FW

"The Welspun controversy has thrown up questions on whether there is any foolproof technique to differentiate fake and original cotton fabric? There are various methods of finding out. With the news of US-based client, Target Corporation, terminating business contract with textile major Welspun India, on the grounds of using a different variety of cotton instead of Egyptian cotton in the production of sheets, it has become a reason for debate for many in the industry."

The Welspun controversy has thrown up questions on whether there is any foolproof technique to differentiate fake and original cotton fabric? There are various methods of finding out. With the news of US-based client, Target Corporation, terminating business contract with textile major Welspun India, on the grounds of using a different variety of cotton instead of Egyptian cotton in the production of sheets, it has become a reason for debate for many in the industry. For starters, Target sells luxury bath and bedding products under the Fieldcrest brand in the US.

Just as the news broke, Welspun’s shares took a beating on the and market capitalisation declined by more than Rs 5,000 crores that particular week. As a result, share trading was suspended for two consecutive sessions and Welspun arranged an urgent conference call with investors and analysts to put across its version of the news.

“In the manufacturing process, we source a lot of raw materials, such as cotton, cotton yarn or greige fabric, from various vendors. We, thus, want to revalidate all our supply processes and systems,” Rajesh Mandawewala, Group Managing Director, Welspun, said. To solicit its claim, the company has taken Ernst & Young on-board to audit its supply systems & processes. This entire incident has acted as warning for other global partners such as Walmart and Bed Bath & Beyond, to be extremely cautious while sourcing products from India.

Lacking tech arm

Earlier in March, the Cotton Egypt Association, the world’s only trademark and licensing authority for the commodity, had tested home textile products labeled as Egyptian cotton and found that around 90 per cent of the products did not contain the premium cotton variety at all. Welspun was licensed to use the Egyptian cotton logo too and the Association has now launched an investigation following the Target case. Is this the case of counterfeiting & mislabeling? Ask trade pundits.

Lack of tools & technologies to verify the authenticity of Egyptian cotton can be the probable reason towards increasing cases of counterfeiting in the industry. Cotton Incorporated, a US-based industry-funded body, highlights there is no physical test to determine the authenticity of cotton products once the fibre is converted into yarn. But agencies like the Cotton Egypt Association have turned to DNA testing of cotton products.

Years of research has led Mohamed AM Negm of the Interregional Cooperative Research Network on Cotton for the Mediterranean & Middle East Regions & Suzan H Sanad of the Cotton Research Institute, Egypt, to develop the CTAB (cetyl trimethylammonium bromide) method to extract DNA from Egyptian cotton fibres throughout the supply chain, from farming till the finished product. The isolated DNA is then used to identify varieties of cotton, thereby establishing authenticity of the product.

For India to make its mark globally, counterfeiting has to end. With increased pressure to produce at the lowest cost, much of the ELS cotton manufacturing and final assembly has migrated to other countries, mainly China, India, Portugal, and Pakistan. The incentive to substitute lesser quality Upland cotton in place of the premium ELS cotton is high and opens the door for mislabeling, feel experts.

Some even think that the reducing supply of Egyptian cotton and its higher price are giving rise to clones. Stats show in 1980s, Egypt grew cotton on as much as 500,000 hectares of land per year but the area under cotton fell to 223,000 hectares by 2000-01, says US Department of Agriculture (USDA).

Drop in production of Egyptian cotton is mainly due to changes in consumer preferences and new technologies. Over time, consumer preference has shifted to garments, which require short- or medium-staple cotton such as denim and T-shirts. This shift in demand has overtaken the demand for clothing and bedsheets made of extra-long and long-staple cotton varieties.

The slump in Egyptian cotton production has also occurred in other countries, including India, China, Pakistan, and Brazil. Global production has decreased by 18 per cent to 21.3 million tonnes in 2015-16, according to Negm.

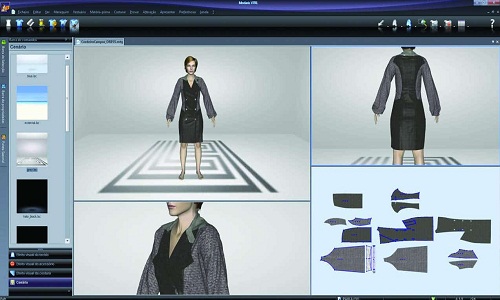

"Digitisation of the production chain is going to dramatically transform the entire apparel manufacturing space, believes Holger Max-Lang, newly appointed MD of Lectra Germany. Talking about the transformational journey over the decade, he said that Lectra is moving strongly in the direction of mobile production lines. For example, there are container solutions that can be integrated into a pop-up store - individual production for local sales, made possible by automation and robotics. The key question will be which functions clothing will assume in the future. Here, two areas are increasingly merging, nanotechnology and the textile industry."

Digitisation of the production chain is going to dramatically transform the entire apparel manufacturing space, believes Holger Max-Lang, newly appointed MD of Lectra Germany. Talking about the transformational journey over the decade, he said that Lectra is moving strongly in the direction of mobile production lines. For example, there are container solutions that can be integrated into a pop-up store - individual production for local sales, made possible by automation and robotics. The key question will be which functions clothing will assume in the future. Here, two areas are increasingly merging, nanotechnology and the textile industry. The result is so-called smart textiles, intelligent fabrics with woven-in electrical engineering. The resulting opportunities will transform the clothing industry and production.

Innovation expanse

Fashion and textile companies are investing heavily in the digitisation of the fashion and textile sector as market pressure increases and product lifecycles decrease. With its Speedfactory and the ‘Knit for You’ storefactory concept, Adidas has created groundbreaking examples of the future. According to Max-Lang, customers are particularly interested in 3D virtual prototyping and PLM (Product Lifecycle Management). The cutting room is also moving in the direction of industry 4.0 – digital, networked and intelligent. Robotics certainly plays a role in this respect, but the same degree of automation will not be possible sooner as is the case with the automotive industry.

Biggest challenge & PLM as solution

The biggest challenge for fashion companies is to become faster and more agile. Big players like Amazon, but also new digital startups, raise the bar further. This is one reason why Lectra has developed its current solutions, such as Lectra Fashion PLM, 4.0 compliant. The modular solutions meet the new requirements of companies and adapt to their changing business models. A PLM in a digital supply chain links all departments of a clothing manufacturer, simplifies communication and accelerates the development and production of products. This enables fashion companies to react quickly to trends. In addition, manufacturers are becoming more agile and can offer individual products, for example by allowing customers to influence parts of the design.

Cutting Room 4.0

In Lectra's new Cutting Room 4.0, all departments of a production facility are digitally networked. In this way, it enables profitable mass production with single pieces in series. The topic also plays a major role in the apparel sector, especially in the sports industry in the field of team sports. Tailor-made clothes, but at a price of mass production. Here too, Lectra will offer the right solution.

Talking about the possibilities of the 3D design, Max-Lang elaborated that correctly implemented, prototypes are no longer necessary with the 3D simulation. This saves time and money. This approach is a major step towards the digital development process. Especially companies for women’s wear as well as men’s wear use the Lectra 3D solution Modaris, as this system offers a pool of pre-fabricated cuts. This is the basis on which designers develop their designs. All subsequent departments also benefit from this because information such as grading can automatically be implemented and passed on.

Fit & stretchability in check

For the 3D simulation of fabrics on models, information about the elasticity (chain, weft, diagonal), bending resistance as well as the weight and thickness of the fabric is digitally determined. The techniques used include FAST (Fabric Assurance by simple testing) and KES F (Kawabata Evaluation System for Fabrics). Based on this existing data, users can create their own fabrics or have them digitised by a laboratory. Lectra system already contains more than 300 fabrics.

For some time, Jeanologia has been promoting the Mexican textile sector with sustainable technologies that help increase productivity and competitiveness. The leading Spanish company in the development of sustainable solutions for the finishing of jeans is presenting Exintex 2016 innovations that will transform the Mexican industry towards automation and efficiency.

The company has helped reduce 90 per cent water and chemical consumption and 50 per cent power thanks to the combination of its three sustainable technologies: laser, ozone and e-Flow nano bubbles. Also, its integration of these three technologies power new creative possibilities scalable to large productions.

At Exintex, the company will showcase its latest developments that have been applied to laser, ozone G2 and E-Flow nano bubbles technologies. One can see vintage clothing, novel designs and trends with a common denominator: authentic eco efficient products. Using Light PP Spray and Light Scraper solutions, it is possible to produce pollution-free jeans as the use of the dangerous potassium permanganate has been removed and it’s possible to clone the authentic look of the antique denim in an efficient and ethical manner.

From the October 18th to the 21st Jeanologia will also perform live demonstrations of Flexi HS 3D laser machine that adapts to the needs of each manufacturer or designer and offers maximum versatility. It allows multiple combinations of dial-up thanks to its Swivel Head and optical system that allows you to work both in horizontal and vertical mode on jeans, shorts, shirts, t-shirts, jackets and accessories.

The Mexican clothing industry is a pioneer in the introduction sustainable technologies for manufacturing garments and has become a leading producer in the American market. Currently, 95 per cent of finished garments using laser and ecological processing techniques is done with developments from Jeanologia. Jeanologia has been present in Mexico for last 10 years and works with major brands and manufacturers.

The second quarter (July-September) earnings estimates of the apparels sector by ICICI Securities is out. The brokerage house expects Vardhman Textiles to report a net profit of Rs 346.2 crores up 94.2 per cent quarter-on-quarter Q-o-Q). The revenue of the textile firm is expected to decrease by 0.4 per cent Q-o-Q (down 8.8 per cent Y-o-Y) to Rs 1,502.7 crores. Earnings before interest, tax, depreciation and amortisation (EBITDA) are likely to fall by 9.7 per cent Q-o-Q (down 8 per cent Y-o-Y) to Rs 282 crores.

Consolidated revenues are likely to decline 8.8 per cent YoY to Rs 1,502.7 crores on account of sale of stake in Vardhman Yarns and Threads. On the segmental business front it is expected that the yarn volumes would increase by 2 per cent YoY while the fabric volume is expected to increase by 7 per cent YoY. Consolidated operating margins are likely to increase marginally by 16 bps to 18.8 per cent on account of higher margins in the acrylic business. On the operational front, Vardhman's performance is expected to be moderate.

However, owing to stake sale (40 per cent) in Vardhman Yarns and Threads, an exceptional income to the tune of Rs 210 crores is expected this would boost consolidated net profit to Rs 346.2 crores v/s net profit of Rs 125 crores in Q2FY16. Excluding the exceptional profit, net profit is expected to increase by 9 per cent YoY to Rs 136.2 crores.

Diwali bonuses for textile workers in south India are expected to be less than 10 per cent of their annual salary. In comparison automobile parts manufacturers and other sectors offer employees a festival bonus of 12 to 16 per cent of their annual salary. Textile workers say companies are doing financially well, especially the big ones, and so there’s no reason for them not to offer a higher bonus. They say they want a bonus of at least two months' salary or 16.33 per cent of annual salary.

But employers say business is yet to pick up and that the cash flow is yet to improve. They say business volumes and profits margins aren't anything better than what they were in 2013 and they had to face losses in 2014 and 2015. Companies that used to run two shifts earlier say they don't have enough orders to run one shift fully. Employers also say that the bonus is not calculated in terms of percentage of salary and that it is usually given based on an individual worker’s performance and contribution.

However, small scale industries might hike bonus by three to five per cent of what was offered last year.

International Finance Corporation and VF Corp are working together to enhance the long-term competitiveness and sustainability of the textile wet processing sector in Bangladesh. This is being done by reducing excessive groundwater extraction and surface water pollution, energy and chemical use. The project will be carried out by IFC’s Bangladesh Partnership for Cleaner Textile (PACT) program. VF Corp joins 12 other brands in the PACT family, bringing the total partner brands to 13. The program has contributed to water and energy savings of 14.4 billion liters and 1.23 million megawatt hours per year.

IFC is a member of the World Bank Group. In Bangladesh, IFC provides both investment and advisory support and works along with other stakeholders to help the garment sector become globally competitive and safe for its employees. VF Corp is a branded lifestyle apparel, footwear and accessories company. VF aims at assisting its strategic suppliers in reducing their water, energy, waste, and chemical use, while simultaneously reducing the cost of production.

PACT will engage with VF’s supplier factories in awareness building, basic and in-depth cleaner production assessment. Major activities will include factory-level advice on technical assessment of resource efficient textile processing, facilitating implementation through user groups, strengthening corporate water and energy management systems, and investment facilitation in technologies with significant water sustainability benefits.

The United States Department of Labour (US DOL) has removed garments made in Jordan from its 2016 Trafficking Victims Protection Reauthorization Act (TVPRA) list. This was done as incidence of forced labour in the production of garments in Jordan has been significantly reduced, a US DOL report read.

'While there are still some indicators of forced labour present in the sector, their incidence is isolated and consistent with the standard articulated in the Procedural Guidelines, the evidence no longer supports inclusion of garments from Jordan in the TVPRA List,' reads the seventh edition of the List of Goods Produced by Child Labor or Forced Labour issued on September 30.

'The removal of these goods from the list is a result of targeted action,' says the report which includes the collection and reporting of credible information, the investment of significant resources by the government of Jordan, the USG, and the International Labour Organization (ILO). The US DOL also reports that 'one of Jordanian government's most significant steps to combat forced labour in the garment industry has been to collaborate with the ILO on the BWJ program which was launched in 2008 with funding from the USG and from participating garment buyers.'

Invista’s brand Cordura has been making fabrics for the armed forces for nearly 50 years. Cordura has been driving military textile innovation with performance solutions featured in both fabrics and webbings used extensively in combat gear, such as the SDN yarn technology. These solutions are suitable for use in load carriage equipment, boots, body armor covers, knee/elbow pads and other similar tactical gear.

Available in a palette of six military colors that meet both lot-to-lot shade and infrared requirements, the fabrics have built-in reflectance capability as well as resistance to sunlight UV fade and strength degradation. Cordura has made fabric innovations for military gear and apparel. The goal is to develop reliable, innovative fabric solutions that help equip soldiers to meet the battlefield challenges of today and tomorrow.

Cordura nylon 6, 6 fabrics are designed to be the soldier’s first line of defense in protective/ballistic vests. These fabrics are meant for protection against heat, flame and thermal propagation in protective apparel and footwear. Cordura Nyco tactical fabric focuses on lightweight comfort. This optimized fabric is a comfort blend of Invista T420 fiber and cotton. It’s engineered to help provide security and protection for war fighters and their vital equipment through lighter weight and exceptional durability.

The limited edition collection, that won Teatum Jones the 2015/16 International Woolmark Prize for womens wear, is now available at select David Jones stores and its website until stocks last. The launch of the collection at David Jones comes after the winning design duo of Catherine Teatum and Rob Jones visited the source of the fibre they work with.

As one of the original retail partners for the International Woolmark Prize, David Jones is the exclusive stockist of Teatum Jones collection in Australia. The collection will be available globally through International Woolmark Prize retail partners including Boutique 1 (Dubai), Boon the Shop (Seoul) Harvey Nichols (London), Isetan Mitsukoshi (Tokyo), Leclaireur (Paris), mytheresa.com (online), Saks Fifth Avenue (New York) and Verso (Antwerp).

David Jones is Australia’s leading retailer known to showcase several luxury brands and offer customers the finest options across fashion, beauty and home. Its philosophy perfectly aligns to that of the International Woolmark Prize: fostering the development of emerging international designers and being constantly on the lookout for the next big name in fashion.

Following a global search that nominated 41 emerging womens wear designers from across the world British labels, Teatum Jones was chosen as the winner at a final event staged during New York Fashion Week in February. Using fine Australian Merino wool for their winning collection, the designer duo partnered with a specialist guipure lace mill in France and convinced them to use wool for the first time in a particular way to create innovative and vibrant geometric Merino laces.

The International Woolmark Prize celebrates outstanding fashion talents from across the globe that showcase the beauty and versatility of Merino wool. First held in 1953 as an initiative of the International Wool Secretariat, the award was won by the then relatively unknown and now iconic fashion designers Karl Lagerfeld and Yves Saint Laurent the following year.

A free trade agreement with the European Union would boost exports of garments and fabrics from India and help tackle competition from Bangladesh. While Bangladesh enjoys preferential treatment and tax benefits for textile exports in the EU, India has a greater competitive advantage in terms of environmental compliances. Countries of the EU lay huge importance to environmental compliances.

Once an agreement between India and the EU is in place, and exporters from India also get tax preferences, it would be easier to face competition from Bangladesh. The Indian textile industry is at a turning point. China’s export growth in textiles is decreasing and India is enjoying cost advantages, while it is also among the very few countries which have the entire value chain existing within the country. Several states are coming out with their own policy and incentive schemes for the textile sector.

FTA proposals have hit a roadblock. The negotiations were launched in 2007. There are some disagreements in areas such as duty cuts on automobiles, wines and spirits, data security status and easier temporary movement of services professionals.

The EU is India’s number one trading partner. India is the EU’s ninth trading partner. Among EU exports to India are engineering goods, gems and jewelry, other manufactured goods and chemicals. Among EU imports from India are textiles and clothing, chemicals and engineering goods.