FW

ITMA 2015, Reiners + Fürst (R+F) said, was one of the most successful exhibitions ever in the company’s 70 year history. More than 450 visitors visited the R+F booth to see latest innovations by the brand. A large number of professionals showed keen interest in the latest developments by Reiners + Fürst.

During the show R+F presented the next generation of Turbo chromium coated rings and a selection of enhanced ring travellers. The German manufacturer has reported a three times higher order intake during ITMA than it anticipated to achieve.

Many clients utilise R+F’s solutions in rings and travellers and seek advice about possible optimisation of the whole spinning frame. The company claims expertise in the field of ring spinning with its world-wide network of agents and warehouses and enjoys the status of being a reliable partner to the ring spinning industry across the globe.

www.reinersfurst.de

Among the innovative latest technologies displayed at ITMA in Milan, Oerlikon’s Manmade Fibres Segment witnessed a number of trade visitors placing large orders totalling more than CHF 50 million for their Oerlikon Neumag staple fibre plant engineering technologies.

The company said that orders were received from key customers from Europe and Asia (outside China), for the production of staple fibres. These plant solutions will be delivered to customers over the next two years. The signing of the orders took place after ITMA 2015 in Milan.

The company also said that the new orders confirms its lead position in staple fibre production technologies, and value that its customers find in its innovative solutions. Oerlikon Neumag offers an extensive portfolio of technologies for the production of synthetic staple fibres. It delivers both one-step and two-step technology solutions, which enable customers to produce a flexible range between five and 300 tons of polypropylene, polyester, recycled polyester, polyamide, and other similar materials per day.

The Oerlikon Manmade Fibres Segment’s technologies are also offers customisation as per the customers’ requirements.

www.oerlikon.com

Firms from Singapore, Japan, Taiwan and South Korea, which have traditionally relied on low-cost production in China are seeing Chinese textile firms shifting out of China and making their way to Bangladesh as a result Bangladeshi textile value chain is rising faster than any other Asian countries according to Asian Development Bank.

With rising production costs in other economies in general, setting up operations such as in Bangladesh and Vietnam has been on the rise, the report states. Apart from rising domestic value added shares, the foreign value added to Bangladesh and Vietnam exports is also increasing in a much faster pace than that experienced by the rest of their peers (excluding China). Bangladesh has attracted FDI in garments and generated new trade, but has had limited success in upgrading and diversifying Special Economic Zone (SEZ) exports.

According to the ADB’s Asian Economic Integration Report 2015, the progress in sector-level value chains’ intraregional production activities within sectors appears to be changing, with shares within industrial exports showing interesting shifts between 2000 and 2011. The report examines trends in trade, finance, migration, foreign direct investment and other economic activities in the region.

Intraregional trade within the labour-intensive Asian textile industry still increasingly dominated by the China—which covers about two-thirds of intraregional exports—shows Bangladesh and Vietnam emerging as important players, said the report. In the meantime, it said domestic value added shares of three East Asian economies—Japan, Korea and Taipei, China—have declined 6-8 percentage points during this period.

However, the report found that trade in Asia has slowed faster than that of world trade in recent years. The region’s trade expansion has witnessed low gross-domestic product growth since 2012. It found that governance gaps and lack of focus undermined performance in some zones, while successful zones managed to build close ties with the domestic economy. Economies with low incomes and young population (high ratios of 20-34 years old to total population) are generally relied on migrant sources —such as India, Bangladesh, and Afghanistan, it said.

www.adb.org

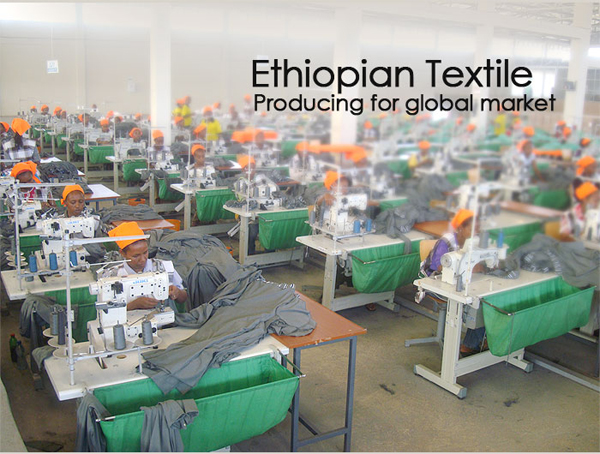

"Ethiopia has many positives from a stable and peaceful political environment, affordable electricity to cheap labour. Entry-level salaries for workers in Ethiopia's textile industry range from $35 to $40 a month, lower than Bangladesh's minimum wage of $68 per month and far below the average wage of $500 in the China. Ethiopia doesn't follow any minimum wage rule, hence, workers are often willing to work for whatever wage they are offered."

While on one hand, low wages, cheap power and a stable political situation are posing as lucrative reasons for foreign textile companies like H&M to move its sourcing needs to Ethiopia, experts warn that extremely low wages could trigger protests, where workers continue to struggle to make a daily living.

Positive factors lure western buyers to Ethiopia

Ethiopia has many positives from a stable and peaceful political environment, affordable electricity to cheap labour. Entry-level salaries for workers in Ethiopia's textile industry range from $35 to $40 a month, lower than Bangladesh's minimum wage of $68 per month and far below the average wage of $500 in the China. Ethiopia doesn't follow any minimum wage rule, hence, workers are often willing to work for whatever wage they are offered.

With global brands shifting their attention to Africa for their sourcing requirements, and Africa being a major cotton producer is one of the few places in the world, where garment makers can establish the entire supply chain from fibre to fabric in one location. Unlike Bangladesh, African countries also have duty-free access to the US market under the African Growth and Opportunity Act (Agoa). Both jurisdictions have duty-free access to the EU, so African countries still tend to be outcompeted there.

With the help of global brands and government, Africa can look into resolving the challenges and emerge a strong sourcing destination, before it faces Bangladesh-like situation.

Minimum wages still a concern

While rising foreign investments in the country have brought hopes to the Ethiopian industry since it means more jobs, extremely poor wages are forcing workers to make ends meet. For instance a shoe factory in Duken, about a half hour drive from the Debre Zeyit garment plant, run by Chinese company Huajian employs around 3,800 Ethiopian men and women. Shoes made at this plant are supplied to big brands such as Guess, Naturalizer and Toms but basic salary of an employee is just 600 birr of €26 for working eight hours and when worked for 10 hours, the pay increases by mere €6.

On the other hand, workers also lack skill-sets required to create a quality product. The Huajian company, founded in China in the 1980s by former military officer Zhang Huarong also follows a military drill to motivate its staff. However, employees already tired of doing daily chores like fetching water from long distance do not really enjoy more physical exercise at work.

Also around 75 per cent of all Ethiopian companies still refuse to permit trade unions, which companies fear would lead to protests and bargaining for higher minimum wages and other benefits. However German clients like Tchibo have been putting pressure on the company working for them in Ethiopia to increase the minimum wages, which led to the factory offering 25 per cent rise. Now industry players expect more companies like H&M to put pressure on Ethiopian factories to raise salaries.

www.hm.com

The government is looking to inject new life into the jute industry by diversifying into new avenues to promote the use of jute bags. These include a range of products like waste paper baskets, folders and laptop bags to molded items. Children’s school bags can be made of jute. An important characteristic of jute is that it absorbs and retains moisture. This makes it very effective to be used for the construction of roads.

India accounts for an estimated 70 per cent of the world’s total production of jute products. Over 90 mills are currently operational, 67 in West Bengal alone. The rest are in Bihar, Assam, Tripura, Uttar Pradesh and Andhra Pradesh. The industry supports about 40 lakh farmers and 3.7 lakh jute laborers.

Unrest is growing among jute producing farmers and mill workers. However, the industry’s overdependence on government orders is considered to be a major factor behind the current state of affairs. The government buys jute sacks worth Rs 5,000 crores a year for the packaging of food grains and sugar.

Large scale imports from Bangladesh, which offers a 10 per cent subsidy on domestic jute products and huge funding to its mills and exporters, have added to the stress.

Momad Metrópolis will be held in Spain from February 5 to 7, 2016. This is an international fashion fair for clothing brands. The event has become the largest fashion fair for apparel brands in the Iberian peninsula, with its September edition recording a turnout of 17,000 visitors. The event showcases products like apparel and clothing, textiles, fabrics and yarns.

Exhibitors would include companies and decision makers through the fashion, clothing and design markets such as manufacturers, wholesalers and importers. Attracting exhibitors mainly from Spain, Portugal, France and Italy, it is an important meeting place for retailers and buyers. The event’s organisers expect to reach 800 brands and exhibitors and international buyers from 70 countries. Already confirmed labels include: Roberto Verino, Simorra, Mathilde Cano, Coronel Tapioca, Almatrichi, NKN, Tiffosi and Alba Conde.

The trade show’s organising body, IFEMA, has set up a team of experts, who are scouting for exciting designers across Spain with the goal of bolstering its value as a major meeting space in the Spanish fashion industry. Next year, the show will also feature a Winter Terras area, where entertainment activities will take place organised by some of the exhibitors. Additionally Momad Metrópolis is launching a Retail Forum with talks and discussion panels around a number of topics.

www.ifema.es/momadmetropolis_06/

The 13th edition of Techtextil North America, and the third edition of Texprocess Americas will be held from May 3-5, 2016 at the Gerorgia World Congress Center in Atlanta. JEC Americas will once again be co-located on the same show floor, to provide a dynamic synergy creating the largest technical textiles, nonwovens, textile machinery, composites, sewn products and equipment trade show in the US.

Techtextil North America, Texprocess Americas and the co-location of JEC Americas are expected to draw visitors from top industry executives, buyers, engineers, technical directors, plant managers, product development managers, media and more. The 2014 three in one event hosted 759 exhibitors from 29 countries attracting over 9,000 visitors.

With exhibitors from around the world, the event will bring decision makers from all of the major industries that touch technical textiles, sewn products, equipment, technology and composites together in one place to experience the latest in innovation. Many new country pavilions are expected to be on the show floor this year. Countries include Turkey, Pakistan, Taiwan and Belgium. Visitors can expect to see returning pavilions from Italy, Portugal, China, Germany and Supply Chain USA.

During Techtextil North America and Texprocess Americas exhibitors will have the opportunity to present to the press new and innovative products or technologies they have produced. Visitors can once again also expect a symposium held concurrently with the show floor. For three days over 100 speakers will present during Techtextil North America and Texprocess Americas. A must visit show floor attraction is the annual Graduate Student Poster Program Posters. Graduate students from around the world will have a platform to share their research findings with peers and potential employers/sponsors.

SEAMS Association will once again organise the Supply Chain USA Pavilion. Dedicated to promoting sound economic growth for the US sewn products companies, the not-for-profit organization supports the industry through various measures which includes attending important international trade shows. In 2014 the Pavilion supported by SEAMS hosted 34 exhibiting companies.

www.techtextilna.com

Garment factories in Myanmar are expected to benefit from the United States' decision to ease trade restrictions with the country. Players are of the opinion that it would not only give a thrust to exports to the US but also strengthen domestic industries.

In 2014, Myanmar-US trade value stood at $185.6 million (Bt6.67 billion), with Myanmar exports valued at $92.7 million, according to the US Department of Commerce. In the first 10 months of this year, exports to the US rose to $116.7 million, along with an increase in bilateral trade value to $306.1 million. The US put a lid on Myanmar imports in 2004. The activity resumed only in 2013, with goods valued at $19.9 million shipped to the US. Myanmar exported $1.56 billion worth of garment products in 2014, according to the Myanmar Garment Manufacturers Association, which expects the value to hit $2 billion this year from just over $900 million in 2012. According to the association, GAP is a pioneering US company to source "Made in Myanmar" garments. Others are H&M, Primark and Adidas.

Now the industry experts are looking forward to the US lifting all economic sanctions and GSP-like status is offered to the country like the EU, which will prove to be the major push to expand its business in the foreign countries.

According to the industry insiders, Welspun Group has decided to hive off its yarn-spinning business into a separate entity called Welspun Syntex, which will be managed by cofounder Rajesh Mandawewala's elder son Abhishek. Mandawewala is also said to be looking at acquiring partner and Shairman BK Goenka's stake in Welspun Syntex.

According to the company sources, the process is a part of the company’s efforts to ensure separation of ownership and management, while simultaneously planning a smooth succession of the business to the next generation. The three-decade old group brought consultant McKinsey on board earlier this year to craft `Vision 2020', a programme aimed at building a new organisational structure for the group where promoters will step away from operational responsibilities to take up a more strategic role.

Chairman BK Goenka and MD Rajesh Mandawewala founded the $3-billion conglomerate from a small town in Maharashtra in 1985. Today, the group gets most of its revenues from selling pipes to global oil companies, and towels and bed sheets in both local and overseas markets. Welspun Syntex posted Rs 835 crores of revenue last fiscal year.

www.welspunindia.com

In early 2016, Invista will launch a new campaign for Coolmax and Thermolite brands, two leading fibres used within the company’s apparel and non-apparel segments. The ‘Embrace the Elements’ campaign reflects the new brand positioning forboth the brands and includes a contemporary look and feel with new logos, hangtags, websites, and simplified brand architecture.

With the brand campaign, the company is also introducing a new logo for both the brands. Based on extensive consumer research, the new logos reveal a more contemporary look for the brands while also symbolizing the product benefits with appropriate colour tones – blue for cool and dry with Coolmax brand and red for lightweight warmth with Thermolite brand.

In addition, the branding architecture has been streamlined with four sub-brands - Coolmax brand, Coolmax Pro brand, Thermolite brand, and Thermolite Pro brand. The addition of the PRO designation represents Invista’s advanced innovation in moisture management and warming technology.

To further complement the new brand campaign, Invista will launch the all-new Thermolite Infrared Technology under the Thermolite PRO brand in the first half of 2016. Activated by solar technology, fabrics have been engineered to warm up through exposure to the sunlight.

www.invista.com