FW

China and Britain want to fully tap their potential in bilateral trade, particularly of high value-added and hi-tech products, and in service trade and infrastructure projects. The intention is to have an upgraded and closer bilateral relationship in all aspects, especially in economic and trade exchanges.

China wishes to promote the export of high value added products to Britain while making good use of Britain’s advantage in high-end manufacturing, high and new technology, and research, to expand bilateral trade.

Potential areas of cooperation are technological innovation, e-commerce, financial and legal services, medical care and creative industries. Other areas are high-speed trains, nuclear power, life science, satellite application, new energy, and new energy cars.

Britain is China’s second largest trading partner within the European Union, while China is Britain’s fourth largest trading partner. In 2014, bilateral trade value increased 15.3 per cent year on year, with the growth rate ranking the first among all China’s trade partners in the European Union.

China hopes Britain will play a positive role in promoting the export of European high tech products to China. An early realisation of a China-Europe investment agreement and a feasibility study on the China-Europe free trade zone will be conducive to sustainable bilateral trade and investment cooperation.

The factory safety assessment reports provided by the ILO-hired firms were not being accepted by the Accord on fire and building Safety in Bangladesh. The apparel exporters told this to a high-powered International Labour Organisation delegation.

Bangladesh’s readymade garment factories (RMG) are undergoing double inspections because of the rejection from the European retailers’ group. The delegation of the ILO’s Direct Contacts Mission, in a meeting with the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), wanted to know about the country’s progress on the ongoing safety assessment and whether the amended labour law had been implemented in the RMG sector or not.

Md Siddiqur Rahman, President, BGMEA said that the ILO team wanted to know about the trade union activities, number of Workers Participation Committee in the factories, activities of the Department of Inspection for Factories and Establishments, and formation of Occupational Health and Safety Committee in the RMG sector.

He added that they had informed the ILO team that the labour law was implemented and the registration of trade unions had increased in the sector. Besides, the team was told that the labour law implementation rules were just passed and the formation of Occupational Health and Safety Committee remains under process, Rahman stated.

The ILO team wanted to know in detail about the progress on the factory inspection programme, Rahman said. He added that the trade body informed that Accord, the platform of the EU retailers, was not accepting the inspection reports provided by the ILO teams.

www.bgmea.com.bd

Bangladesh’s garment makers have huge opportunities in the sweater industry. Right now the world sweater market is dominated by China. But since China is gradually inclining to the hi-tech and heavy industry, Bangladeshi apparel makers can easily grab the sweater market.

Sweaters are one third of the world knitwear market. And in Bangladesh too sweater production is one third of the country’s knitwear production. Sweater production can be enlarged by introducing automated machines. Many sweater manufacturers in Bangladesh have already introduced automated jacquard machines that are helping them enjoy a robust volume of production. Different sweater factories in Bangladesh have installed some 10,000 machines imported from Japan and South Korea.

Producing sweaters and functional fabrics in large volumes would be a pathway for Bangladesh’s apparel sector to reach its export target of $50 billion by 2021.

The knitwear sector in Bangladesh currently supplies 90 per cent of the knit fabric requirements. Many garment units have their own dyeing and finishing units. In fact a separate dyeing and finishing industry also has grown up over time to support the sector. There are more than 2000 knitwear factories and the industry has strong backward linkage facilities. The knitwear is exported to 153 countries of the world.

The second largest employer in that country, Omani companies have been encouraged to invest in India’s textile sector. Around 35 million people would be employed directly due to this.

At an exhibition entitled ‘Vastram—Splendid World of Indian Textiles’ which featured more than 30 traditional Indian textiles, Indra Mani Pandey, India’s ambassador to the Sultanate, said that textiles were an important part of India’s exports to the Sultanate and India whole-heartedly welcomes Omani investments in this industry.

There was Oman-India Investment Meet held recently and in the next two months, another investors’ meet was to be organised, Pandey said. He added that they were looking forward to Omani companies investing in India. There are 1,500 joint ventures between the two countries and there must be many textile-oriented ones among them. Besides, there is one, which is being created in Salalah, the ambassador stated.

Former assistant to Sultan Qaboos bin Said’s adviser at the Ministry of Information, Mohamed Al Riyami also encouraged this investment and felt that Omani investors should go to India and invest, but get the items in Oman and put them for sale there.

Pandey, while highlighting the diversity of Indian textiles in terms of production, material and the processes involved said that the purpose of the exhibition was to showcase this diversity to the people of Oman and the Indian community.

As the 40th edition of IHGF Delhi fair organised at the India Expo Mart in Greater Noida, by Export Promotion Council for Handicrafts (EPCH), the nodal agency for promotion and development of handicrafts in the country, drew to a close, business enquiries worth Rs 2,700 crores were generated.

Rakesh Kumar, ED EPCH, mentioned that over 7,300 trade visitors interacted with India’s handicraft sector making it the world’s largest fair of Indian handicrafts, home, lifestyles and fashion products. The visitors included international buyers, buying agents and domestic volume retailers.

The IHGF Delhi fair played host to over 2,750 exhibitors spread over 1,90,000 sq mts area, this year, with more than 1,600 product lines and styles at state-of-the art India Expo Centre & Mart, Greater Noida.

Over 110 countries and Indian volume retail visitors mesmerised overseas volume buyers with their spectacular display of traditional Indian art and craft. Products on display included house ware, tableware, kitchenware, hotel ware, home furnishing, home textiles, linens, festive decor, Christmas, Halloween, birthdays, anniversaries, celebrations, fashion jewellery, bags, scarves, ties, fashion compliments, luggage, leather bags, furniture, hardware and accessories, carpets, rugs and floorings, bathroom accessories, candles, incense, potpourri and aromatics, stationery, lamps and lighting, chandeliers, lanterns, decorative articles & giftware, garden ornaments, lawn accessories, sustainable products, jute, cane, bamboos, natural fibres, educational games, etc.

Moreover, various knowledge seminars were held along with cultural programmes and fashion shows. Besides, Bhagwat Saran Gangwar, Honble Minister of State for SSI & EP, government of Uttar Pradesh presented the prestigious Ajay Shankar Memorial Awards for best display and design in 10 product categories.

www.epch.in

The oldest registered textile association in Tirupur knitwear cluster, South India Hosiery Manufacturers Association (SIHMA), celebrated its 60th founding day.

S A Khader of Travancore Knitting Company, was the President, when the journey started with 106 member textile units in 1956. Since then, the membership rose to over 1,500 at a point and presently stands at 555 units.

A C Eswaran, SIHMA President said that earlier units that constitute entire apparel production chain such as knitting, dyeing, compacting and garment-making were members of the SIHMA. However, he said, the membership dipped once the segment specific-Associations for different stages of production such as exports, dyeing, compacting, fabrication and knitting, etc., started coming up. A majestic diamond jubilee building has been constructed by the SIHMA at an outlay of Rs 1.1 crore.

The rapid strides in the growth of the region as a knitwear cluster apparently happened after the formation of SIHMA, although Tirupur had gradually started becoming the investment destination for apparel production from a single textile unit that functioned in 1928.

Eswaran stated that the formation of SIHMA had facilitated arrangement of institutional loans for the hosiery industry and import of high quality machines for apparel production in the 1960s. Besides, during the mid-70s, SIHMA initiated the first modernisation drive in the cluster, after which it started gaining its prominence as an export hub, he added.

Moreover, SIHMA initiated the periodic wage pacts since early 1970s. This was non-existent in majority of the industrial clusters across the country at that period, say the workers.

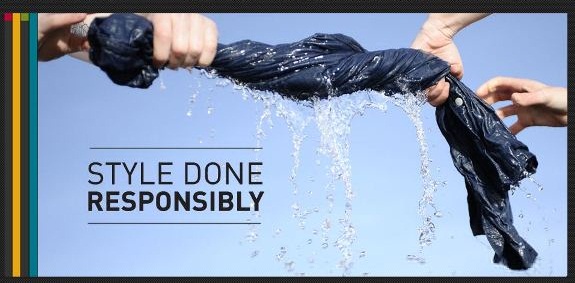

With sustainable buying making huge strides among consumers, there’s still a huge disconnect between consumer demand for more ethical products and a lack of awareness of how and where the clothes are made. Lee said that this is because the complexity of the apparel chain and also the trend of ‘fast fashion’ augmenting the issue.

Since ‘fast fashion’ is frowned upon, as it moves quickly from production to retail to offer the latest trends, Lee believes we need a cultural shift towards endurance of apparel products to address this.

He said that durability and quality have to be the value proposition for our clothing, instead of the thrill of buying the next new thing. He also predicted that the industry has almost reached a tipping point with consumers, however, the industry is still struggling with how to make those consumer connections.

‘Remake’, a start-up seeded by the Levi Strauss Foundation, Lee said, is working to engage consumers in a fresh way to learn about the people behind the products they buy. The organisation’s vision is to create a community of conscious shoppers through films, visual story-telling and immersive journeys.

Ayesha Barenblat, Remake’s founder said that they aim to move away from the pain narrative that has for long paralyzed consumers into inaction. They instead, build human connections between shoppers and makers, she added. By pain narrative, Barenblat refers to changing the conversation from scare tactics, shaming or short-lived calls, to boycott after a factory disaster, toward more meaningful engagement.

Other stakeholder groups such as labour/human rights advocates and shareholders are increasing their expectations of transparency from apparel brands, while consumers are demanding more responsible products. Companies though, feel the pressure to do more than just follow the law; they feel the need to demonstrate actual social impact within their supply chains.

Penetration in the supply chain

One company to put efforts and resources into moving from compliance to deeper engagement with its supply chain and saw results, is Levi Strauss & Co. Lee told the SXSW Eco audience how the company has put millions of dollars in supply chain worker programmes to address issues such as health and financial security.

In 1991, the early days of apparel outsourcing of labour, Levi Strauss adopted a code of conduct called its ‘Terms of Engagement’ (TOE), or as Lee put it—‘the code that launched a thousand codes’. In 2011, Lee partnered with the business side to establish the ‘Improving Worker Well-Being’ initiative for apparel workers in communities where Levi Strauss’s products were manufactured. From just a compliance-focused ‘do no harm’ labour policy, the idea was to move and truly collaborate with suppliers on the ground to make a tangible impact on workers’ lives.

Recently, the finished pilots of the ‘Worker Well-Being’ initiative in Bangladesh, Cambodia, Egypt, Haiti, and Pakistan. Here, it provides support, surveys and curricula to suppliers on topics such as financial security and women’s health, connecting suppliers with local partners to help them meet the TOE.

Looking into workers’ well-being has resulted in Levi Strauss witnessing a return of up to $3 for every $1 invested in ‘Worker Well-Being’ initiatives, across the supply chain.

Finding the right partners is one of the biggest obstacles in implementing these programmes. To build capacity in developing nations to better serve workers, the NGO sector serving supply chains needs help. Thus, the company focuses its programmes in nations with the most marginalised communities. Lee said that they look at who is the most impacted, and invest in nimble organisations to build bridges with suppliers.

Standing up marginalised people isn’t really reinventing the wheel for Levi Strauss, Lee mentioned. It, in fact, builds on a 163-year history of being a values-driven company.

www.levistrauss.com

Switzerland’s Bluesign Technologies has selected Archroma’s One Way calculation tool as the engine behind its resource tool that is due to be launched in 2016. Archroma is a global leader in colour and specialty chemicals. It was the first to introduce a tool that would help its textile customers make the best choices in favor of resource optimisation.

The new tool BlueXpert represents a milestone in resource-efficient textile production, as it enables manufacturers to immediately save 50 per cent water, 30 per cent energy and 15 per cent chemicals during the production process.

Via this initiative, Archroma is joining with other textile chemical leaders to help textile brands, retailers and manufacturers to make the best choices for more sustainable processing of textiles.

One Way was designed to demonstrate it is possible to bring together the dual objectives of ecology and economy. The tool provides a fast, measurable and reliable approach to selecting chemical product and resource-saving process solutions.

BlueXpert operates within the high-security IT environment of Bluesign technologies, as it is hosted in the firm’s state-of-the-art data center in Switzerland. BlueXpert also includes proprietary algorithms specific to Bluesign criteria, such as the air emission factor. This tool is exclusively available to Bluesign partners only.

www.bluesign.com

The European Union (EU) will give the GSP plus trade concession to Sri Lanka next year, says the country’s government.

Harsha de Silva, Deputy Foreign Minister said that the EU and the Sri Lankan Government are working together to regain the key trade concession. While speaking at an event attended by several garment factory workers and officials of the garment industry, he stated that they were working together with mutual respect to get it done by mid 2016 since they had established a government of good governance with respect for human rights.

A recent technical paper on the ‘World Economy’ showed that the loss of the trade concession had a negative impact, with the worst affected being the low-income workers in the cities, de Silva said.

When the former Government was in power after it failed to meet the criteria to continue as a beneficiary, Sri Lanka had lost the GSP plus trade concession from the EU. The new Government, however, had reapplied for the concession and had made commitments to meet the required criteria.

Philippines has begun preliminary negotiations to join the Trans Pacific Partnership (TPP) countries. But there is a possibility that joining the TPP might result in the Philippines’ getting flooded with duty-free American products.

The major textile and apparel countries – China, Bangladesh, Cambodia – are not going to join the TPP. This presents a golden opportunity for the Philippines to revive its textile and apparel industries.

Since China is organizing its own common market, the manufacturing hub of the TPP will be Vietnam and, hopefully, the Philippines. The Trans Pacific Partnership is envisioned to be similar to the European common market. The goal is to eliminate trade barriers, especially tariffs and quotas, among countries in the Asia Pacific region.

Joining the TPP will mean more jobs, faster economic growth and reduction in poverty. The biggest beneficiary of the TPP would be Vietnam. This country has the lowest wages compared to the other TPP members.

The United States is interested in joining because the TPP will open up new markets for its service industries. This will present potential competition for local companies in the financial and professional services.

The TPP will create the most powerful and wealthiest economic region in the world. The 12 countries now in the TPP account for 40 per cent of the world economy.