FW

CHIC Organizing Committee has informed that given the need to prevent and control a new corona virus infection, a top-level response mechanism for major public health emergencies has been launched in Shanghai. In order to effectively protect the health of exhibitors, trade visitors, staff and the public and to ensure an efficient trade fair for all participants, the date of the CHIC, China International Fashion Fair, originally planned from March 11 to 13, 2020, has been postponed.

"Sicomin has partnered with GREENBOATS on the supply of Green Poxy bio-based resins for the FLAX 27- an 8.2m classically styled day sailer, the most complete natural fibre composite project realised by GREENBOATS to date. Sicomin’s hand lamination and infusion production processes have been optimized for natural fibre composites, providing an uncompromising performance."

Sicomin has partnered with GREENBOATS on the supply of Green Poxy bio-based resins for the FLAX 27- an 8.2m classically styled day sailer, the most complete natural fibre composite project realised by GREENBOATS to date. Sicomin’s hand lamination and infusion production processes have been optimized for natural fibre composites, providing an uncompromising performance.

Sicomin has partnered with GREENBOATS on the supply of Green Poxy bio-based resins for the FLAX 27- an 8.2m classically styled day sailer, the most complete natural fibre composite project realised by GREENBOATS to date. Sicomin’s hand lamination and infusion production processes have been optimized for natural fibre composites, providing an uncompromising performance.

Vacuum infusion with Sicomin’s InfuGreen 810, produced crystal-clear natural fibre laminates with outstanding mechanical properties, whilst the closed mould process also improved working conditions in the factory.

Available with a choice of hardeners to adjust the curing time as required, InfuGreen 810 also carries DNV-GL approval, providing a reassuring 3rd party confirmation of the product’s exceptional quality, performance and consistency.

approval, providing a reassuring 3rd party confirmation of the product’s exceptional quality, performance and consistency.

GREENBOATS typically apply a bespoke life cycle assessment tool to optimize their projects for performance as well as sustainability. This detailed view of a project’s environmental impact and GREENBOATS expertise in product development has now created a number of larger scale composite applications for bio-based resins.

Sicomin are looking forward to continuing to work along side GREENBOATS in 2020, with industrial production capacity for their market leading range of GreenPoxy bio-based epoxies positioning the company to support the forecasted large scale growth in the natural fibre composite market.

“Our goal is to really get people excited about Natural Fibre Composites. Sicomin’s GreenPoxy products help us create sustainable composites with no compromise in performance or appearance.” Commented GREENBOATS founder, Friedrich Johann Deimann.

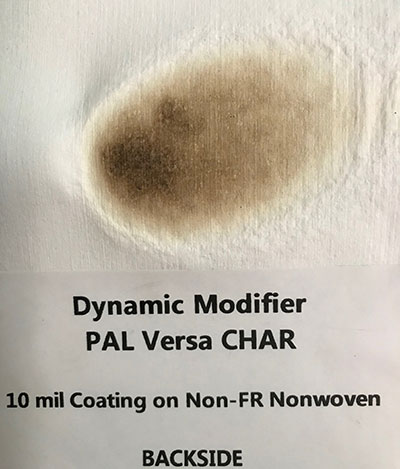

A new non-halogenated FR compound called PAL...VersaCHAR can achieve a new level of flame retardant performance as a coating for nonwovens and technical textiles.

It is being introduced by Dynamic Modifiers, a specialty compounder focused on custom polyolefin compounds and concentrates, based in Atlanta, Georgia.

PAL...VersaCHAR has been tested to 1,950°C – the highest to date – and shown to prevent all flaming drips of polymer. Char bodies form on the compound surface, protecting against flame creation and delaying heat transfer. Rapid self- extinguishing burn behaviour protects any underlying substrate to which it is adhered.

The compound has passed ASTM E84 (Class A) with a 15/10 rating, which includes ‘clean’ smoke generation of only 2.3% of the allowable ASTM smoke limits. In addition, the compound is light weight, at a specific gravity of 1.0, and 100% non-toxic in every respect, being free from heavy metals, halogens and VOCs.

Other properties include excellent cold crack performance, hydrophobicity, printability, extreme chemical resistance and the ability to be custom tailored for specific needs such as UV or antimicrobial performance, as volume warrants.

In addition to its use as a coating, PAL...VersaCHAR compound can be produced as a flexible film or sheet and moulded to shape or over-moulded to most materials, including metal for corrosion resistance As a polymeric compound it can be cast or calendered and typical durometers from 80-99A for flexible-to-high rigid formats are practical.

Separately, an adhesive has been created which bonds to many surfaces. In internal evaluations of two laminated plies of woven carbon fibre and two plies of glass fabrics, both passed a 60 second vertical burn with no ply separation, distortion or flaming drips from the adhesive.

Dynamic Modifiers envisages many uses for PAL...VersaCHAR, from aerospace to the protection of rigid structural materials in building interiors etc.

Gucci has partnered with The Lion Share's Fund to support wildlife conservation and tackle the crisis in nature, biodiversity and climate change. A program established in June 2018 by the United Nations Development Programme (UNDP), the Fund aims to raise over $100 million annually for next five years by asking brands to contribute 0.5% of their media spend every time an animal is featured in their advertisements. Marco Bizzarri, President and CEO of Gucci, said: “The Lion’s Share Fund is an important addition to our conservation strategy. Nature and wildlife provide Gucci with inspired creation that is an integral part of our narrative through our collections and campaigns. With the increasing threats to the planet’s biodiversity, groundbreaking initiatives like The Lion’s Share Fund have the potential to be transformative by organically connecting the business community with direct action to protect our natural habitats and most threatened species.”

Pure Origin will be held in the UK, February 9 to 11, 2020.

This is a show for international garment, fabric and supply chain sourcing. For this edition the spotlight will be on Turkey. Over 20 Turkish brands will participate. As the world’s seventh largest apparel exporter, and with 72 per cent of total apparel exports going to the EU, Turkey represents a huge opportunity for UK brands and designers, with short delivery times and integrated supply chain capabilities.

Pure Origin brings the entire fashion supply chain, from fiber to finished collection, under one roof. Pure Origin provides access to seven curated sectors across supply and manufacturing. It also features its own dedicated platform for content including talks, workshops, trend presentations and catwalk shows. Pure Origin is the UK’s number one destination for sourcing and manufacturing, knowledge and solutions. It offers apparel, fibers and raw materials, denim, footwear and accessories, and tech and innovations. As a convenient and cost-effective way for buyers to meet with UK and international manufacturers, the show brings together over 200 exhibitors from dozens of countries to create a wide range of business and networking opportunities, new thinking and innovation attracting buyers, sourcing, and technical personnel.

Vietnam’s raw material imports from China have dwindled because of the coronavirus.

The outbreak is expected to negatively impact ten major industries in Vietnam, including textiles. If the disease persists, supply and transport chains will be in trouble and in the worst case scenario manufacturing will have to stop or be delayed. So for instance leather factories may have to shut down if they can’t source the material from China. Production of rubber and plastic in Vietnam is largely dependent on China with 70 per cent of materials imported from the country. China accounts for 55 per cent of Vietnam’s fiber imports. China has shut down manufacturing in many cities to contain the virus. So textile companies in Vietnam have to tap other markets to meet production targets. They would have to source from say Japan or South Korea where prices are much higher. Profitability will be challenged by higher material costs as companies have fixed prices with customers since the end of last year.

In January, Vietnam’s imports of fabric from China fell 18.1 per cent. Exports of textiles, a key sector, in all markets fell 21 per cent year on year in January, while that of footwear fell 9.7 per cent.

Gartex will be held in Mumbai, March 19 to 21, 2020.

This is a trade show on garment textile machinery. Exhibitors will present the latest innovations, machines, plants, processes and services to various stakeholders in the industry, including manufacturers and suppliers. The event is aimed at providing business opportunities to international and national suppliers as well as trade visitors through networking sessions with industry experts and engaging in investment opportunities. Gartex unifies various stakeholders within the garment and textile manufacturing supply chain and provides stakeholders greater accessibility to their buyers in the western and southern regions. The objective is to reach out to the major textile hubs of west and south India. This edition will complement the existing New Delhi edition while also increasing the expanse of the show by reaching out to smaller-sized companies and start-ups in the region. The show will provide insights on technological developments in the garment and apparel manufacturing sector. Innovative products and technologies, defining the latest trends in the industry, will be showcased at the four concurrent shows -- Denim Show, India Laundry Show, Fabrics and Trims Show and Digitex Show-- during the three-day event.

India’s textile and apparel exports are expected to go from five per cent to 15 per cent by 2024-25.

Cotton ginners are hopeful that notwithstanding the present slump, India will be able to export at least 40 lakh bales each of 170 kg of cotton in the current season. Ginners believe that in case the trade slump caused by the spread of coronavirus in China ceases, the export could be more than 45 lakh bales. Meanwhile, raw cotton from India is expected to find favour in the international markets as the produce is around 5 to 7 per cent lower than the international prices.

Estimates by the Cotton Association of India (CAI), the industry body that represents the cotton value chain, have shown that till January 31, 192.89 lakh bales have arrived in markets, which industry sources say, is around 55 per cent of the produce.

The Cotton Corporation of India (CCI) under its Minimum Support Price (MSP) operations have procured 56 lakh bales while the country has seen 10 lakh bales of imports. Robust procurement by the CCI and a spike in prices of cotton seed has seen average traded prices of kapas (which contains 33-34 per cent lint, with the balance accounted for by seed) in the Rs 5,100-5,200 per quintal range in majority of the wholesale markets of the country.

Ginners from Khandesh — comprising Nandurbar, Jalgaon, Dhule, Nashik and Ahmednagar districts — are hopeful to export directly to Bangladesh. In this regard, a special team will be leaving for Bangladesh towards the end of February.

According to the International Cotton Advisory Committee’s (ICAC) February update of cotton conditions, the global cotton trade will grow by 2 percent in the 2019-20 season, to reach 9.4 million tonne. China will remain the world’s top importer at 1.8 million tonne, but that would represent a year-over-year decline of 14 percent

Production is expected to decline in some major producing countries, with Turkey revised downward to 815,000 tonne and Pakistan to 1.35 million tonne. As a result, imports will increase for both countries to 818,000 tonne and 967,000 tonne, respectively

Latin American countries should meet some of that additional demand. Brazil’s production is expected to remain high at 2.76 million tonne and exports are expected to grow 19 percent to 1.7 million tonne. Argentina is also forecast to increase its production, to 358,000 tonne, posting a gain of 39 percent, while imports are expected to increase by 57 percent to 186,000 tons. The latest U.S. Department of Agriculture (USDA) report forecast U.S. production to be 20.1 million bales in the current season compared to 18.4 million bales in 2018-2019.

USDA expects U.S. exports to be unchanged at 16.5 million bales for the season, which represents the second-highest volume on record. Stability in the export forecast caused each of the four consecutive decreases in the U.S. production forecast, representing a decrease of 2.3 million bales since August, to result in four parallel decreases in ending stocks.

The current projected increase in U.S. ending stocks of 11 percent, or 550,000 bales, has dropped from a forecast 48 percent gain to 2.4 million bales in August.

Bangladesh’s apparel exports to the US grew 9.83 per cent last year. Bangladesh’s readymade garment exports to the US in January to June 2019 were 14.49 per cent higher than in the same period of 2018. From July to December they grew by only 5.19 per cent.

That means export growth to the US market was satisfactory until the first half of 2019 but it declined in the second half of the year. The country failed to achieve the required export growth in the US market in 2019 as it could not take advantage of the US-China trade war. The export growth of Vietnam and Cambodia, two competing countries of Bangladesh, to the US was much higher than Bangladesh as they grabbed most of the business shifted from China due to the trade war. Bangladesh’s competitiveness is eroding due to the increasing production cost and overvalued local currency. Exports are expected to decline more in the coming months. The country’s export earnings have continued to slump as the major economies of the world are facing a recession amid the US-China trade war, reducing the buying aspirations of consumers. Europe is the pivotal export market for Bangladesh. While Bangladesh relies on apparel exports consumers have cut back on clothing and entertainment.