FW

A few Washington lawmakers are advocating for the passing of the House Bill 1107 for increased transparency in the fashion industry’s environmental and labor practices.

Introduced by Rep. Sharlett Mena (D-Tacoma) at the start of the 2025 legislative session, the bill targets fashion companies with gross income exceeding $100 million, requiring them to disclose their impact on the environment and labor standards.

The bill responds to growing concerns over fast fashion's environmental toll, including excessive waste, pollution, and resource consumption. For instance, producing a single pair of jeans requires up to 10,000 liters of water, equivalent to 10 years of drinking water for one person, according to the United Nations.

Past iterations of the bill failed to advance in 2022, 2023, and 2024. However, this year’s version includes updated requirements for fashion manufacturers to report on chemicals in clothing, environmental marketing claims, disposal practices for unsold items, and pollution-reduction initiatives. The reports would help Washington’s Department of Ecology develop policies to minimize the industry’s environmental impact.

Companies that fail to comply could face penalties, with funds directed to underserved communities impacted by environmental harm.

Supporters, like Kathryn Horvath, WashPIRG argue the bill provides much-needed transparency, enabling the state to mitigate waste and pollution. They note that many large companies, such as Nike, already produce similar reports.

However, critics raise concerns about the bill’s feasibility. The Washington Retail Association warns it could lead to higher costs for consumers and fewer clothing options in the state. The Department of Ecology, which remains neutral, has expressed reservations about its ability to oversee global supply chains and suggested involving other state agencies.

As Washington’s 105-day legislative session unfolds, lawmakers will determine whether the state is ready to lead the charge on fashion industry accountability or if this proposal will remain on the shelf.

An operator of PET plastic and polyester fiber recycling technology, Loop Industries has ended its joint venture with South Korean company Geo Centric (SKGC). Established in early 2023, the partnership aimed to build and operate an Infinite Loop manufacturing facility in Ulsan, South Korea.

The decision to terminate the agreement aligns with Loop’s strategy to focus on deploying capital in low-cost regions and prioritizing a licensing and engineering services model in higher-cost countries. A regulatory filing also cited strategic restructuring and reorientation within the SK Group as factors in the decision.

As part of this reorganization, Jonghyuk Lee, SKGC stepped down from his position as the Board Member with Loop on January 13, 2025. Despite the termination, SKGC plans to maintain its financial investment in Loop.

While the dissolution of the South Korean agreement poses a challenge for Loop, the company is advancing its plans for a facility in India. Following a land study, Gujarat was identified as the optimal location for the project. In partnership with local firm Ester, Loop is conducting due diligence on land acquisition and has engaged third-party contractors to manage construction and accounting.

The Indian facility is expected to be launched in Q2, FY25 with construction set to be completed by late 2026. Commercial operations are projected to begin in 2027.

The Indian facility will cater to the growing demand from circular fashion brands for textile-to-textile (T2T) polyester. By utilizing waste polyester feedstocks from India, the facility will produce polyester resin made entirely from textile waste, supporting sustainable practices in the fashion industry.

World’s largest spandex manufacturer by market share, known for its Creora and regen brands, Hyosung will showcase customized solutions for the denim industry at Kingpins New York. The event will be held at Basketball City from January 22–23. 2025.

The company will present its new denim innovations including an expanded regen BIO range featuring regen BIO+ and regen BIO Max, both containing higher amounts of renewable content.

It will also showcase the RCS-certified 100 per cent recycled regen, made from industrial waste, along with Creora 3D Max. This product provides excellent stretch and recovery with minimal spandex content, making garments easier to recycle. Additionally, Hyosung will unveil Creora Slip Free, which enhances seam slippage resistance.

Simon Hong, Global Marketing Director, Hyosung opines, it is important to provide tailored solutions to meet brands’ unique needs as they diverse approaches to sustainability, using recycled and bio-based materials or focusing on recyclable product.

Hyosung continues to support the Kingpins Future Fits Forum and will host a seminar on denim fashion trends during the forum. The company will exhibit in Stand 10 in the green area in the exhibition.

India and the United Kingdom are set to resume negotiations for a proposed Free Trade Agreement (FTA) in early February 2025, as confirmed by a commerce department official. The talks, which initially began in January 2022, aim to deepen trade ties between the two nations and foster economic collaboration.

Simultaneously, efforts are underway to revise the India-ASEAN FTA, with the next round of discussions scheduled to start in Indonesia on February 10. The talks will concentrate on resolving lingering issues related to goods trade, according to Rajesh Agrawal, Additional Commerce Secretary.

Progress is also being made on the India-Eurasian Economic Union (EAEU) FTA. The commerce department announced that the terms of reference for the agreement are nearing finalization. The EAEU includes Armenia, Belarus, Kazakhstan, Kyrgyzstan, and Russia, presenting significant trade opportunities for India.

In an innovative move to enhance trade insights, the Indian government is developing an AI-powered data analytics platform. Highlighting its capability to assess export trends and resilience, providing critical insights for decision-making, Sunil Barthwal, Commerce Secretary Barthwal notes, whether there is consistency in our growth or not, these kinds of insights are now coming.

To address discrepancies in trade data, a joint committee of commerce and finance ministry officials has been formed. This follows prior errors in gold import calculations, prompting the creation of a mechanism for publishing accurate and consistent trade data.

Meanwhile, the Department for Promotion of Industry and Internal Trade (DPIIT) is pursuing foreign direct investment (FDI) reforms. Consultations have been held with private equity firms, venture capitalists, and pension funds to reverse declining FDI inflows, which have averaged $70 billion annually over the past five years. The government is targeting $100 billion in annual FDI inflows over the next five years by streamlining policies and making India a more attractive investment destination.

Earlier, the DPIIT engaged with industry associations and legal experts to gather feedback on the FDI framework, underscoring its commitment to fostering a robust investment environment.

Fueled by advancements in technology, increased global cotton production and a growing demand for efficient harvesting methods, the cotton picker market is experiencing significant growth. As per a TMR study, valued at $707.4 million in 2023, the market is projected to expand at a CAGR of 5.2 per cent from 2024 to 2034, reaching $1.2 billion by the end of the forecast period.

The adoption of cotton pickers is revolutionizing agriculture by improving efficiency, reducing labor dependency, and increasing productivity. It has led steady rise in global cotton production with key producers—India, the United States, China, and Brazil—contributing around 73 per cent of total output. According to the USDA, cotton production increased by 6 per cent during the 2021/2022 season, driven by growing demand from the textile industry, where cotton accounts for nearly 50 per cent of all fabrics.

Automation in agriculture is transforming cotton harvesting. Cotton pickers enable faster, more efficient harvesting, especially in regions requiring multiple harvests per season. Mechanical harvesting is particularly popular in countries like the US, Australia, and parts of Europe, where it reduces labor costs and enhances productivity.

The Asia-Pacific region dominates the cotton picker market, accounting for over 60 per cent of global production in 2023. Key contributors include China, India, and Pakistan, where government incentives and a booming textile industry drive demand. Other regions, like North America, emphasize technological innovations, while Europe focuses on sustainable solutions, and Latin America works to improve agricultural productivity.

Modern cotton pickers feature advanced technologies, including GPS tracking, sensors, and real-time monitoring, ensuring precision and reducing waste. As the demand for eco-friendly solutions grows, manufacturers are adopting sustainable practices and forming partnerships to expand their global presence. These advancements make cotton pickers essential for the future of efficient, sustainable agr iculture.

A logistics firm under the DHL group, Blue Dart which currently handles about 8 per cent of e-commerce shipments in India, aims to increase its share to 25 per cent within the next five years Pablo Ciano, Global CEO, DHL E-commerce, says, the company is investing in infrastructure, technology, and capacity expansion to achieve this ambitious goal.

Independent logistics providers, including Blue Dart, currently manage around 6 million e-commerce shipments daily across India, while in-house operators like Amazon handle approximately 8 million shipments per day.

The company inaugurated a new integrated facility in Bijwasan, Delhi, capable of processing 200,000 e-commerce shipments daily. Ciano describes this as a ‘mid-level’ facility, noting that a larger ‘main hub’ for surface transport in northern India will open in July. This hub will handle ground shipments exclusively and will be 2.5 times the size of the Bijwasan facility, reflecting Blue Dart’s strategy to expand capacity nationwide.

In addition to infrastructure, Blue Dart is making significant investments in customer-facing technology.

Ciano also announced plans to modernize Blue Dart’s air fleet. The company operates eight aircraft, including six B757s and two B737s. Over the next three to five years, the capacity of the B757 planes will be increased by 50 per cent, bringing them on par with the B737s, which currently handle up to 45,000 tons annually.

To further boost its market presence, Blue Dart will launch an ‘export-deferred cross-border product’ service within the next 12 months. This service will allow e-commerce exporters to defer export duty payments for up to 60 days, providing a cost-effective solution for global trade.

Kim Glas, President and CEO of the National Council of Textile Organizations (NCTO), issued a statement praising US Customs and Border Protection’s (CBP) proposed rule to limit the use of the de minimis exemption for imports, a loophole that has been detrimental to US manufacturing and consumers.

In her statement, Glas highlighted that the proposed rule seeks to exclude de minimis benefits for imports affected by US trade remedies, such as Section 301 tariffs on Chinese goods. These imports, which typically enter the US duty-free under the de minimis provision, often evade penalties normally imposed on products that violate US trade laws. Glas argued that this loophole has led to a surge of illegal imports, harming US manufacturing jobs and industries, particularly the textile sector.

CBP noted that de minimis shipments entering the US have skyrocketed over the past decade, rising from 139 million shipments in fiscal year 2015 to over 1.36 billion in FY 2024. This exponential increase, CBP stated, has posed significant challenges to enforcing trade laws, as well as ensuring consumer protection, intellectual property rights, and health and safety standards.

Glas emphasized the need for swift reform, urging the administration to act quickly on this overdue rule. She also called on the incoming Trump administration to not only support the proposed rule but also implement more comprehensive measures to address the de minimis issue, including an executive order to end the exemption entirely. Furthermore, she urged Congress to collaborate with the new administration to provide a permanent solution to the problem, ensuring fair competition for US manufacturers.

NCTO expressed its commitment to working with CBP, the administration, and lawmakers to resolve this pressing issue.

British fashion retail sales to the EU have plummeted post-Brexit, with exports dropping over 60 per cent from £7.4 billion in 2019 to £2.7 billion in 2023, according to the latest Brexit to Breakthrough report by Retail Economics and Tradebyte. Overall, UK retail sales to the EU have fallen by £5.9 billion.

Clothing, once a top UK export, has been overtaken by health and beauty, electricals, DIY, and gardening, which now account for three-quarters of non-food retail exports. Despite inflation softening the impact, the total value of UK non-food retail exports to the EU has still declined nearly 18 per cent since 2019.

Brexit-related trade frictions including higher logistics costs, customs complexities, and regulatory hurdlescontinue to stifle international online retail. These barriers are limiting UK brands access to the EU’s £322.6 billion e-commerce market.

However, onlinee marketplaces have emerged as a key survival strategy, now accounting for £133 billion (40 per cent) of EU e-commerce. Richard Lim, CEO of Retail Economics, emphasized their importance in helping UK retailers navigate Brexit’s long-term effects.

While Brexit has reshaped UK retail, digital marketplaces are proving essential for brands looking to rebuild European trade and drive future growth.

Record international participation and visitor growth

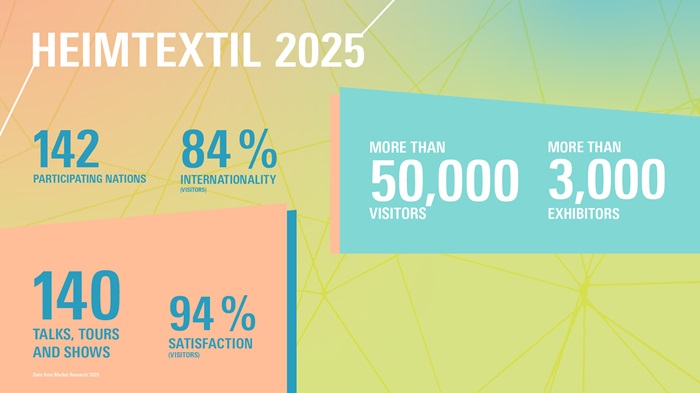

Heimtextil 2025, held in Frankfurt, Germany, wrapped up as a resounding success, with full exhibition halls, 142 participating nations, and significant increases in both exhibitors and visitors. Over four days, the event welcomed more than 50,000 buyers who experienced the latest collections, materials, and textile solutions from over 3,000 exhibitors. With a marked increase in international participation, the exhibition reinforced its position as the leading global trade fair for home and contract textiles.

Notably, the international share of exhibitors rose to 96 per cent, with leading countries such as China, India, Pakistan, Turkey, Germany, Italy, Spain, Portugal, and Belgium dominating the showcase. On the visitor side, international attendance also surged to 84 per cent, with particularly strong growth from markets like Argentina, France, Great Britain, India, Japan, Canada, Sweden, South Korea, Spain, the United States, and the United Arab Emirates.

Detlef Braun, Member of the Executive Board of Messe Frankfurt, highlighted the growing demand for trade fairs, stating that in challenging economic times, market presence and resilience were essential. "Heimtextil enabled industry and retail to access new markets and shape global competition," Braun explained. Exhibitors also reported high satisfaction, with 81 per cent achieving their trade fair goals. Visitor satisfaction hit an impressive 94 per cent, demonstrating increased engagement and decision-making among top buyers.

Patricia Urquiola’s immersive textile design

A key highlight of the event was Patricia Urquiola’s immersive installation, ‘among-us,’ which set new standards for textile-based interior design. The installation, aimed at hospitality and retail decision-makers, demonstrated the potential of textiles in architecture and interior design. The atmospheric space combined functional design with innovative textile solutions, offering a forward-thinking vision of future living environments.

Urquiola’s showcase exemplified the increasing role of textiles in shaping progressive, sustainable, and aesthetically bold interiors for retail and hospitality sectors, creating a buzz among trade visitors seeking new concepts and ideas.

Heimtextil trends 25/26: Shaping textile design’s future

The Heimtextil Trends 25/26, curated by the Milanese design platform Alcova, provided critical guidance to the retail sector amid evolving consumer preferences and restrained spending. The trend themes ‘Naturally Uneven,’ ‘Radically Restructured,’ and ‘Regenerative’ highlighted the growing consumer demand for durable, high-quality products with ethical and ecological considerations.

Alcova’s Trend Arena showcased contemporary materials, techniques, and production processes, offering solutions for the industry’s ongoing challenges. The 2025 color palette, including tones such as Revival Mud, New Green Deal, and Syntropic Forest, captured the essence of a more sustainable and conscientious approach to interior design.

AI and Circularity: Leading the way in innovation

Heimtextil 2025 also placed a strong emphasis on innovation, with a comprehensive content program featuring over 140 lectures, workshops, and guided tours. Key topics included AI-driven design, circular production processes, and sustainable business practices. The event’s focus on AI demonstrated how artificial intelligence is reshaping traditional textile production and customer care, opening up new business opportunities in the industry.

Olaf Schmidt, Vice President of Textiles & Textile Technologies at Messe Frankfurt, emphasized the importance of Heimtextil as a hub for global knowledge exchange. "With our new partnerships and expertise on circularity, we are helping businesses thrive in a changing world," Schmidt remarked.

The event's extensive program not only addressed the industry's technological advances but also provided a platform for promoting sustainable practices and economic growth within the retail, hospitality, and interior design sectors.

Heimtextil 2026: Driving textile innovation forward

The success of Heimtextil 2025 has set the stage for the next edition, taking place from January 13 to 16, 2026. Patricia Urquiola will return to further develop her innovative design concepts, setting new benchmarks for textile-based room designs. Alcova Milano will also continue its exploration of innovative materials and emerging trends, providing valuable insights that will shape the future of textile interior design.

As Heimtextil continues to drive transformation in the textile industry, the 2026 edition promises to deliver even greater value for exhibitors, visitors, and the global textile community.

To enhance its position in the luxury fashion industry and advance its strategic goals, Lanvin Group announced significant leadership and board changes recently.

The group appointed Andy Lew, CEO, St John Knits as the new Executive President of the Lanvin Group. He will replace, Eric Chan, the current CEO, who will transition to the role of a board director. The company says, these changes reflect its commitment to fostering a dynamic leadership team capable of driving innovation and sustainable growth in a rapidly changing market.

With over 35 years of experience in the fashion industry, Lew has a proven track record in leadership and operational excellence within the luxury sector. In his new role, he will oversee Lanvin Group’s global operations including strategic management, business development, financial management, supply chain, IT and brand operations. He will also lead the establishment of the group’s second headquarters in Europe.

Lew’s extensive background includes senior roles at Brooks Brothers Group, Ermenegildo Zegna Group, and Nordstrom Inc., where he led business expansions, high-performing teams, and operations in complex global markets.

In addition to the leadership changes, Lanvin Group has also expanded its board members from eight to nine. It appointed Alan Liu as a director, replacing Grace Fang with Eric Chan’s new role as a director also coming into effect immediately.