FW

Turkey’s cotton crop will fall by 17 per cent this season. The fall in production is the result of lower planting which is at 3,70,000 hectares, down from 4,30,000 hectares in the previous season. Rains had also adversely affected during the picking season. There was an increase in support price of cotton this season but the announcement came late, hence had limited effect on farmers’ planting decisions.

The fall in cotton crop is estimated to help boost import demand. Turkey is the world’s second largest cotton buyer. Moreover Turkey has been carrying out an antidumping investigation against imports from the United States. There are fears the investigation may impose retroactive duties on importers of US products. The Turkish textile industry hopes the investigation will be finalised without any anti dumping duties. It feels such a move will make Turkish textile exports more expensive and will cause Turkish products to lose market share in international markets.

Cotton grown in Turkey is of the upland type, whose lint characteristics have proved to suitable for most textile applications. Various attempts to grow long staple cotton have so far produced limited success. Therefore, there will always be a need by the Turkish textile industry to import long and extra-long staple cotton.

Cotton imports have become a necessity for Turkey to meet the increased demand from the booming textile and garment sector.

Many garment factories in Bangladesh are yet to be equipped with safe exit facilities, leaving workers vulnerable to fires. Most factories do not have a safe exit. They do not have fire protected doors. They have collapsible gates and gates that shut automatically.

Buildings without fire-proof exit stairs, including fire doors, which swing in the direction of exit are death traps. Exit paths are not accessible at all times. About 55.2 per cent of 32 platinum factories in Bangladesh that produce apparel products for Swedish retailer H&M still have sliding doors and collapsible gates. Over 60 per cent of factories lack fire-preventive doors and staircases.

It has been proved that installation of fire-rated doors and enclosure of stairwells is perhaps the single most important step a factory can take to prevent workers from being killed in a fire. Alliance, a retailers’ group from North America, says almost all its listed factories need fire doors. It has expressed concern over the slow progress in remediation in line with the action plans.

The only sign of change is that though garment factories still use collapsible gates, the tendency of keeping those locked during work hours has decreased to some extent.

Sustainability is a buzz-word across the textile and clothing industries the world over. Players are increasingly investing energies in making their supply chains as well as end products green. Now brands are turning to recycled feathers recovered from old blankets and pillows for their new collections.

This year, two outdoor clothing manufacturers introduced winter ranges made with recycled down feathers in the US market. Spanish brand Ternua and American company Nau both have unveiled jackets and vests featuring feathers extracted from old blankets and pillows. While such items have been common in the European market for a last couple of years, even the American market seems to be adopting this trend.

Concerns about the ethical side of down production have been on the rise especially because of live-plucking of the birds for high-quality winter clothing products. However, experts feel that usage of recycled feathers is emerging as a viable solution. However, some players argue that the process of cleaning required for recycled down is similar to that of the new down.

www.nau.com

Taiwan Textile Federation (TTF) in collaboration with Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA) organised Taiwan Textile Fair South Asia-2015 on Novemeber 23, 2015 showcasing latest fibres, yarns, fabrics and apparels from Taiwan.

The aim of this two day textile fair is to introduce Taiwanese innovations like value-added fibers, yarns, fabrics, trimmings and apparels to the industry in Bangladesh. The creativity and functionality of Taiwanese textile products have long been recognized by international designers, brands, importers and retailers in all major importing countries.

The fair was inaugurated by Shubhashish Bose, Vice-Chairman of Export Promotion Bureau (EPB). BKMEA second vice president Mansoor Ahmed and Taiwan External Trade Development Council (TAITRA) Dhaka office Director Danny Yang were also present during the inauguration programme. After the inauguration, Bose said that Taiwan is very crucial for Bangladesh as the two countries are major RMG product producers of the world. Taiwan exported garment products worth $31 billion last year while the country has set a $33 billion target for the next fiscal.

Taiwan Textile Fair of fabrics and accessories is a gateway to business matchmaking opportunities between top apparel manufacturers and exporters of Bangladesh and fabric and accessory manufacturers from Taiwan. The fair is showcasing a wide variety of products ranging from Raschel knitting lace, functional active-casual fabric, texture fabric, double knit fleece, R+Spandex jersey, garment trims and accessories like buttons, snap buttons, jean buttons, rivets, eyelets, single and double knit fabric, acrylic yarn, technical stretch fabric, tweed fabric, lightweight fabric, bi-stretch fabric and many other innovations.

www.ttf.wordexindia.com

As per the figures provided by the organisers of recently concluded ITMA 2015, Indian visitors were second in number followed by the hosting country. Rajinder Gupta, Chairman of the Trident group represented Ludhiana at ITMA textile machinery exhibition. According to him, the world’s leading machinery exhibition succeeded in bringing a host of sustainable, energy efficient and less labour-intensive machinery, which is the need of the day.

According to him, green practises and efforts towards sustainable future are becoming important for companies, ITMA was able to fulfil their requirements by displaying equipment for recycling, waste reduction and pollution prevention. Exhibitors showcasing such machineries received an enthused response from visitors for innovations such as spinning machinery or design and data monitoring software. He is now looking forward to the next edition of ITMA to be held in Barcelona, Spain, from June 20 to 26, 2019.

Gupta is of the opinion that over the years, players would start focusing more on low input costs, low wastage and, usage of less labour-intensive machinery for growth and to compete with its rivals. He demanded that to uplift and modernise the textile sector, especially the MSME segment, the government needs to announce new schemes and incentives along with the existing Technology upgradation fund scheme (TUF) to assist players in easily upgrading their production units.

www.itma.com

Hemp, a leader in the industrial hemp industry, said that sales for the 3rd quarter ending September 30, 2015 increased 53.8 per cent over the 2nd quarter.

Commenting on the company’s performance and prospects of hemp, Bruce Perlowin, CEO of Hemp, stated, “The industrial hemp industry is really booming. More states are beginning to realise it is more advantageous for them to legalise it. As you know, North Carolina, home to our industrial hemp commercial decortication facility, legalised hemp. Farmers in North Carolina now have the option to cultivate hemp crops with easy access to Hemp's multipurpose industrial hemp commercial processing facility.

” The legalization of industrial hemp in North Carolina has been a game changer for Hemp. The direction of the company has shifted towards more advanced processing in the milling line. Perlowin said the company will still continue to market its hemp-based cosmeceutical and nutraceutical product line. "In terms of generating profit, our multipurpose industrial hemp processing facility in Spring Hope, North Carolina by far outweighs any sales revenue generated from our product line, which is why we feel it best to shift focus," said Perlowin.

As the industry continues to boom, Hemp, Inc. is expecting millions of dollars in revenue to be generated per year pending the completion of its multipurpose industrial hemp processing plant that vertically integrates growing, decortification, milling, and more. The burgeoning demand for hemp, the plant used for thousands of years that became illegal decades ago, in the United States continues to increase.

The company recently also announced that it has entered into a definitive 5-year term agreement to sell its industrial hemp fiber from its decortication plant in North Carolina to a premium hemp denim apparel company, Hemp Blue. Hemp Blue, specialises in environmentally friendly clothing and advocates for the return of agricultural hemp as a sustainable crop in the United States.

Hempinc.com

Bigger brands lead the pack

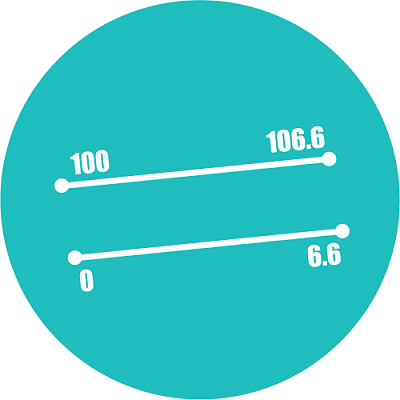

Q2 Apparel Index clocked in 6.68 points growth. This is approximately 56 percent higher than the index for Small Brands (with turnovers of Rs 10 to 25 crores) which stood at 4.28 points. For Mid Brands (turnover of Rs 25-100 crores), growth is 7.7 points. In fact, Mid Brands performed much better than Small Brands, but it’s the Large Brands with 8.95 points and Giant Brands with a high index value of 9.15 points that have shown a real growth.

This is a clear indication that Mid, Large and Giant Brands are doing much better compared to Small ones. Index pattern this quarter, much like earlier quarters, reflects as the size of brands goes up, performance improves. Interestingly, Mid Brands are racing ahead to catch up with the growth momentum of Large and Giant Brands. The gap between the rate of growth of Small Brands and Mid Brands is considerably high than previous quarters.

To an extent, this quarter’s growth has got a boost from sales as the results includes the EOSS period of July and August, where Large Brands usually offer high discounts, and the focus is on Top Line, resulting in high Sales Turnover. On the other hand, a period of heavy discount is normally accompanied by a reduction in Inventory. These factors probably explain why Large and Medium Brands are faring much better than the Small Brands, which typically are under some stress during this period.

Sales Turnover high for bigger sized company

The Index points out that Sales Turnover also increases in the same pattern as the size of the brand. For Small Brands, growth in sales turnover is just 3.38 and it grows on increasing. For example, for Mid brands it is 5.19, for Large - 5.33 and for Giant Brands, it is 5.54. This pattern follows a reverse order in case of Inventory Holding, clearly indicating that the impact of Sales Turnover and Inventory on the company’s performance.

As Vinod Kumar Gupta, MD, Dollar says, “It has been a satisfying year for us with the brand making inroads in newer territories and consolidating its position in existing hosiery markets of India and abroad. We have achieved a massive product growth of 88 percent across India as a result of the team’s aggressive marketing and advertising strategy backed by superior product range, technology upgradation and capacity expansion.”

A close look at Sell Through (Small-1.31, Mid-1.78, Large-2.36 and Giant-1.27) and Inventory Holding (Small-2.31, Mid-1.48, Large-0.83 and Giant-0.58) reveals that the reason for Small Brands not growing is related to the rise in Inventory Holding, which is higher than the improvement in Sell Through, whereas in case of Mid, Large and Giant Brands Sell Through improvement is much better and there’s much better control on Inventory Holding. Thus, index improves with size of brands.

Hemant Gupta, CFO, Blackberrys explains, “In the past two quarters, there is a major decrease in footfalls at stores, which is mainly responsible for decrease in Sales Turnover and impacts Sell Through as well. However, our conversion ratio and basket size has increased but due to lower sales the sell through has impacted. Increase in inventory holding also is one of the prime reasons for that. This is not with us only but with other brands as well. I am hopeful that situation will definitely improve in 3rd and 4th quarter of 2015-16.”

Speaking on the co-relation between Sales Turnover, Inventory and Sell Through, Rajiv Nair, CEO, Celio says, “Reducing inventory continues to be a core area of focus at Celio. Sales in the last quarter have been lukewarm. Hence, we ensured renewed focus on liquidation through specific promotions and EOSS. We are on our inventory targets which we keep reassessing every month. We avoid overfilling stores and focus on timely replenishment to avoid inventory risks.”

While Sooraj Bhat, Brand Head, Allen Solly opines, "An increase in inventory for us has been to fund aggressive expansion of company owned stores."

Future outlook positive

A comparison of Apparel Indices of Q2 July-Sept 2015 and 2014 reveals the Index Value was higher at 7.96 last year compared to 6.68 for 2015. The reason, it says is low performance of most of parameters except Inventory Holding in Q2 2015. Overall, the apparel industry failed to grow as much as it grew in the same quarter last year on all aspects be it Sales Turnover, Sell Through or Fresh Investments. On the other hand, Inventory Holding showed much lesser increase for good in 2015, as a lower increase reflecting better control on inventory causing lesser impact on bottom line.

However, nearly 41 percent of brands feel that the outlook for next quarter is good. Like last quarter 27 percent brands say their outlook is ‘Excellent’ for the next quarter. Nearly 30 percent, much higher than that of last quarter at 23 per cent, foresee an average outlook for next quarter and 2 percent feel that it will be ‘Below Average’. October-December being a quarter that enjoys better sales during festive seasons around Diwali, Christmas and New Year, brands predict an improvement in market sentiments.

Several global retailers and brands now plan to increase investments in their production facilities in Vietnam after it became clear that the country would significantly benefit from the Trans Pacific Partnership, once it reaches the concluding phase.

While American manufacturer and retailer of everyday apparels – HanesBrands has decided to increase its total investment in Vietnam to nearly $55 million by the end of 2015, up $11 million compared to last year, several other clothing and textile brands are exploring the destination. HanesBrands Vietnam is the largest consumer of US yarn in Southeast Asia, with over $1 billion of US yarn consumed by its sewing plants. It has two manufacturing plants in the northern province of Hung Yen and one plant in the central province of Thua Thien-Hue, with the annual capacity of 475 million units, accounting for 20 per cent of the group’s total production. Last year, with the inauguration of its third plant in Hung Yen, the company’s total exports surged to $334 million, and the figure is expected to reach $355 million this year.

However, the experts warn that as foreign direct investments in Vietnam increase, they will have an adverse impact on the country’s local manufacturing units. Smaller ones may have to shut shops, while big production houses may get reduced to small businesses.

www.hanes.com

CanopyStyle, the global campaign with the fashion industry to protect endangered forests has gained new influential champions in Topshop and their parent company Arcadia, C&A China and Lindex.

“With 55 brands representing $85 billion in annual sales now joining together to protect forests there is a clear market signal to fabric producers: eliminate sourcing from endangered forests,” said Nicole Rycroft, Founder and Executive Director of Canopy, adding, “What’s exciting is how this momentum is already translating back through the supply chain to alleviate stress on critical forest hotspots like Indonesia’s rainforests and Canada’s Boreal.

” Since the public launch of the CanopyStyle campaign two years ago, brands are working to ensure future supply doesn’t harm critical forests or contribute to deforestation while encouraging solutions such as manufacturing fabrics from recycled clothing instead. In their commitment, Arcadia Group declared their support for a future that does not use ancient and endangered forest for fabrics such as rayon and viscose.

In June of 2015, Canopy, H&M, Inditex/Zara, Stella McCartney, Eileen Fisher and Marks & Spencer hosted a summit of global brands and the world’s largest viscose producers in China. “C&A is excited to join such an important effort and one that aligns with our global sustainability strategy. We are starting with our operations in China, as it is a key retail market for us,” said Jeff Hogue, Chief Sustainability Officer C&A Global.

Lindex too has formed a strong policy to allow their customers to mix and match styles and functionality that don’t cost the earth. “Lindex has a strong handle on our supply chain, we see Canopy as a well-positioned partner to help us build a clear picture of who our viscose suppliers should and shouldn’t be moving forward”, said Anna-Karin Dahlberg, Production Support Manager at Lindex.

www.canopyplanet.org

Leading for over two decades

“What you see here is compilation of two decades of ongoing research, development and refinement in technology” says Masaki Karasuno, Incharge for Planning Group (Total Design Centre), adding further, “Perhaps it was before time then in 1995, it has improved over time and is more relevant to industry now. Earlier, one worker could manage just 5 machines, whereas the latest machine needs one worker for 35 machines.”

Shima Seiki proposes several novel ways to produce WholeGarment knitwear even more efficiently by exploiting 3D shaping and tubular knitting characteristics. Furthermore with Italy and the rest of Europe in its radar, Shima Seiki emphasizes on the economic and logistic advantages of WholeGarment knitting for local production in domestic markets, which further increases the sustainability factor by eliminating time, cost and energy otherwise spent in shipping from off-shore locations.

Looking at the world's market conditions and taking into account possible future scenarios in the manufacturing and distribution of goods, technology reflects a much bigger picture as how technology users can successfully maintain a profitable business; how the industry can transform itself from one relying on labor to one fueled by information and creativity; and how a sustainable material-to-manufacture-to-distribution system can be established with limited resources and limited factory capacity despite steady growth in global population.

“Technology is sustainable as it reduces manpower thereby reducing cost. Furthermore, machines can be installed where the market is, closer to the consumption centre, producing straight from yarn to garment, cutting processes in between, saves lot of costs giving economic and logistic benefit beside being quick to market.”

WholeGarment was inspired from glove manufacturing, recalls Karasuno. Today Shima Seiki enjoys 10 per cent share of knitting machines worldwide, contributing much higher in production volume, as their machines produce much higher and quicker than others. Italy being the largest market for WholeGarment, followed by the US, Shima Seiki is world leader in knitting technology.

Shima Seiki machines both WholeGarment as well as conventional knitting machines are used for various end applications including fashion, home furnishing, sports, medical, automotive, aerospace and other industrial textiles.