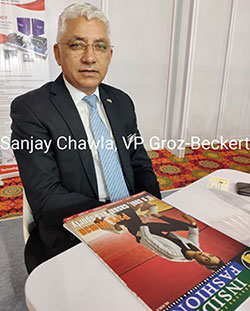

The world’s leading provider of industrial machine needles, precision parts and fine tools, Groz Beckert Asia offers its customers systems and services for production and joining of textile fabrics. The company, founded in 1852, employs more than 9,000 people and has production sites in Germany, Belgium, the Czech Republic, Portugal, the USA, India, China, and Vietnam. Sanjay Chawla, Vice President-Sales of the company expounds on its operations and the Ludhiana market.

A manufacturer of fabric forming machinery components, Groz Beckert Asia makes components for knitting and sewing, weaving, felting, tufting machines and card wires. “Our innovations help us to increase the productivity of our machines besides improving the quality of our final products and the efficiency of our systems,” notes Sanjay Chawla, Vice President-Sales of the company.

A manufacturer of fabric forming machinery components, Groz Beckert Asia makes components for knitting and sewing, weaving, felting, tufting machines and card wires. “Our innovations help us to increase the productivity of our machines besides improving the quality of our final products and the efficiency of our systems,” notes Sanjay Chawla, Vice President-Sales of the company.

Demand for machinery increases in Ludhiana

Winter has led to good sales in Ludhiana. The city is a big hub for suppliers to the domestic market. “These suppliers have already sold out their entire production, and are now adding more machines,” observes Chawla. Industry in the city is also getting more organised as focus on quality, productivity and efficiency is increasing. “This is not only increasing the demand for better machinery and components but also encouraging a better work culture and adoption of better systems,” adds Chawla

However, the knitting industry in the city is a bit stressed and facing a liquidity crunch. “As most of the knitting and garmenting manufacturers are unorganised, they are grappling with GST issues,” avers Chawla

Vertically integrated units to counter competition

The consumption of non-wovens is rising in India. “To deal with this, knitting and organised factories need to increase their production,” notes Chawla. Garment making costs are lower in Vietnam and Bangladesh as per unit time consumed in making a garment is lower in these two countries. “To compete with these two countries, India needs to set up vertically integrated units that make everything from fabrics to garments in one place,” adds Chawla.

Though India has the capability to emerge as the world’s major production hub, it first needs to cater to its domestic market which looks quite promising. “However, things move at a very slow pace in the country. On one end, we have units thinking of adopting the 4.0 technology, while on the other hand, there are units completely engaged in basic job works,” views Chawla

In future, the consumption of manmade fibers is set to rise while the knitting segment is likely to move toward finer gauges. Fashion is likely to become more sustainable,” adds Chawla.