FW

For the three month period ended June 30, 2018, Grasim’s net sales were Rs 17,089.65 crores as compared to Rs 11,222.17 crores during the three month period ended June 30, 2017. Net profit was Rs 1,399.51 crores, as against Rs 1,248.10 crores for the three month period ended June 30, 2017.

Grasim, a part of Aditya Birla, is the world’s fourth largest pulp producer. It is one of India’s largest viscose staple fiber producers and is expanding capacity by 2.4 times. Grasim has ensured control over 80 per cent of the costs through backward integration, giving it an important competitive advantage over nonintegrated players. Its manufacturing input of caustic soda, power and steam and carbon disulfide is fully captive and the company has control over 60 per cent of the pulp requirements.

After the successful introduction of its fabric brand Liva in 2015 in the Indian market, Grasim is planning to take the brand abroad. Indonesia will be next stop, followed by Turkey.

Net sales of Nandan Denim in the three month ended June 30, 2018, was Rs 359.62 crores as compared to Rs 424.44 crores during in the same period in 2017. Net profit was Rs 5.23 crores for as against Rs 16.31 crores for the three month period ended June 30, 2017.

Nandan Denim is India’s largest denim fabric manufacturer. From a year-on-year perspective, Nandan completed capacity expansions at the denim fabric, shirting fabric, and yarn manufacturing units. The company’s fabric manufacturing capacity is 110 million meters per annum. Going forward, emphasis will be laid on fashion denim fabrics to target better realizations compared to regular denim material.

A combination of higher sales volumes and value added products is likely to fuel top-line growth in the coming fiscals. Denim fabric contributes 80 to 90 per cent to Nandan’s annual turnover. Nandan is gradually steering the business towards the value added denim category. A new yarn dyeing plant has been commissioned to meet input requirements of the shirting fabric department.

In the midst of the US-China trade dispute, Chinese companies will participate in Canada’s largest apparel and textile trade show, Apparel Textile Sourcing Canada (ATSC) to will be held from August 20-22, 2018 in Toronto. The show, featuring over 500 international exhibits, will include three days of seminars and panels, an on-site business matchmaking service and a spectacular fashion show spotlighting established and up-and-coming Canadian designers.

More than 5,000 visitors are expected to attend over the three-day event – now in its third year – including apparel and fashion executives, influencers, designers, retailers, importers, wholesalers, merchandisers, buyers and suppliers. ATSC is being supported by many international governments and associations, headed by the China Chamber of Commerce for Import and Export of Textile and Apparel (CCCT) and the Bangladesh High Commission on behalf of the Export Promotion Bureau and the Bangladesh Garment and Manufacturers Export Association.

The event is also being supported by the Taiwan Textile Association, the Federation of Indian Chambers of Commerce and Industry (FICCI), India’s Apparel Export Promotion Council (AEPC) and TFO Canada, experts in trade for developing countries.

Bangladesh targets a 6.33 per cent rise in readymade garment exports for fiscal 2018-19. Apparel occupies 83.79 per cent of the total exports. The target for knitwear is a rise of 7.21 per cent and woven growth target too is 7.21 per cent.

Cash incentive for garment exporters has been hiked to four per cent. With the higher cash incentives, garment exports to some new destinations like India, China, Japan and Australia are expected to grow a lot this year.

Bangladesh has had an impressive run in 2017-18 fiscal, making great strides in increasing garment exports. During the fiscal, apparel exporters marked a 8.76 per cent gain on a year-to-year basis – which is indeed encouraging in a competitive market where prices of apparel are falling.

Bangladesh targets readymade garment exports worth $50 billion by 2021. Buyer confidence in Bangladesh improved due to improvement in safety standards. However, manufacturers want a business friendly environment. They feel Bangladesh should focus on product diversification and go beyond the apparel sector and identify five sectors which would be able to earn over a billion dollars in the next five years. Bangladesh’s export earnings from readymade garment sector in the last fiscal year grew 8.76 per cent.

Ashapura Intimates’ Q1 net sales was, Rs 73.43 crores as compared to Rs 64.11 crores during the three month period ended June 30, 2017. Net profit stood at Rs 4.60 crores for the three month period ended June 30, 2018, as against Rs 3.99 crores for the three month period ended June 30, 2017.

Ashapura Intimates Fashion incorporated in 2006, is a fashion house that designs, brands, markets and retails intimate garments for men, women and children. The company is in the business of designing, branding, marketing and retailing clothing products such as lounge wear, sleep wear, bridal night wear, honeymoon sets, bathrobes, women’s inner wear, sportswear and kids’ lounge wear under the brand name Valentine.

Products across categories such as nighties, maternity feeding nighties and bridal night wear are marketed under the brand Night & Day. Their brand Valentine offers clothing that is comfortable, stylish and classy. The Valentine sportswear range is in 15 EBOs across India. The company plans to foray into the kids’ wear segment in the coming years.

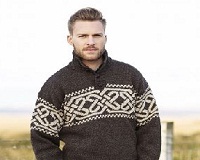

"The industry attributes growth to expanding winter season in the western hemisphere as well as technological upgrades in manufacturing sweaters. Additionally, favourable conditions such as political stability and low cost funds are aiding the growth of sweater exports. In fact, industry leaders opine export growth could be even greater if there is enough logistical support at ports and in the transportation sector. They also hoped exports earnings will contribute $8 billion annually by 2021, if the government provides proper infrastructure and policy support."

Data from the Bangladesh Export Promotion Bureau (EPB), for the fiscal 2017-18, reveals the country earned $3.67 billion in exports, which is 9.32 per cent higher than the $3.36 billion it earned in FY16-17. The country’s export earnings from sweater products grew 9 per cent to $3.67 billion in the last fiscal year. Sweaters contributed nearly 12 per cent to the total RMG exports of $30.61 billion of FY17-18.

Data from the Bangladesh Export Promotion Bureau (EPB), for the fiscal 2017-18, reveals the country earned $3.67 billion in exports, which is 9.32 per cent higher than the $3.36 billion it earned in FY16-17. The country’s export earnings from sweater products grew 9 per cent to $3.67 billion in the last fiscal year. Sweaters contributed nearly 12 per cent to the total RMG exports of $30.61 billion of FY17-18.

Growth drivers

The industry attributes growth to expanding winter season in the western hemisphere as well as technological upgrades in manufacturing sweaters. Additionally, favourable conditions such as political stability and low cost funds are aiding the growth of sweater exports. In fact, industry leaders opine export growth could be even greater if there is enough logistical support at ports and in the transportation sector. They also hoped exports earnings will contribute $8 billion annually by 2021, if the government provides proper infrastructure and policy support.

The second growth driver, according to the BGMEA is upgrading of manufacturing machines from manual to automatic. This has not only increased production capacity but also boosted worker productivity. Global climate change has also impacted Bangladesh with the winter season in the western hemisphere expanding beyond its normal period. This has increased demand for winter clothing.

automatic. This has not only increased production capacity but also boosted worker productivity. Global climate change has also impacted Bangladesh with the winter season in the western hemisphere expanding beyond its normal period. This has increased demand for winter clothing.

Shift in focus

Rising worker wages in China has led to manufacturers shifting their businesses to include higher-end products whereas buyers are searching for new sourcing destinations. Bangladesh offers a quality product at reasonable prices, this in turn, creates an opportunity for the country’s manufacturers.

Manufacturers say, global buyers are offering lower prices for their products, whereas the cost of production has gone up. To meet global demand, therefore they have to invest in automation, pushing production cost further up. However, the price of sweaters has not increased; rather, buyers have further reduced the prices of finished goods.

In order to grab a larger market share, Bangladesh has to increase port capacity to reduce lead-time. Inefficiency of infrastructure is another impediment that the country needs to be addressed. Bangladesh is unparalleled in product quality, so there is room to grow in the global market. However, there are challenges, including the lack of raw materials to produce high-end goods, technical expertise, and latest technology. Only about 60 per cent workers here can make higher-end products.

A stable and long-term policy, which would provide all out facilities to create a business friendly atmosphere, can pave the way to remove obstacles that stand in the way of new investments. The policy should be comprehensive and unified in order to ensure a level playing field for all.

For the first six months of 2018, Turkey’s apparel and clothing exports went up 7.7 per cent. The share of apparel and clothing exports in the country’s overall exports stood at 10.8 per cent. The share was 11.1 per cent for the first half of 2015, 12.3 per cent for the first half of 2016 and 10.7 per cent for the first half of 2017.

Turkey exports ready-to-wear apparel mostly to Germany, Spain and the UK followed by the Netherlands and France. For the first six months, the country’s apparel exports to Germany rose 7.2 per cent while exports to Spain rose 26.8 per cent. Turkey’s exports to the UK, increased 1.9 per cent.

Knitted garments were the most exported product group from Turkey in the first six months of 2018, increasing by 6.3 per cent. Woven apparel goods and accessories were the second most exported product group that saw an increase of 9.7 per cent. Exports of readymade goods, including home textile products, surged 7.6 per cent.

During the first six months, the unit prices for knitted apparel products fell 0.5 per cent from what they were in the first six months of 2017. Woven apparel unit prices increased 6.7 per cent.

Net sales of Vardhman Textiles during the three month period ended June 30, 2018, were Rs 1604.67 crores as compared to Rs 1525.69 crores during the three month period ended June 30, 2017. Net profit, was Rs 145.78 crores as against Rs 139.27 crores for same period last fiscal.

The company is one of the largest textile companies in India manufacturing cotton yarns and fabrics, constituting about two per cent of the country’s yarn production. The fabric processing capacity is 110 million meters a year. The product basket is diversified. It is now not only in cotton but creates blends like cotton tencel stretch, cotton modal super stretch and difficult products like bi-stretch.

Besides cotton yarn and blends, it is looking at more synthetic and blended yarns and is also taking steps to expand its existing fabric processing capabilities. Vardhman has improved its technology platform, so that its process automation, product quality and monitoring processes can be upgraded to deliver higher and better output.

Trade union representatives from Coimbatore have urged the Union textile minister Smriti Irani to resolve the payment issues faced by National Textile Corporation (NTC) mill workers. The seven NTC mills in Tamil Nadu employ around 1,400 regular workers. On May 31, 2018, the four-year wage agreement of these workers had expired. NTC workers recently sent a wage hike demand to its Southern Region office seeking a 50 per cent increase in basic wages and finalising the employment of workers who had worked for 480 days. It also sought Rs. 421 a day for casual workers.

The management had neither invited them for proper talks nor arrived at a solution, forcing the workers to hold demand meetings and wear demand cards to the mills. On August 7, a group of trade union leaders met the Union textile minister and sought her intervention. The minister assured them that necessary steps would be taken.

Net sales of Suryalakshmi Cotton Mills during the three month period ended June 30, 2018, was Rs 183.60 crores as compared to Rs 174.95 crores during the three month period ended June 30, 2017. Net profit, was Rs 0.54 crores as against Rs 0.52 crores for the three month period ended June 30, 2017.

Suryalakshmi has a denim fabric manufacturing capacity of 40 million meters a year. The company has launched new variants from the Amravati spinning unit to be used in manufacturing high-end denim fabrics. It has a capacity of 25,000 spindles for the manufacture of high quality value added and fancy yarns like stretch, slub and Elitwist yarns.

Suryalakshmi Cotton is one of India’s leading integrated premium yarn-to-denim-to-garment manufacturing companies. It has become the Original Denim Manufacturer to leading global and domestic brands with a dominant market share in the premium denim sector.

With cutting-edge designs, the latest spinning technology and end-to-end manufacturing plants, Suryalakshmi creates the finest yarns, premium denims and garments for leading private labels, fashion brands and retail chains in 31 countries across the globe.