FW

In its ambitious ‘Fashion Pact’,luxury brand set following objectives for 2025: to reduce its environmental impact by 40 per cent and cut its CO2 emissions in half, compared to results from 2015. All of this is to be achieved with entirely traceable raw materials and on the same timetable.

From 2015 to 2018, the brand reduced its ‘environmental global impact’ by 14 per cent and its greenhouse gas emissions by 36 per cent. Across the same period, the greenhouse gas emissions related to its stores and other worldwide placements were reduced by 77 per cent.

The group will use renewable energy sources for 67 per cent of its operations. It has reached 100 per cent in seven countries and is at 78 per cent in Europe. In 2018, the company became carbon neutral across its entire business and supply chain, including through forest protection programs.

Moreover, Kering has put in place new standards for raw materials and manufacturing processes. This has formalized the best procedures in terms of environmental protection, social compliance, traceability, the use of chemicals and the wellbeing of animals. These measures have already been implemented across 68% of the group’s suppliers.

The Clothing Manufacturers Association of India (CMAI) has welcomed the Union Budget presented by Finance Minister Nirmala Sitharaman on February 1, 2020 as positive and growth oriented for the apparel industry. Rakesh Biyani, President of the association says the most important step in this Budget for the textile industry was the removal of the anti-dumping duty on PTA, which was a long standing demand of the textile manufacturing value chain. This will potentially open up the MMF value chain, and give a fillip to the entire MMF industry and enhance its global competitiveness.

According to Biyani several other measures could also benefit the textile industry such as the technical textile mission, a review of the Rules of Origin especially in our FTAs, a review of cheap imports of goods being made by our MSME Sector, refund of all the taxes and levies for exports, and the targeting of making every district an export hub. The proposed financing of invoices of the MSME sector could again be a huge benefit to the Industry, which is largely comprised of the MSME units.

Levi Strauss is set to open 100 stores in 2020, as the denim giant is seeing strong gains on the international front and in e-commerce. The brand posted a 3 per cent gain in net revenue in the first quarter of the fiscal year. The company expects its net revenue to grow by 6 per cent in fiscal 2020 This estimate incorporates anticipated benefits of a Black Friday week in the first quarter, and a 53rd week, which will fall in the fourth quarter and will include a second Black Friday.

During the fiscal, Levi’s adjusted earnings before interest and taxes (EBIT) margin expansion is expected in the range of 30 to 40 basis points, reflecting gross margin expansion partially offset by an increase in adjusted sales, general and advertising (SG&A) expense as a percentage of revenues. Its adjusted diluted earnings per share (EPS) are forecast in the range of $1.18 to $1.22.

Capital expenditures are expected to be approximately $200 million to $210 million, with nearly 100 new company-operated store openings on a gross basis in 2020, in addition to 80 stores from the company’s acquisition in South America.

Forever 21 looks t to sell assets to a consortium that includes mall owners Simon Property Group and Brookfield Property Partners and brand management company Authentic Brands Group. The sale of Forever 21’s assets includes its side brands, such as beauty store Riley Rose, and its e-commerce platforms.

US-based Forever 21, filed for bankruptcy protection in September and has since closed 100 stores. Fast fashion retailer Forever 21 became a multibillion dollar operation in over 40 countries before it filed for bankruptcy in September 2019. It plans to close most physical stores in Asia and Europe while continuing to ship to international customers through its US website. The fashion chain had become successful due to its coolness factor and its ability to identify the needs of its customers. But these same customers started to move to online and other retailers. The brand specialised in the fast fashion principle as it made outfits for young teenage girls, who wanted to dress like their favorite celebrities. Forever 21 helped them by providing these fast and at affordable rates. Customers would form huge lines for new store openings. The company also became an attractive tenant for most malls, usually becoming the anchor tenant with its huge sized stores.

Cambodia may soon lose its tariff-free access to Europe. Less than two weeks remain until the European Union decides whether it will revoke Cambodia's trade privileges, granted under the Everything But Arms scheme for least developed nations, due to the country’s systematic violations of human and labor rights. Losing EBA privileges would add a 12 per cent tariff to Cambodian apparel exports to the EU and between eight per cent and 17 per cent for shoes. Europe is a crucial market for the country’s apparel and footwear export sector. Other countries competing in the cutthroat world of low-cost apparel will be keen to snatch market share from Cambodia.

Much work still needs to be done to n improve labor and living conditions in Cambodia. Much progress including wage increase and social security benefits, have been accomplished already. But this many not be enough for Cambodia to retain trade privileges. The EU feels the country has not done enough to maintain its EBA access. The EU also has the option of applying a partial suspension of trade privileges.

Despite the uncertainty, Cambodia’s total exports in the first 10 months of 2019 grew by 6.45 per cent. Exports of textiles, apparel, footwear, travel wear and headwear remained stable.

McKinsey has joined Global Fashion Agenda (GFA) as a strategic knowledge partner. Together, they will work to tackle the biggest challenges facing fashion. GFA and McKinsey will embark on a joint redesigning growth venture. The overall aim of the collaboration is to look beyond existing solutions, to seek inspiration from experts, academia, and other industries to identify the systemic changes needed for the industry to become leaders in sustainability. It seeks to challenge the traditional concept of growth and prosperity, by collaborating to identify solutions for the industry to meet the demands of the future within planetary boundaries. GFA and McKinsey will provide new assessments and reports for the industry to track and follow progress on sustainable development. The alliance is setting ambitious goals to accelerate the pace on sustainability and to push for real industry transformation.

GFA is the leadership forum for industry collaboration on fashion sustainability. Sustainability and corporate responsibility have risen to the top of every industry executive’s agenda. Still, the industry has a long way to go before achieving transformative change. Companies are not implementing sustainable solutions fast enough to counterbalance the negative environmental and social impacts of their rapid growth.

Mango is consolidating its presence in Africa. The brand is now present in Kenya, Angola, Egypt and South Africa, among other African countries. The African store count totals 52 retail outlets, including four Mango megastores, a retail concept that the company introduced in late 2013. Compared to the traditional average store format of 300 sq mts, megastores have surface areas of between 800 and 1,500 sq mts, while flagship stores could be as large as 3,000 sq mts. Mango was one of the first European fashion brands to expand in Africa when it opened its first store on the continent 18 years ago. The company founded in 1984 has an extensive store network extending across 111 countries.

Mango has a new logistics center in Spain. Approximately 600 people work six days a week at the highly automated facility, where around 400 operations are machine-driven, to process items for store deliveries. The 186,000 sq mt facility can stock up to seven million hung garments and 20 million folded garments and accessories at the same time. By incorporating the latest automation technologies, the center can process 75,000 garments an hour. As soon as hung garments arrive at the facility they are unloaded onto one of nine automatic loading bays, which can process 27,000 garments an hour.

Polyester or synthetic yarn could become cheaper in India. The anti-dumping duty on Purified Terephthalic Acid (PTA) has been abolished in this Budget. This will make imports of the petrochemical from Iran, China, Indonesia, Malaysia, Korea, Taiwan and Thailand cheaper. Removal of the anti-dumping duty will put pressure on realisations of domestic PTA manufacturers and will lead to accelerated imports at a time when the market is facing a glut emanating from large capacity additions in China recently. The duty removal will now allow Indian synthetic yarn spinners to access cheaper, good quality raw material from outside India, making their cost structure more efficient. The move will open up the manmade fiber value chain, benefiting technical textiles, home furnishing, sportswear, saris and dress materials, among others.

Once this key textile raw material becomes cheaper, domestic yarn manufacturers are expected to pass on the benefit to consumers. China has added huge capacities in recent quarters and there is a possibility of cheaper imports from that country after removal of this duty.

PTA is a key raw material in synthetic yarn production on which anti-dumping duty was imposed to protect domestic manufacturers. These produce nearly 3.5 million tons PTA for the domestic market. The rest is exported.

"Though brands remain committed to reduce greenhouse gas emissions, buy carbon offsets and develop new sustainable materials, experts have raised doubts over the genuineness of these commitments. This is owing to the fact that though the industry has been introducing innovations periodically besides running pilot projects, it hasn’t yet brought any of it to the scale that’s needed. Today, the industry produces about 8 per cent of the total carbon emissions."

Though brands remain committed to reduce greenhouse gas emissions, buy carbon offsets and develop new sustainable materials, experts have raised doubts over the genuineness of these commitments. This is owing to the fact that though the industry has been introducing innovations periodically besides running pilot projects, it hasn’t yet brought any of it to the scale that’s needed. Today, the industry produces about 8 per cent of the total carbon emissions. And, as per Ellen MacArthur Foundation, this is expected to rise to 26 per cent of the total emissions by 2050.

Though brands remain committed to reduce greenhouse gas emissions, buy carbon offsets and develop new sustainable materials, experts have raised doubts over the genuineness of these commitments. This is owing to the fact that though the industry has been introducing innovations periodically besides running pilot projects, it hasn’t yet brought any of it to the scale that’s needed. Today, the industry produces about 8 per cent of the total carbon emissions. And, as per Ellen MacArthur Foundation, this is expected to rise to 26 per cent of the total emissions by 2050.

Redesigning supply chain for sustainability

Though dozens of brands signed the Kering-led Fashion Pact last year, in order to be truly sustainable, the industry needs to transform its supply chain entirely. However, supply chain transformation is costly as most brands don’t own their suppliers. This separates them from associated environmental impacts — and benefits if they invest in upgrades.

Government policies play a major role

The industry’s progress on sustainability largely depends on government reforms. If the government fails to introduce appropriate policies, brands that invest on sustainability will be at a loss. To avoid this, brands must invest in sustainable supply chains through public financing of upfront costs for things like shifting agricultural practices. In turn, they should commit to buy materials from farms making changes.

introduce appropriate policies, brands that invest on sustainability will be at a loss. To avoid this, brands must invest in sustainable supply chains through public financing of upfront costs for things like shifting agricultural practices. In turn, they should commit to buy materials from farms making changes.

Fashion can also influence many government’s decisions as apparel and footwear manufacturing makes up a large portion of exports. For instance, though fashion comprises 84 per cent of Bangladesh’s exports, its government is currently planning an expansion of coal-fired plants.

Impact of legal policies

Similarly, a country’s laws can significantly influence the behavior of brands. UK’s Modern Slavery Act and California’s Transparency in Supply Chains Act have led to many brands introducing new reforms in their supply chains. Some of these brands have implemented ethical trade policies or commissioned audits on labor conditions at suppliers or recognised unionisation efforts.

Brands are redesigning supply chains to minimise costs at every step. However, to be truly sustainable, they need to amend their legal governing documents to balance profit and purpose. Though this may lead to increased costs for consumers, it will help the industry curb overconsumption and overproduction.

Exploring the rental market

Another way brands are being sustainable is by exploring the $1 billion rental market. Primarily a North American phenomenon, rental services are gaining popularity in Europe and Asia, although its impact on the consumers’ shopping behavior remains unclear.

"The focus of most denim brands in 2020 will be on sustainability as they introduce new initiatives to eliminate hazardous chemicals such as per- and polyfluorinated chemicals from their supply chains. Pioneering this campaign is G-Star, the Dutch denim brand which henceforth plans to use only 100 per cent sustainably sourced cotton, such as Better Cotton Initiative cotton, organic cotton and recycled cotton, by the end of next year. Of its non-cotton components, the company promises a target of 90 per cent."

The focus of most denim brands in 2020 will be on sustainability as they introduce new initiatives to eliminate hazardous chemicals such as per- and polyfluorinated chemicals from their supply chains. Pioneering this campaign is G-Star, the Dutch denim brand which henceforth plans to use only 100 per cent sustainably sourced cotton, such as Better Cotton Initiative cotton, organic cotton and recycled cotton, by the end of next year. Of its non-cotton components, the company promises a target of 90 per cent.

The focus of most denim brands in 2020 will be on sustainability as they introduce new initiatives to eliminate hazardous chemicals such as per- and polyfluorinated chemicals from their supply chains. Pioneering this campaign is G-Star, the Dutch denim brand which henceforth plans to use only 100 per cent sustainably sourced cotton, such as Better Cotton Initiative cotton, organic cotton and recycled cotton, by the end of next year. Of its non-cotton components, the company promises a target of 90 per cent.

Launching the most sustainable jeans ever

In 2017, G-Star employed 57.3 per cent sustainable materials and 69.8 per cent sustainable cotton. In 2018, it launched its most sustainable jeans ever. As a part of the process, the brand developed the world’s first denim fabric to be certified Gold by the Cradle to Cradle Products Innovation Institute’s rigorous standards, which take into account factors like material health and reutilisation, renewable energy, water stewardship and social fairness. Made with 100 per cent organic cotton, the jeans were dyed with 70 per cent fewer chemicals, used no salts and are 98 per cent recyclable at the end of their life.

launched its most sustainable jeans ever. As a part of the process, the brand developed the world’s first denim fabric to be certified Gold by the Cradle to Cradle Products Innovation Institute’s rigorous standards, which take into account factors like material health and reutilisation, renewable energy, water stewardship and social fairness. Made with 100 per cent organic cotton, the jeans were dyed with 70 per cent fewer chemicals, used no salts and are 98 per cent recyclable at the end of their life.

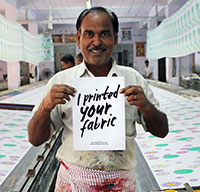

The company also aims to focus on transparency. It has introduced a “Where is it Made?” button that discloses not the just country of origin of each of its garments but also the name and address of the originating factory, any special programs or certifications that distinguish the facility and the number and gender breakdown of its workers.

On its part, Levi’s aims to slash its carbon emissions by 90 per cent and use 100 per cent renewable energy in all owned-and-operated facilities. It also vows to reduce carbon emissions across its global supply chain by 40 percent, which is proving both a challenge and opportunity because it requires directing so many moving parts. The brand is also working on its goal to make 80 percent of Levi’s products using its water.

Chasing globally relevant goals

For Wrangler, it is important to achieve globally relevant goals that reflect its most material issues. By 2020, the company plans to use 100 per cent “preferred chemistry” throughout its supply chain besides conserving 5.5 billion liters of water. Five years hence, the brand aims to source only sustainable cotton and power all owned-and-operated facilities with 100 percent renewable energy. Having its own manufacturing facilities gives the brand multiple opportunities that other brands many not have.

Eyeing carbon neutrality by 2025

Aiming to be the world’s most sustainable denim company, by 2020, Nudie Jeans aims to increase the number of own-brand jeans it takes back by 20 percent and the number of own-brand secondhand jeans it sells by 30 percent globally. That same year, at least one style in its collection will comprise post-consumer recycled Nudie Jeans from its garment-collection scheme. All targets are at their midway point and just require one final sprint, Gelsi noted. By 2025, the company wants to be carbon neutral along its entire supply chain, from raw materials to finished product.

Conserve 10 billion liters of water

Old Navy has set one of its most ambitious goals till date. The brand plans to conserve a total of 10 billion liters of water by the end of 2020. Till date, its parent company Gap Inc has saved 5.7 billion liters.

In 2020, Gap Inc. signed a 90-megawatt virtual power purchase agreement for a wind project with Enel Green Power North America. One of the largest offsite renewable energy contracts by an apparel retailer, the partnership will generate enough wind energy to power the equivalent of more than 1,500 Gap Inc. retail stores By 2030, Gap Inc. aims to reach 100 percent renewable energy across all owned-and-operated facilities globally.