FW

Egypt’s Giza-86, long-staple luxury cotton is renowned the world over. However, the government’s decision to divide large acres of land among small farmers and interference at every stage of the production process limited its growth and potential.

Egypt is known for producing eight cotton varieties. Each is grown in separate regions, with a carefully controlled system to make sure they remain uncontaminated by other varieties. Giza-86 has long formed the bulk of the crop, but other even finer varieties, including Giza 45, 87 and 92, have catered to more expensive niche markets. However, later to make quick money, people started packing low quality cotton in between the layers of high quality one, which led to the mixing of superior and inferior seeds. An inventory made a year ago indicated that the impact was such that the country only had enough pure Giza-86 to plant 21,000 hectares.

Adding to the woes, in January 2015, the government announced it would no longer subsidise the cotton crop. However, it changed the decision a few months later. It has now guaranteed a purchase price of 1,400 pounds per qintar (157kg) for the newly rescued Giza-86 seed cotton, which on the open market would have fetched about 800 pounds (Dh373). But it then offered to pay almost as much for common cotton, which was fetching 600 to 700 pounds on the open market.

Now the state-owned cotton holding company that buys the cotton plans to sell the Giza-86 to private traders at 1,520 pounds per qintar, a premium of 120 pounds over the inflated price it has promised farmers. Experts say that because of the government monopoly over cotton purchases, some of the countryʼs 240 licensed traders are likely to go bankrupt. On the other hand, it has put a curb on imports by making it difficult to get licences from the Egyptian quarantine office.

Rhodia, a Solvay Group company, launched the world's first biodegradable polyamide yarn Amni Soul Eco during the 2015 edition of ITMA. The company invested almost five years of research in developing the fibre. It is a polyamide 6.6 textile yarn whose formula has been enhanced so that the properly disposed garments get quickly decomposed in landfills.

Unlike other fibres which take decades to decompose, it only takes about three years for Amni Soul Eco to get absorbed in the soil. Amni Soul Eco offers the many benefits of Rhodia's polyamide for consumers, such as its soft touch, extreme comfort, breathability, moisture management, easy-care, easy washing, and it is easily dyed in different colours so that the industry can produce any kind of garment for all types of segments.

The newly launched product is internationally Oeko-Tex certified (standard 100, class 1) and has been recognized with two awards: the Kurt Pulitzer Prize, awarded by ABIQUIM (an association of chemical industries); and by the American Chamber of Commerce (AMCHAM). Rhodia has already been recognised as the pioneer in introducing the Far Infrared technology with the Emana fibre and biodegradable technology.

www.solvay.com

Geratex participating for the first time in technology exhibition ITMA, introduced its innovative technology for textile wet processing using Ultrasonic, which received a positive response from visitors. It displayed SonicPreg, which is an applicator based on ultrasonics. The product is based on the characteristics of ultrasound technology.

Ultrasound with a frequency of more than 20,000 Hertz is used to invigorate the medium for inducing high absorption and facilitating effective liquor exchange. The most appealing feature of this machine is its adaptability as it can integrate into an existing range, be it singeing, bleaching, mercerizing or washing. Many visiting textile companies finally found an apt solution to their absorption issues. The company received a lot of potential enquiries and finalized orders from Brazil, El Salvador, Turkey and India at ITMA.

Visitors from countries like Argentina, Brazil, Mexico, El Salvador, Honduras, Portugal, Spain, Switzerland, Turkey, Iran, Pakistan, Bangladesh, Indonesia and South Korea visited the Geratex stall to get introduced the innovative solution.

Geratex-india.com

Traders in the currency futures market heavily depend upon the fluctuation of Indian rupee against the other foreign currencies, however, with the Reserve Bank of India's (RBI) decision to intervene in the currency futures, its excessive movement is expected to come under control.

Governor Raghuram Rajan announced last month that the central bank would also trade in the currency derivatives market to "manage excessive volatility and to maintain orderly conditions......" The industry experts are of the opinion that while the RBI’s move may help in regulating the market fluctuations, on the other hand, it would deprive arbitrageurs from benefiting from differential rates in different markets.

Indeed, in its December bulletin, the banking regulator revealed its purchase and sale of $355 million in the currency futures market in September. Currently an exchange member had exposure limit of 15 per cent of market wide open interest. Currency derivatives trading since August 2008 on NSE, has grown with annual/daily trading volume averaging Rs 16,915 crores in FY16 (April-January period), from just Rs 1,167 crores in FY09.

www.rbi.org.in

Bannari Amman Spinning Mills has decided to set up a new garment unit at the Palladam hitech weaving park known as ACCEL Apparels to make knitted garments. The company is infusing Rs 30 crores with a plan to generate employment for almost over 1,000 people in the new unit which is expected to start production by the end of December and reach a full capacity by mid-2016.

The plant will have an annual capacity of producing 6.2 million pieces of knitted garments for men, women and kids. Bannari Amman Spinning turns out cotton yarn, woven and knitted fabrics and garments, as well as wind power generation for captive consumption. A substantial portion of cotton yarn and the entire garment production are exported to different countries. The entire green power generated by windmills is being captively consumed.

The company already has two modern spinning units near Dindigul with an installed capacity of 1,44,240 spindles, a weaving unit located at Karnempettai near Palladam with an installed capacity of 147 looms, a processing unit located at the SIPCOT Industrial Growth Center, Perundurai, to process 3,600 tonnes of fabrics per annum, a knitting unit near Karnempettai to produce 7,200 tonnes of knitted fabrics per annum, a garments unit at Palladam Hi-tech Weaving Park to produce 12 lakh pieces of garments per annum, and 32 windmills with installed capacity of 29.95 mw power.

www.bannarimills.com

Textile mills in north and south India are outraged because of the adulterated cotton coming from Gujarat. Since cotton farmers are holding on to their raw cotton inventories for the prices to improve, ginners are mixing lower quality cotton with higher quality to cater to the demand from other states and reduce losses.

Mills and traders, who procure cotton from Gujarat have said that this year the level of adulteration, which used to be around 10-15 per cent, has climbed to 40 per cent. Same is the case with cotton supplied by ginners from the state of Maharashtra.

A bale of 170 kg raw cotton contains 32 per cent lint, 63 per cent seed and another 5 per cent is waste. The cost to ginners is Rs 8,500 per bale and Rs 500 for production. Ginners are being offered Rs 8,000-8,200 per bale for ginned cotton. After adulteration, the loss is being reduced to Rs 200-300 per bale.

Since even the good quality cotton such as Shankar 6 from Gujarat, is being mixed with lower quality cotton, south Indian mills are now importing it from Africa. Industry insiders have said that imports could further increase if Gujarat ginners don’t stop mixing high and low quality cotton.

Rising number of Chinese investors has acquired existing Vietnamese apparel manufacturing to avoid strict regulations since the local Vietnamese authorities are against investments in the textile industry since textile factories lead to several environmental hazards. So to expand their businesses in the country, Chinese investors are acquiring local production units in Vietnam.

According to Thai Tri Dung from the HCM City Economics University, its high time, Vietnamese give a thought to the fact that they are becoming satellite companies in Chinese chains. Most of the skilled Vietnamese workers are poached by the Chinese investors, which Dung says could influence human resource development and exports. He went on to say that once Vietnamese companies become Chinese subsidiaries, Vietnam’s export markets would become China’s markets and most of the businesses would be under China’s control.

Most of the industry experts are of the opinion that Vietnamese companies are running a huge risk by letting their companies merge with Chinese ones. And since textile and garment is Vietnam’s key export industry, China’s control over it can lead to the country getting access and control over other business fields such as agriculture and seafood as well.

Vietnamese experts are against Chinese investments in the country since they are of the opinion that they mostly bring outdated technologies to Vietnam which causes environmental pollution.

TRENDSPOTTING 2016 : "Fashion and textile industry has never been in a more interesting spot ever before. When human imagination and innovation is taking industry and businesses to a new height with the help of cutting edge technology, fashion and textile industry is also being a part of it. 2016 seems to be a benchmark year for the textile and fashion industry paving the way for new opportunities."

Fashion and textile industry has never been in a more interesting spot ever before. When human imagination and innovation is taking industry and businesses to a new height with the help of cutting edge technology, fashion and textile industry is also being a part of it. More than ever before, the garment industry is going to witness a phase which is marked by innovation and technology. With all the pioneering changes taking places in technology, manufacturing and even in the consumer mindset, 2016 seems to be a benchmark year for the textile and fashion industry paving the way for new opportunities.

Technology to play a pivotal role

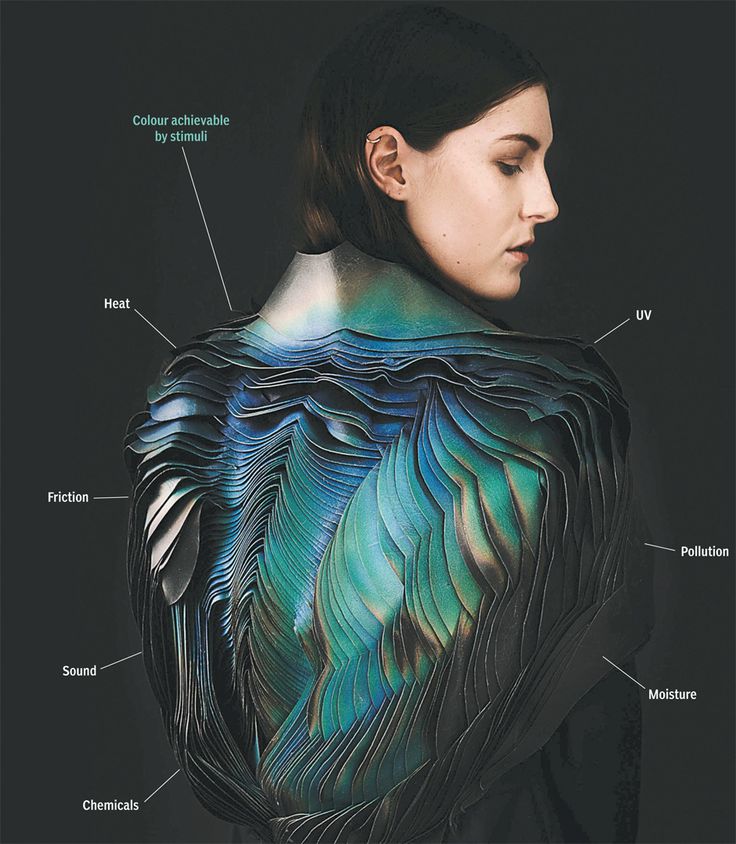

With some trendsetting changes taking place in technology sector, fashion and textile, like all other industries is witnessing a major impact on what we produce and conceive. Smart fabrics, interactive fabrics, 3D printed fashion and many other innovations have opened up a whole array of possibilities that will have a huge impact on the world of fashion as we know it. However, it is technology coupled with innovation that is setting the trend for fashion in 2016. Young designers, entrepreneurs and forward thinking brands that explore the boundaries of fashion are now conceiving alternatives to traditional materials and fabrics that we know today.

Innovations in sustainability to trend in 2016

Continuing with increased environmental awareness the major trend for the sector would be significant innovations in sustainability – reducing water and energy consumption, which are vital developments for the benefit of the environment and saving costs. Environmental and economic considerations go hand¬ in ¬hand, and have been the driving force for the last few years. Even in areas such as finishing, where water consumption and pollution was a particular issue. Another important development is the rise of digital printing, which doesn’t require water. Digital printing is not only an environmentally friendly technology, it also offers opportunities for re¬shoring because it can produce small lots of printed fabrics. The impact of this new technology will be very important for the downstream industry.

There has been a revolutionary change in the mass mindset which has fuelled fashion players to think of their environmental responsibilities. Initiatives like ‘the shoe that grows’ will inspire brands to consider sustainable alternative to grow their brands. In this new development a sustainable production process and the use of water-based polyurethanes and water-based finish is of great importance to support the mindset of sustainable fashion. Solutions we have been working on for years because we think this development is of great importance in ensuring a sustainable future full of opportunities for all of us.

Emergence of technical textiles to grow robust

In recent years, technical textile has become a major segment globally because of several advantages like functional requirement, health and safety, cost effectiveness, durability, high strength etc. The global technical textile industry has witnessed an increase in consumption from 25 per cent in 1998 to 37 per cent 2010. The largest segments are Mobiltex, Indutex and Sportex which contribute to about 55-57 per cent of the total Technical Textiles globally. In the US and Western European countries, there is legislation for mandatory use of such products which has further fuelled growth in demand. China, Brazil and Canada are some other countries to play important role in shaping the technical textile industry in 2016.

Crowdfunding, the new buzzword in fashion

Ever since the establishment of denim and basics brand DSTLD in 2013, it has raised $4.3 million, turning to venture capitalists including CAA Ventures and Wavemaker Partners and then DSTLD’s sales increasing by 640 per cent to more than 34,000 units crowdfunding became the business buzzword of the year. Instead of turning once again to venture capital firms, the co-founders decided to launch a campaign on equity crowdfunding platform SeedInvest, which allows companies to raise money from Internet users. Although companies are projected to raise $34.4 billion in crowdfunded investments in 2015, according to research and advisory firm Massolution, just a sliver of those using crowdfunding operate in the apparel sector. Of the 93,546 projects successfully funded on Kickstarter since the platform launched, only 3,163 (or 3 percent) have been fashion-related. However the concept is expected to gain strength in 2016. Even venture capitalists themselves seem to be opening up to the idea of fashion crowdfunding platforms.

Spinning sector to see smaller order sizes

In 2015, spinning industry witnessed a trend of smaller order sizes which is likely to continue in 2016. The combination of high demand and decreasing raw material costs has also provided spinners with the opportunity to enhance margins, which have historically been very thin for this industry. Perhaps the biggest change in 2015 over past periods of sustained prosperity is the size of orders. Orders are relatively small, at least for most specialty spinners, and the variety of yarns spun is on the rise.

Inking and colouring the efficient way

The overall printing industry across the globe is estimated to be about one trillion US dollars, out of which textiles is about $150 billion constituting about 15 per cent of total value. A major area which is promising for technical innovation is ink, which has the ability to get better and print on more types of fabric. With a Silicon Valley-based company such as EFI getting deeply involved in textiles, the market is going to see a very meaningful innovation in software applications, helping colour to be accurate and improving efficiency in the printing process to save customers time and money. There is no doubt that this is an exciting time for innovation in the textile industry. Industry 4.0, the concept of interconnected production chains with the potential for cloud or mobile- based management - speaks to the evolution path of technological innovation that textile professionals need.

"Gone are the days when almost 95 per cent sold in America was a product of the New York City’s Garment District spread over 7.7 million sq. ft. of manufacturing space, generating over 100,000 jobs. Today, the space has shrunk to mere 1.1 million sq. ft employing just above 7,000 people. However, realising the need to salvage ‘Made in New York’ apparel manufacturing, several designers and labels are initiating measures."

Initiatives to boost ‘Made in USA’

Gradually, apparel manufacturing activity which had moved out of the US is returning back to the nation for good. Even consumers are now demanding fashion Made in USA. Other than ‘Made in USA’, ‘Made in New York’ according to the experts carries its own sentimentality. Five factory owners, for example, came together in 2007 to launch ‘Save the Garment Centre’, a nonprofit organisation to promote manufacturing in New York. And Stefan Siegel, a former model turned investment banker based in London founded ‘Not Just A Label’ (NJAL) in 2008 - a global platform to promote domestic products and works of emerging designers. NJAL has also opened pop-up stores in Berlin, Dubai, Venice and finally in New York.

Stakeholders are putting in serious efforts to revive New York’s manufacturing hub. The Garment District houses many design offices including Public School to Engineered Garments and Aimé Leon Doré, whose production still happens in NYC. For designers ‘Made in New York’ means something close to their hearts than the ‘Made in USA’ label.

For instance, designers like Greg Rosborough, who focus on ‘Bespoken’, a label that won GQ’s ‘Best New Menswear Designer in America’ award in 2014, and Abasi Rosborough, his own line of futuristic clothes designed with his partner Abdul Abasi, call ‘Made in New York’ label something akin to being made in Paris instead of France.

High production costs, not a deterrent

While the cost of making garments in New York is not less since it involves high production costs and rentals, among other things. However, despite being the most expensive place to make clothes, designers like Dominic Sondag, manufacturing in New York is of advantage since he can oversee everything and if a sample is not according to his expectations, he can quickly work upon it. So while the cost of the end-product tends to be a little higher, making in New York also helps these designers support the local economy.

Also since designers are involved at every level of production process, it also means they can be responsible for everyone, who is a part of the supply line resulting in fair wage practices and unity among workers. Also the garment district’s artisans possess the required skill-sets to create an ensemble so the designers don’t really have to depend upon a factory and its workers at some faraway place, whose skill-sets are not known. Workers in the garment district are experienced pattern-makers and tailors, whose skills are polished since they are engaged in the business for last several decades.

Garmentech will be held in Bangladesh from January 13 to 16, 2016. This is an apparel machinery trade show which brings technology suppliers, agents and garment manufacturers under one roof.

More than 200 exhibitors will be there at the fair this year. Also the 2016 edition will be 20 per cent bigger than last year. There will be eight halls in total at the show. The previous show witnessed near about 12,851 visitors. The new venue which is closer to many buying houses and garment factories will attract more visitors. It is more comfortable and organised and therefore, it will be beneficial for exhibitors as well as visitors.

Companies such as Duerkopp Adler, Eastman Technocraft, Typical, Juki, Vibemac, ASS, Focus, New Tech and many more are set to exhibit their latest products and technologies at the show.

Garmentech has been the most preferred technology and machinery sourcing forum in Bangladesh for the past 14 years. Among the exhibits are international and domestic machinery, chemicals, accessories and allied products. Manufacturers and distributors will showcase their latest products and services to the tanning and finished leather, footwear and leather goods manufacturing industries in Bangladesh.