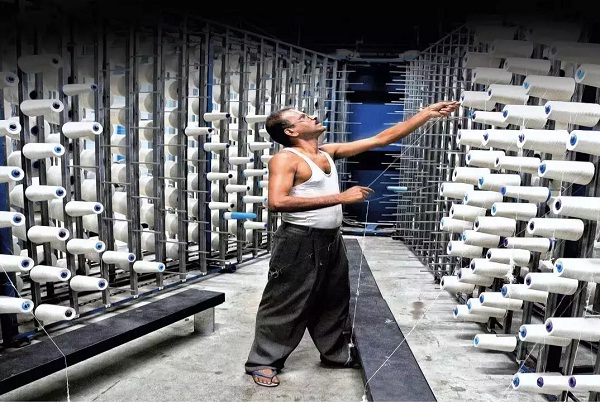

The entire textile value chain in Gujarat has been reeling under the effects of rising cotton prices that has reached almost Rs 1.1 lakh per candy (365kg). The price rise has eroded the profit margins of almost all spinning mills in the state. In fact, three mills have already been sold since Diwali 2021 and another four in Saurashtra are up for sale.

Low yarn prices pressurize input costs

Despite a rise in cotton prices, weak demand in the domestic and export markets has not caused yarn prices in the state to rise, leading to a rise in input costs of spinning units. Most yarn manufacturers in the state are facing losses of around Rs 30-50 per kg depending on the quality of their yarn. The unprecedented hike in cotton prices followed by a decline in demand is pressurizing the industry, says Jayesh Patel, Director Omax Cotspin.

Having a capacity of 70,000 spindles, the Dhrangadhra-based company recently acquired a spinning unit in Rajula region of Amreli district. The spinning unit, with a capacity of 51,000 spindles, was under pressure even before the hike in cotton prices. Its owner wanted to exit the business completely and sold the unit to Omax Cotspin. The acquisition will enable Omax Cotspin double its capacity, says Patel.

Likewise, Jasdan-based MM Group has acquired two spinning mills in the past one year. The group added 53,000 more spindles besides acquiring mid-size units, adds Natvarlal Navadiya, Director, MM Group.

Weak demand leads to 15% less valuations

More spinning units in the state are likely to be sold if the situation does not improve, explain experts. Unable to meet input costs due to rising cotton prices, mills are reducing capacity utilization over the past four months. Some have finally decided to sell off and diversify business.

Spinning mills in Gujarat have been affected by a continuous weak demand. Their valuations have reduced almost 15 per cent. With the situation showing little signs of improvement, potential buyers are adopting a wait and watch policy. Weaving units face heat of rising costs

Textile weaving and processing units in Gujarat have also been affected by the rise in input costs and a dip in demand. The state has around 200 cotton weaving units that are currently running at low capacities. Demand for grey fabrics in the state is low, making prices volatile. Operation of spinning units at low capacities is impacting weaving units in the state, claims Bharat Chhajer, Former Chairman, Powerloom Export Development Council