FW

Unrest in Hong Kong, France and Chile has affected retail sales as they have fallen 24 per cent in Hong Kong.

Even the Christmas season couldn’t help fashion retailers to get their numbers up. Historically, Hong Kong is known for being one of the key markets for luxury in the world. It represents five per cent of global luxury sales with a higher-than-average profitability for luxury groups. But the ongoing protests have led companies like Hugo Boss, Levi Strauss and Ralph Lauren to close some of their stores. Similarly, retail sales have fallen in 30 per cent in France, and 27 per cent in Chile. Strikes have crippled French transport. Sales were down 30 per cent to 50 per cent in the holiday season, a time when most retailers expect to achieve their full year results. French consumer confidence fell more than expected in December, hitting a five-month low. Paris is the headquarters of many of the fashion and luxury houses of the world.

Chile is one of the main regions in Latin America for fashion. About 60 per cent of Chilean consumers spent less amount of money during the season than the same period last year due to an increasing concern for the future of the economy as well as reducing debts.

Adidas has opened a new 45,000 sq ft hub in New York. The space houses office space and showrooms with latest products and collections.

The offices are designed according to the innovative Adidas workplace concept: it combines open, communicative areas with those of retreat areas focused for activities and meetings.

The space is intended to advance the group’s creations and give endless opportunities to their creators, and to shape the future of sport in the heart of North America.

Adidas’ also completed its building-expansion with a new office in its hometown, Herzogenaurach in Germany. The office is known as Arena, due it architectural façade, displaying the office in blocks resembling a stadium, hence the Arena christening.

The sportswear company has been growing at a steady and positive pace for that past years in both North and South America. Last December, the sportswear retailer opened new headquarters in Greenwich Village, New York. The penetration into the US market, Nike’s kingdom, is Adidas’ strategy to gain more market share.

Data from Bangladesh’s Export Promotion Bureau (EPB) shows, export earnings from the readymade garments (RMG) sector fell by 6.21 per cent to $16.02 billion during the July-December period of the 2019–20 fiscal following lower shipments of apparel items. Earnings totaled $16.08 billion in the corresponding period of the last fiscal year (2018–19).

The fall in RMG exports was due to instability in international markets and the economic recession in Europe and North America. US-China trade tensions, continuous fluctuations in world’s stock markets, devaluation of the taka against the US dollar and a rise in production costs against low prices offered by foreign buyers have caused the drop in exports.

According to AM Chowdhury Selim, Vice-President, Bangladesh Garments Manufacturers and Exporters Association (BGMEA), international economic recession and rise in the prices of utilities, gas and electricity are responsible for lower production. These have further eroded the association’s competitiveness in the international markets. As a result, the prices in international markets have dropped and export earnings show negative growth. The revised pay structure for the garments sector is also responsible.

As countries participating in the BRI initiative are expected to sign the Regional Comprehensive Economic Partnership (RCEP) this year, China’s textile industry needs to accelerate the adjustment of its products, capacity and trade structure to better integrate regional development in the next stage.

The RCEP will further enrich regional cooperative content in areas such as digital economy and intellectual property protection, paving the way for future cooperation among industries across the mega trade bloc. The rise of emerging markets such as Vietnam, India and Bangladesh has also changed the division pattern of labor and trade in the global textile business.

As data from Beijing-based CNTAC reveals: affected by weak demand from developed markets and the rise of protectionism, China’s textile and apparel exports dropped 2.2 per cent year-on-year to $232.31 billion between January and October last year.

In the meantime, the country’s shipments to the US, the EU and Japan declined by 4.5 per cent, 5 per cent and 5.5 per cent year-on-year respectively, while its total exports to countries and regions participating in the BRI grew by 1.3 per cent, and exports to Africa jumped 6.6 per cent from the same period a year earlier.

Pakistan’s textile industry is unable to meet export orders and cannot expand its operations to create an export surplus. Among the factors hindering Pakistan’s textile exports are the withdrawal of the zero rating status, the high energy cost and the cotton shortage. The industry wants the energy package continued for another five years. Sales tax is collected on value added items at each stage but refunds are only available after export. The production cycle requires 185 days to complete. This has triggered a huge liquidity crisis. Adequate finance and credit availability are stressed as vital for the growth and enhancement of the industry. Over the last five years Pakistan’s cotton production has fallen by 22 per cent which has caused a loss of almost two per cent of the total GDP. The textile industry will have to import five million bales to meet the requirements in the ongoing financial year.

Over the last one year, interest rate has increased from 5.75 per cent to 13.25 per cent, further restraining investment in the sector, along with increased working capital requirements owing to the recent devaluation of the currency. One suggestion by the industry is that advanced seed technology be available for quality seed development. Seed technology controls weeds and insects.

Lenzing is committed to reduce its carbon dioxide footprint by half by 2030. The vision is to become a carbon dioxide-neutral group of companies by 2050. With the growing wellness trend among consumers, Lenzing is developing fibers that keep users pleasantly cool and dry with natural comfort and versatility. Tencel Active is a group of cellulose fibers of botanic origin that keep the body pleasantly cool and dry with their natural comfort and versatility, enabling freedom to move with confidence. Lenzing is focused on introducing its award-winning Refibra technology and Lenzing Ecovero fibers to the active wear segment as well as the Lenzing Modal Black solution for colored fibers. Lenzing’s pioneering Refibra technology reinforces circularity through recycling cotton scraps with minimal emissions. The fully sustainable Lenzing Ecovero branded fibers offer transparent identification ensuring these viscose fibers are cleanly sourced and produced.

Water conservation is another environmental concern in the industry. Synthetic materials that are frequently used for sportswear, such as polyester, are naturally hydrophobic, making them more difficult to dye. To tackle this, Lenzing has introduced Lenzing Modal Black fibers, a spun-dyed fiber that incorporates the pigment during the extrusion production process. It can help lower energy and water consumption by 50 per cent compared to conventional dyed fabrics.

US imports of textile and clothing increased in value by 4.9 per cent in 2018. In volume terms, these imports rose by 5.9 per cent in 2018. The average price of US textile and clothing imports fell in 2018 for the seventh year in succession. The average import price declined 14.2 per cent over the seven- year period. The main cause for this was a decline in the average price of imports from China. US textile and clothing imports from China were up by 4.8 per cent in value and by 6.7 per cent in volume. While the price per sq. m. equivalent dropped year on year, the value and volume increased. As a result, the share of US textile and clothing imports which came from China accounted for 49.3 per cent in volume terms and in terms of value it accounted for 36.5 per cent. Cambodia, Bangladesh, India and Vietnam also showed a rise in value and volume to the USA. However, the shares of US imports from these countries are not really significant in value and volume terms. From January to October 2019, US apparel imports increased 2.6 per cent year on year, of which the cumulative value from China was down by 5.6 per cent.

New investments by Bangladesh garment manufacturers are focused on compliance and technology to meet buyers' requirement and workplace safety. Some are also concentrating on producing value added products. The latest technology and innovations are core in the investment as consumers’ behavior and taste are changing very fast in the fashion industry. As of now, Bangladesh has capacity in excess for some products and segments. So the new investment and expansion are focusing on new products having scope to grow. New ventures need more investments, modern technology, enhanced efficiency, productivity, compliance and environment-friendly measures to be sustainable and competitive in the global supply chain.

In 2019, many knitwear manufacturers in Bangladesh, mostly small and medium, shut down, making thousands of people jobless. Non-compliance and lack of implementation of the new wage structure are largely blamed for the closures. Other reasons are a lack of enough work orders and loss of competitiveness due to a rise in production costs. Units also complain of not getting banking support in improving compliance and meeting other necessary expenses. This is a tragedy of sorts since small factories have the capacity to offer specialized and small quantity products, which would suit the changing tastes of consumers.

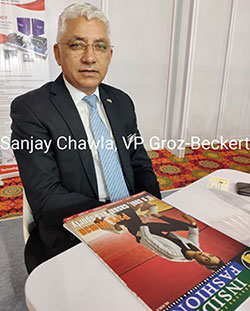

The world’s leading provider of industrial machine needles, precision parts and fine tools, Groz Beckert Asia offers its customers systems and services for production and joining of textile fabrics. The company, founded in 1852, employs more than 9,000 people and has production sites in Germany, Belgium, the Czech Republic, Portugal, the USA, India, China, and Vietnam. Sanjay Chawla, Vice President-Sales of the company expounds on its operations and the Ludhiana market.

A manufacturer of fabric forming machinery components, Groz Beckert Asia makes components for knitting and sewing, weaving, felting, tufting machines and card wires. “Our innovations help us to increase the productivity of our machines besides improving the quality of our final products and the efficiency of our systems,” notes Sanjay Chawla, Vice President-Sales of the company.

A manufacturer of fabric forming machinery components, Groz Beckert Asia makes components for knitting and sewing, weaving, felting, tufting machines and card wires. “Our innovations help us to increase the productivity of our machines besides improving the quality of our final products and the efficiency of our systems,” notes Sanjay Chawla, Vice President-Sales of the company.

Demand for machinery increases in Ludhiana

Winter has led to good sales in Ludhiana. The city is a big hub for suppliers to the domestic market. “These suppliers have already sold out their entire production, and are now adding more machines,” observes Chawla. Industry in the city is also getting more organised as focus on quality, productivity and efficiency is increasing. “This is not only increasing the demand for better machinery and components but also encouraging a better work culture and adoption of better systems,” adds Chawla

However, the knitting industry in the city is a bit stressed and facing a liquidity crunch. “As most of the knitting and garmenting manufacturers are unorganised, they are grappling with GST issues,” avers Chawla

Vertically integrated units to counter competition

The consumption of non-wovens is rising in India. “To deal with this, knitting and organised factories need to increase their production,” notes Chawla. Garment making costs are lower in Vietnam and Bangladesh as per unit time consumed in making a garment is lower in these two countries. “To compete with these two countries, India needs to set up vertically integrated units that make everything from fabrics to garments in one place,” adds Chawla.

Though India has the capability to emerge as the world’s major production hub, it first needs to cater to its domestic market which looks quite promising. “However, things move at a very slow pace in the country. On one end, we have units thinking of adopting the 4.0 technology, while on the other hand, there are units completely engaged in basic job works,” views Chawla

In future, the consumption of manmade fibers is set to rise while the knitting segment is likely to move toward finer gauges. Fashion is likely to become more sustainable,” adds Chawla.

"After a successful four decades experience in the home furnishing segment, Medusa Source ventured into the fashion apparel business. The company supplies garments to some of the top brands of North America, Europe, Latin America, Middle East, Asia Pacific and Australia. It follows the best modern supply side practices with added refinements based on its experience in the segment. Medusa constantly innovates to reduce costs that help in making the clients more competitive in the market. Sonal Jindal and Chetan Mathur, Managing Partners of the company elaborate on their operations and future plans."

After a successful four decades experience in the home furnishing segment, Medusa Source ventured into the fashion apparel business. The company supplies garments to some of the top brands of North America, Europe, Latin America, Middle East, Asia Pacific and Australia. It follows the best modern supply side practices with added refinements based on its experience in the segment. Medusa constantly innovates to reduce costs that help in making the clients more competitive in the market. Sonal Jindal and Chetan Mathur, Managing Partners of the company elaborate on their operations and future plans.

After a successful four decades experience in the home furnishing segment, Medusa Source ventured into the fashion apparel business. The company supplies garments to some of the top brands of North America, Europe, Latin America, Middle East, Asia Pacific and Australia. It follows the best modern supply side practices with added refinements based on its experience in the segment. Medusa constantly innovates to reduce costs that help in making the clients more competitive in the market. Sonal Jindal and Chetan Mathur, Managing Partners of the company elaborate on their operations and future plans.

Highlight your company’s operations and achievements over the years.

A supply chain management company, Medusa Source provides product-sourcing solutions to brands, retailers, labels and wholesalers worldwide. Our work includes identifying and evaluating factories, design and development assistance, production follow-ups, stringent quality control, logistics and shipping consolidations. We have a wide network comprising 150 suppliers and manufacturers across India, Nepal and Sri Lanka.

What is the vision behind the company?

We have been involved with product sourcing for over four decades. However, our method of functioning has transformed over years as we have adopted new methods of doing business to suit client’s interests.

business to suit client’s interests.

What has been your experience so far?

A production-oriented business faces new challenges every day. However, these challenges teach a manufacturer to deal with people in changing demographics, different working conditions, and different cultures. So far, our journey has been extremely rewarding and we plan to elevate our business to new highs in future.

Which services and solutions do you provide to your partner brands?

We are involved in complete supply chain management cycle. From identifying the right vendor, factory audits and compliance checks, assisting product development, order follow-ups, quality control to shipping consolidations, we provide complete sourcing solutions.

Who are the people responsible for growth and journey of your company?

Our Managing Partners, Sonal and Chetan navigate the ship. They are ably supported by a young and enterprising team of designers, merchandisers, quality controllers, audit and compliance managers, IT, admin & HR. Each member of the team is committed to his or her job responsibilities and understands the importance of delivering quality and efficiency. Some team members have been with us for over 20 years, and have contributed immensely to the company’s growth. They are trained to handle delicate situations especially ground level production issues and response time to the clients, etc.

What are the new opportunities in this segment?

India is seen as a major production hub for value-added garments and accessories. However, we are capable of delivering much more than this. With adequate access to raw materials, and investments in machinery and technology, our manufacturers can produce high quality and fashionable products at similar or better quality levels than Western countries.

What challenges do you face as a supply chain management company? Fluctuating currencies, rising labor and material costs, increasing competition, lack of skilled labor, political changes, complicated and high tax structure, traceability and accountability in the production cycle and lack of infrastructure are some of the challenged we currently face.

Which is the most scalable segment for you? Who are your competitors?

Amongst all categories that we currently handle, Ready-to-Wear (RTW) garment is the most scalable product segment. Our competitors are large sourcing and supply chain management companies. However, we consider them more as peers rather than competitors and look up to them to achieve the same level of technological advancements that they have achieved. We are also investing in IT-driven tools to make our processes more sustainable, improve our performance levels and be a leader in the industry.

What is your take on the global and domestic apparel and fashion market?

The emergence of e-commerce companies and penetration of fast fashion product lines have changed the whole ball game for both global and domestic apparel and fashion makers. Changing trends, looks, themes and fashion are giving established brands a run for their money. Consumers can buys outfits similar to those offered by high-end luxury brands at a fraction of price. This has pushed manufacturers and sellers to focus on price-driven product lines rather than only quality driven.

What are your future plans?

We plan to increase RTW exports to the European and American markets in the next two years.