FW

Confirming its plans for ITMA Milan, Karl Mayor has said the firm will launch at least seven new warp-knitting machines in the international textile machinery fair. Karl Mayer feels launch at the leading trade show will help it catch more eyeballs from international buyers, and, in return, will help it to write a success story for the new innovations. The fair is considered the most important international meeting point for the industry. The machines will be showcased under the banner, ‘We care about your future’ on the 1,400 sq metre stand.

Optimistic over the company’s plans, Oliver Mathews, Director (Sales), Warp Knitting Business Unit, said that their products are so efficient and technology-driven that visitors will not resist from seeing their business making a mark with the help of them. The range intended to bring maximum benefits for users will strengthen their position as a market and technology leader in the industry.

The company’s optimism is supported by the fact that it has been successful in the past also in making good fortunes out of the launches pretty similar to this. Four years ago, the firm in ITMA Barcelona had launched the finest ever version of its HKS 2-3 E tricot warp knitting machine, which went to become a best seller for it.

At the next edition of Première Vision Paris, specialized Upper Jeanswear area, Eco Denim will present its sportswear and jeanswear collection made of pants, jackets, shirts, shorts, skirts, dresses. In each of its collections, the manufacturer will introduce new washing and design techniques combined with denim innovations and the latest trends.

Eco Denim is a vertically integrated company offering technological innovations in fields ranging from patterns, sewing, washing, all types of dyeing and special treatments, embroidery, laser to ozone treatment. All processes are 100 per cent controlled in-house, in one production site.

The company will bring some of its novel technologies to Paris including different dyeing machines, new techniques and also special prints and treatments on fabric rolls. Upper Jeanswear at Pemiere Vision, the updated jeanswear concept dedicated to fashion brands will present a complementary offer of weavers and manufacturers.

www.premierevision.com

South Korea’s emerging labels Munsoo Kwon and J Koo won the Asia finals of International Woolmark Prize 2015-16 the men’s wear and women’s wear categories held in Shanghai. Selected from 12 promising fashion talents in Asia, both winners earned A$50,000 in prize money, and will take part in next year's international finals.

This year's panel of judges consisted of a cross-section of industry leaders, including designer Thom Browne, Chinese supermodel Lu Yan and Cyril Rahon, head buyer of 10 Corso Como. Women’s wear category winner Jinwoo Choi and Yeonjoo Koo of J Koo showcased an oversized denim jacket paired with matching trousers. The pair's innovative fabric development transformed the material with artful use of bleach and strategic fraying to add to the illusion.

Men’s wear winner Munsoo Kwon displayed a well-tailored suit that proved new ways of working with wool. Traditional pinstripe suiting was transformed into a modern look with white ombré along the sleeves and trouser legs. The final for menswear will be held in Florence in January 2016, and the womenswear final will take place in New York in February next year.

www.woolmark.com

The four-day Sourcing at Magic fair starts from August 16 at Las Vegas. The show will represent more than 1,000 apparel, accessories, footwear and home textile resources, along with a range of some 200 fabrics, based out of about 43 countries. During the event, seminar series will be held keeping in mind special features, needs and interests of that particular area. The second day of the event will see Apparel Magazine taking part in the ‘Sourcing Summit at Magic. A session on apparels with a theme of Sourcing’s Emerging Role-Achieving Breakthroughs From Concept to Delivery, will carry out an executive research summary from its 9th Annual Apparel and Kurt Salmon Sourcing Survey.

The event will see special emphasis on wearable technology, home sourcing and buzz boutique. Wearable technology comprises of prototype garments, stretchable electronics screen printed onto textiles and compression shirts with integrated dry electrodes for electrocardiogram monitoring. The concept of ‘Home sourcing at Magic’ is devised to integrate the fashion and home communities. It will see the participation of more than 50 countries. The model of ‘Buzz Boutique’ will stress on marketing solutions, apps and social media trends.

Global artisans will showcase their unique and culture-based products from the countries such as Philippines and Indonesia.

Benzene prices went up in February till April and after that, remained sluggish till June this year. Caprolactum, which had been following benzene values, lagging behind by only a month, continued doing so. Contract prices for benzene in the US plunged 21 per cent to $2.25 per gallon. The equivalent contracts in Europe also declined 14 per cent to €707 a ton. Spot prices, meanwhile moderated in early June, then jumped in the second week and fell again in the third week, finally bouncing in the last week across regions.

Asian markets remained strong

The Asian markets tracked firmer downstream styrene monomer and had active discussions. Asian marker, the FOB Korea gained 5 per cent in June, but was down but 40 per cent on the year. Prices had touched a 12-month low in January to just above US$600 a ton. Since then, it has recovered about US$200 a ton till June.

In Asia, caprolactam prices eased last month, which was driven by falling benzene prices and lusterless demand by the end of June, particularly from the textile filament sector. As demand was disappointing, several caprolactum units decided to shut for maintenance over the next two months this may balance out the weak demand. As for Europe, the May caprolactum contract was settled at an increase of

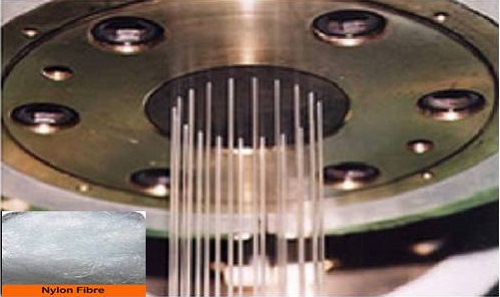

Demand for Nylon filament yarn dips

In late May, demand for nylon filament yarn began to dip, showing that the busy season was over earlier than expected and normal business cycles had emerged. Thus, prices dipped last month as the cost of raw material eased with lower caprolactum and nylon chips prices, and lack of demand. Downstream converters faced liquidity issues and limited fresh order intakes. As downstream sectors had entered the seasonal lull, nylon FDY markets swayed from stable to weak.

US too was struggling in the nylon filament segment, with slow demand and polyester as a substitute in some applications. The pressure from polyester was experienced by both markets.

Austrian company Andritz operating in over 250 places worldwide, provides full lines and individual solutions for spun lace, wet laid, needle punch, bonding and finishing for spun bond applications. In the spun lace, for direct or cross lapped lines, Andritz focuses on high performance with regard to productivity, fabric quality, process reliability, and energy consumption.

In needle punch sector, Andritz nonwovens products generate high value added. For both light and heavy fabrics, Andritz neXline needle punch optimizes the production rate of every individual machine along the line, providing higher tensile strength and greater evenness.

The in-house expertise of Andritz through-air dryer technologies and in developing high performance systems brings new process solutions to the spun lace industry.

Andritz is also a system supplier of complete wet laid nonwoven lines for innovative and versatile end uses in hygiene, medical, and technical product ranges. The Andritz wet lace process is suited for production of flushable, dispersible, and 100 per cent biodegradable wipes.

www.andritz.com/

The Tirupur knitwear cluster has been allotted Rs 15 crores for setting up a facility center for product innovation, testing and training. The common facility centre will be equipped with latest machinery to produce innovative knitted denim products, woolen fabrics with additional thermal properties and quilt fabrics. The testing equipment will ensure that the knitted fabrics produced are of high quality and can help producers of end products with greater value addition in the textile export market.

The training centre will impart skills to workers in a systematic manner for producing a workforce that can cope with the changing needs of the industry including product diversification at periodic intervals. Another set of people will be trained on maintenance of imported knitting machinery so as to reduce breakdown hours.

Tirupur township, 60 kilometers from Coimbatore in Tamil Nadu, is an important garment cluster. This township started with the production of low valued cotton hosiery items mainly undergarments during the 1920s and started with exports from 1974. There are around 700 active exporters and 1700 domestic garment suppliers at Tirupur. There are more than 2000 small units which specialize in knitting, compacting and calendaring, bleaching, dyeing and embroidery.

A centralised cotton buying system has been introduced by Zimbabwean cotton merchants to curb side marketing which has become rampant. Farmers have described the move as an attempt to promote monopolistic tendencies. They say the new cotton buying system has taken away competition. The Cotton Ginners’ Association, which represents the merchants, is buying the crop on behalf of all ginners, and the volumes are shared on a pro rata basis depending on level of investment in the production.

About 98 per cent of production is funded by ginners under contract schemes introduced at a time when farmers were failing to access finance due to lack of collateral. While cotton production has been on the rise over the past few years, the viability of the sector has been adversely affected by side marketing. The challenges arise from a situation where some merchants were deliberately paying higher prices to lure cotton growers including those holding the contracted crop.

There is a feeling the cotton industry needs to have a model to achieve better efficiencies, viability and sustainability. Liberalization of marketing will not work if regulatory enforcement is weak. Market forces are great for freely produced crop but not when all production is under contract.

The fashion designer now occupies a space between creative, technician and merchandiser, a framework and skill-set imposed by an increasingly competitive and demanding marketplace. The biggest pressure on designers, according to the Lectra/CFDA survey results, relates to speed to market: getting collections out quicker and quicker to continually renew the in-store offer.

Consumer expectations and shopping habits are also changing. In addition to shorter time to market and more collections, designers now have to deal with more competition. Brands need to differentiate themselves, while attempting to appeal to a consumer who is informed, empowered, less brand-loyal, mixing high and low pieces and not squeamish about shopping for the best price online.

According to the survey results, technical innovation means production techniques and the tools used for design and development that have become more advanced. Designers need to have a grasp of these latest advances. Designers and development teams need to share information in real time with external partners and suppliers. Even consumers, through social media, now have a platform to communicate with designers and express their top brand picks and preferences.

Manufacturers, marketers, merchandisers and even consumers have become inseparable parts of fashion design. New forms of communication via social media platforms, combined with a market where everything is available to everyone, have empowered a once passive consumer. As a consequence, designing has become more an interpretation of—rather than a suggestion of –consumer desires. The design-dedicated silo is being shattered and collaboration has become the new framework.

The forgotten 'blue gold', as it's termed, for the wealth it brought to dye-makers, was revived by an American in southwest France. This ancient blue dye that once brought riches to the region and was also praised in Chaucer’s poetry, and used by Napoleon for his army’s uniform is back in trend. Denise Simeon-Lambert said that they brought this ‘pastel’ as the tint was called in the region’s old Occitan-language, back in fashion. Acclaimed designers such as Dior and Chanel are wooing this ‘natural’ and ‘non-staining’ shade as well.

Simeon-Lambert is one of the two business owners that aim to restore international acclaim to this forgotten shade of blue. Today, they have customers from far as Asia as well. Simeon-Lambert stumbled upon this concoction, which is made from a plant and also has curative values, by accident though. The common name for the plant is ‘woad’, which carries the within the dye, which was quite popular during the Renaissance period. Simeon-Lambert revived an ancient tannery to revive the dye.

The dye lost to the more concentrated and easier to produce indigo from India, in the 17th century. This also was replaced in the last 50 years by synthetic tints. However, Simeon-Lambert, after discovering the history of the dye launched a company, which now produces 600 kg of the dye each year.