FW

Though Pakistan seems to have placed a lot of faith in the ‘game-changing’ China-Pakistan Economic Corridor (CPEC) but local business community is concerned. Stakeholders in the country’s textile sector are anticipating a further decline fearing if Chinese companies started relocating their textile units in different tax-free industrial zones in Pakistan, they would go out of business.

In a talk, Pakistan Readymade Garments Manufacturers and Exporters Association (PRGMEA) Senior Vice President Jawad Choudhry said whenever China enters any country, it damages the domestic market. He observed that the readymade garment industry was currently facing a decline due to the high cost of doing business and productivity whereas China plays with price by increasing its production, he added.

Experts believe if China locates textile units to Pakistan, they will have an edge over existing players due to tax-free zones, under CPEC. An additional benefit for them would be the energy prices as they are setting up their own power plants to feed their industries in Pakistan.

With its intention to train unskilled workforce and help them make a good living by earning more, the Khadi and Village Industries Commission (KVIC) has sent a proposal to the Central government seeking inclusion of khadi in MNREGA, says Vinay Kumar Saxena, Chairman, KVIC.

He said the proposal was sent not only to have more artisans under the scheme but also to make unskilled workers earn more through it. These artisans will train the 5.40 lakh unskilled workers before involving them in khadi production. This in turn would help them raise their annual income from Rs 20,000 to Rs 73,000.

Besides, National President of the Textile Association (India) Arvind Sinha claimed the move will generate employment and enhance skill development amongst youth. He said the move will not only help the workers but in the long run will be very fruitful for the textile industry especially the Micro, Small and Medium Enterprises (MSMEs). It will also help enhancing technology in the related sectors, he added.

National Rural Employment Guarantee Act 2005 (or, NREGA No 42) which was later renamed as the ‘Mahatma Gandhi National Rural Employment Guarantee Act’ or MGNREGA is an Indian labour law and social security measure that aims to guarantee the 'right to work'. It aims to enhance livelihood security in rural areas by providing at least 100 days of wage employment in a financial year to every household whose adult members volunteer to do unskilled manual work.

Canadian apparel maker Gildan Activewear has bought US fashion retailer American Apparel in an auction. Gildan will not take control of any of American Apparel's 110 stores but will own the brand and assume ownership of some of American Apparel’s manufacturing plants in southern California, one of the largest garment-making operations in the United States, with about 3,500 employees.

Gildan makes most of its garments offshore, with close to 90 per cent of its 42,000 employees in low-cost Caribbean and Central American countries. It has yarn spinning and distribution centers in cheaper parts of the United States, including North Carolina and Georgia.

American Apparel filed for bankruptcy after the failure of a turnaround plan implemented by its owners, a group of former bondholders. The company's finances deteriorated and sales declined. The iconic company was founded in 1998 and grew to become a part of US popular culture thanks to its racy advertising.

American Apparel’s struggles show the major challenges facing brick-and-mortar retailers as more consumers shop online. Several US retailers, including Aeropostale and Pacific Sunwear, have filed for bankruptcy in recent months. The spending habits of young people have shifted and they visit malls less often and are increasingly going online.

Pitti Uomo is being held in Italy, January 10 to 13, 2017. This men’s fashion event has dance as its guiding theme and is presenting the Autumn/Winter collections of 1,220 brands, 44 per cent of which are non-Italian. The trade fair has become a global leader in men’s fashion thanks to its alchemy between fair and events outside it, innovation that is contagious for brands, ways of presenting collections and the ability to mix things up.

This year the number of international experimental brands represents more than 40 per cent of the 1,220 brands present and 20 per cent of the turnover. The Italian men's fashion industry closed 2016 with a slight increase in turnover. However, it is losing steam due to competition from countries outside the European Union. Purchases are declining in particular from the United States, the main end market of Italian men's fashion. In the January-September 2016 period, exports to the US fell by 10 per cent. But the Far East is showing a dynamic trend. In the first nine months of 2016, exports were up 14.6 per cent to Hong Kong, 11.3 per cent to Japan, 5.6 per cent to China and 1.8 per cent to South Korea.

Planet Textiles will take place in Bangalore on May 24 in Bangalore. This is about environmental issues facing the global textile sector. This year’s event will tackle the crucial issue of textile waste water pollution, chemical management and natural resource conservation including both energy and water use.

Last year the event took place in Denmark and attracted around 450 senior industry executives and speakers from brands such as VF Corporation, Nike, Marks & Spencer, Puma, Gap and Levi Strauss.

The Planet Textiles event on sustainability was first launched in Hong Kong in 2009. It features innovators in the global textile and retail businesses who are reshaping the industry. It explores company engagement, collaboration and transparency. Visitors learn about radical new environmental initiatives and business models in the textile supply chain.

Speakers will present methods for improving and managing global sustainability measures with emphasis on third party, independent certifications as important and effective business tools. Calls for increased sustainability and transparency, especially at the consumer level, are growing substantially around the world. This international megatrend will require companies along the entire global textile supply chain to accelerate their sustainability initiatives in order to meet the market’s demands. Brands and retailers are tweaking their supply chains to become more compliant, more transparent, and more responsive.

Arvind, India’s top denim producer has installed the nation’s first Monforts Eco Line. The particular Eco Line denim finishing range in India has been installed at the company’s Ahmedabad mill. The installation will increase production, reduce energy usage and respond more quickly to customer requests for specified designs and finishes.

Monforts Area Sales Director for Southeast Asia, Hans Gerhard Wroblowski said Arvind’s early investment in this new technology gives the company at least a year lead ahead of competition. The Eco Line, which can handle fabric widths of 1800 millimeters and operate at high speeds of up to 80 meters/minute, is being operated alongside four Montex foam finishing stenters that are also able to handle this same width of material.

Arvind is rated in the top three denim producers in the world, and sees further export potential. Aamir Akhtar, CEO of Arvind Lifestyle Fabrics’ Denim division, says in India, the denim industry is growing at a CAGR of 13 to 15 per cent. Arvind’s own export-domestic output is around 50:50, but some of the domestic production is worked up into garments and exported, so distorting the figure: taking that factor into account, Akhtar believes that the export proportion is closer to 60 per cent.

Founded in 1931 as a maker of traditional Indian clothing, Arvind modernised in 1984 and brought denim into the domestic market thus starting the jeans revolution in India. Today, it retails its own brands like Flying Machine, Newport and Excalibur and licensed international brands like Arrow, Lee, Wrangler and Tommy Hilfiger through its nationwide retail network.

The 12th edition of Shenzhen International Brand Underwear Fair (SIUF) would be held in Shenzhen, Southern China from April 19 to 21. Organized by Shenzhen Shengshi Jiuzhou Exhibition and owned by Tarsus Group, the joint trade fair SIUF, also named as China (Shenzhen) International Brand Underwear Fair & Shenzhen International Underwear OEM/Materials and Fabrics Fair has made its way to become the most influential fair in Asia.

The 2017 show will be on track to be the largest edition yet. The focus will continue to be on offering the whole supply & distribution chain of intimate apparel industry including fabrics, accessories, brands, production and solutions for intimates, swimwear, sportswear and lounge wear. Featuring 825 exhibitors and 105,600 industry visitors from 27 countries in 2016, SIUF is an important industry resource for intimate apparel professionals, distributors and retailers, suppliers, brand owners and designers of lingerie industry. Covering over 73,000sq. m. the show will be heavily supported and endorsed by official bodies: China Knitting Industrial Association, Guangdong Province Textiles Association, Shenzhen Underwear Association, HKIAIA and Taiwan Textile Federation.

Adapting the show's content to consumer trends, the 2017's edition will offer a package of activities in its three-day run, comprising distributor awards, brand awards, design contests, trend forums, brand fashion shows and the ultimate Super-model Talent Show. Covering over 650 brands, many with enlarged and upgraded booths, there will be more product launch and trends on display than ever before. Exhibitors include: Invista, Lenzing, Taubert, Muehlmeier, Penn Textile Solution, Pressless, Creora, Asahi Kasei, Toyobo, Eurojersey, Bemis Hong Kong, Bluesign as suppliers and as brand owners.

"B2B Exhibition at New Delhi & Kolkata, India by India Trade Promotion Organisation" during Feb 21-24, 2017".

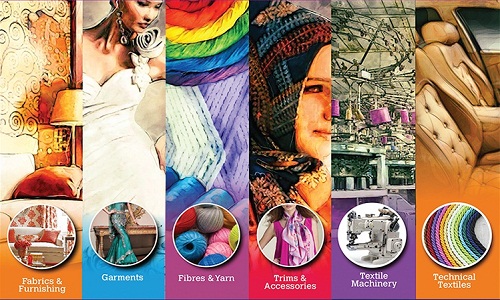

The 18th edition of Tex-Styles exhibition will open doors in Delhi from February 21 to 24, 2017 at Hall No. 11, Pragati Maidan. The fair is being organized by trade promotion agency India Trade Promotion Organisation (ITPO). Following Delhi, the exhibition will also debut in Kolkata from February 26 to 28, 2017 at Milan Mela Complex. Since its inception in 1995, Tex-Styles India Fair has emerged as an ideal forum for presenting multi-faceted splendor of Indian textile industry and established itself as the leading fair of its kind in Southeast Asia.

The major attractions

Tex-Styles India covers the entire gamut of products in textile industry. The display profile covers furnishings; fabrics yarns and fibres; apparel (men, women and kids apparel) - outer wear and jackets, pants, skirts, one-piece dresses, blouses, shirts, tunics, cut and sewn garments, technical textiles - nets, surgical, medical and sanitary textiles, technical & safety apparels, car seat covers, HDPE woven sacks, sports wear, upholstery, labels and laces, belts, ropes and hoses, nylon tyre cord fabric & geo-textiles; trims & accessories shawls, tussar, laces, threads and other embellishments to enhance the look and feel of the modern apparel and furnishings; technical textiles, textile gifts, textile process machinery, textile working machinery, looms and support services - CAD/CAM Systems, colour & trend forecasts, trade publications and support services for the textile & furnishing industry.

The Delhi show will have companies displaying products from woolen, silk, handlooms of North India, cotton, synthetics and rayon from West India , handloom, powerloom and silks from South India. The Kolkata edition will focus on products from the Eastern India with silk from West Bengal, Bihar and Jharkhand with different weaves, Muga and Eri silks from Northeast India, shawls from Nagaland, handloom cottons and silks from Orissa, the widespread garment export hub in West Bengal and eco-friendly jute fabric. The show offers buyers a one-stop-shop to view and source a large range of textile products of varying genres.

The USPs of the exhibition is that it offers comprehensive coverage of Indian textile industry with the best companies in each field such as cotton, silk, wool, synthetics, powerloom, jute, blended and other fibres. It is the only textile show in India which provides buyers a one-stop platform for purchase of every conceivable textile products produced by India i.e. furnishings, selected floor coverings, fabrics, garments, accessories, etc. Products displayed here are specially adapted for overseas markets and cater to the forthcoming Spring/Summer and Autumn/Winter seasons.

The range, quality and diversity of products exhibited are rarely seen elsewhere under one roof. The show assists buyers in selecting the most appropriate products. Special pavilions and facilities like Theme Pavilion, Fabric Folio Pavilion depicting the collection of swatches from all sectors of the Indian textile industry including participating firms and others are set up apart from forecasters depicting designer interpretation of trends. Tex-Styles India draws the best of participants and buyers from India.

Analysts in Pakistan believe in the absence of adequate business-friendly environment, the upcoming Rs 75 billion package for six export oriented sectors would not ensure full scale recovery of export oriented industry, say analysts. Reports say that Prime Minister Nawaz Sharif is likely to announce an incentive package for five or six export-oriented sectors to the tune of Rs 65-75 billion of which the textile sector would be the top beneficiary.

According to Zeeshan Azhar, an analyst at Foundation Securities feels, the package could go some way in making textile sector competitive internationally but core issues like uncompetitive exchange rate, higher electricity/gas prices, poor power supply, outdated technology, undiversified product base and low cotton quality will continue to hamper a full scale recovery of the sector.

The said incentives would add to the incentives already in place since the effect of Textile Policy FY14-19 and the FY17 budget. Currently, rebate on local tax varies between 1-4 per cent of Free on Board (FOB) value on 10 per cent incremental exports over last year.

This rebate could go up to 3-8 per cent of FOB value. The new tax rebate could be on 10 per cent incremental exports or be extended to full FOB value. The impact on companies' bottom line would be muted in the former case but sizable in the latter, Azhar added.

The government believes the package is necessary to encourage exporters who are struggling due to lower demand from major export markets, stable US dollar-Pakistani Rupee parity, and incentive package announced by competitors like India, Bangladesh and Vietnam. The downward trajectory in textile exports has shown some respite over the last two months but prognosis of the sector remains weak. The scope and impact of the upcoming textile package is still to be seen.

Tejidos Royo has launched its new Suave capsule collection for Spring/Summer 2018. Developed with TENCEL fiber, the Suave capsule S/S’18 includes fabrics of 100 per cent TENCEL as well as new blends with linen that for a special level of elegance and comfort. Royo draws in the past and future to the present, with its tagline: ‘Looking at the past with eyes of the future.’

Founded in 1903, Tejidos Royo has been a leader in Europe’s textile sector for more than a century. Its two production facilities in Valencia, Spain produce fabrics exported to customers in more than 30 countries. Calling denim the ‘protagonist’ of the collection, Royo’s versatility aided by TENCEL, in colors from baby blue to black and indigo in between. The collection takes its cues from three fashion trends which Royo describes as ‘Marine Soul’ inspired by nautical explorers, ship sails and sailor knots; ‘Adventure Dream’ touched by the unique romanticism of pioneering women and ‘Wild Life’ with a wild, Latin sensibility brought by tropical prints and exuberant summery color. This is another iteration of denim, where the ability of lightweight fabrics to flow contradicts their strength, something that shareholder Jose Rafael Royo attributes to the silkiness of TENCEL and its ability to work in blends.