FW

The Tirupur knitwear cluster has been allotted Rs 15 crores for setting up a facility center for product innovation, testing and training. The common facility centre will be equipped with latest machinery to produce innovative knitted denim products, woolen fabrics with additional thermal properties and quilt fabrics. The testing equipment will ensure that the knitted fabrics produced are of high quality and can help producers of end products with greater value addition in the textile export market.

The training centre will impart skills to workers in a systematic manner for producing a workforce that can cope with the changing needs of the industry including product diversification at periodic intervals. Another set of people will be trained on maintenance of imported knitting machinery so as to reduce breakdown hours.

Tirupur township, 60 kilometers from Coimbatore in Tamil Nadu, is an important garment cluster. This township started with the production of low valued cotton hosiery items mainly undergarments during the 1920s and started with exports from 1974. There are around 700 active exporters and 1700 domestic garment suppliers at Tirupur. There are more than 2000 small units which specialize in knitting, compacting and calendaring, bleaching, dyeing and embroidery.

A centralised cotton buying system has been introduced by Zimbabwean cotton merchants to curb side marketing which has become rampant. Farmers have described the move as an attempt to promote monopolistic tendencies. They say the new cotton buying system has taken away competition. The Cotton Ginners’ Association, which represents the merchants, is buying the crop on behalf of all ginners, and the volumes are shared on a pro rata basis depending on level of investment in the production.

About 98 per cent of production is funded by ginners under contract schemes introduced at a time when farmers were failing to access finance due to lack of collateral. While cotton production has been on the rise over the past few years, the viability of the sector has been adversely affected by side marketing. The challenges arise from a situation where some merchants were deliberately paying higher prices to lure cotton growers including those holding the contracted crop.

There is a feeling the cotton industry needs to have a model to achieve better efficiencies, viability and sustainability. Liberalization of marketing will not work if regulatory enforcement is weak. Market forces are great for freely produced crop but not when all production is under contract.

The fashion designer now occupies a space between creative, technician and merchandiser, a framework and skill-set imposed by an increasingly competitive and demanding marketplace. The biggest pressure on designers, according to the Lectra/CFDA survey results, relates to speed to market: getting collections out quicker and quicker to continually renew the in-store offer.

Consumer expectations and shopping habits are also changing. In addition to shorter time to market and more collections, designers now have to deal with more competition. Brands need to differentiate themselves, while attempting to appeal to a consumer who is informed, empowered, less brand-loyal, mixing high and low pieces and not squeamish about shopping for the best price online.

According to the survey results, technical innovation means production techniques and the tools used for design and development that have become more advanced. Designers need to have a grasp of these latest advances. Designers and development teams need to share information in real time with external partners and suppliers. Even consumers, through social media, now have a platform to communicate with designers and express their top brand picks and preferences.

Manufacturers, marketers, merchandisers and even consumers have become inseparable parts of fashion design. New forms of communication via social media platforms, combined with a market where everything is available to everyone, have empowered a once passive consumer. As a consequence, designing has become more an interpretation of—rather than a suggestion of –consumer desires. The design-dedicated silo is being shattered and collaboration has become the new framework.

The forgotten 'blue gold', as it's termed, for the wealth it brought to dye-makers, was revived by an American in southwest France. This ancient blue dye that once brought riches to the region and was also praised in Chaucer’s poetry, and used by Napoleon for his army’s uniform is back in trend. Denise Simeon-Lambert said that they brought this ‘pastel’ as the tint was called in the region’s old Occitan-language, back in fashion. Acclaimed designers such as Dior and Chanel are wooing this ‘natural’ and ‘non-staining’ shade as well.

Simeon-Lambert is one of the two business owners that aim to restore international acclaim to this forgotten shade of blue. Today, they have customers from far as Asia as well. Simeon-Lambert stumbled upon this concoction, which is made from a plant and also has curative values, by accident though. The common name for the plant is ‘woad’, which carries the within the dye, which was quite popular during the Renaissance period. Simeon-Lambert revived an ancient tannery to revive the dye.

The dye lost to the more concentrated and easier to produce indigo from India, in the 17th century. This also was replaced in the last 50 years by synthetic tints. However, Simeon-Lambert, after discovering the history of the dye launched a company, which now produces 600 kg of the dye each year.

The US and Peru had signed a trade promotion agreement in 2009. It covers the garment, textile and agricultural export sectors. But Peru failed to enforce basic garment sector labor laws under the terms of free trade pact. The export law exempts employers from key parts of the general labor code by allowing them to hire virtually their entire workforce for an unlimited duration on a series of renewable, temporary contracts, some as short as 15 days.

Moreover, garment and textile employers have taken advantage of the law by systematically declining to renew the contracts of thousands of workers who joined unions in an effort to improve wages and working conditions. Major Peruvian companies in export sectors violate Peruvian labor laws with impunity, dismissing workers for union activity, employing workers on fraudulent contracts, and failing to pay legally mandated bonuses.

Even in cases where labor inspectors have found violations, fines are too low to deter employer misconduct and often go unpaid. A number of US and Peruvian human rights and union groups have filed a complaint with the US Department of Labor. These allege failure to adhere to labor provisions in the US-Peru trade promotion agreement. Peru happens to be a partner country involved in the 12-nation TPP negotiations.

It may take three or four years for the US and world markets to work themselves out of the surplus cotton stocks they face. The cotton industry has to reverse the trend towards greater use of manmade fibers. When prices start to rally, if they rally too soon, the United States becomes uncompetitive. The cotton that is being held in India all of a sudden becomes competitive and cheaper and takes away the market share of United States. Meanwhile, as prices weaken, China continues to roll out its reserve stocks.

When the market realises the US has extra bales to sell, it doesn’t help if growers and merchants hold cotton. Access of Chinese mills to competitively priced cotton has been strangled. As a result, they have turned to spinning polyester. The cotton blend in China has gone down from 53 per cent five years ago to 39 per cent currently. The result is China’s cotton use is down nine million bales.

Adding to the blend problem in China is the fact that Chinese companies produce more than 70 per cent of the world’s polyester, and its polyester staple fiber plants are only operating at about 63 per cent of capacity. So Chinese mills have a strong incentive to buy and run synthetic fibers instead of cotton.

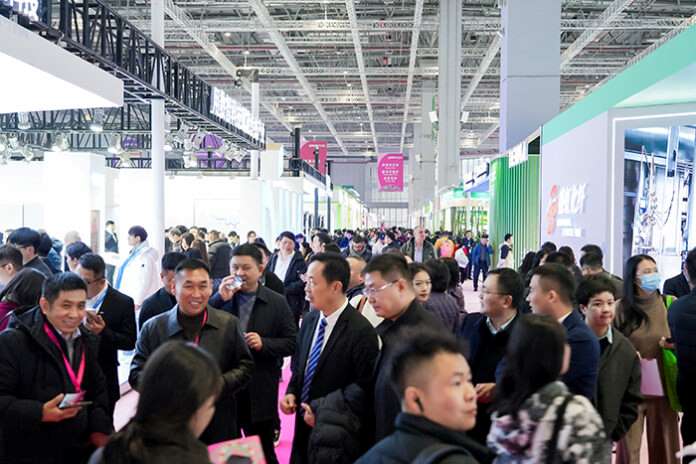

A textile and garment show will be held in Colombia, July 28 to 30. The show takes place every July in Colombia and is one of Latin America’s largest fashion events where leading clothing companies take part. Business conferences, forums, seminars and exhibitions of Colombian and international designers’ fashions are held during this festival.

This is the 26th version of Colombia Moda and will see a large number of international buyers. The show has three main areas: commercial hub, academia axis and axis of knowledge. The commercial area will have over 600 exhibitors and over 11,000 national and international buyers. There will be a lot of buyers from Japan.

Projections regarding business expectations are higher than in previous years. In 2010 the fair had 3,600 sq. mt. of exhibition space. This year the space is 7,300 sq. mt. The junior category will have double the number of exhibitors. The designer category will have jewelers and designers. The 25th Colombia Moda had seen 670 brands, 6,300 buyers, 1,700 of them from other countries. More than 15,000 visitors also took part. Colombia Moda aims at integrating the textile and clothing production chain in one event of national and international stature.

colombiamoda.inexmoda.org.co/en/

Pakistan’s textile industry has been suffering due to lack of energy supply, input cost, subsidies, machinery import and value addition against its rivals. This has led to a drop in share in the world market declining from 2.2 to 1.8 per cent during last five years. In a letter to Prime Minister and Finance Minister, Pakistan Apparel Forum (PAF) has asked the ministry to look into revamping the policy that has almost pushed the sector in its current state.

PAF said that the vital sector faces immense problems and hurdles which must be removed to pave the way for smooth and efficacious working of units and for boosting exports. Pakistan is the 4th largest cotton producer in the world, but lags behind rivals China, India and Bangladesh, the letter added, quoting the World Bank which expects global apparel market to reach $1.18 trillion by 2020 and $2.11 trillion by 2025 and also declares that Pakistan stands at highly disadvantages position in the international market.

Pakistan’s compounded growth rate for the textile and apparel exports, from 2005 to 2013 stood at 3.6per cent. On the other hand, India’s share stood at 11.3 per cent, while Bangladesh’s at 16.2 per cent. In Pakistan, value addition for every one million bale is $1.17 billion, in India it is $1.79 billion and in Bangladesh it is $6 billion. Pakistan electricity tariff is $0.15KWH, in India, it is $0.13KWH and Bangladesh electricity tariff is $0.09KWH. Also Pakistan’s gas tariff is $6.27MMBTU, India’s gas tariff is $4.66MMB and Bangladesh’s gas tariff is $1.86 MMBTU, the letter further pointed out.

It was further pointed out in the letter that Pakistan was the only country in the region which did not provide tax subsidies, interest rate support in investment, zero rating on exports, capital support, cluster development schemes and long-term policy supports. PAF has also proposed appointment of advisers to Textile Ministry from Textile Centers of Pakistan viz. Karachi, Lahore, Faisalabad and Gujranwala from the value added sector as the move will help the government in taking vital decisions, with special attention and concern for more value addition as well as for bringing down the cost of doing business.

Following the government's go-ahead to lay-off workers under Section 25-M of the Industrial Disputes Act, 1947, the 110-year-old Anglo French Textile (AFT) mill, is all set to lay-off workers in its units A, B and C. The spinning unit is barred from these lay-offs though. The lay-offs are for a span of six months. The action will help the defunct mill to bring down its expenses from Rs 3.25 to Rs 1.25 crore a month as salary to workers. Workers will be paid only half wages during the period. The mill is involved in lay-off exercise since November 2013.

The government has been consistent in its efforts to provide assistance to the mill by infusing funds in the form of share capital to the tune of Rs 367.35 crores and grant-in-aid to the tune of Rs 201.11 crores. Though this amount has been insufficient to run the mill, the management has been able to pay compensation and wages to workers.

The Pondicherry Textile Corporation, at the helm of running the mill, is already in a dicey situation. The firm is running short of funds to such an extent that it has become difficult to meet day-to-day expenses, said the management. Adding on to the predicament is government’s, banks’ and other institutions’ reluctance to grant any loan to settle the statutory and non-statutory liabilities of the mill, which stand at Rs 130.02 crore. Given the current state of the mill, which requires modernisation on a big scale, the shortage of funds clearly indicates that revival won’t take place any time soon. In its attempt to settle dues, the mill may sell the 54.64 acres land in Villupuram district.

In order to speed up the task of cotton plucking and make it more efficient, the SIMA Cotton Development & Research Association (SIMA CD & RA), an affiliate of the Southern India Mills’ Association (SIMA), has launched a battery-powered, handheld cotton-plucking machine. The machine was launched by the Confederation of Indian Textile Industry (CITI)’s Chairman, Prem Malik, at a function held in Coimbatore.

On the occasion, SIMA’s chairman, C K Narayanasaami said the step will help farmers to cope up with shortage of labour, further heightened by crop conditions of the country, which offer 4 to 5 pickings in a season. Elaborating on the efforts that led to this feat, Narayanasaami said the success of this project was followed by the failure of two earlier ventures, one of which was a tie-up with the Tamil Nadu Agricultural University and the second was a test of Chinese-make hand picking machine. He said, they dropped out of both the projects due to lack of scale and technological viability.

The cotton-plucking machine, priced Rs 9,900, including all necessary accessories, taxes and agent commissions, has been developed in collaboration with Point Industries, Coimbatore. Narayanasaami also stated that the association has requested the state government to provide a subsidy of Rs 5,000 per machine and a cut in VAT to the tune of five percent to make it more cost-effective. The machine is expected to cut the cost of picking by about 5 to 7 per cent.