FW

According to a new World Bank report, Pakistan has been successful in establishing and growing its apparel manufacturing industry, however, more can be done to realize its potential as a regional hub and to continue to boost opportunities, especially for women and the poor.

The report, The Stitches to Riches Apparel Employment Trade and Economic Development, launched in Pakistan, is aimed at demystifying the global and South Asian apparel markets, estimating the potential gains in exports and jobs and identifying policies that can unleash country’s export and job potential compared with those of their closest competitors in the Southeast Asia region – Vietnam, Cambodia and Indonesia.

The report finds that it is important for South Asian economies to remove existing impediments and facilitate growth in apparel to capture more production and create more employment as wages rise in China.The successful manufacturers will be those who can supply a wide range of quality products to buyers rapidly and reliably, not just those who offer low costs.

China currently dominates global apparel trade but that may change in coming years due to the rising prices in China.

Grasim Industries has announced impressive results led by robust volume growth in all its businesses viz. VSF, Chemical and Cement. For the current quarter, consolidated revenue rose by 13 per cent at Rs.10,001 crore and EBITDA at Rs. 2,059 crore was higher by 24 per cent. Net profit (before EI) grew by 40 per cent to Rs.724 crore (Q4 last year: Rs.516 crore). For the full year, consolidated revenue was higher by 12 per cent to Rs. 36,637 crore. Consolidated EBITDA was up by 24 per cent at Rs. 7,025 crore and Net profit increased to Rs.2,387 crore compared to Rs.1,753 crore last year.

The Board approved Rs. 513 crore for brownfield expansion of Caustic soda capacity at Vilayat plant from 219K TPA to 363K TPA along with a Captive Power plant of 44 MW. The expansion is expected to be completed in around 24 month’s time. On completion of the proposed expansion and debottlenecking of capacity at various plants, Caustic capacity will increase from 804K TPA currently to 1,048K TPA.

Fairtrade International’s new Textile Standard comesinto play to improve working conditions across the textile supply chain in the month of June, but the Clean ClothesCampaign says it targets the wrong organisations and does not go far enough.

The textile industry has been underpressure to regulate working conditions since the collapse of the Rana Plaza incident in Bangladesh in 2013. The building housed several clothing factoriesand the disaster killed more than 1,100 people and injured over 2,500.

The Textile Standard is the first stepin the larger Fairtrade Textile Programme which assesses all stages ofproduction. If all measures are met along the chain, the product can carry aFairtrade Textile Production Mark on its packaging.

According to Martin Hill, interim CEO at FairtradeInternational, they are inviting all textile companies to work togetherwith their staff and with Fairtrade to create a fairer production process fortextiles.

Fairtrade saysthe move goes far beyond any existing standards, and SubinduGarkhel, product manager for cotton at Fairtrade, said it would not rely solelyon audits, with an onsite programme to support workers and factories.

The six-year implementation time forliving wage was described as a “realistic approach”. Factories must showimprovement from year one, then again in year four, and at the end of year six.If the living wage was in place immediately, it would punish the companieswilling to take it up by making them uncompetitive.

In a significant move, Levi Strauss & Co. has promoted Roy Bagattini to the role of executive vice president and president of Levi Strauss Americas. In his new role which takes effect from June 1, Bagattini will be responsible for leading the San Francisco company’s largest commercial operations, covering all brands and channels across the United States, Canada, Mexico, Brazil and the balance of Latin America.

Previously, Bagattini served as Levi’s executive vice president and president of the company’s Asia, Middle East and Africa operations. Prior to joining Levi Strauss three years ago, Bagattini was a senior vice president for Asia and Africa at beverage and brewing company Carlsberg, where he was responsible for the group’s Asia strategy and was credited with the company’s significant growth in that region. In 2015, Levi’s had $4.5 billion in net revenues with net income of $209 million.

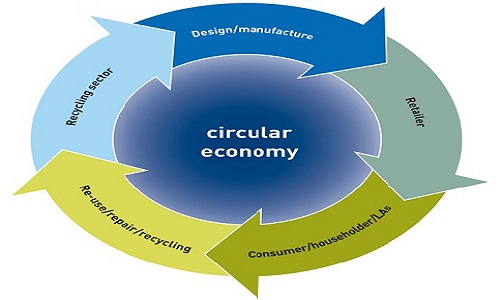

"The circular economy gives us a chance to create a new story for the global economy. Recycling has a place within that story, but rather than simply eking out our materials a bit further, a systemic shift based on circular economic principles offers greater business opportunity, and the potential to decouple growth from finite resource inputs."

Many businesses have invested in recycling practices that seem like a natural starting point for more involved circular economy activities. Characteristics of a circular economy suggest that more fundamental shift required to decouple growth from finite resources and move to a circular development path.

As per the circular economy, there is a fundamental shift in the way resources, energy and information flow through our economy. A key characteristic of this framework is that products and components remain at their highest levels of integrity and performance.

The perception is that a circular economy is just ‘recycling on steroids’ - recycling more stuff, and doing it a bit better. This confusion is understandable. Since the 1970s, recycling has become synonymous with ‘doing good.’ What’s more, many businesses have invested in recycling practices that seem like a natural starting point for more involved circular economy activities. However, the characteristics of a circular economy - and existing research - suggest that returning a product to the material level would be ‘the loop of last resort,’ with a more fundamental shift required to decouple growth from finite resources and move to a circular development path.

The real opportunity

Economic analysis conducted by the Ellen MacArthur Foundation and McKinsey & has demonstrated how, in a circular economy, greater value can be obtained by operating in the ‘inner loops’ of a technical cycle. Activities such as sharing, service, maintenance, refurbishment and remanufacturing preserve the integrity of a product. We often hear about how a company has recovered a product and then processed the materials so they can be used as a resource. But think about it - by returning a product to its constituent materials you lose all the energy, labour and expense that went into creating it in the first place. In some cases, the recycling process may even be more costly than extracting virgin resources. This can severely undermine recycling efforts - in the current context of depressed commodity prices.

Consider that recycling is a generic term, with a range of possible nuances. More often than not, emphasis is placed on post-consumer recycling. This shifts responsibility to the public, but also misses the point. A significant amount of waste is generated at the extraction and production phase when making new products - another reason to suggest that the real opportunity might lie elsewhere.

Real opportunities for higher levels of valorisation exist in the ‘inner loops’ of a product cycle and it is here that businesses, users and governments can really start to see the benefits of a circular economy. In fact, studies have suggested that seizing these types of value creation opportunities wouldn’t just achieve a one-off dent in resource demand, but could actually change the run rate of required material intake. The pursuit of this circular economy development path could see European GDP increase as much as 11 per cent by 2030 and 27 per cent by 2050, compared with 4 per cent and 15 per cent in the current, linear development scenario.

Recycling, a necessity

At some point products and components will break down, and it won’t be possible or sensible to keep them in service any longer. At this point, a recycling option will be necessary. Even then, we need to rethink the process. Widespread legislation on recycling rates has encouraged businesses to look to end-of-pipe solutions, and whilst these are often commendable, they naturally revolve around making do with the scraps at hand. Frequently this means dealing with stuff designed in a linear, take-make-dispose mindset. Toxic materials, integrated design and irreversible adhesives are all design choices that can get in the way of positive and scalable recycling activities.

The ‘New Plastics Economy’ report, released at the World Economic Forum, revealed the scale of material leakage from today’s plastics system. Even when we can recover dispersed materials, current recycling techniques rarely preserve all the material. For example, around 80 per cent of recycled PET bottles are turned into polyester fibers for carpet, clothing and other non-packaging applications. With paper recycling, fibers diminish after six or seven cycles, and they can no longer be used for paper production. Important progress is being made, but this still represents significant material losses over time. To truly optimise resource flows, future pathways should be considered at the design phase. In the Towards the Circular Economy report series, this is summarised by ‘the power of pure inputs.’

The circular economy gives us a chance to create a new story for the global economy. Recycling has a place within that story, but rather than simply eking out our materials a bit further, a systemic shift based on circular economic principles offers greater business opportunity, and the potential to decouple growth from finite resource inputs.

Italy will host a textile machinery roadshow in Iran from May 22. A total of 26 Italian manufacturers (of which 23 are ACIMIT associated members) will be taking part in a series of technology symposia programmed in some of the Country’s major cities (Teheran, Yazd, Isfahan, Mashad) until May 30.

Organized by the Italian Trade Agency and ACIMIT, the Association of Italian Textile Machinery Manufacturers, with the support of Ministry of Economic Development, this mission will allow Iranian textile manufacturers to measure their knowhow with some of Italy’s primary producers of textile machinery, and become acquainted with the most up-to-date solutions for the different steps involved in the textile production process.

In 2015, Italian exports towards Iran amounted to 8 million Euros. Iranian demand is spread out over all types of production, but Italian finishing and spinning machines are the primary exports. ACIMIT represents an industrial sector comprising around 300 manufacturers (employing close to 12,000 people) and producing machinery for an overall value of about 2.6 billion Euros, with exports amounting to 86 per cent of total sales. The quality of Italian textile technology is evidenced by the high number of Countries in which Italian machinery is sold: around 130 Countries worldwide.

"After the success of last year’s Wool Runway, a design challenge for university students, The Woolmark Company successfully completed the second edition on a high note. Envisioned as a celebration of tertiary fashion designers, the competition also educated young designers on working with Merino wool. Leading fashion universities, NIFT (Mumbai, Delhi, Gandhinagar, Shillong, Bengaluru, Chennai, Hyderabad, Patna and Kolkata), NID (Ahmedabad and Gandhinagar) and Pearl Academy (Mumbai, Delhi- Noida, Naraina and Jaipur) participated, educating more than 700 students on the benefits and versatility of Merino wool."

After the success of last year’s Wool Runway, a design challenge for university students, The Woolmark Company successfully completed the second edition on a high note. Envisioned as a celebration of tertiary fashion designers, the competition also educated young designers on working with Merino wool. Leading fashion universities, NIFT (Mumbai, Delhi, Gandhinagar, Shillong, Bengaluru, Chennai, Hyderabad, Patna and Kolkata), NID (Ahmedabad and Gandhinagar) and Pearl Academy (Mumbai, Delhi- Noida, Naraina and Jaipur) participated, educating more than 700 students on the benefits and versatility of Merino wool. Another 84 students participated in the competition.

A panel of industry influencers judged the final designs. The judges include designers Rahul Mishra and Nachiket Barve; menswear designer, Dhruv Kapoor; Mehernaaz Dhondy, Editor, Grazia India; Ermenegildo Zegna, Head – marketing, Diesel; Surabhi Negi, Head – marketing, Bally; and Arti Gudal, Country Manager India, The Woolmark Company. All the designs were evaluated on a strict criteria that included the use of at least 80 per cent wool per outfit, garment construction, overall presentation and more.

Displaying an eclectic mix of finalists’ designs as live installations, participants presented outfits that were an exploration of the versatile nature of Merino wool with their signature aesthetics. Ravi Manil Prakash won the Wool Runway, Abhinav Tyagi was the 1st Runner Up and Nikita Chhajer and Saachi Khattar were jointly announced as the 2nd Runner Up.

The start

The students’ journey started in August 2017 where final-year design students of leading fashion institutes were given Wool Appreciation Courses. After submitting their designs online, 14 top finalists were selected by mentor Gautam Vazirani, Fashion Curator, IMG Reliance and their respective counsellors from each institute. The finalists then designed and constructed one wool garment for the finale. “The designs were a breath of fresh air and it was amazing to see the efforts the students have put in to showcase Merino Wool at its finest.” explained Arti Gudal. “We have always believed in educating consumers on the benefits of Merino, and Wool Runway does that at a student level. It has been our constant effort to promote budding talent and give them the chance to explore possibilities in the industry while working with Merino wool. We are excited to see how the Wool Runway experience will enrich and develop the students’ careers.”

Award-winning Designer Rahul Mishra said, “I have always been honoured to associate with The Woolmark Company as they have been an essential part of my journey as a designer. Wool Runway has given me a chance to share my learning and experience in working with the intricacies of Merino wool. The fibre itself is absolutely versatile and the different dimensions that the students have added to it with their techniques is great to see. It is a great initiative and I have thoroughly enjoyed judging the wonderful talent and understanding their inspiration and the thought process behind their designs.”

Designer Nachiket Barve added, “Wool Runway is an enriching design and learning platform for aspiring students as they challenge their ability and gain recognition for their work. It has been fascinating to see how the students have managed to hero a natural fibre like Merino wool in their garments and have maximized its potential to present garments that have a balance of design aesthetic, quality and comfort. They are definitely on their way to becoming Gen Next talent!”

“It is a remarkable competition for students who want to further their understanding in the field of fashion and design through the study of Merino wool,” highlighted Dhruv Kapoor. “I have seen numerous innovative designs while judging and have noticed that the competition has exposed students to the range of roles and career paths available within the wool industry.”

A new colour-changing thread developed by researchers in the US that could open up the possibility of using garments as tactile displays worn on our bodies. Not only could one switch from a black T-shirt to a green, one could also change the logo on top. The new technology called Ebb is showing plenty of promise and could eventually lead to brand new types of smart clothing.

The colour-shifting threads change their hues in response to electrical charges. It's being developed as part of Google's Project Jacquard - one of the company's spin-off endeavours that are looking into the potential of making our clothing touch-sensitive and interactive.

The demo video released by researchers, UC Berkeley in California looks incredibly awesome, it's been sped up significantly, and that's one of the downsides of the tech in its current form. Right now, it takes a while to change colours, so any kind of fast, responsive display is out of the question for the time being.

The government’ decision to remove restriction under the Incremental Exports Incentivisation Scheme (IEIS) has been welcomed by R K Dalmia, Chairman, The Cotton Textiles Export Promotion Council (TEXPROCIL). Dalmia feels the decision of to issue duty credit scrips under the IEIS without any restriction will certainly improve the cash flow of the exporters.

IEIS for the last quarter 2012-13 was introduced vide DGFT Notification No. 27 dated 28.12.2012. The scheme extended duty credit scrip of two per cent on the incremental growth in exports during the period from January 1, 2013 to March 31, 2013 as compared to the period from January 1, 2012 to March 31, 2012 on the fob value of exports to the US, EU and Asian countries. Subsequently, DGFT issued a Notification in September 2013 restricting the entitlement under the scheme to 25 per cent growth or Incremental growth of Rs.10 crore in value, whichever is less. Many of the exporters were affected because of this restriction which was not there in the original scheme, pointed out Dalmia.

Dalmia also complimented the government for including exports of made ups falling under chapter 63 to Group C countries under the Merchandise Exports from India Scheme (MEIS). According to him, this will promote exports of Made ups to countries like Australia and New Zealand which falls under group C of the MEIS.

Apparel opportunity is finally coming towards South Asia as exports from East Asian giant China and start-ups Cambodia and Vietnam is on decline at least in the United States. According to the US Department of Commerce’s Office of Textiles and Apparel reports, after textile and apparel exports started declining in the recent months, China, Vietnam and Cambodia took the largest hit with a decline of 43.3 per cent, 22.4 per cent and 22 per cent respectively in the month of March compared with February 2016.

Textile exports decline in March ’16 compared with March ’15 was 42.1 per cent for China, 22.6 per cent for Vietnam and 34.4 per cent for Cambodia. Textile and apparel exports from India increased by 15.3 per cent in March compared with exports of same items in February 2015. Bangladesh recorded an export increase of 7.9 per cent during the same period while Pakistan’s exports in textiles and apparel increased by 8.8 per cent.

However, when compared with March 15 the increase in exports from these countries was much lower. The increase in exports from India was only 1.4 per cent, Bangladesh and Pakistan recorded negative exports of 0.1 per cent and 2.9 per cent respectively.