FW

The Maharashtra Textile Department and Industries Department has called for investment in its recently inaugurated mega textile park Nandgaon Peth in Amravati district. As per the state textile policy, the Maharashtra Industrial Development Corporation (MIDC)-initiated project will have benefits of 10 per cent capital subsidy and up to seven per cent subsidy. It has seven stars facilities including a common effluent treatment plant.

Nandgaon Peth is intended to be India’s one-stop textile destination for investors. It also has other benefits like an industrial promotion subsidy and stamp duty and electricity duty exemption incentives by the industries department.

The park, houses A to Z support structure in textile manufacturing. At present 500 hectares land has been acquired and out of that 100 hectares have been allotted. Till date, one project is operational, two are under construction and other projects are in progress.

This Amravati textile park has eight major textile units with an investment of Rs 1,243 crores, giving direct employment to 3700 people. More such parks will be set up in Maharashtra. Some of these will be in Yavatmal, Parbhani, Buldana, Nanded, Beed, Jalana and Aurangabad. Cities are selected on the basis of cotton production in the last five years.

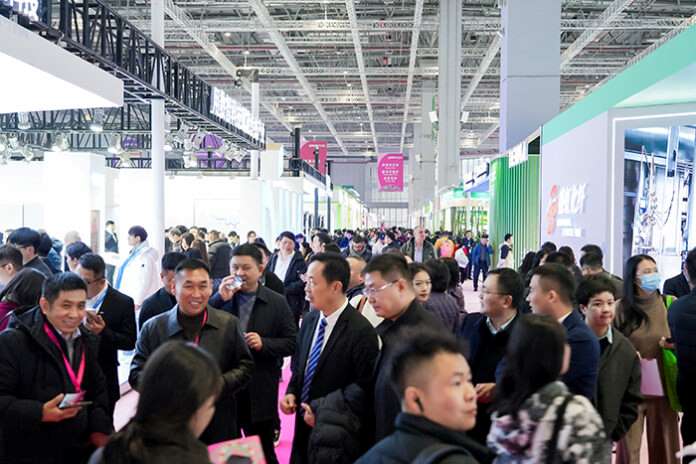

Planet Textiles 2015, a conference, which addresses environmental and social impacts of global textile supply chain, will take place on October 14, 2015 alongside the Intertextile Shanghai Apparel Fabrics trade fair. Jointly presented by MCL Global and the fair’s organiser Messe Frankfurt (HK), the conference features 10 presentations from leading experts in the field of sustainability, covering both global and China-specific topics.

After announcing keynote TED.com speaker Hans Rosling, the organisers have said that three high profile presenters from Adidas, VF Corporation and the Beijing-based NGO: Institute of Public & Environmental Affairs will be part of the conference. Ma Jun, Director of the Institute of Public and Environmental Affairs (IPE) will be speaking, along with confirmed speakers Philip Courtenay, Senior VP of apparel sourcing at Adidas Group, and Sean Cady, Vice President of product stewardship and sustainability at VF Corporation.

Ma Jun is a very well-known Chinese environmentalist, environmental consultant, and journalist, who received the Goldman Environmental Prize in 2012 and made the list of FP Top 100 Global Thinkers in the same year. In addition to Cady and Courtenay, speaking on behalf of VF Corp and Adidas respectively, other speakers for the event include senior executives at Bayer Materials and Bluesign technologies. Hans Rosling’s award-winning lectures cover contemporary environmental, economic and social world changes, accompanied by animations and graphics of global trends.

MCL Global, publishes Ecotextile News, Sustainable Nonwovens, Detox Deconstructed, Knitting Trade Journal, EcoComposites, Cotton Horizons and the biannual Eco-Textile Labelling Guide.

www.mclglobal.net

A comprehensive energy management system (EMS) was implemented by 71 textile units who came together for this initiative, coordinated by the Indian Texpreneurs Federation (ITF). The EMS helps monitor energy consumption of every machine round the clock. With this initiative ITF’s aim was to continuously evaluate the machine health and operating practices via the hardware and software installed as part of the EMS.

Karthik Durai, Executive Member, ITF and the coordinator of EMS implementation opines that EMS is unique, in that, it ensures that every machine in these 71 units is fitted with a metre. This metre is capable of reading various parameters such as voltage, current, load consumed and other power factors and the data generated is sent to a common server in the unit to monitor using a software programme.

In the usual energy audits that are occasional, they analyse the total energy consumed with respect to what is required. However, this conventional method can’t find the micro-level defects that are the cause for energy losses. Thus, the new method would not only help the units identify the defects and aspects in individual machines that lead to energy losses, but also the units can adopt corrective measures accordingly. Besides, the ITF has also placed orders for the metres and software solutions that form the EMS with two companies in Chennai and Bangalore. The ITF, instead of just buying products from what these two manufacturers could offer, has based the orders on the monitoring requirements of units.

Karthik added that about 10 per cent energy could be saved by the textile units when the EMS becomes operational, as there’s a round-the-clock monitoring facility.

The world's largest spinner of pure wool and wool blend worsted yarns for circular and flat knitting sectors, Südwolle Group, has developed a new, environment-friendly treatment technology that promises excellent quality yarn. The company says, the new technology delivers fibres with the same strength, the same or better pilling performance, and improved ability to absorb moisture, than conventionally processed yarns. This alternative, Naturetexx Plasma is supposed to be a sustainable alternative to current industry standard super wash, chlorine-hercosett process.

The Südwolle Group purchased the Richter F+A dye house and treatment facility in Stadtallendorf, Germany last year. The facility possesses the technology, and the group has since refined the process for producing the plasma treated yarns. Talking about how the technology works, Hamish Allan, Marketing Manager, Südwolle Group said that process used electricity and air, and is a huge environmental leap forward. It also sets a new standard for wool processing, he added.

Plasma is created by controlled discharge of an electric voltage across a non-conducting gas. The gas is ionised by the voltage into a more reactive fundamental state. When the wool top passes through the plasma field, the surface of the fibre reacts with energised gas, modifying the cuticle scales and removing the wool felting effect.

Naturetexx Plasma, claims the Südwolle Group, is being developed as a genuine alternative to Superwash, rather than just a specialty organic niche treatment.

The Textile Ministry has nominated three kota doriya weavers for National Award as master weavers. This award is to be handed over by Prime Minister Narendra Modi in Chennai on August 7 on National Handloom Day. Mustkin Bhai, Hazi Abdul Hakim Kachra and ex-chairman, municipal corporation of Khetun, Nasiruddin Ansari, have been nominated for this award. All the three weavers have been chosen for their excellence in weaving and hail from Kota’s Khetun village.

All three will be given Rs 1 lakh each under the award, a tamrapatra citation and an angavastram. The brochures, presented on the occasion will carry information about the weavers’ and their art.

Nasiruddin Ansari said that her himself had designed the sari for which he is being awarded. The sari was approved by a jury in Delhi for its uniqueness in design and technicality. He added that this was the first time he was getting such national recognition. However, Ansari has been in the limelight, when the government of Rajasthan had sponsored him for trip to Baku in Russia to showcase his skill in 2006. In 2008 again, the Rajasthan Tourism Department took him on a seven-day trip to Karachi and seven days to Lahore to showcase his talent.

He has also been the corporator for the Nagarpalika in Khetun four times. Besides, he the chairman of the Khetun Nagarpalika from 1994-99 and was the Director, State Handloom Development Corporation, Jaipur, from 1995-2000.

For the first half of 2015 Coats' revenue was up four per cent on a like-for-like basis and down three per cent reported. Adjusted EPS was up 20 per cent. Coats is the world’s leading industrial thread and consumer textile crafts business. There was a nine per cent increase in operating profit. The specialty business continued to deliver double digit sales growth, with product innovation playing a key role. There were further market share gains in the core apparel and footwear businesses. Both factors contributed to 15 per cent growth in industrial profit.

Performance in ongoing crafts business was impacted by reduced fashion hand knitting sales, although there was encouraging growth in some product ranges. Non-operating items, primarily foreign exchange losses on parent group cash and discontinued losses related to EMEA Crafts, had a negative impact on earnings. However, on an adjusted basis the group continued to deliver good growth. Consistent delivery of good levels of free cash flow provides a solid platform for ongoing investment in organic and inorganic growth opportunities.

Supported by its defined growth strategy, key differentiators and strong underlying business performance, Coats is well positioned for 2015 and beyond.

www.coats.com/

About a month back Egypt imposed a ban on cotton imports. This was aimed at bolstering local cotton production and marketing. But the ban has now been removed. One reason is that Egypt’s ready-made garment sector, worth an estimated $2 billion a year in exports, is heavily reliant on imported cotton. Bulk manufacturers feared losing their competitive edge as lower count cotton yarn from Egypt is more expensive.

Manufacturers had already been suffering from currency exchange controls imposed by the Central Bank of Egypt in February to limit black market dealings. Currency exchange controls restrict imports by local manufacturers if they cannot access foreign currency. And these controls, on top of the ban on cotton imports, were having a serious effect on manufacturers.

With subsidies to cotton farmers scrapped earlier in the year, imports are expected to rise by 30 per cent this year. Most of the cotton is imported from India, the US and West Africa. Exports of raw Egyptian cotton slumped from 120.3 million bales in 2012-13 to 83.8 million bales in 2013-14. Conversely imports surged from 51.3 million bales to 117.8 million bales in the same period.

China's expansion in the US textile and apparel makers does not seem very promising as the country is selling into an economy whose GDP growth has slowed down. As Lei Shengzu, Manager of China Textiles (Shenzhen) feels the outlook for the US textile and apparel market remains clouded as fewer people are buying clothes in the US unlike before. Buying power and consuming habits of US customers have changed over the years especially since the start of the slowdown in 2007.

As per the US Census Bureau, last year, the US imported $467 billion worth of goods from China, compared to $440 billion in 2013. However, through May 2015, imports from China have averaged $37.1 billion a month, which would project to a yearly total of $445 billion.

From 2000 to 2009, textile and apparel imports from China flattened. The total textile and apparel imports were $41.8 billion last year, compared to $41.7 billion in 2013, a rise of only 1.49 per cent, as per the Office of Textiles and Apparel (OTEXA) in the US Department of Commerce. In the first quarter of 2015, consumer spending was tepid, which was also a key factor in slowing the economic growth.

According to Commerce Department data released in May, the US GDP contracted at a 0.7 per cent seasonally adjusted annual rate in the first quarter, from an initial estimate of 0.2 per cent. Moreover, the US Federal Reserve forecasts a growth of 2.5 per cent for the next two years.

Lenzing Chief Commercial Officer Robert van de Kerkhoff and Technical Customer Service Director Albert Leitner, are to open Lenzing’s new customer service centre in Hong Kong soon. Lenzing, a leading manufacturer of man-made cellulosic fibres, recently announced the opening of this centre. With the launch of this centre, Lenzing’s customer service in North Asia would be strengthened. This will be one of the biggest centres amongst the 10 existing customer service sites.

Lenzing is well-known for its customer service for textile and nonwovens. It has a network of nearly 100 technicians, who offer customers a worldwide service in processing Lenzing fibres. Besides, they also offer special processing know-how in spinning, knitting, weaving and finishing to its global customers, which is in all stages of the textile and nonwovens industry.

Albert Leitner, Technical Customer Service Director stated that they had invested in the best equipment available in the market in Hong Kong. He also added that Hong Kong was the ideal place for this centre to serve their Asian customers efficiently.

The new centres’ main tasks are technical consulting, training and education through workshops and in-house trainings, product and process development, quality management and fabric certification for the fibre-brand license programme of Lenzing.

Being diverse it covers everything from hand-spun and hand-woven sector to capital-intensive, sophisticated mill sector. Besides, the close link to ancient cultures and traditions and agriculture make it unique compared to other countries. This also provides the industry with the capacity to produce a variety of products, which are suitable for different markets, both within and outside the country.

The industry has a potential to grow five-fold over the next 10 years and touch the $500 billion on the back of growing demand for polyester fabric. This includes domestic sales of $315 billion and exports of $185 billion. Currently, the domestic market comprises of $68 billion and exports of $40 billion. The total fabric production in the country is expected to grow to 112 billion sq. mt. by 2016-17. Moreover, India’s fibre production is expected to reach 10 million tons in the same period.

Peek into exports, imports

The textiles and clothing industry is also one of the largest contributors in exports across the world. Exports of textiles and clothing are estimated to touch $64.41 billion by end of March, 2017 as predicted by Working Group constituted by the Planning Commission. In 2015, export of textile products increased marginally by 0.46 per cent to $37,137.32 million as compared to $36,967.56 million in last year.

Also, India is not dependant on import when it comes to textiles. Majority of import takes place for re-export or special requirement. In the fiscal year 2015, the import of textile products increased by 13.98 per cent touching $5,511.95 million as compared to $4,835.93 million in 2014. The textile industry is trying to get a duty cut on man-made fibre as high cost of the key raw material for making blended garments is making Indian goods uncompetitive in the global market. The industry is in consultation with the finance and revenue departments regarding this. Man-made fibre draws and excise duty of 12.5 per cent, but it has import restrictions. These lead to a cumulative duty of 29 per cent.

Positive future ahead

The last five years have seen a spurt in investments in this sector. All segments of the industry, including dyed and printed attracted FDI worth $70.82 million or Rs 444.43 crores during April 2015. The government too has launched various schemes to support the industry. Minister of State for Textiles launched a scheme to promote usage of Geotechnical Textiles in the Northeastern states, in Imphal. Also launched was a new institution, Handicrafts & Carpet Sector Skill Council to promote skill development among artisans, crafts people and workers at grassroots level. Corporates too are supporting the industry in many ways through partnerships and joint ventures with industry players. Overall, the future looks promising.