FW

From January 1, 2019, Mayer & Cie. (MCT) is manufacturing braiding machines, in addition to circular knitting machines, at its Albstadt works. Mayer Braidtech, a wholly-owned company subsidiary, is responsible for sales and service of the new machines manufactured for the past 40 years by the US-based affiliate Mayer Industries. With Mayer Industries due to cease operations in the medium term, Mayer & Cie. has decided to integrate and take forward this successful line of business at its Albstadt location.

“We see this step as an opportunity to come much closer to our target of sensible diversification,” says Marcus Mayer, Managing Director at Mayer & Cie. and in charge of technical development. “As a manufacturer of circular knitting machines we are subject to the vagaries of the textile machinery market, which experience has shown to be liable to strong fluctuations. A sector-unrelated product such as braiding machines will make us a good deal more independent.”

“We see this step as an opportunity to come much closer to our target of sensible diversification,” says Marcus Mayer, Managing Director at Mayer & Cie. and in charge of technical development. “As a manufacturer of circular knitting machines we are subject to the vagaries of the textile machinery market, which experience has shown to be liable to strong fluctuations. A sector-unrelated product such as braiding machines will make us a good deal more independent.”

It was apparent right now how important diversification is, Benjamin Mayer, Mayer & Cie. Co-Managing Director, noted. He is responsible for sales. After a fast and furious start to 2018 demand for circular knitting machines had tailed off in the second half. That was mainly due to turbulence in the international trade policy, he said, in the wake of which uncertainty had spread widely in many important circular knitting markets. Order books for braiding machines, in contrast, are full for months ahead because other laws apply to the hydraulic hoses used, for example, in automobile manufacturing and aviation. That is also true of tubes that drive pumps on the seabed in offshore operations. Braiding machine manufacturing capacities are currently fully booked until the beginning of 2020.

Although circular knitting and braiding machines are only distant relations, there are many synergy effects between the two lines of business. “That was a powerful argument for integration,” says Benjamin Mayer. “Our new investment stays within limits because we can make many braiding machine parts with our existing machine tools and production machinery. Assembly employees can not only assemble circular knitting machines, shipping employees can not only ship circular knitting machines.”

Mayer & Cie. also anticipates a positive effect in the key sector of research and development, but with the stated aim of setting up a separate research department as soon as possible.

up a separate research department as soon as possible.

Series manufacture in Albstadt from January

In January 2019, Braidtech is embarking on series production in Albstadt-Tailfingen. Preparations for this milestone took nearly 12 months. Premises needed to be provided, the production line prepared, procurement organised and the team lined up. At the moment, it has 12 employees who do production-related work in, say, assembly, quality assurance and logistics. They are currently working flat out on the prototype of their first braiding machine, an MR 15 24 Carrier.

Patrick Moser, head of the new Mayer Braidtech business unit, explains that “the model as such is tried and established, but for us here, in new conditions, it is an ‘original’.”

The plan for the first half of 2019 provides for shipment of two double-deck systems, each consisting of two MR15 24 Carriers per month. Preparations are also on for series production of the second model in a range consisting of six products.

Distribution structures are well established. Mayer Braidtech has handled world sales of braiding machines for years. “Our business,” Moser says, “is project business, so the largest sales markets can vary from year to year, but for some time we have had many orders from Italy and China.”

FESPA has received fantastic Award entries from our valued print community. We speak to our esteemed judges, who have given us an insight into what they are looking for in your entries. In part 5, FESPA speaks to Jacek Stencel.

In the final part of our Awards series, we have spoken to Jacek who is the fifth member of our 2019 judging panel. Jacek has over 30 years of experience in the print industry and runs PASJA – a successful print business in Poland, specialising in special effects printing.

What made you want to be on the judging panel of the 2019 Awards?

“First of all, a proposal from FESPA for me to be a judge is a great honour and brings me happiness to be a part of that panel. I’m still working and am an active screen printer with over 30 years of experience in the printing industry. In previous years, my company won many FESPA Awards in different categories. My company PASJA, (established in 1992) in Polish means ‘passion’ - it illustrates clearly that printing for me it's not only business, it is much more. I’m glad that my skills can be used in discovering something new and exciting in entries.”

What are you looking for in an entry?

“One of the most fantastic moments during judging is to be surprised by the quality, perfection, creativity, design, combined technologies and very often creation of new products followed by new advantages/needs of the market. Printing is still an active part of everyday life and thanks to the human creativity and new technologies, it can be still be used on undiscovered fields which is great thing.”

What is your favourite category to judge?

“As I said earlier, I’m a printing fan and love the world of print so it is difficult to choose my favourite category. Closer to my heart are: Serigraphies, Special Effects, Special Effects Garments categories.” Where do you see the future of print going?

“Besides existing parts of market where position of printing is stable and constant, our industry will grow in a few areas. For example, thanks to the sharing of printing technologies and modern finishing processes such as CNC cutting different materials, and special mounting and new lighting systems which can create new products for interior and external decoration industry, POS market, furniture industry or collaboration in marking large sports and museum facilities, allows to manage such a project in a manner and scale not possible a few years ago. Fashion industry, textile, automotive and printed electronics are using printing techniques for creating their goods successfully. High quality, fast reaction, flexibility, eco friendliness, high durability and cost effectiveness makes all those factors important for different new market sectors in printing. Another strong trend is knocking - 3D printing - from small to big scale objects.”

What is the biggest challenge that you feel entrants have?

“Entrants should show what they love in work and what they create with passion. To show how they are discovering new fields of printing, high quality of realisations, new techniques, materials etc. and maybe sometimes breaking some old rules!”

We look forward to welcoming Jacek to FESPA’s Head Office to judge the Awards entries in February. There’s still time to enter the 2019 FESPA Awards, with entries closing on the 25th January 2019. Remember – you don’t have to supply your physical sample until the 20th February 2019.

Mimaki Europe announced its collaboration with over 10 inspirational world-leading designers for Heimtextil 2019 (8-11 January 2019, Frankfurt, Germany - Stand J81, Hall 3.0). Under the theme of ‘The Fusion of Innovation and Design’ and celebrating digital print within all elements of art, interior design...

Mimaki Europe announced its collaboration with over 10 inspirational world-leading designers for Heimtextil 2019 (8-11 January 2019, Frankfurt, Germany - Stand J81, Hall 3.0). Under the theme of ‘The Fusion of Innovation and Design’ and celebrating digital print within all elements of art, interior design...

and fashion, Mimaki commissioned work from designers including Sigrid Calon and Claire Vos (Studio Roderick Vos), that will be showcased throughout the Mimaki booth and used to demonstrate the power of digital print to increase the creative process.

Seeing printed applications on a diverse range of textiles, fabrics and interior materials, visitors will learn how they too can use advanced Mimaki technology to drive design innovation and profitability. From designers including Anousjka Röben displaying shoes; creative studio Deux d’Amsterdam showing a unique kimono designed specifically for Mimaki and Heimtextil, all designs were digitally printed by Textiles & More (T&M). The Mimaki stand will showcase a printer for almost every type of textile application, with additional digitally printed textiles applied to design classics in the ‘Pode’ range from Leolux, and feature walls utilising photography from Arjan Benning also being displayed.

“Heimtextil is always a really good show for us. For 2019, we’re excited to share the results of our collaboration with these amazing designers and to demonstrate what’s possible with our comprehensive range of printers,” says Mark Sollman, Mimaki Application Manager EMEA.

“From entry-level printers to production workhorses, each Mimaki system delivers premium quality print and profit-enhancing productivity. What’s more, using our wide range of inks, a huge variety of substrate applications now becomes available too. So, whether you’re a designer seeking to push the creative boundaries of textile printing, or a brand looking to increase your productivity and lower your environmental footprint, a visit to the Mimaki stand is a must,” continued Sollman.

Heimtextil visitors will experience Mimaki’s broad portfolio of printing solutions, split into three distinct areas including interior design, fashion and art. In the art section, the UCJV150-160 inkjet printer with environmentally-friendly UV-curable inks, will be used to produce wallpaper. Textiles will be printed in both the interior design and fashion areas, with the ultra-productive TS55-1800 sublimation transfer inkjet printer focusing on upholstery. Using a belt-conveying solution, the TX300P-1800B entry-level direct-to-textile system will also be printing onto stretchable fabrics used in fashion.

interior design, fashion and art. In the art section, the UCJV150-160 inkjet printer with environmentally-friendly UV-curable inks, will be used to produce wallpaper. Textiles will be printed in both the interior design and fashion areas, with the ultra-productive TS55-1800 sublimation transfer inkjet printer focusing on upholstery. Using a belt-conveying solution, the TX300P-1800B entry-level direct-to-textile system will also be printing onto stretchable fabrics used in fashion.

Claire Vos, introduced by Textiles & More (T&M) and a graduate of Design Academy Eindhoven, studied her craft in Italy, Switzerland and Indonesia before settling in the Netherlands. With a contemporary graphical industrial flavour to her work, many of Vos’s products are produced using Mimaki printers for Textiles & More. Her work, shown under the theme of ‘The Dressing Room’, will be shown at Heimtextil through Mimaki-printed upholstery including chairs and cushions.

Bringing vivid colour and fine graphical elements into her work, Sigrid Calon is a visual artist. At Heimtextil, the detail and vibrancy of Calon’s art will be brought to life by a 2x2 metre artwork utilising Mimaki’s latest printhead technology delivering smooth gradations and sharp and precise details. Examples of Calon’s work will also be shown in various materials, produced by Mimaki advanced print technologies including UV and 3D printing.

The brand-new, next-generation, single-pass EFI Reggiani BOLT textile digital printer from Electronics For Imaging, Inc., made its debut at a recent open house event held at the EFI Reggiani facility in Bergamo, Italy. The advanced, ultra-high-speed digital single-pass printer has the potential to revolutionize the textile printing market, providing users with high uptime and reliability, outstanding performance, superior printing uniformity and accuracy, long printhead life and minimal maintenance.

The EFI Reggiani open house had huge response, with nearly 300 customers and journalists attending to see the new BOLT in action.

The EFI Reggiani open house had huge response, with nearly 300 customers and journalists attending to see the new BOLT in action.

“The innovative development of our new single-pass printer comes from Reggiani’s speed of innovation in digital textile printing, its 70 years of history, and our proprietary knowledge of high-volume analog rotary printing,” said EFI Reggiani Vice President and General Manager Adele Genoni. “Our EFI colleagues’ proven, worldwide expertise in single-pass technology and, most importantly, EFI Reggiani’s serious commitment to listening to, and addressing our textile customers’ needs, have allowed us to achieve incredible results with our newest print technology. The EFI Reggiani BOLT re-writes the rules of digital textile single-pass printing, delivering superior throughput and quality with a highly competitive return on investment for customers. We are excited to bring this technology to our customers and see their businesses succeed and grow.”

Cutting-edge printhead technology

The BOLT offers an innovative, low-maintenance, fast-startup recirculation printhead that delivers better, more-uniform printing with superior uptime. Thanks to the cutting-edge printhead concept and the high-performance ink delivery system, the BOLT has throughput speeds of up to 295 feet per minute (more than 86,100 square feet per hour) at a 600 x 600 dots per inch (dpi) resolution. It features high-end grayscale imaging in drop sizes from 5 to 30 picoliters, and also provides premium-quality 600 x 4,800 maximum-dpi resolution printing, allowing customers to address the full range of design needs. The printhead has been developed in partnership with a leading printhead manufacturer, and will be available exclusively for EFI Reggiani.

The EFI Reggiani BOLT meets the growing requirements for high-quality, ecologically sustainable digital textile imaging in apparel, décor and other markets. Paired with an EFI Fiery digital front end (DFE) print server offering unique, high-speed processing capabilities on demand, the BOLT printer is a robust industrial platform designed for 24/7 operation and continuous productivity that drives high-volume throughput while reducing the cost per meter.

The EFI Reggiani BOLT meets the growing requirements for high-quality, ecologically sustainable digital textile imaging in apparel, décor and other markets. Paired with an EFI Fiery digital front end (DFE) print server offering unique, high-speed processing capabilities on demand, the BOLT printer is a robust industrial platform designed for 24/7 operation and continuous productivity that drives high-volume throughput while reducing the cost per meter.

Additional new features and enhancements on the printer include:

Enhanced maintenance features – The printer’s contactless wiping system prolongs the printhead life and quality. Plus, the printer comes with an assisted alignment system for its test calibration scan unit and features extractable printing beams for easier maintenance.

Extended color gamut and superior imagequality – Thanks to EFI expertise in color management and flexible color configurations, customers can easily reproduce a wider variety of work, including designs featuring plain colors, geometric patterns, fine lines, deep blacks and smooth gradients.

Proprietary IP combining digital and rotary technologies – One or more analog printing stations, which may be easily connected as an optional feature, can be integrated into the digital printer for special effects.

High-powered EFI Fiery technology

The Reggiani BOLT is a Fiery Driven printer, featuring an EFI Fiery DFE with RIP and color management technologies running on the Fiery XB bladed hardware for maximum performance. Fiery technologies for the printer enable textile printing businesses to successfully produce highly challenging jobs with the finest detail, demanding colors, smooth gradients, etc. EFI color scientists developed special algorithms and custom screening for this Fiery system to deliver vivid print results, including high saturation without losing detail, and superior color even when using the fastest print mode.

Fiery technologies for the new Reggiani BOLT printer also will include a 1-year subscription to EFI Fiery DesignPro, a powerful textile and fashion design suite that runs inside designers’ Adobe Creative Cloud applications. Fiery DesignPro reduces the time needed to create color books, repeats, colorways and prepare files for production to minutes instead of hours. Together, the new Reggiani BOLT single-pass printer and Fiery technologies address key market trends as customers face pressure for faster time-to-market, quick fashion cycles, shorter print runs and more customization.

Fiery technologies for the new Reggiani BOLT printer also will include a 1-year subscription to EFI Fiery DesignPro, a powerful textile and fashion design suite that runs inside designers’ Adobe Creative Cloud applications. Fiery DesignPro reduces the time needed to create color books, repeats, colorways and prepare files for production to minutes instead of hours. Together, the new Reggiani BOLT single-pass printer and Fiery technologies address key market trends as customers face pressure for faster time-to-market, quick fashion cycles, shorter print runs and more customization.

EFI Reggiani high-speed innovation in digital printing

The BOLT printer is the newest in an important series of EFI Reggiani innovations. In the last 15 months, the team has developed a totally renewed range of digital scanning printers with cutting-edge technologies, launching a new model every quarter to offer customers solutions to whatever their requirements may be for easily scalable textile printing. The list of EFI Reggiani advancements includes two recent launches – the COLORS digital printer which provides unparalleled performance with up to 12-colour printing, and the TERRA pigment ink with binder solution featuring in-line polymerization, a process that speeds up customers’ printing with one of the industry’s greenest production technologies.

In the first semester of 2018, Itema registered an unprecedented growth in its weaving machine sales, gaining market share across the globe. The second part of the year has been affected by two main factors – the trade war between the US and China and the financial issues in Turkey. Nevertheless, Itema will close 2018 with positive results consolidating its position at the pinnacles of the worldwide weaving machinery industry.

In 2018 Itema achieved a new technology milestone by introducing a breakthrough, never-before seen innovation featured on the R9500²denim, the rapier machine exclusively dedicated to weaving denim fabrics. The iSAVER developed by ItemaLab – the Itema advanced research and innovation incubator – is in fact capable of eliminating the waste selvedge on the left side of the fabric, thus leading to unparalleled cost savings and setting a new benchmark in sustainable weaving.

In 2018 Itema achieved a new technology milestone by introducing a breakthrough, never-before seen innovation featured on the R9500²denim, the rapier machine exclusively dedicated to weaving denim fabrics. The iSAVER developed by ItemaLab – the Itema advanced research and innovation incubator – is in fact capable of eliminating the waste selvedge on the left side of the fabric, thus leading to unparalleled cost savings and setting a new benchmark in sustainable weaving.

Itema provides rapier and airjet weaving machines to weave home textile fabrics, covering the widest application range from bed sheetings to furnishing, curtains and upholstery fabrics. Focusing on terry cloth fabrics, the Itema rapier R9500terry is the most successful rapier terry machine in the market, dominating worldwide high-end terry production unleashing endless creative possibilities and providing top fabric quality.

Key markets

The home textile market segment includes different fabric types that may vary considerably from each other. Furnishing is historically one of the main market segments for Itema, and it is the leading supplier of rapier weaving machines for furnishing fabrics production in Turkey, India and China, which are the main volume markets, and also in top quality, premium markets such as Italy, the US, Germany and Portugal.

Bed sheeting fabrics are mainly woven as grey fabric and therefore the airjet technology is often adopted. Key bed sheetings producers in Turkey, India and Europe weave their fabrics on the Itema airjet and rapier machines. In 2018 a special mention goes to curtain and terry fabrics. The first one registered a significant revival, especially in Turkey, whilst for premium terry fabrics Itema experienced a substantial and constant positive trend for new machinery.

Why Itema?

Technologically speaking, especially when it comes to weaving fancy yarns, such as chenille and lurex, Itema provides dedicated and patented devices on its rapier machines to ensure superior performances and top fabric quality with no limitations for creativity, such as the Motorized Weft Cutter and the Free Positive Approach (FPA) Weft Transfer System.

On the airjet side, innovative devices such as the Brush Lycra Clamp (BLC) which ensure a perfect insertion of elastic yarns and the Double Tandem Nozzles which guarantee superior textile performances and a reduced air consumption represent undeniable technological advancements. Moreover, Itema, with its global presence,

On the airjet side, innovative devices such as the Brush Lycra Clamp (BLC) which ensure a perfect insertion of elastic yarns and the Double Tandem Nozzles which guarantee superior textile performances and a reduced air consumption represent undeniable technological advancements. Moreover, Itema, with its global presence,

guarantees a timely and accurate aftersales service to its customers.

Future potential

The home textile market is expected to constantly grow, both in the niche, premium quality fabrics and in the mass production market. Weaving machines will play a key role by ensuring to weavers superior productivity and increased textile versatility. And that’s where Itema comes in, with its tireless commitment to provide the market with the most advanced technological solutions.

When it comes to producing high quality, premium terry fabrics (towels, bathrobes and bath mats, ndr) Itema is the undisputed market leader, thanks to the strong heritage and know-how in rapier terry weaving coming from Itema and its former brands (Vamatex and Sulzer, ndr) experience. The Itema rapier R9500terry represents in fact the preferred choice of the most renowned terry weavers in Portugal, Japan, South Korea and Turkey, but also in Italy, Pakistan, Latin America and India.

Curtains is another fabric segment where Itema excels and holds the largest market share due to the great versatility of its rapier weaving machines.

The Itema airjet and rapier machines in wide width are installed in major bed sheeting producers in Turkey, India, Europe and Latin America, and we expect this segment to grow in the future due to the increasing creative possibilities provided by the digital textile printing technology.

Rieter is further upgrading its end spinning product range with the new ring spinning machines G37 and G38 and the new compact spinning machines K47 and K48.

Rieter is the leading supplier of ring and compact spinning machines. Customers particularly appreciate the high productivity, low energy consumption and consistent excellent yarn quality. The two models established on the market, the ring spinning machine G 32 and the compact spinning machine K42, have been joined by four new models – the ring spinning machines G37 and G38 and the compact spinning machines K47 and K 48. But which machine is the best choice for which market? What advantages do the new models offer? And how will Rieter customers benefit?

Choosing the right spinning machine

The machines G38 (Fig.1) and K48 are particularly suitable for markets which have limited personnel availability and which require particularly high levels of flexibility and yarn quality simultaneously. With these “all-inclusive models,” customers benefit from the highest levels of automation, the best performance, complete flexibility for standard and special yarns, an electronic drafting system drive, integrated individual spindle monitoring (ISM premium) and the integrated slub yarn device.

The machines G38 (Fig.1) and K48 are particularly suitable for markets which have limited personnel availability and which require particularly high levels of flexibility and yarn quality simultaneously. With these “all-inclusive models,” customers benefit from the highest levels of automation, the best performance, complete flexibility for standard and special yarns, an electronic drafting system drive, integrated individual spindle monitoring (ISM premium) and the integrated slub yarn device.

The G37 and K47 were developed for markets where there is not a shortage of available personnel and the requirements for flexibility and yarn quality are high. They provide customers with a high level of flexibility thanks to their unrestricted application range at full machine length and for all special yarns. The electronic drafting system drive reduces downtime for article change. The integrated individual spindle monitoring, ISM basic, increases operator efficiency – and therefore machine efficiency.

For customers who rarely change their assortment and who are active in markets where personnel are always available, the 2 series machines are the ideal solution. The proven ring spinning machine G32 and compact spinning machine K42 with mechanical drafting system drive are ideal for standard applications with medium and fine yarn counts.

Outstanding performance

The machine concept for the G38 and K48, which features double-sided suction, allows unrestricted spinning for all applications at full machine length. Thanks to the integrated VARIOspin system for slub yarns, customers can change between standard and slub yarns simply at the touch of a button. The machines are equipped with the electronic drafting system drive FLEXIdraft as standard. FLEXIdraft makes it easier to set yarn parameters. The desired values can be entered directly on the operating unit. Unlike with the G32 and the K42, there is no need to make mechanical adjustments. This reduces downtime for article change from 75 minutes to 5 minutes and maximises production time.

The premium version of the individual spindle monitoring (ISM) is also integrated (Fig.2), meaning customers can save personnel costs by 5% and more compared to the 2 series. The three-stage indicator concept, which features signal lamps on the ends of the machine and LEDs at every spinning position and section, controls the running behaviour of each individual spinning position, optimises operator guidance and increases machine efficiency. The customer can access important data directly on the operating unit of the machine. Detailed evaluations are possible on request with the spinning mill monitoring system SPIDERweb. All the applications given for both models can be produced at maximum machine length. Both models were designed in Switzerland.

The premium version of the individual spindle monitoring (ISM) is also integrated (Fig.2), meaning customers can save personnel costs by 5% and more compared to the 2 series. The three-stage indicator concept, which features signal lamps on the ends of the machine and LEDs at every spinning position and section, controls the running behaviour of each individual spinning position, optimises operator guidance and increases machine efficiency. The customer can access important data directly on the operating unit of the machine. Detailed evaluations are possible on request with the spinning mill monitoring system SPIDERweb. All the applications given for both models can be produced at maximum machine length. Both models were designed in Switzerland.

The new machines G37 and K47 also offer the electronic drafting system drive FLEXIdraft. The extremely quick downtime for article change of under five minutes when changing to another yarn count increases the productivity of the machine. Both models are equipped with the integrated basic version of the individual spindle monitoring-ISM basic -as standard. Thanks to LEDs at every spinning position and every section, customers can save around 3% on personnel costs. At the customer’s request, the machines can also be supplied with ISM premium.

Compact spinning with unbeatably low energy requirements

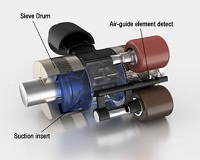

For customers who want fully compacted yarns of the highest quality with maximum strength, the Rieter compact spinning machines K42, K47 and K48 are the best solution. Their unbeatably low energy requirements for compaction are outstanding: Less than one watt per spindle, just 20% of that of other solutions. In addition to the well-known sieve drum, the main reasons for this are the large cross-section of the central suction duct and the air guide element Detect, which guides the air flow in a specific manner (Fig.3).

For customers who want fully compacted yarns of the highest quality with maximum strength, the Rieter compact spinning machines K42, K47 and K48 are the best solution. Their unbeatably low energy requirements for compaction are outstanding: Less than one watt per spindle, just 20% of that of other solutions. In addition to the well-known sieve drum, the main reasons for this are the large cross-section of the central suction duct and the air guide element Detect, which guides the air flow in a specific manner (Fig.3).

The air guide element Detect, the sieve drum and the suction insert are also at the heart of the Rieter compact spinning machines. They form the basis for the unique air routing and the guarantee of fully compacted yarns. The air guide element also simultaneously monitors quality by creating deviations from the air flow and therefore from the vacuum. When a limit value is reached, a marking on the air guide element indicates that the compacting unit needs checking (Fig. 4). This monitoring allows a consistently high yarn quality.

With all compact spinning machines, there is no need to replace compacting aprons: therefore machine downtime is avoided. Increased efficiency can be achieved as a result, making it simpler to plan production.

With all compact spinning machines, there is no need to replace compacting aprons: therefore machine downtime is avoided. Increased efficiency can be achieved as a result, making it simpler to plan production.

One notable difference between the two new models and the existing K42 is the expanded application range. The K47 and the K48 are equipped with a new sieve drum, which now allows customers to spin blends containing polyester and 100% viscose alongside cotton (Fig.5).

Opportunities for even more flexibility

The flexibility of customers, i.e. quick adaptation to market requirements, is a key criterion for remaining competitive today. Systems for producing soft and dual-core yarns, as well as twin yarns, are available for all ring and compact-spinning machines on request. A quality package, also known as the Q-Package, offers cotton spinners the opportunity to improve their already-optimized quality yarns even further (Fig.6). Rieter offers various solutions for ring and compact-spinning machines which allow the reliable and productive processing of man-made fibers.

The “EliTe® compact spinning system” is available as an option on the three conventional ring spinning machines G32, G37 and G38. It can also be retrofitted at a later date. The system facilitates the production of high-quality compact yarns. It covers all yarn counts and can also be used for 100% polyester.

Minimal workload

The new tube loader ROBOload “wild loading” is available as an option for the G37, G38, K47 and K48 (Fig.7). It is now performing the task of sorting the tubes. There is no need for manual alignment. The tubes are placed in a trolley at the end of the machine. A tilting unit dumps the tubes into the ROBOload; another device automatically aligns the tubes and guides them correctly to the cop transport system SERVOdisc, significantly reducing manual effort. For existing models of the G32 and K42, Rieter offers suitable solutions with RieterAfter Sales.

The new tube loader ROBOload “wild loading” is available as an option for the G37, G38, K47 and K48 (Fig.7). It is now performing the task of sorting the tubes. There is no need for manual alignment. The tubes are placed in a trolley at the end of the machine. A tilting unit dumps the tubes into the ROBOload; another device automatically aligns the tubes and guides them correctly to the cop transport system SERVOdisc, significantly reducing manual effort. For existing models of the G32 and K42, Rieter offers suitable solutions with RieterAfter Sales.

Keeping the well-proven

Well-known, successful solutions will remain an integral part of both the ring and compact spinning machines. Such as the SERVOgrip system, for example. This prevents thread underwinding when doffing, and thus keeps the machine clean, thereby ensuring yarn quality. All models are still equipped with the reliable and low-maintenance cop transport system SERVOdisc. The customer saves energy here, as the conveyor belt is driven not pneumatically, but by two electric motors.

Capital machinery import for the garment and textile industry has declined in the first quarter of the current fiscal year due to financial sectors uncertainty and liquidity crisis.

According to Bangladesh Bank (BB) data, in July-September period of the current fiscal year, Bangladesh’s garment machinery import has seen a 9.53% fall to $698 million, which was $771 million in the same period a year ago.

According to Bangladesh Bank (BB) data, in July-September period of the current fiscal year, Bangladesh’s garment machinery import has seen a 9.53% fall to $698 million, which was $771 million in the same period a year ago.

Meanwhile, import of textile machinery also went down by 1% to $698.41 million, which was $705.44 million in the same period last year.

Talking to Textile Today, trade analyst and apparel sector people blamed the election for the downtrend in the import of capital machinery for the garment and textile sector as investors are seeing a bumpy situation in the banking sector, also the political transition in making an investment decision.

The country’s textile sector is going through a dull time in terms of new investment as the investors are not getting the connection of gas and electricity.

KHORSHED ALAM, DIRECTOR, BTMA

“The country’s textile sector is going through a dull time in terms of new investment as the investors are not getting the connection of gas and electricity. While setting up a textile mill is too expensive but the fund is not available,” Khorshed Alam, a Director of Bangladesh Textile Mills Association (BTMA) told the Textile Today.

As a result, the import of textile machinery fall in recent time but the sector will rebound soon if the gas and electricity connection is available, he added.

“Usually, there is uncertainty ahead of the national election over the transition of power, which made the investors cautious in opening new Letter of Credit (LC) to import machinery,” Ahsan H Mansur, executive director of Policy Research Institute (PRI) told the Textile Today.

As a result, the import of capital machinery for the country’s apparel and textile industry witnessed a decline, said the economist.

I think, the downtrend of import will not continue as after the election investors will move for new investment, said Ahsan.

The textile industry is an immensely global value chain that has a great impact on every country in the world either directly or indirectly. For example, solid waste problem generated mainly in the west from the ‘Fast Fashion’ trend has created a demand of establishing ‘Circular Fashion’ and the whole textile world is likely to feel the corresponding changes. The advent of ‘Industry 4.0’ and its impact also will not only be confined in its developers mainly the European country.

So whether it is a problem or an innovation, everything has to be shared globally in the age of globalization. So, the global platforms are very important which are setting the trends and changing businesses of the future. In addition, whether it is sustainability or anything else, all the stakeholders in the textile industry are looking forward to ITMA 2019 to be held in Barcelona, Spain.

So whether it is a problem or an innovation, everything has to be shared globally in the age of globalization. So, the global platforms are very important which are setting the trends and changing businesses of the future. In addition, whether it is sustainability or anything else, all the stakeholders in the textile industry are looking forward to ITMA 2019 to be held in Barcelona, Spain.

ITMA has been called, as the Olympic of textile machinery is the world’s most important textile and garment machinery exhibition since 1951. It has been a catalyst for changing and competitiveness for the industry over the years. This time the exhibition will be held from 20 to 26 June 2019 at Fira de Barcelona, Gran Via venue where over 1,600 exhibitors will exhibit their latest technologies and sustainable solutions.

Why sustainability is the center focus

In recent time, sustainability issues are getting priority in all aspects of the textile and apparel industry. The drive towards sustainability in the entire textile and garment value chain is increasingly integrated with enlightened business practices, and innovative technology holds the key to environmental sustainability.

Sustainability to-do is not only about reducing economic, environmental and social risks it also means to integrate things in a single objective for living a better life. Thanks to the latest developments in science and engineering and more in data processing, communication and digital integration of concepts and processes which are giving industries a complete change. In addition, the next generation textile industry is going to be completely different because of below-mentioned technologies. Everything, which not even we can imagine, is to be showcased in ITMA 2019.

ITMA to set new trends

Industry 4.0

Innovation is vital for the textile and apparel industry’s success as Industry 4.0 gains momentum in the manufacturing world. The use of artificial intelligence, processing of big data and connecting the dots together in quick and fast decision-making would be the key changes in the industry.

Companies will shift towards open innovation and so will result in the increased exchange of knowledge and new types of cooperation among educational institutions, research organizations, and business.

And so technology providers are ready to showcase their latest developments in integrating the concept of Industry 4.0 and presenting the outlook of next-generation machinery. All are likely to break the earth in ITMA 2019.

Maria Ludovica Murazzani, Commercial Consul of Italy in Shanghai recently has told that the Italian government has set up a clear vision for Industry 4.0 and Italian companies are making significant progress in this by the legal and others support from the Italian government. Alessandro Zucchi President, ACIMIT further confirmed it and declared that many of those amazing developments will be showcased for the first time in upcoming ITMA 2019 to be held in Barcelona. Companies from Germany, Switzerland, and the UK will not fall short as well.

Digitalization & Automation

Every company’s solution need to complete in a digital way, which aims to maximize profits while achieving zero inventory loss, zero leftover stock, and zero, lost sales opportunity and most importantly zero waste through smart, speedy and sustainable production. Without automation and integral decision making it won’t be possible.

Machinery companies are continuously working on bringing new featured machinery making things digitalized connected through smart devices. They will be showcasing the latest technology for better productivity to cope up with fast fashion trends as automation can offer cost reduction and value-addition in garments products.

Automation, especially in an integrated textile and garment manufacturing chain, will help address the fashion and clothing industry’s current concerns of short production cycles and sustainable business practices, according to CEMATEX, the European Committee of Textile Machinery Manufacturers.

What is new in ITMA 2019?

ITMA innovation lab is the main attraction of the people aims at driving industry focus on technological research and development. Innovation Lab will provide an opportunity to connect and exchange ideas with a truly international gathering of expert researchers and academics who are involved in a vast range of textile-related projects.

ITMA 2015 a remarkable number of global visitors turned up Figure 2: At ITMA 2015, a remarkable number of global visitors turned up for textile solutions. Christine Karin Schmidt, Chair of the CEMATEX working group of the ITMA Innovation Lab, and Technical Director of VDMA Textile Machinery Association explained, “There is much more to be discovered at the ITMA Innovation Lab. The Innovation Video Showcase will spotlight the most groundbreaking exhibits at ITMA 2019.

turned up for textile solutions. Christine Karin Schmidt, Chair of the CEMATEX working group of the ITMA Innovation Lab, and Technical Director of VDMA Textile Machinery Association explained, “There is much more to be discovered at the ITMA Innovation Lab. The Innovation Video Showcase will spotlight the most groundbreaking exhibits at ITMA 2019.

“By presenting these latest innovations in a video format at the Speakers Platform, CEMATEX aims to further promote excellence in R&D and make the Innovation Lab a hotspot that will inspire visitors from all sectors of the textile and apparel making industry.”

Automation and Industry 4.0 are one of the key focus areas in Europe, and Germany’s Institutes of Textile and Fibre Research Denkendorf (DITF), for example, has recently been involved in the multi-company co-ordination of digital textile micro-factories. These have involved fully automated and interlinked textile production lines for ‘make on demand’ products – from design through to the finished and printed garment.

Many major textile institutions from across Europe, organizations will also be present at the show from North and South America, Asia and Australia. Adding to the vibrancy of the area will be a number of first-time participants, such as Fundació Eurecat, Leitat Technological Centre, Manchester Metropolitan University, Mittelstand 4.0-Kompetenzzentrum Textil Vernetzt, Thomas Jefferson University, and Universidad De Buenos Aires’ Fadu, Cátedra Nirino Diseño Textil.

Within Europe, some key research trends in individual countries are notable, even as the European Union’s comprehensive research programs strive towards encouraging co-operative projects across borders.

In both France and Germany, for example, there is a strong emphasis on the further development of textile technologies for the composites industry, backed by major end-user organizations such as Airbus, as well as car brands such as BMW, Daimler, Peugeot-Citroen, Renault and Volkswagen.

Reinforcements for composites involve a wide range of technologies, which will be displayed at ITMA 2019, including weaving and knitting, as well as nonwovens manufacturing, embroidery and braiding.

One nerve center for developments in this area is RWTH Aachen University, where more than 20 university institutes focus on state-of-the-art production techniques and are cooperating with machinery makers, robotics companies and software developers to make manufacturing processes efficient enough to allow high-wage countries such as France and Germany to compete on a global level.

Another intriguing development from a German research institute is the Fibre Dynamics Simulation Tool (FIDYST), which makes it possible to simulate the movement of fibers in turbulent air currents for the first time. This was developed at the Fraunhofer Institute for Industrial Mathematics, another R&I Pavilion participant, and will have a very positive effect on the process planning of nonwoven manufacturers.

"As per the US Bureau of Labor Statistics, retail apparel prices, following months of rise, fell to a seasonally adjusted 0.9 per cent in November. The prices, compared to year earlier, declined by around 0.4 per cent. Now some of these retailers expect prices to increase as cotton prices spiked by $1 per pound in June only to level off at around a current 75 cents a pound. According to Cotton Incorporated, average import prices for cotton-dominant apparel increased 0.9 per cent month-over-month in October. Year-over-year, cotton-dominant apparel import prices were 2.7 percent higher."

As per the US Bureau of Labor Statistics, retail apparel prices, following months of rise, fell to a seasonally adjusted 0.9 per cent in November. The prices, compared to year earlier, declined by around 0.4 per cent. Now some of these retailers expect prices to increase as cotton prices spiked by $1 per pound in June only to level off at around a current 75 cents a pound. According to Cotton Incorporated, average import prices for cotton-dominant apparel increased 0.9 per cent month-over-month in October. Year-over-year, cotton-dominant apparel import prices were 2.7 percent higher.

As per the US Bureau of Labor Statistics, retail apparel prices, following months of rise, fell to a seasonally adjusted 0.9 per cent in November. The prices, compared to year earlier, declined by around 0.4 per cent. Now some of these retailers expect prices to increase as cotton prices spiked by $1 per pound in June only to level off at around a current 75 cents a pound. According to Cotton Incorporated, average import prices for cotton-dominant apparel increased 0.9 per cent month-over-month in October. Year-over-year, cotton-dominant apparel import prices were 2.7 percent higher.

Glenn J Chamandy, President and CEO, Gildan Activewear, recently said that cotton and polyester prices have gone up during the year, as have other costs across the supply chain. Gerald W Evans Jr, CEO, Hanesbrands, also instituted price increases of around 4 to 5 per cent in its innerwear business due to higher raw material costs.

Labor and other cost inflation causes concern

As per Moody’s Investor Services, apparel companies face input cost inflation from labor and cotton. However, it’s the US- China trade war and threats of stiff tariffs on the industry that poses the biggest dilemma. The uncertainty has already caused importers to make major changes in their sourcing strategies, while increases labor and other costs in Asia and elsewhere have made it more challenging than ever to chase the cheapest needle.

China trade war and threats of stiff tariffs on the industry that poses the biggest dilemma. The uncertainty has already caused importers to make major changes in their sourcing strategies, while increases labor and other costs in Asia and elsewhere have made it more challenging than ever to chase the cheapest needle.

Tariff rise to be a long-term trend

A tariff survey by Purchasing Manager’s Index, IHS Markit revealed that the US manufacturers expect tariffs to increase prices over the next two years. In the survey, conducted in second half of October, 44 per cent respondents expect tariffs and trade wars to lead to higher domestic prices for their goods in the US over the next two years.

Nicole Bivens Collinson, President of International Trade and Government Relations at Sandler, Travis & Rosenberg sees the tariffs and their threat as a long-term, multiyear trend. The results will be an overall rise in global prices. President Trump first imposed $50 billion worth of tariffs aimed at China that left the apparel industry largely unscathed. The next 10 per cent tranche came in the form of an additional $200 billion in tariffs, hitting certain apparel items, some leather, and hats and handbags. Now a threatened 25 per cent tariff–first set for January but postponed for 90 days–would likely hit apparel, textiles and footwear.

Fear leads to the inevitable

Fear is an important factor that will lead to price rise, believes Rick Helfenbein, President and CEO of the American Apparel & Footwear Association. The retailers, even with all the leverage they have will not be able to avoid increase in prices. They may force some of it back to their vendors—and that would be part of the natural process—and vendors will try to force some of it back to their factories. At the end of the day, there will be an increase in prices.

Bangladesh has the opening for fresh investment in woven fabrics production. Currently, local spinners can supply 85 per cent of the raw materials to the export-oriented knitwear sector and 35 per cent to 40 per cent to the woven sector.

There is scope for investments in the primary textile sector over the next five years as demand for locally made fabrics has been rising in both domestic and international markets. Bangladesh garment makers use 12 billion meters of fabrics a year for making export-oriented garment items. Of the quantity, domestic weavers can supply three billion meters of fabrics, with the rest imported from India and China.

If local weavers can supply 60 per cent of the requirement for woven fabrics in the next five years, that will reduce the dependence on imports. In the last one year, entrepreneurs set up 19 spinning mills, 23 fabrics mills and two dyeing printing mills. The main impediments for the sector are land and energy. Supply of energy and industrial land at a reasonable price can encourage spinners and weavers to invest in the sector.

The listed textile mills have been unable to give dividends for years mainly due to higher bank interest rate, high energy prices and other operational costs.