FW

"With a 15 per cent jump in visitors compared with the previous year, the second autumn event of the CHIC Autumn, Shanghai ended on a positive note. The China International Fashion Fair (CHIC) bolstered companies’ confidence on the domestic industry and presented their innovative streak to the world with this power-packed show. CHIC Autumn was in a true sense a confluence of established brands and young start-ups, capturing 837 brands from 21 nations; attracting more than 65,700 visitors, CHIC projected global insights, Impulses designer area, next to the exhibitors of the Secret Stars section (accessories, shoes, bags). "

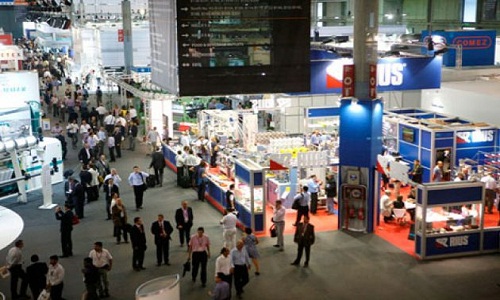

With a 15 per cent jump in visitors compared with the previous year, the second autumn event of the CHIC Autumn, Shanghai ended on a positive note. The China International Fashion Fair (CHIC) bolstered companies’ confidence on the domestic industry and presented their innovative streak to the world with this power-packed show. CHIC Autumn was in a true sense a confluence of established brands and young start-ups, capturing 837 brands from 21 nations; attracting more than 65,700 visitors, CHIC projected global insights, Impulses designer area, next to the exhibitors of the Secret Stars section (accessories, shoes, bags). CHIC Shanghai is considered the ‘window of fashion’ and being a leading trade show in Asia it is the bridge for entering into the Chinese market.

Record number of visitors a sign of positivity

The organisers of CHIC Autumn expressed their gratitude with 15 percent rise in visitors compared to CHIC autumn last year. Chen Dapeng, Executive Vice President, China National Garment Association and Head of CHIC said, “CHIC Autumn fulfills a different task than CHIC Spring. It gives an overview of leading brands and offers smaller brands the possibility to meet prospective buyers.” Moreover brands at CHIC Autumn profit from adjacent activities, such as the gathering at Intertextile. CHIC Autumn presents the right mix of established brands and start-ups.

The clear segments of CHIC Autumn guided visitors through the trade show. The new location of the Impulses area (for young designers) next to the fashion show center was eye-catching. Another success at the fair was the section ‘Secret Stars’ (accessories, shoes, bags), which attracted a lot of attention. Chen Yanrong, Marketing Manager, Henney Bear, confirmed that all important department stores like Wanda, Maoye, Jingying, Dashang visited his booth for discussions. Exhibitors at the sections for menswear and womens wear were satisfied with their results at CHIC Autumn.

Also the organisers of ‘shows-in-show’ expressed their full satisfaction. Nobrand and EcoChic at Pure Shanghai have already announced their next year’s participation. Another highlight was ‘Chic Young Blood’. A strong presence and performance was given by Korean brands, among others by Twee with their brand Te.Stones. They run 30 big stores in Korea and are now building up their business in China thanks to CHIC.

Frankfurtstyleaward Collection 2016 received a lot of attention. The innovative styles of young designers have been presented at the show. Also the joint fashion show of Brazilian Footwear of Apexbrasil EA Asia with trends spring/summer 2017 was well attended and led to a large number of visitors at their joint pavilion. Further fashion shows gave impressive ideas on new trends and tendencies for spring/summer 2017.

Delighted with the response, many of the exhibiting brands have already signaled their participation fosr CHIC Spring to be held in March 2017. Stefano, Giovanni Fabiani (Italy), said, “We started in China some time ago, for the 4th time now at the CHIC and have our own showroom in Shanghai. CHIC is the largest and most efficient show with more and better qualified visitors. At this exhibition, we wrote orders with shopping malls and new contacts, which we have to follow. This time we also had many visitors from the tier III cities. CHIC is an important part of our marketing strategy. It is good to be here, which creates trust with our customers and buyers.” Happy with the response, Bernd Michael Ostwald, Owner, OWA bags, Germany, said they are regular exhibitors at CHIC and welcomed qualified distributors with multi-brand stores e.g. from Beijing at their booth.

The vent saw an increase of 15 per cent with a total number of 65,714 visitors. CHIC Shanghai will be back in March between 13-15, 2017.

"It was all about Industrie 4.0, energy efficiency and sustainability on the first day of ITMA ASIA + CITME 2016. Significant German participation at ITMA ASIA + CITME 2016, flagging off today is offering perfection and precision through tech competency to companies globally. German technology has a major role to play in bringing out eco-friendly and energy efficient process in textile industry globally. With their products and services, VDMA member companies have already taken steps towards Industrie 4.0, in China called intelligent manufacturing."

It was all about Industrie 4.0, energy efficiency and sustainability on the first day of ITMA ASIA + CITME 2016. Significant German participation at ITMA ASIA + CITME 2016, flagging off today is offering perfection and precision through tech competency to companies globally. German technology has a major role to play in bringing out eco-friendly and energy efficient process in textile industry globally. With their products and services, VDMA member companies have already taken steps towards Industrie 4.0, in China called intelligent manufacturing. The VDMA booth (H1F81) is the first point for visitors interested in German technology. Here visitors get an overview of manufacturers and their products in the useful pocket guide, listing all exhibiting VDMA members by halls and showing their stand location in the hall plans.

Visitors can witness the high-technology display by more than 100 German machinery manufacturers exhibiting at the fair, covering all aspects of textiles vis-à-vis spinning, nonwoven, weaving, knitting, warp knitting and finishing spread across 7,000 sq .mts.

Mission sustainability

On the opening day of ITMA ASIA, Fritz P Mayer, Chairman, VDMA Textile Machinery and Associate of Karl Mayer Textilmaschinenfabrik emphasised German technology can play a major role in efforts to make the environment cleaner, to increase energy efficiency and competitiveness of textile producers. “For some time now, VDMA member companies have been focusing on the issue of sustainability for their products, in order to satisfy the demand for efficient technology solutions that effectively cut back on consumption, and consequently on production costs” explained Mayer. New technology is the key to better products and competitive production. And, technology is one precondition for resource and energy saving, he explained. Professionally investing customers are happy to pay for sustainable technologies and improved energy efficiency. VDMA calls this ‘Sustainability meets profit’, Mayer explained.

In 2011, VDMA started its sustainability initiative ‘Blue Competence’, to which over 40 textile machinery companies have adhered. Instead of scientific certification experiments and theoretical approaches, VDMA focused on best practice examples. First to mention is an analysis by VDMA experts that examined the energy saving effects over the entire production chain of five textile products: a cotton T-Shirt, a functional T-Shirt a textile billboard, an architectural textile and a hygienic nonwoven. The result of this in-depth analysis is impressive: In the production of these products up to 30 per cent energy can be saved with today’s German technology compared to the one available one decade ago.

Towards Industrie 4.0

The future of the textile industry is determined by Industrie 4.0. This interconnection of information technology and manufacturing processes is on track. As Thomas Waldmann, MD, VDMA Textile Machinery says, “Leading customers are increasingly interested in condition monitoring and predictive maintenance, including remote services.” Other hot topics are: virtual machines, traceability, remote control data exchange, self-optimising, intelligent user interfaces or individualisation. Smart machine controllers will correct process parameters automatically according to the sensors report. Or, if delivery deadlines are not met, downstream production processes will be adjusted immediately. Without discussing the potential of new business models, immediate advantages of Industrie 4.0 are improved plant efficiency, more economical production processes, energy savings, more flexible production, just to name a few.

China a big market for Germany textile machinery

Between January and May this year, the Chinese textile industry imported machinery worth $1.04 billion, with an increased focus on advanced technology. With a market share of 35 per cent, Germany is the biggest supplier. Against the trend of decreasing imports, the deliveries of spinning machinery increased by 20 per cent from January to May, from Germany by 25 per cent.

"The 5th ITMA ASIA + CITME 2016 exhibition which opened today is a landmark as it’s the largest show in the series since inception. The exhibition has as many as 1,673 exhibitors from 28 countries and economies showcasing a wide array of machinery and solutions to an expected visitorship of around 100,000 during the five-day exhibition that closes on October 25. "

The 5th ITMA ASIA + CITME 2016 exhibition which opened today is a landmark as it’s the largest show in the series since inception. The exhibition has as many as 1,673 exhibitors from 28 countries and economies showcasing a wide array of machinery and solutions to an expected visitorship of around 100,000 during the five-day exhibition that closes on October 25.

The exhibition covers over 170,000 sq. mt. exhibition space, 12 per cent larger than the last edition. This year’s exhibition happens to be the biggest showing since the first edition. These numbers attest to the combined strength of ITMA ASIA + CITME brands making the combined show Asia's most important textile machinery show in terms of exhibiting space and technology. Another first is the staging of combined show at a new venue, the National Exhibition and Convention Centre, Shanghai. Occupying six halls, the modern exhibition centre is easily accessible from the Hongqiao Transportation Hub.

Fritz Mayer, the new President of CEMATEX, is happy with the response to the exhibition. As he says “Despite the current sluggish economic climate, there is a great need for an industry-leading platform in Asia where established textile machinery manufacturers can showcase their products and services and connect with their customers.” Agreeing with Mayer, Wang Shutian, President of China Textile Machinery Association (CTMA) points out the combined show is an Excellent platform to reach Asian buyers. “The overwhelming response is also partly due to the Chinese government's call to embrace automation which will help the industry improve the quality of textiles and cost-effectiveness. Even though economic conditions may be difficult at the moment, textile makers recognise that it is even more critical for them to invest in better technological solutions and to upgrade their facilities,” he says.

China has the biggest number of participants at the show with 69.4per cent of the exhibition space. This is followed by Germany with 6.5 per cent, Italy at 5.5 per cent, Japan 4.7 per cent and Switzerland 3.2 per cent. The exhibition ends on 25 October 2016.

ITMA ASIA + CITME 2016 is jointly owned by CEMATEX and its partners in China - the Sub-Council of Textile Industry, CCPIT (CCPIT-Tex), China Textile Machinery Association (CTMA) and China Exhibition Centre Group Corporation (CIEC).

At its general assembly meeting held in Amsterdam, CEMATEX, Zurich-based European Committee of Textile Machinery Manufacturers appointed Fritz P Mayer as its new president. Mayer takes over from Charles Beauduin who retires after being at the helm for four years.

A German national, Mayer joined Karl Mayer Textilmaschinenfabrik in 1975 after graduating from the University of Darmstadt with a degree in industrial engineering. In 1981, he was appointed managing director of the company and also became a member of the Management Board of Karl Mayer Group. Later in 2007, he was appointed as the CEO of the group.

Though he retired from the operational management of the Group in 2013 Fritz still represents the Mayer family on its Supervisory Board. Fritz has also been president of the German Textile Machinery Association, (VDMA) since January 2016. CEMATEX comprises of national textile machinery associations from Belgium, France, Germany, Italy, Netherlands, Spain, Sweden, Switzerland and the United Kingdom and is the owner of Itma and Itma Asia.

Taiwan’s leading Textile Company the Far Eastern New Century Corporation is planning to shift operation to Vietnam and hopes to capitalize on the country's cheap labour. In a statement, Eric Hu, President of Far Eastern New Century Corporation said they cannot think of a better place to build their new manufacturing base than Vietnam which offers cheap, high-quality labour and stands to possibly benefit from the Trans-Pacific Partnership. He said the company expects to triple its annual output of its fabric-dyeing and finishing plants in Binh Duong Province. Hu also reaffirmed a plan announced earlier this year to more than double the company's investment in Vietnam from $300 million to $760 million.

Formosa Plastics Group paid Vietnam $500 million in August to release an untold quantity of toxic waste into the East Sea. The government, there, is in the process of distributing the funds to affected fishermen and businesses. In this regard, Hu said his operations won't be affected negatively by fellow Taiwanese conglomerate Formosa that caused an ecological disaster. The textiles industry has become notorious, in recent years for using obsolete, polluting dyeing technology.

Following repeated violations of the country's environmental and water resource management regulations, provincial authorities in Ba Ria-Vung, Hu shut down the dyeing operations of the Mei Sheng Textiles Viet Nam last May. This happened to be the seventh shut-down of the Taiwanese firm's 28 yarn and fabrics-dying machines for an illegal water discharge. Way back in 2010, a similar scandal had erupted due to similar practices at the Pangrim Neotex firm of South Korea. Vietnam has become a destination for foreign polluters seeking cheap labour and low trade tariffs. The country's rogues gallery includes MSG producers Vedan and Miwon.

In order to meet the growing global demand for high added-value nylon, Japan-based Ube Industries has decided to invest in additional nylon manufacturing capacity at its subsidiary, UCE (UBE Corporation Europe S.A.U.) in Castellon, Spain. As reported, the expansion will add 40,000 tonnes to make the total capacity reach 70,000 tonnes per year.

The new facility is expected to start operations in the beginning of February 2018. The nylon plant, would utilize Ube proprietary technology and will be able to manufacture various types of medium and high viscosity nylons and copolymers for technical applications such as the automotive industry, food packaging, the manufacture of industrial monofilaments, fishing nets among others.

Ube Industries is one of the largest nylon producers in the world for engineering applications, manufacturing nylon 6 resin at three plants worldwide with a total annual production capacity of 158,000 tonnes. By region, the production capacity is 53,000 tonnes in Japan, 75,000 tonnes in Thailand and 30,000 tonnes in Spain. In particular, UBE Group manufactured nylon has an outstanding reputation for quality and processing stability for extrusion applications such as packaging films.

Thanks to an ambitious program being fast tracked by value chain players, cotton farming in Kenya is well on the path of recovery. The program aims at filling gaps along value chain, equipping farmers with farm inputs, credit, and provision of extension services and linking them to the market.

Just a day before, various national government agencies, county government of Tana River County and stakeholders of the private sector signed a Sh32.9 million agreement with cotton farmers. And as Anthony Mureithi, Interim Director of fibres crops directorate under the Agriculture and Food Authority (AFA) says the initiative is part of other strategies being fast tracked to help farmers revive cotton farming. In 1970s and 1980s when cotton farming was second in the country in terms of employment after public service, Bura used to produce 30 per cent of the national production.

Under the programme, farmers will receive certified seeds sourced from Israel and other global market segments. Bura MP Ali Wario welcomed the new initiative saying farmers stand to gain after a long period grappling with grinding poverty among other miseries.

If local exporters are found guilty of dumping, Bangladeshi jute and jute goods may be subjected to 25 to 30 per cent duty upon entry to Indian market. This decision comes after the Directorate General of Anti-Dumping and Allied Duties (DGAD) concluded its probe into the matter last week, an official of Bangladesh Tariff Commission has reportedly said. The report is likely to be disclosed next week.

Negotiations will start with the Indian government once the official statement is received, he added. Currently, Bangladeshi jute and jute goods enjoy zero-duty benefit on export to the Indian market under the South Asian Free Trade Area agreement. Three years ago, the Indian Jute Mills Association had accused Bangladeshi exporters of selling jute products at prices lower than those in India's domestic market. Then in October last year, the Indian anti-dumping authority started its investigation into the matter.

As a part of the investigation, a team of DGAD visited some factories in Bangladesh and collected data including export prices of the shipped products to India and the sales prices in domestic market, say industry insiders. Officials of the tariff commission attended several hearings in India before the conclusion of investigation.

In many countries, forced labour remains to a problem with textiles and garments industry. Despite progress in the last few years due to rising awareness, forced labour still occurs in cotton fields and factories across the world. Forced labour is the use of coercion to force people to work for little or no pay. Mostly, it takes the form of modern day slavery but also perpetuates itself through less overt practices such as debt bondage where workers are forced to work to pay off high-interest loans with no other means to pay off their debt.

In the garment industry, forced labour can be seen in two areas. One is the beginning of the supply chain, labour-intensive crops such as cotton often require abundant work for cultivation and harvest. And forced labour is not uncommon in the fields. Forced labour happens in fields around the world, but one of the worst scenarios unfolds in Uzbekistan, a dictatorial country in Central Asia. The cotton harvesting season turns huge parts of the nation into vast forced-labour plantations with Uzbek cotton being exported to East Asia from where it is sent around the world.

Forced labour is also pervasive in garment factories, where fabrics are transformed into the countless pieces of apparel we wear every day. Few factories remain in developed, Global North countries these days, with cheap labour costs resulting in the mass migration of garment labour to Asia and Africa. It is generally easier to understand forced labour at this level.

In fact, advocacy groups have found countless instances of forced labor in factories, but the sheer complexity of the industry makes it hard to paint broad pictures. Factories that treat workers well can be found in the same regions as those using forced labour. And from the outside, it can be nearly impossible tell the difference. The problem is that, too often, products created from both good and bad factories end up in the same supply chain.

Cotton production, once considering a key culture for the rural areas of Azerbaijan, is now on the path of a revival following a gradual decline during several past years. In the ’70 and ’80s, cotton production was of crucial importance for the national economy accounting for approximately 25 per cent of agricultural revenue. Then, Azerbaijan harvested a million tons of cotton per year. Now, the country is struggling to be listed among global cotton growers. This year is expected to be a period of development of cotton growing in Azerbaijan as the government is keen to support cotton production to give a new life to this industry. As of October 17, the country produced 38,890 tons of cotton that was 1.7 times more than the same period last year. This year cotton was sown in 52,060 hectares and this was 2.8 times more than last year's crop area.

The largest volume of cotton was harvested in Saatli region. Moreover, cotton-growing is developing in the south western region Salyan this year.Experts claim that the sector brings great incomes both to people and the state. Development of cotton growing, along with the solution of economic issues, is also a social issue, says President Ilham Aliyev,. About 70,000 people will work on cotton fields of 24 regions this year. This would mean an increase in employment. He also added that next year, cotton production will lead to the creation of more than 100,000 jobs.