequins as well as for laser-cutting patterns further broaden the variety of possible creations.

UK fashion designer Stella McCartney has launched a new collection of biodegradable jeans in partnership with the Italian manufacturer Candiani Denim. The new line uses Coreva stretch technology and is produced using organic cotton wrapped around natural rubber, which as a result, produces a fabric that is free from plastics and micro-plastics. It will be presented at the McCartney’s autumn/winter 2020 show in May.

The collection includes 10 pieces in two colors and five styles. There are two flared pairs, one cropped, the other long, and a beautiful straight leg cut with a mid-waist. The biodegradable jeans will be available in-store and online globally from May 2020.

Stella McCartney held a 50:50 joint venture with Kering until last year, before the designer bought back 100 per cent of the company and pursued new partners in France. The sustainable luxury company sealed an agreement with France’s other luxury giant, LVMH, which has bought a minority stake in the brand.

Burberry, the British luxury fashion giant, plans to hold its Fall 2020 runway show in Shanghai on April 23, 2020. The show will include new looks designed specifically for the Chinese market, which will be available to purchase exclusively in China in stores and online.

The brand’s Fall 2020 show will be presented in London on February 17, during London Fashion Week. Its catwalk last season saw the brand leverage the star power of its brand ambassadors — singer Kun Chen, actress Dongyu Zhou, and rapper Lucas Huang.

Burberry has 61 stores in China and is set to open a social retail store in Shenzhen Bay as part of an exclusive partnership with Tencent during the first half of 2020. Previously, Burberry hosted a holographic show in 2011 for the opening of its Beijing flagship store and another catwalk in 2014 for the opening of the Shanghai Kerry Center. Nonetheless, this is the first time the brand has chosen to show a full collection in China and with new looks created entirely with Chinese consumers in mind.

In a classic case of administrative delays hampering development, tax refunds worth Rs 5,000 crore ( .70 billion) are pending with the government. In March 2019, the government introduced a new scheme for the garment exports sector. Called the Rebate of State and Central Taxes and Levies (RoSCTL), the scheme sought to refund the taxes on inputs paid by the sector. However, it’s been 10 months since the introduction of the scheme and refunds are still stuck with the government.

In a classic case of administrative delays hampering development, tax refunds worth Rs 5,000 crore ( .70 billion) are pending with the government. In March 2019, the government introduced a new scheme for the garment exports sector. Called the Rebate of State and Central Taxes and Levies (RoSCTL), the scheme sought to refund the taxes on inputs paid by the sector. However, it’s been 10 months since the introduction of the scheme and refunds are still stuck with the government.

In a classic case of administrative delays hampering development, tax refunds worth Rs 5,000 crore ( .70 billion) are pending with the government. In March 2019, the government introduced a new scheme for the garment exports sector. Called the Rebate of State and Central Taxes and Levies (RoSCTL), the scheme sought to refund the taxes on inputs paid by the sector. However, it’s been 10 months since the introduction of the scheme and refunds are still stuck with the government.

Tax rebates and subsidies to deal with capital crunch

Schemes including RoSCTL and the Merchandise Exports from India Scheme (MEIS) total 9 per cent of the total sales of these exporters. There is no clarity yet on the new rates under the two schemes, which has pushed Indian garment exporters into distress. Dominated by small businesses, these exporters face a huge capital crunch with salaries of their employees and vendors remaining unpaid. Some stakeholders say, the garment industry is on a ventilator and is about to die. To revive, the industry needs urgent action including tax rebates and subsidies. Any inaction, on part of the government is likely to push the industry towards bankruptcy and unemployment.

Employment generation and policy revamp

One of the government’s biggest worry is creating jobs for the masses. In the January 2018 edition of Economic Times, Arvind Panagariya, the ex-vice chairman of NITI Aayog noted the Indian apparel sector needs to create jobs like RIL and Shahi Exports do. For this, it needs to tackle its shortcomings like low productivity levels of its garments. For this, India can create plug-and-play hubs with facilities like effluent treatment plants and dormitories for workers.

noted the Indian apparel sector needs to create jobs like RIL and Shahi Exports do. For this, it needs to tackle its shortcomings like low productivity levels of its garments. For this, India can create plug-and-play hubs with facilities like effluent treatment plants and dormitories for workers.

India also needs to revamp its trade policies and provide duty free access to its markets like Vietnam and Bangladesh who have grabbed the majority pie of the global apparel market.

Use of smarter fabrics

Another change that India needs to make is the adoption of smarter sophisticated fabrics that are capable of absorbing moisture, are heat resistant and have greater stretchability. Measures such as lowering the duty on synthetic raw material, strengthening weaving and processing industry and becoming FFI compliant will help the industry to grow.

Though the government has introduced initiatives such as flexible labour laws and wage subsidies, these efforts thus far have been half-hearted and piecemeal. To capture a major share of the $480 billion industry, we need a more coherent and coordinated strategy.

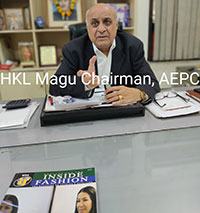

Technology is making big strides across the global apparel industry. However, India lags behind countries like Vietnam and Cambodia in the adoption of these technologies. “Around eighty percent of our players own medium to small units. They need to be directed in terms of increasing their exports. They also need big plug and play workstations to operate their businesses,” says HKL Magu, Ex-Chairman of AEPC.

Technology is making big strides across the global apparel industry. However, India lags behind countries like Vietnam and Cambodia in the adoption of these technologies. “Around eighty percent of our players own medium to small units. They need to be directed in terms of increasing their exports. They also need big plug and play workstations to operate their businesses,” says HKL Magu, Ex-Chairman of AEPC.

The investment required for this trade is not easy to absorb. “To avail of this investment, we need to exploit available technologies and upgrade our operations,” opines Magu. One of the factors that ails this industry is increasing competition. “To survive, we too need to more competitive. However, this is only possible if our production increases,” he adds.

Compliance is also increasing. Most of the factories, especially those in the international areas are becoming safety and environment-complaint. “Without compliance, even smallest of our importer would not be in a position to take order,” states Magu adding, “It’s also a time to be sustainable. We need to be sustainable in order to grow in this industry.”

The Prime Minister has also called for certain suggestions from the industry which it plans to duly incorporate in the upcoming budget.

The National Council of Textile Organizations (NCTO), shows the full spectrum of U.S. textiles from fiber through finished sewn products, it stated the following statement on the Phase One Deal on 301 tariffs signed today by the U.S. and China.

“While we are still studying the details of the deal signed today, we applaud the administration for finally pressing China for a more rational and equal trade relationship,” said NCTO President and CEO Kim Glas. “Our industry has been severely damaged by China’s predatory practices over the past 30 years and we are anxious to see a new era of sound trade principles and balanced trade.

On the same end, we question the last-in, first-out approach to the tariff reductions. In our sector, this means that the penalty 301 tariffs on finished apparel and sewn products the areas where tariffs have the most potential to effect reforms in China while bolstering the Western Hemisphere supply chain are cut in half while U.S. manufacturers continue to face full tariffs on certain inputs and equipment not available domestically.

NCTO is a Washington, DC-based trade association that represents domestic textile manufacturers, including artificial and synthetic filament and fiber producers.

All Pakistan Textile Mills Association (APTMA) has opposed Pakistan government’s decision to charge more than 7.5 cents per unit for providing electricity to the textile industry.

The association says, the government has already imposed various surcharges after the withdrawal of zero-rating alongside GST and income tax. Besides, the textile industry is burdened with Quarterly Tariff Adjustments (QTA) and introduction of the Additional Distribution Surcharge to the industry retrospectively from the beginning of the current fiscal 2019-20.

The addition of extra charges in the tariff will further burden the industry with an additional 30 to 35 percent on account of electricity charges. Therefore, the industry is demanding electricity supply at the committed tariff of 7.5 cents per unit with no other charges added to it.

Ireland has formulated a ‘radical’ new strategy to focus on reducing plastic packaging waste and waste generated by fast fashion and food items in the country. Ireland’s department for communications says, climate action and environment, the country generates over 200 kg of waste packaging, 59 kg of which is plastic per person every year.

More than half of fast fashion is disposed of in less than a year, and food waste alone costs the country’s homeowners €700 a year and accounts for a loss of €1 billion to the country’s enterprises, according to Irish media reports. The department has sought views on measures to tackle fast fashion, better labeling for recyclable goods, targets to ensure correct bins are used, providing clearer information on what goes into each bin, measures to halve food waste, ending the use of non-recyclable plastic, how to further crack down on illegal dumping, incentivising the use of recycled materials in the construction industry, working with other European Union (EU) member states to design the structure of an EU-wide plastic packaging tax to encourage the further prevention of plastic packaging and raising awareness on how best to manage their waste.

The Irish government plans to ban single use plastic plates, cutlery, straws, balloon sticks, cotton bud sticks, polystyrene cups and food containers and introduce fees on non-recyclable plastics, like on food packaging in supermarkets.