FW

At the second annual meeting of the Bangladesh-US Trade and Investment Cooperation Forum Agreement (TICFA) held on Monday in Washington, Bangladesh has expressed that the newly formed Trans-Pacific Partnership (TPP) may have an adverse impact on the country’s exports.

The Bangladesh embassy in Washington, in a statement, said Dhaka believed this TPP might “adversely impact” its exports to the US and some other TPP countries. The US, Australia, Canada, Japan, Malaysia, Mexico, Peru, Vietnam, Chile, Brunei, Singapore and New Zealand are the members of the recently formed TPP. However, US Embassy’s Deputy Chief of Mission David Meale had earlier said before the TICFA meeting that if “Bangladesh decides it is willing to meet the overall TPP standards, it might one day wish to signal interest in joining”.

Commerce Secretary Hedayetullah Al Mamoon led the Bangladesh side while Assistant US Trade Representative Michel Delany headed his side in the TICFA meeting. They discussed issues including progress on workers’ rights, Sustainability Compact and GSP Action Plan, investment climate in Bangladesh, transformation of Bangladesh, market access and responsible business conduct. The meeting also deliberated on the Istanbul programme of action, Bali package implementation, fair pricing, TPP, blue economy, and infrastructure, among other things.

Bangladesh presented the progress it had made in workers’ rights, and factory safety norms. It also urged the US to grant duty- and quota-free market access to its products as per Hong Kong Ministerial Declaration and Bali package, adopted in Bali WTO Ministerial.

Ustr.gov

Mincom.gov.bd

The state of Rajasthan is emerging as one of the most important textile hub and owing to the labour-intensive nature of the sector, the state government has identified it as one of the thrust areas.

At an event held in New Delhi recently, the Rajasthan government signed MoUs worth Rs 2,530 crores with several private companies eyeing establishments in various textile units. The move is expected to generate about 8,000 direct jobs as well as thousands of indirect ones. The investment proposals received by the government covers wide spectrum of the textile industry such as technical textile, recycled fibre, spinning, yarn, seamless garments and denim fabric, among others.

Rajasthan has also emerged as the largest producer of polyester viscose yarn and synthetic suiting material in the country with Bhilwara becoming the leading centre of production. While Barmer has been added in the list of towns of export excellence, Pali and Balotra are developing as centres textile processing. Besides PV suiting, the state has also made a name for itself in the processing of low-cost and low-weight fabric. Bhilwara and Kishangarh are major power loom centres in the state with over 20,000 functional looms and over 95 crores metres of different blends of polyester fabrics such as polyester wool, polyester viscose modal, and polyester viscose elastane produced annually in the state.

And other places like Jodhpur, Pali, Sanganer, and Kota are popular for traditional handloom, fabric and printing and Jaipur for fashion garments. Apart from these industries, quality cotton cultivation is also being promoted in the districts of Bhilwara, Chittorgarh, Ajmer, Jodhpur, Bikaner, Nagaur, Ganganagar and Hanumangarh. And the quality of wool produced in the western belt is ideal for carpet weaving. The Centre has established Wool Development Board of India, headquartered in Jodhpur for growth and development, marketing, testing of raw materials, marketing intelligence, price stabilisation, product development, and for advising the government on policy matters and coordination.

owing to the importance and potential of the textiles sector in the state's economy, textiles, including technical textiles have been included in the state's list of thrust sectors in the Rajasthan Investment Promotion Scheme, 2014. Six integrated textile parks have also been sanctioned in Rajasthan with product categories ranging from hand printed fabrics, garments, weaving, spinning, and carpets to textile processing units.

Rajasthan.gov.in

Invista, which started building two new plants for hexamethylene diamine (HMD) and a nylon 6.6 polymer at the Shanghai Chemical Industry Park in China, March last year expects the HMD plant to be operational by the end of 2015 and the nylon 6.6 in early 2016.

The facility, upon becoming operational, will be well-positioned to serve the quickly growing Asia Pacific markets for a variety of nylon 6.6 applications. It will also provide customers with a local resource for the production. The HMD plant will have a production capacity of 215,000t a year, whereas the nylon 6.6 polymer plant will have a production capacity of 150,000t a year. Invista further plans to add a 300,000t adiponitrile (ADN) plant at the site in future using its proprietary technology.

The new plants are expected to be among the world's most energy-efficient nylon intermediates sites and will be equipped with Invista's most advanced technologies for ADN, HMD and polymer production. The combined investment on the three plants will exceed $1billionn, marking the biggest investment ever undertaken by Invista.

Hexamethylene diamine, adiponitrile and nylon 6.6 polymer products are used in the production of nylon 6.6 fibres and polymers that are eventually used to manufacture automobile parts, airbags, apparel, carpet, outdoor equipment and more.

www.invista.com

Cotton procurement by government agencies has begun in Maharashtra. The Maharashtra State Co-Operative Cotton Growers Marketing Federation ( MSCCGMF) has procured around 39,641 quintals so far this season. Some 34,732 quintals of cotton have been procured from Nagpur and 4,929 quintals from Aurangabad. Another 33,000 quintals have been procured by traders.

The federation at the start of the season had said it was ready to procure up to 100 lakh quintals as against the 27 lakh quintals it had purchased last season. The government has fixed the Minimum Support Price at Rs 4,100 per quintal for long staple cotton and at Rs 3,800 per quintal for medium staple for the 2015-16 marketing year. The amount will be credited directly into the bank accounts of farmers.

Meanwhile, the Cotton Corporation of India (CCI) has begun its MSP operations across Andhra Pradesh, Telengana and Maharashtra. It has so far purchased 3,000 to 4,000 bales in Telengana and Andhra Pradesh. Cotton procurement will be much lower this season because prices have not fallen below the MSP in most places. CCI will buy at comparatively higher prices. The corporation plans to open over 300 centers across the country and will procure mainly in Telengana, Andhra Pradesh and partially in Maharashtra.

Focus on green technologies a big draw

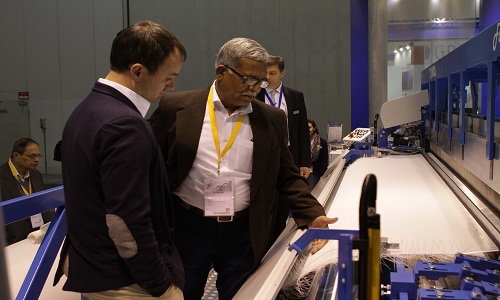

Themed ‘Master the Art of Sustainable Innovation’, ITMA 2015 featured exhibits from the entire textile and garment making value-chain spread over 108,268 sq. mt. of net exhibition space at Fiera Milano Rho. Organised by MP Expositions, it also featured several conferences with the sustainable agenda, as well as the first ITMA Sustainable Innovation Award.

“Sustainability as a theme is not just a word visible everywhere, rather it has been truly reflected in innovations that technology producers have presented showing industry has accepted sustainability as a way the way forward. Exhibitors have been able to integrate this theme in their innovations and developments. We have taken few initiatives towards conducting sustainability awards and so on. Introduction of new technology, innovations that are sustainable is the main challenge considering the global economic conditions,” said Charles Beauduin, President of CEMATEX.

Conventionally sustainability is seen as an emphasis at the front end of value chain such as brands and consumer level, found prime place at ITMA. The fair integrated sustainability as the main agenda and theme, that was visible and felt everywhere not just in discussion forums, conferences and interactions, but also as a part of exhibitors’ offerings. The emphasis was on how technology could save manpower, energy, water and costs and cause less impact on environment. Introductions of waterless technologies, dry processes, methods to recycling the resources and using natural sources of dyes and chemicals, usage of less pollutant raw material etc, in all sectors of technology made the exhibition much more relevant to the current global economic and environment conditions.

“The theme for 2015 is sustainable innovation. The topic of sustainability has always been important. We have been trying to push that message across since the last edition in 2011. In 2015 we have stressed on sustainability even more strongly. We have encouraged our exhibitors to incorporate the topic of sustainability into their displays and presentations. Sustainability is not just a marketing strategy. It is small steps by each of us toward a better future. We have organized a Sustainable Innovation award. I think we have achieved what we set out to do,” opined Eileen Ng, Executive Director, MP Expositions, organising partner of ITMA.

Overwhelming response mark of success

CEMATEX, the European Committee of Textile Machinery Manufacturers, and owner of ITMA and ITMA ASIA, saw an encouraging and overwhelming response from the industry, both from exhibitors and visitors alike. As Beauduin, says, “We registered a 20 per cent jump in visitor numbers compared to ITMA 2011. More importantly, from participants’ feedback, we can confidently say that this is one of the best ITMA exhibitions. Our message on sustainability has resonated greatly with buyers.”

He praised the industry’s resilience and forward-looking agenda, adding that global players have understood the importance of investing in innovations that are planet-friendly and which can also help improve their business bottomline. “Our exhibitors have discovered that visitors, whether they are seasoned ITMA visitors or those attending the exhibition for the first time, are serious about checking out new innovative solutions to improve their competitive edge.”

Reiterating a similar sentiment, Regina Brückner, CEO of Brückner Trockentechnik, Germany, said, “We felt for the first time there’s a real understanding and interest in energy efficiency and green technology. There’s a trend among our customers to want and upgrade their old equipment because they understand the necessity of a highly productive and efficient production over the entire textile production process.”

Overall, exhibitors felt that the quality of visitors was high with a strong buyer interest. Visitors from Italy formed the biggest contingent. They accounted for 18 per cent of the visitors. Outside Italy, the top visiting countries were India (9 per cent), Turkey (8 per cent) and Germany (7 per cent). Among other countries the top 10 in terms of visitor numbers were: France, United States, Iran, Brazil, Pakistan and Spain. The lifting of sanctions on Iran in the near future has buoyed the country’s textile and garment sector, resulting in more visitors.

Indians mark their presence

ITMA 2015 welcomed many groups from the Indian sub-continent. The number of visitors from India was highest after the hosting country. The who’s who of India’s corporate including Sanjay Lalbhai of Arvind Mills and Vardhman Textiles, who managed to clinch multibillion deals. Nahar Textiles and Trident with group strength of almost 50 technical professionals respectively, showed the seriousness and high involvement of India’s industry in ITMA.

There were delegations from Central Asia, a region where the textile and clothing industry is slated for development as the sector has the potential to create jobs. A 140-strong Uzbekistan textile and garment industry delegation spent three days at the exhibition. It was coordinated by the Textile and Garment Ministry of Uzbekistan.

“ITMA 2015 is really the world’s largest textile and garment manufacturing technologies platform which also introduces innovative and eco-friendly machinery. The Ministry aims to modernise the industry with innovative technologies which can create additional value and eco-friendly solutions which will help our manufacturers to compete in the textile world market. We have signed contracts with a number of ITMA exhibitors in the weaving, printing, dyeing and finishing sectors and we will start installation from early 2016 up to 2019,” said Khaydarov Ilkhom Utkirovich, Minister of Textile and garment industry from Uzbekistan.

In addition, there was a delegation of 48 representatives from small and medium-sized enterprises (SMEs) from the textile and clothing sectors in Kyrgyzstan and Tajikistan. The group was coordinated by Geneva-based International Trade Centre (ITC), a joint agency of the World Trade Organisation and the United Nations. A Russian delegation of 60 members was led by Evgeny Ryzhov, Deputy Director of the Russian Ministry of Industry and Trade. “ITMA 2015 allowed our domestic companies to learn about the latest technologies for the light and textile industry, enabling them to consider implementing them in their own production, purchase production equipment and to exchange experience with foreign colleagues,” he pointed out.

Printing, a new chapter at ITMA

Launched as a dedicated sector at ITMA 2015, the printing chapter featured many established and new exhibitors. First-timer Fujifilm showcased its capabilities as a complete solution provider in digital textile printing. Terry O'Keeffe, Strategic Customer Support Manager of Fujifilm, said, “ITMA has been an excellent platform for us to feature many exciting new developments in the digital sphere to a targeted audience. Our technology was well received with good customer feedback that our technologies significantly contribute to the current and future digital textile market needs.”

Exhibitors from other sectors were also impressed with the quality of visitors. As Etienne Leroi, General Manager of NSC Fibre to Yarn said, “This year’s ITMA has fully met expectations. We have received numerous customers from all over the world, who have shown great interest in our latest developments. This confirms once more the importance of such an international event.”

“We have also had good participation from research and innovation institutions. This is one area where we see growth. Technology for this is growing a lot faster. Whole garment knitting technology allows room for smaller players as well to be in the game. We see a movement toward customised requirements. There is a lot more machinery for increased productivity,” avers Eileen Ng, Executive Director, MP Expositions.

At the close of the exhibition on November 19, 2015, Carlo Rogora, CEO of ITEMA Group, said, “Considering the current situation in the textile industry in some markets, we are pleasantly surprised with these results. ITMA 2015 has been especially satisfactory, both in terms of the organisation and logistics of the show and the significant level of attendance of customers. The contacts and orders we established, above all from India and Turkey markets, largely exceeded our expectations.”

ITMA 2019 will be held from June 20 to 26 at Fira de Barcelona Gran Viafairground. “The over enthusiastic response the event has generated , with never before kind of visitors, the event certainly gives us a great confidence that our members of CEMATEX will experience the demand in revival of machinery industry as well as textile and apparel industry across the world. Going forward, for 2019 ITMA in Barcelona, we will surprise you with the new theme of the event,” exclaims Beauduin.

www.itma.com

Karl Mayer known warp knit machines has launched tricot machines that has attracted a lot of attention. The HKS 2-SE machine is very convincing especially by its low energy option. The HKS 4-M EL is impressive because of its flexibility during pattern change, made possible by the EL equipment. As for warp preparation unit, the new all round sectional warper Pro Warp and the extra-wide multi matic MM 128/3.600 are grabbing attention.

Moreover, Karl Mayer’s new weft tronic HKS for producing semi-technical articles of completely new styles is generating a lot of buzz. Karl Mayer’s tricot machines are available in a number of different versions. Depending on the intended end use and fabric construction, customers can choose between machines equipped with two, three or four guide bars. Specialist machines are also available for producing stretch and non-stretch fabrics and the company also offers flexible, all round machines.

The warping machine program is guided by the requirements of yarns to be processed. The DS-DNC series provides a concept for manmade filament yarns that is tailored individually to the current warp beam sizes. Machines having a width of 50 inches and over offer the option of tandem warping where two warp beams are produced in parallel.

www.karlmayer.com/

Textile exports from Pakistan in October 2015 fell 0.17 per cent compared to September 2015. Total exports during the July-October period fell 13.48 per cent compared to the corresponding period last year.

In October, cotton exports clothes rose 3.60 per cent in value over September 2015 but recorded a downfall of 0.14 per cent as against October 2014. Knitwear exports plunged 6.55 per cent in value over September this year and against 7.98 per cent in the corresponding period last year. Exports of readymade garments from Pakistan registered an increase of 13.01 per cent in value over September this year and 1.32 per cent in October last year.

On the other hand in the month of October, bed wear witnessed a dip of 5.46 per cent in value over September this year and 7.39 per cent against October last year. Similarly in October 2015 towels noted a 15.40 per cent dip in value over the ninth month of the year and 16.76 per cent against October last year. However export of cotton yarn in October this year registered an increase of 0.03 per cent in value over September this year and 27.58 per cent over October last year.

Imports into Pakistan increased 12.65 per cent in October 2015 compared to September 2015 but recorded a plunge of 7.41 per cent as compared to October 2014.

In the 3rd quarter of 2015, VF Corporation’s total revenue was $3612.83 million, out of which Jeanswear was $747.87 million which is a 20.57 per cent share of the total revenue. The share of jeanswear has fallen marginally while Outdoor & Action Sports has taken a big jump of about 2 per cent in sales. Athleisure trend seems to have brought this change at VF. The increase of about $100 million in VF sales can be mainly attributed to the Outdoor and Action Sports segment.

Even total sales reported during the nine months suggest that only Outdoor & Action Sports segment managed a positive growth while all other segments experienced a fall in turnover. The increase of sales this year of about $260 million can be wholly attributed to the outdoor segment. For the first nine month of 2014, the sales figure was $8,703.30 million while for the same period in 2015, the sales increased by about 3 per cent amounting $8,963.99 million. The major part of this increase is contributed by outdoor and action sports and a small contribution by contemporary brands. Jeanswear is on a shrinking mode as it reduces marginally trying to keep the share of 2014.

Even the contribution of different segments to the profit margin indicates that it is driven by the outdoor segment, while all other segments reported reduced profits.

www.vfc.com

With Turkey planning to increase the minimum wage by 30 per cent from January, the experts are of the opinion that it could negatively impact sourcing of big retailers such as Carrefour, who largely depend on lower-wage employees. The ruling AK Party (AKP) campaigned in the November election on a pledge to lift the monthly net minimum wage to 1,300 lira ($461), appealing to the roughly five million minimum-wage earners struggling to make ends meet.

With minimum wage workers making up around a fifth of Turkey's 26-million strong workforce, the increase is expected to cost the private sector around $9.2 billion, according to an estimate by Umit Ozlale, an economics professor at Istanbul's Ozyegin University. While retailers could announce job cuts to rise in wages, margins are expected decline by 50-100 basis points across the sector.

Experts are of the opinion that the rise in the minimum wage could lead to further stoke inflation, now at around 7.6 per cent. It could also undermine confidence in the AKP's promises to strengthen fiscal discipline, risking further pressure on the lira, which has lost nearly a quarter of its value against the dollar this year.

Chemical maker Teijin is developing a new type of fibre that contains ingredients that protect the skin. The company has got an approval to manufacture and sell the new clothing material as a ‘beauty product you can wear’, the first allowed under the Japanese law. The company will partner with athletic clothing maker Descente to sell sportswear made for yoga and running from next summer. Teijin also plans to sell underwear under its own brand in fiscal 2016.

The fiber will be made of modified polyester polymer containing malic acid that will retain the skin's low acidity. Whenever perspiration forms and dries, the skin becomes alkaline, making it susceptible to microbes and other irritants. The fibre also releases compounds that interact with the skin's moisture to enhance beauty.

Synthetic fibre manufacturer Toray Industries is also seeking an approval to sell a type of clothing material as a medical device. The textile will be made for "smart clothing" that can monitor physiological data such as the heartbeat. The company plans to make a full jump into the medical device market after building trust in the product as a type of sportswear.

www.teijin.com