FW

After decades of decline, the US textile and apparel industry is growing once more, and many factories are competing with low-wage operations in countries like China. In North Carolina, where textile industry was once dominant, the industry has reinvented itself by using technology and employing far fewer people than in the past.

Robots do most of the heavy lifting at the National Spinning Company in Burlington, North Carolina. This factory dyes over 110,000 kg of yarn per week in a variety of colors. The yarn is sent to clothing and upholstery makers both in the US and around the world. There are only two technicians who service the dye producing machines.

Technology is helping bridge the wage gap between labor-intensive factories overseas that pay workers only a few dollars a day and this North Carolina plant where about 100 employees make between $10 and $20 an hour.

Factories are realizing it's important to limit labor costs and to provide higher quality and better customer service to compete in the global market place. So they are diversifying into niche markets. Companies and enterprises are bringing their core activities to where they have a skilled workforce, where they have innovation talent and where they’re able to develop the next generation of innovation that drives manufacturing.

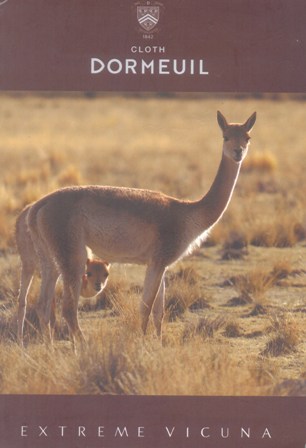

The House of Dormeuil known for sourcing and selling rare and precious fibres from around the world is making a mark in India. Its collection of pure wool suiting in basic counts, pure cashmere suiting, super 180 and super 230 stand out because of their quality. “The Indian market is becoming stronger every year. We have big sales during weddings and are growing at 10 to 25 per cent per annum in the country,” explains Richard Boide, Commercial Director, Dormeuil. A top supplier of luxury fabrics in India their prices range from Rs 10,000 a metre up to Rs 2,00,000 a metre.

The House of Dormeuil known for sourcing and selling rare and precious fibres from around the world is making a mark in India. Its collection of pure wool suiting in basic counts, pure cashmere suiting, super 180 and super 230 stand out because of their quality. “The Indian market is becoming stronger every year. We have big sales during weddings and are growing at 10 to 25 per cent per annum in the country,” explains Richard Boide, Commercial Director, Dormeuil. A top supplier of luxury fabrics in India their prices range from Rs 10,000 a metre up to Rs 2,00,000 a metre.

The company has 60 to 70 retailers in India. Because of the nature of the product and the climate the biggest markets are Delhi and north India. However, Mumbai is fast emerging as a strong market. “We work with some designers in Mumbai,” says Boide. In some countries it also works with suit manufacturers. “We have a big business in Japan for suit manufacturing and this will be one of the strategies for growth in India as well,” Boide explains.

the climate the biggest markets are Delhi and north India. However, Mumbai is fast emerging as a strong market. “We work with some designers in Mumbai,” says Boide. In some countries it also works with suit manufacturers. “We have a big business in Japan for suit manufacturing and this will be one of the strategies for growth in India as well,” Boide explains.

Its latest search is the native vicuna. The protected animal is treated with great care and respect during the shearing process, which takes no more than 10 minutes. Each animal is only sheared once in two years. Each vicuna provides approximately 300 grams of wool.

Taking its quest forward, Dormeuil has also used Argentinean fibres. Extremely rare, pale and difficult to weave, the exclusive raw material gives this Extreme Vicuna Collection its supremacy. The fibres are extremely fine, at just 12 microns in diameter which makes it seem as if a breath of wind could blow it away. A carefully controlled production process, from shearing to weaving and finishing ensures the traceability of this precious material.

Vicuna wool fibres have an unmatched brightness which is the secret of their beauty and lustre. These qualities have allowed Dormeuil’s master weavers to create cloth of rare colour and brilliance from the world’s finest wool. The new palette of ten colours features several unexpected choices, including beige, light grey and plum, which recall views of the South American mountains. In addition to the surprising colour range achieved, vicuna wool allows scope for genuine technical virtuosity. The focus on discovery has been maintained throughout the generations and the quest for the rare and precious is woven into Dormeuil’s history and into its fabrics.

Set up two years ago, Dormeuil India is based in Delhi. It is one of the first European companies to export its fabric. It has a strong English association. “We were distributing in India even before 1947. Now we have a network of retailers across the country with high end customers. We have our own production facility in England and deliver anywhere in the world within 48 hours,” Boide sums up.

The Chinese sewing machinery industry is facing many challenges and needs to upgrade. It has the advantage of low price and good quality. However, the recession in Europe and US has affected China’s sewing machine industry. Yang Xiaojing, Secretary General Senior Economist CISMA reveals, “We are facing a slowdown and demand for sewing machines is falling.” With rising labour costs, buyers are looking for machines that are easy to use and reduce labor costs. As for currency fluctuations, there are some bad effects on China’s sewing machines especially on companies that want to upgrade and save costs. At the moment the percentage of lock stitch sewing machines is more than 50 per cent and it’s rising.

The Chinese sewing machinery industry is facing many challenges and needs to upgrade. It has the advantage of low price and good quality. However, the recession in Europe and US has affected China’s sewing machine industry. Yang Xiaojing, Secretary General Senior Economist CISMA reveals, “We are facing a slowdown and demand for sewing machines is falling.” With rising labour costs, buyers are looking for machines that are easy to use and reduce labor costs. As for currency fluctuations, there are some bad effects on China’s sewing machines especially on companies that want to upgrade and save costs. At the moment the percentage of lock stitch sewing machines is more than 50 per cent and it’s rising.

In China, for large garment factories most of the sewing machines are bought from  Germany and Japan. But medium and small garment factories buy sewing machines from China. The quality difference between Japanese and Chinese machines is narrowing. Last year, production of sewing machine sets in China was more than 800 million, of these 355 million were exported. If the global production of regular sewing machines is taken into consideration, more than 80 per cent are produced by China.

Germany and Japan. But medium and small garment factories buy sewing machines from China. The quality difference between Japanese and Chinese machines is narrowing. Last year, production of sewing machine sets in China was more than 800 million, of these 355 million were exported. If the global production of regular sewing machines is taken into consideration, more than 80 per cent are produced by China.

Talking about the India as a buyer for Chinese machinery, Xiaojing says, “Before 2010, India bought a lot of sewing machines from China. Since then there has been a fall because of the recession. But in the first half of 2013 the trend is going up again and especially for embroidery machines. The Indian apparel industry has a huge scope to buy Chinese machines. India has a huge population. Our association held a show in India in 2006. It was the first time we had a show outside China. We have a great relationship with the Indian garment industry associations.”

In 2011, India imposed an anti-dumping duty on import of sewing machine needles to protect domestic players from cheap Chinese shipments. This duty was levied for a period of five years. The country had already imposed duty on imports of fabric, yarn, nylon tyre cord and several chemicals. The Directorate General of Anti-Dumping and Allied Duties (DGAD), a nodal agency under the Commerce Ministry, had recommended the imposition of the duty after an investigation. The DGAD concluded in its probe that the domestic industry had suffered a material injury on account of dumped imports of the product from China.

Unlike other safeguard duties, which are levied in a uniform way, anti-dumping duties vary from product to product and from country to country. Countries initiate anti-dumping probes to check if the domestic industry has been hurt because of a surge in cheap imports. As a counter-measure, they impose duties under the multilateral World Trade Organization regime.

The Turkish textile sector aims to strengthen its success in both traditional and emerging markets with its own brands. The positive and strong relations Turkey has been pursuing with the global partners have also been initiated between these countries’ industrialists and exporters. Turkish textile sector provides top quality in several areas ranging from production to promotion, quality standards to marketing. “Success has been achieved by focusing on value added products that highlights design and brand quality as part of Turkey’s export boosting strategy. This success is a result of the hard work of SME’s as well as large, modern and vertically integrated companies which are capable of producing and exporting their own unique collections,” says Ibrahim Burkay, Chairman of the Uludag Textile Exporters Association.

Turkish textiles are extensively used for supplying to the middle and high end segment needs of both the fashion sector and the apparel industry worldwide. This sector is in line with global trends and latest innovations in the world of fashion. Turkish textile sector has established itself as a cornerstone of Turkey’s success story in industrial development and exports. “It has been a critical source for major international labels, ranging from the high-end to countless popular fashion houses as well as design studios and fashion schools around the world. Turkey is the third largest textile exporter to Europe ($8 billion in 2012), the sixth largest apparel exporter in the world ($16 billion in 2012),” said Burkay.

Turkish textile sector’s top five markets are: Russia, Italy, Germany, UK and the US. These are the classical markets of Turkey. “There are no expectations about a change among this ranking. On the other hand it is observed that some emerging markets climbing towards the top ten such as China and Brazil,” sums up Burkay.

Apparel consumption pattern is going through a drastic change worldwide. For instance, consumption is very high in the West. The per capita consumption in the US is 60-62 pieces a year, which includes everything from socks to suits. Achim Berg, McKinsey explains, “People are buying more pieces at lower prices. If apparel sourcing prices go up, big retailers are not able to mitigate that, we may see an increase in apparel prices and that may affect fast fashion and consumption patterns.”

There is proliferation in the market. In the luxury or upper mid market, it’s about quality and prices are not an issue. However, in Germany for example, the apparel discount segment that plays on price is very active. Elaborating on global sourcing trends, Berg says, “Europe and the US will continue to source the lion’s share from the Far East. We expect Africa and some points of Latin America to open up.” He further added, “In Germany, the apparel discount segment that plays on prices is very active. On the other hand, in the western world, cupboards are full. So when people buy something, it’s mainly for entertainment purpose. In countries like Africa, apparel still has a growing share of the wallet.”

The apparel industry is engaged in a process of reorientation from the production perspective. Local demand in China is becoming evident and hence several labels are looking at other countries for sourcing. South East Asia and Eastern Europe are benefiting from fashion labels looking to bring parts of production closer to the European end consumer market. Locating production near to the final customer contributes to sustainability due to the lower energy costs for transport.

Europe and the US continue to source the lion’s share from Far East as far as sourcing is concerned. Africa and some Latin American countries are expected to become sourcing destinations in the future. Olaf Schmidt, Vice President, Textile Technologies, Messe Frankfurt Exhibition reiterates that local sourcing is the trend said, “In the global textile industry as we go up the buyers’ side companies are looking more towards local sourcing. In Europe, medium to high class garment producers are looking for sourcing platforms in East Europe, North Africa and a bit of Middle East. The aim is to have shorter delivery and smaller quantities. One reason is the price increase in the Asian region. The difference between sourcing in Asia and in East Europe and North Africa is not as big as it was in the past. But China remains the largest producer of textiles.”

Apart from China and India all the other consuming economies are expected to grow at less than 5 per cent. If apparel sourcing prices go up and big retailers are not able to mitigate, apparel price rise is inevitable, this will affect fast fashion and consumption patterns.

www.messefrankfurt.com

With the aim of creating breast cancer awareness, Gomitolo Rosa initiated the Pink Ball of Wool project. Running since October 2012, the project aims to be the most effective tool of communication and fund raising association operating in the world of oncology. The Pink Ball of Wool began in Biella valleys where excess production had become a problem and the wool ended getting destroyed. Today, the knitted wool produced in Italy on behalf of farmers has become an important tool to help women and environment. The project supports women’s organizations that work for breast cancer in Italy and in Europe, making use of wool that is not absorbed by the market and contributing to a better balance of the environment.

Pink Ball is an initiative which aims to support this essential component of the fight against breast cancer, and its name derives from the material chosen to achieve this support, the wool. Its theme is ‘Knit a wool, warm life’.

A group of Italian donors has given resources to buy a significant quantities of wool, which would have been burned because of lack of demand from the market. Nearly 70,000 pink balls of wool have been prepared by factories in Biella (Northern Italy) with years of expertise in wool production. These are now available and come in boxes of 200 at a cost of three euros each. No advanced payment is required. The association can sell them at five 5 euros each or more and keep all the profits for itself.

Staying ahead with technology

Apart from eco-friendly processes and products the Korean textile industry is highly

The current Korean fashion market is very strong and many international fast fashion companies are strongly competing with Korean companies.

Korea is also well known for its high end fabric. As far as prices are concerned, Korean fabrics are high end and therefore, expensive. Park reveals, “The current position of Korean fabric is in between Chinese, known for low prices and Japanese, for high prices. However, China is no more considered low cost and Chinese companies are coming closer to Korean prices”

The Korean Federation of Textile Industries (KOFOTI) contributes towards long term development of the textile industry as well as advancement of the national economy. It has been performing a leading role in the development of the textile industry and its national economy for the last 37 years. KOFOTI formulates innovative strategies for the textile and fashion industries to actively take measures and respond to sharp changes in the global market performing a pivotal role in the textile industry. The federation also plays an active role in different areas including the development of distinctive products that feature new technologies as well as high quality, cutting edge textile products and state of the art dyeing and finishing technology among others.

Park revealed, “In 2000, we had a sales of export of 18.8 billion which was the highest, we were at the peak at that point of time. Our exports accounted to 18.8 billion USD. In 2009 this figure came to 11.6 billion USD which was the lowest and from then it has been improving. In 2012 it was 15.6 billion USD out of which the fabric export was 12.4 billion USD and apparel export amounted to 3.2 billion USD. The target set for 2013 was 16.3 billion USD. In terms of imports, in 2012, we had an import of 12 billion USD.”

In the 1960s and ’70s the Nigerian textile industry got a lot of encouragement from the government. One of these major schemes was a ban placed on import of textiles. So many investors came into the textile sector. This led to backward integration in the industry. Many textile mills became fully integrated. Some even became spinning mills. The industry worked on shuttles, shuttleless and sulzer looms, knitting, spindles, real wax printing technology.

In this period the Nigerian textile industry was the most technologically advanced in sub-Saharan Africa. By 1985, there were about 180 textile mills in the country, employing about one million Nigerians. The country’s textile capacity accounted for 60 per cent in West Africa.

However in 1994, many textile manufacturers began to feel the pinch of the unstable political situation, massive smuggling, high production costs due to poor infrastructure, taxes and levies, among others. The situation worsened in 1997, when the ban on import of textiles was lifted. Inferior imported products flooded the market. Consequently, many big players could not survive.

From 60 per cent capacity utilisation in 1996 it deteriorated to about 28 per cent in 2002. At the end of 2009, only about 34 textile companies were still functional, employing less than 25,000 workers. There is an urgent need to take steps for the one million Nigerians who have been rendered jobless due to the decline of the industry.

The 8th edition of Interfiliere Hong Kong will be held at the Hong Kong Convention and Exhibition Centre. The emphasis this time will be on harmony of body, mind and well-being. The trade show will encompass a more comprehensive, innovative and quality offer to respond to the market needs and visitors’ requirements. Nearly 170 specialized intimates and swimwear exhibitors from more than 15 countries including Austria, China, France, Germany, Hong Kong, India, Indonesia, Italy, Japan, Korea, Taiwan, Thailand, Turkey, Vietnam etc, will be participating making it a truly international sourcing platform at the hub of Asia, between mainland China and the emerging South East Asia.

Interfilière Hong Kong works closely with its exhibitors and visitors to understand the requirements of Asian and international buyers and to respond to the market needs. As a result, the 2014 sourcing platform will focus on functional and natural fabrics, ecological and sustainable manufacturing and the further diversification of the product range while underlining quality. The 8th edition of Interfilière Hong Kong is also expanding its offer by developing the lounge wear sector with an additional selection of fabrics.

The Sustainable Development project co-organized with the French Knitwear and Lingerie Federation will add value to the visitors experience and their product and industry knowledge. A playful area will engage the visitors’ 5 senses: sight, hearing, taste, smell and touch. It will offer visitors and exhibitors an educational and explanatory overview on the eco-concept of natural, biological and innovative fabrics, the green textile certifications, sustainable marketing and much more.

Another innovative and creative project called ‘Trend Lab’ formed under the guiding eye of Jos Berry, Director of Concepts Paris, will bring designers and buyers a fresh perspective on the international lingerie consumer.

The New Age woman is inventing another way to shop, dress, be informed et al. It’s called the Instagram Woman, well informed, detail crazy, communicative, seeking style and stories in every element of life. Trend Lab will gather the hottest relevant innovations through finished product prototypes focused on what we know about the needs and longings of this ‘new’ woman.

Trend Forum, will unveil the trends for Autumn/Winter 2015-’16 to decode tomorrow’s trends and most important innovations. Apart from the projects, the event will also have informative seminars and conferences with top-notch speakers on trends, branding, sustainability and several others.