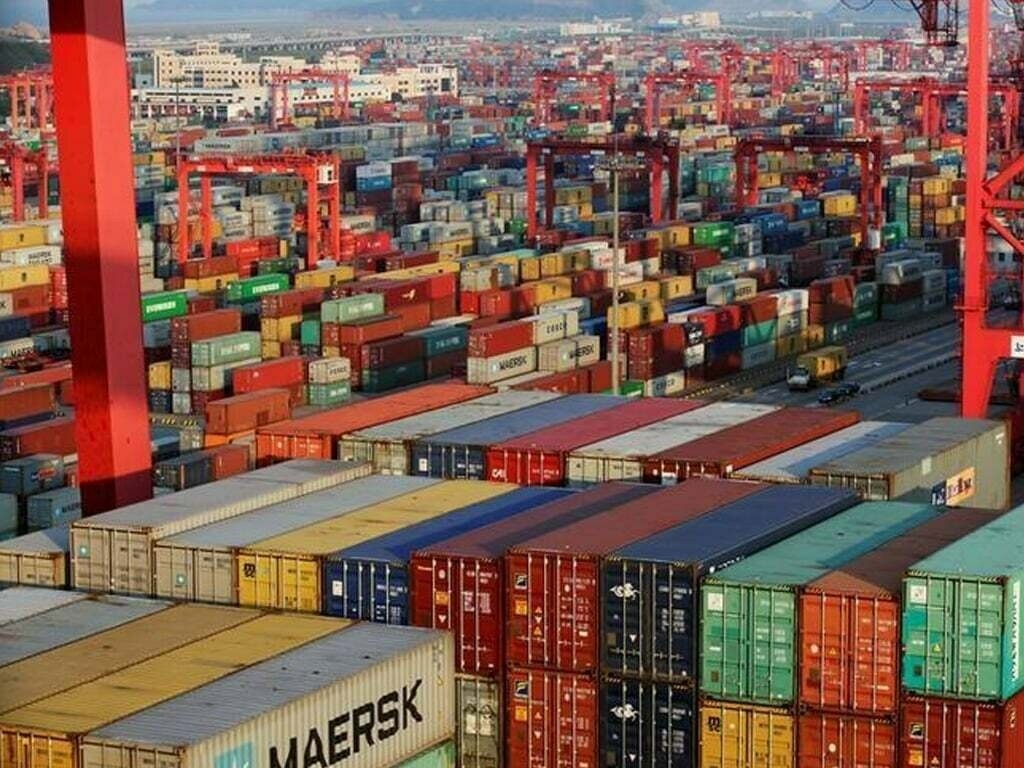

Chinese textile manufacturers are competing to secure import quotas for well-priced and high quality cotton, as the government pressures them to use more expensive lower quality domestic supplies. The spread between Chinese and imported cotton has hit China's textile industry hard. Its one major reason Chinese manufacturers are becoming much less competitive in the global market.

In January, the Chinese government imposed a 3:1 rule on manufacturers. By which they had to use three tons of Chinese cotton to secure quotas to buy one ton of imported cotton. The quality of Chinese cotton is much lower than that of imported cotton, which generates more losses in production.

The goal is to reduce the size of the eight million tons of stocks the Chinese government has bought to assure sufficient local supplies. The policy is already weakening the price of China-made cotton, but with farmers demanding high prices, it is still higher than foreign cotton.

The International Cotton Advisory Committee has warned cotton prices are expected to rise in the 2013-14 season, despite cotton stocks heading towards a new high. The inter-governmental group blamed stockpiling by the Chinese government, and the expected tightening of stocks outside of China.

Hong Kong will host Mega Show Part 1 form October 20-23, 2013 and Mega Show Part 2 from October, 27-29, 2013. These two influential trade shows are the main sourcing focus for gifts, housewares, toys, premiums and stationery in Hong Kong during the annual autumn buying season and must-attend events in the Southern China’s sourcing calendar.

Over 4000 worldwide suppliers from 36 countries will be participating and presenting new ranges and products to worldwide importers, distributors, wholesalers and trade buyers. Both new and established suppliers from Australia, Austria, Bangladesh, Belgium, Cambodia, Canada, Mainland China, Czech Republic, France, Germany, Guatemala, Hong Kong, India, Indonesia, Ireland, Israel, Italy, Japan, South Korea, Latvia, Macau, Malaysia, Mexico, will be participating in the show.

Mega Show Part 1 will present seven major product sectors, gifts, housewares and home decor, Christmas, festive and seasonal, toys and games and baby and child, glassware trends, gift-wrap and packaging, along with Asia and international focus which includes international suppliers presenting a diverse selection of gifts and home wares.

Mega Show Part 2 with exhibitors from 11 countries will present four major product sectors, gifts, home decor and outdoor living, home textiles and house wares, plus Asian stationery with over 200 companies displaying the best of Asian print, pen and paper, as well as office and school supplies.

Over 57,000 buyers attended the shows in 2012, with the growing attendance of buying power from emerging markets. The two shows take place annually at the downtown Hong Kong Convention and Exhibition Centre in Wanchai, Hong Kong.

A dangerous flammable fabric is being imported into the US that fails to meet basic fire standards. Put a lighter’s flame to the fabric and it ignites like a sparkler, dripping molten chemicals that burn into the surface of anything that its drips on. Normal polyester when held to a lighter will roll back on itself and when cooled the polyester becomes quite hard like a plastic.

The fabric is labeled as 100 per cent polyester, although silver-nano particles can be seen with the naked eye. Silver particles generally provide anti-microbial properties. Oddly, the test fabric has been marketed as stain-resistant instead of anti-microbial. The silver particles are not embedded and when ignited, the silver becomes airborne. The nano terminology that was used on the labeling to describe the finishing is totally misleading.

The label doesn’t say what abrasion material was used; cotton or wire, and how many pounds of pressure were used. In the early ’90s a synthetic georgette fabric was banned from import due to its high flammability. There are outdoor performance products which are labeled as containing CoolMax, a moisture wicking fabric developed by DuPont in 1986. However, what CoolMax actually is anyone’s guess.

The National Council of Textile Organizations, a Washington-based trade group that merged with two other textile organizations in March, has a new President. Auggie Tantillo, who for many years was the head of the American Manufacturing Trade Action Coalition, was named the new NCTO president. He replaces Cass Johnson, a University of California, Los Angeles alumni who had been NCTO president since the organization was formed in 2004.

“We wish Cass well in his future endeavours, and look forward to working with Auggie in his new role,” said Scott Elmore, spokesperson for the American Apparel & Footwear Association, a trade organization headquartered in Arlington, VA.

Prior to AMTAC, Tantillo worked under the George W Bush administration as deputy assistant secretary for textiles and apparel in the Commerce Department. He was also chief of staff for former U.S. Sen. Strom Thurmond of South Carolina. Tantillo had been a NCTO consultant after AMTAC was dissolved.

“We are incredibly pleased to welcome Auggie’s leadership and many years of experience to NCTO at such an important juncture of the Trans-Pacific Partnership negotiations,” Bill Jasper, NCTO’s Chairman and Chief Executive and Chairman of Unifi Inc., a North Carolina yarn maker said in a statement. “In his new role as President, Auggie will continue NCTO’s unparalleled commitment to fighting on behalf of American textile manufacturing and jobs at home and abroad.”

AMTAC and the National Textile Association merged with NCTO earlier this year to give the three trade groups more lobbying power and a stronger voice when addressing textile and manufacturing issues before Congress and the Obama administration.

The new Thies iMaster F series from German Thies GmbH is destined particularly for dyeing high pile fabrics, such as terry toweling. The new F series is the latest innovation for the highly successful iMaster range of dyeing machines. It features a large transport winch inside the dyeing kier to be processed with significantly reduced elongation. It results in improved stability, perfect fabric condition and appearance, and ensures economic and environment-friendly operation with advanced automation at low liquor levels, as low as 1:4 for cotton.

The new models are available with capacities of between 250 kg to 400 kg per chamber. The iMaster F series can be delivered with up to maximum eight tubes for the 250 kg/tube, and six tubes for the 400 kg version. They are also able to process a wide range of different articles.

The new machine is equipped with a 100 per cent stock tank, a dosing tank and delivery system for dry salt and is particularly optimized for the production of terry articles. The automatic self-cleaning filter system always helps to achieve every time the same dyeing and treatment conditions. Manual interventions for cleaning are reduced and productivity is increased. Rinse, wash and dye baths are measured online, continuously analyzed and displayed graphically.

The National Tariff Commission (NTC) of Pakistan has decided not to impose anti-dumping duty on import of Polyester Staple Fiber (PSF) from China. The All Pakistan Textile Mills Association (APTMA) had been lobbying for it for a long time. The APTMA feels not imposing duty will have a positive impact on textile imports and will provide a long-term advantage to the textile industry, as polyester use is bound to increase. PSF is an important industrial material. However, the provisional anti-dumping duty continued for four months.

After value-addition on imported fibers, textile products are exported. Pakistan needs to import PSF in view of the acute domestic production shortfall of PSF. APTMA says imposition of anti-dumping duty operates against international competitiveness of Pakistan textile products predominantly meant for export.

Imposition of anti-dumping duty on industrial raw material besides making imports costlier have the effect of raising domestic raw material prices to a level where they become unviable for the textile industry. However, the domestic PSF industry was vociferous in pleading for imposition of anti-dumping duty as it gives the industry an amount of protection by which it raises domestic prices.

All Pakistan Textile Mills Association is the premier national trade association of textile spinning, weaving, and composite mills representing the organized sector in Pakistan. It represents 396 textile mills, out of which 315 are spinning, 44 weaving and 37 composite units.

Shanghai will host Planet Textiles Conference on October, 22, 2013. Jointly organized by Ecotextile News and Messe Frankfurt, Planet Textiles tackles the crucial issue of sustainability in the global textile sector. Now in its fifth year, Planet Textiles is Asia's premiere annual event dedicated to reducing the impact of textiles on the environment.

The head of sustainability at leading Chinese textile mill Jiangsu Lianfa will give a real-world example of environmental and cost savings for a Chinese textile mill through implementation of simple environmental-led steps. Previous attendees at Planet Textiles include: senior executives from Nike, H&M, Wal-Mart, Levi Strauss, Puma, VF Corp, Adidas, H&M, Marks & Spencer, Esprit, Pacific Textiles and Warnaco, to name a few.

Planet Textiles will take place within the same venue as Intertextile Shanghai Apparel Fabrics, Asia’s leading sourcing exhibition, which attracts more than 60,000 visitors. This year, the link between Planet Textiles and Intertextile Shanghai Apparel Fabrics will be strengthened through an innovative new “all about sustainability” zone. This new area of the show will feature three sections: exhibitors: sustainable fabrics producers, and dye and chemical companies; educational Zone: sustainability testing certifiers, trade associations, NGOs and eco publications; display area: recycled fabrics, products, solutions and initiatives.

A New Zealand-based Woolyarns produces an exclusive range of luxury yarn brand for both textile manufacturing and hand knitting markets internationally. It is Woolyarns’ Zealana hand knitting yarn. Zealana uses luxuriously soft and lightweight blended Brushtail possum fiber. It is spun into beautiful yarn that is sought after by handknitters.

Brushtail possum fiber is super soft and prized for its lightweight warmth and breathability. Possum for Zealana yarn is collected from a small number of carefully selected regions, only at certain times of the year. It is then blended with the finest merino or cashmere to guarantee softness and consistency in this high end luxury yarn. Woolyarns uses 40 to 50 tons of possum fiber annually across its product range. This is equivalent to the fiber from more than one million possums.

Woolyarns was established 68 years ago. For several decades, it provided yarns only for commercial purposes. In the early 1990’s, it pioneered the use of possum fiber mixed with wool. In 2006, Woolyarns released Zealana, its first hand knitting and crochet yarns.

Woolyarns offers a select niche range of bespoke yarns, in addition to its classic range. Luxury yarn brands in Woolyarns’ portfolio of bespoke yarns are Zealana (hand knitting), Perino (knitwear, apparel, hosiery yarns), INZpire (carpet yarns) and Callibra (sourced yarns).

As financial results reporting season gains momentum, investors in textile sector are looking to splendid growth in profitability, which would probably match the financial year 2013 performance. Profitability of textile (sample firms) scaled four-fold to Rs 22.8 billion in three-quarters of financial year 2013 (9MFY13) as against Rs 4.4 billion in the same period last year.

“Last fiscal year, FY-’13, was one of the better years for Pakistan textile sector in terms of sales and profits which was also reflected in more than 100 per cent price performance of our sample listed textile firms with market capitalization of over Rs 25 million,” says Zeeshan Afzal of Topline Securities.

Though shortage of power remained the perennial problem, especially in winter, the textile companies’ jump in profits by 400 per cent was mainly attributed to stable cotton prices and strong regional demand.

Moreover, continuous depreciation of rupee against the dollar and cheaper financing also contributed to hefty earnings growth. In FY-’13, Pakistan exported $13bn worth textile products, up by 5.9 per cent in dollar terms but represented improvement by 14.7 per cent in local currency due to the drop in value of the rupee.

The growth in exports was attributed mainly to imposition of cotton floor price in China that encouraged Chinese textile manufacturers to import more yarn and grey cloth instead of converting yarn into costly local cotton. As a result, Pakistan’s yarn and grey cloth exports increased by 24 per cent and 10 per cent to $2.2billion and $2.7 billion, respectively, in FY-’13. The latest results of textile sector are expected to show continuous growth in export for FY-’14 on the back of sustained textile demand from China and substantial depreciation in local currency.

However, analysts caution that much would depend upon international cotton prices, though major volatility was unlikely to be seen in local cotton prices in FY-’14. The encouragement was based on estimates of Cotton Crop Assessment Committee (CCAC) which estimated Pakistan’s cotton production at 13.25 million bales in FY-’14, slightly higher over the 13.0 million bales produced by the country in FY-’13.

Exports and profits of the sector could also improve due to expected Generalised System of Preferences (GSP Plus) status from EU, as lower import duties would provide Pakistan a competitive edge in international markets. “Further operating environment of the textile sector may see further improvement in low interest rate scenario,” analysts said, the caveat, however, being the all-important improvement in energy situation.

The 2013 Théophile Legrand International Prize for Textile Innovation will be awarded on October 5 at ValJoly Eppe-Sauvage resort. The Théophile Legrand Foundation – Institut de France was created in 2007 by Christian Cambier, a descendant of Théophile Legrand. Théophile Legrand is the founder of the wool industry in Fourmies, France.

Since 2009, two Théophile Legrand awards are granted annually. With a value of €18,000, these two awards celebrate two distinguished researchers and/or students who have created original material, fiber or fabric in the field of technical textiles; or an innovative textile design and/or a new textile industrial production technique.

The goal is to foster innovation, research, and imagination by showcasing emerging technical and industrial creations. In 2009, the prize was awarded to Aurélie Cayla for inventing a smart textile that senses specific temperatures. In 2011 Munir Ashraf won it for creating a self-cleaning and antibacterial textile. Last year, Pierre-Alexandre won the prize for a decontaminating textile to treat air and water.

An innovative textile design project can be submitted for consideration providing the entrant or team of researchers is able to prove that the project, product and the invention of newly used elements are their own work. Selection criteria are the same for inventors of new textile fabrics as well as innovators of new processes of textile production. All entrants are judged on their creativity, originality, innovation to the field and the project’s ability to be industrially reproduced.