FW

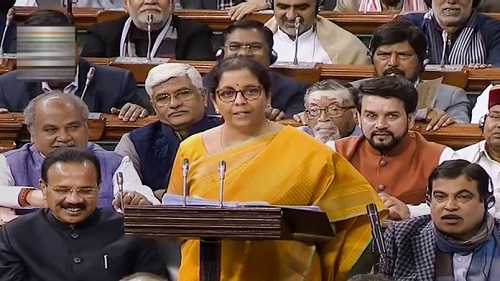

Finance Minister Nirmala Sitharaman presented Union 2020-21, on Saturday, February 1, 2020. The Budget addressed following important points related to textile, apparel and fashion industry:

Finance Minister Nirmala Sitharaman presented Union 2020-21, on Saturday, February 1, 2020. The Budget addressed following important points related to textile, apparel and fashion industry:

• Anti-dumping duty on PTA abolished

• National Technical Textiles Mission to be set up

• Review of Rules of Origin in FTAs

• Schemes for Remission of Duties & Taxes levied on Export Products ( RODTEP)

• Budget Grant for Procurement of Cotton by Cotton Corporation under Price Support Scheme has reduced to Rs 0.01 Cr for 2020-21 compared to Rs 2,017.57 Cr in 2019-20

• Customs duty raised on items like footwear (from 25 to 35 per cent; 15 to 20 on footwear parts)

Removal of Anti Dumping Duty on PTA-A potential game changer

On the proposed abolishan of anti-dumping duty on PTA (Purified Terephthalic Acid), the FM said PTA is a critical input for textile fibres and yarns. Its easy availability at competitive prices is desirable to unlock the immense potential in textile sector which is a significant employment generator. The textile industry has been demanding abolition of anti-dumping duty levied on PTA, the basic raw material used for manufacturing polyester staple fibre and filaments, to remain globally competitive. The Ministry of Textiles envisaged to increase the textile business size from the current level of around US$169 billion to US$350 billion by 2025 and to US$650 billion by 2030 in its draft Textile Policy.

critical input for textile fibres and yarns. Its easy availability at competitive prices is desirable to unlock the immense potential in textile sector which is a significant employment generator. The textile industry has been demanding abolition of anti-dumping duty levied on PTA, the basic raw material used for manufacturing polyester staple fibre and filaments, to remain globally competitive. The Ministry of Textiles envisaged to increase the textile business size from the current level of around US$169 billion to US$350 billion by 2025 and to US$650 billion by 2030 in its draft Textile Policy.

To achieve this ambitious target this step is being seen in the right direction to make polyester fibre and filaments available at international prices as there is a limitation in increasing fibre base within the country.

All industry leaders across board have applauded the removal of anti dumping duty on PTA. “This will give a major boost to Indian textile industry and will go a long way in helping downstream industry staying competitive,” says T Rajkumar, Chairman, CITI. Elaborating on the same Rahul Mehta, Chief Mentor, CMAI says, “The most important step in this Budget is the removal of the anti-dumping duty on PTA, which was a long standing demand of the textile manufacturing value chain, as PTA is a crucial input for polyester production. This will potentially open up the MMF value chain, and give a fillip to the entire MMF industry and enhance its global competitiveness. Technical textiles, home furnishing, sportswear, saris, dress materials etc, will all benefit greatly from this move. It has the potential of being an important game changer for the MMF segment of the Industry.”

Reacting to the Budget proposals 2020-21, Ashwin Chandran, Chairman, Southern India Mills’ Association (SIMA), stated PTA being imported from different countries including China, Indonesia, Taiwan, Iran, Malaysia, attracts anti-dumping duty between US$27 to US$160 per metric tonnes depending on the country of origin, while India often faces shortage of PTA that curtail capacity utilization of polyester segment industry. It shall greatly help the country to enhance its global competitiveness, boost exports and enable domestic manufacturers to compete with cheaper imports.

National Technical Textiles Mission: Boost investments, reduce imports

The FM proposed the setting up of a National Technical Textile Mission with four-year implementation period from 2020-21 to 2023-24 at an estimated outlay of Rs 1,480 crore.

from 2020-21 to 2023-24 at an estimated outlay of Rs 1,480 crore.

“This can position India as a global leader in technical textiles, which includes development of rainwear, sportswear, retarded apparel, fire resistance garments,” opines A Sakthivel, Chairman, AEPC. Agrees Sanjay Jain, former president CITI and says, “This is a fantastic announcement, it will lead to capacity building and import substitution. It has tremendous scope, however we are waiting for the fine print.”

Elaborating further T Rajkumar explains, “The mini mission on technical textiles is welcome. Technical textiles has to be encouraged as a lot of fabrics we use in the sector are being imported, the move will help in starting production of specialised input in our country, a lot of investment will come which will also boost employment in the sector.”

Chandran believes India has an importing technical textiles segment estimated at US$16 billion per year, this Mission would help strengthen the sector which can take advantage of benefits already extended under different State Textile Policies and also the Technology Upgradation Fund Scheme. He also appreciated the enhanced allocation of Rs761.90 crores for A-TUF Scheme as against Rs700 crores allotted previous year. Ujjawal Lahoti, Past Chairman, Textile Export Promotion Council (Texprocil) welcomed the base support given to Technical Textile saying “It will result in to setting up production of import substitute textiles items.”

Review of the Rules of Origin in FTAs to curb imports from Bangladesh

All industry leaders welcomed the intent to review the rules of origin in FTAs. It was being observed that imports under Free Trade Agreements (FTAs) are on the rise. Undue claims of FTA benefits have posed a threat to domestic industry. Such imports require stringent checks. As per the Budget announcement, suitable provisions are being incorporated in the Customs Act and in coming months review of Rules of Origin requirements, particularly for certain sensitive items, shall be done, to ensure that FTAs are aligned to the conscious direction of our policy.

A lot of Chinese fabrics and raw materials converted into garments were entering into India through these FTAs. “The move will help reduce imports from Bangladesh etc, which plaguing textile industry. However, a complimentary step in this direction would be expediting FTAs with EU, Australia, Canada and initiating FTA with UK,” Shaktivel says.

Industry hails RODTEP, NIRVIK and other measures taken

As per A Sakthivel “The AEPC is studying the proposed Scheme for Revision of duties and taxes on exported products where exportr to be digitally refunded duties and taxes levied at the Central, State and local levels, which are otherwise not exempted or refunded. This is an important area which has seen significant shrinkage in policy support in last few months. The new NIRVIK scheme for higher export credit disbursements with greater coverage, reduced premium and simplified procedures for claiming settlements is a welcome step given the increased uncertainties in the global market. We look forward to further details of the scheme.”

AEPC also congratulated the finance minister on effectively addressing some key issues of the sector especially in the areas of Ease of Doing Business, National Logistics policy for making MSMEs competitive, simplified return with features like SMS based filing for nil return and improved input tax credit flow, enhancing digital connectivity, support for working capital, financing for MSMEs, five year exemption from audit for MSMEs & easing of tax filing for startups are some import steps towards easing the day to day functioning of MSMEs as also providing a conducive ground for investors.

On similar lines Chandran hailed the announcement of the Schemes for Remission of Duties & Taxes levied on export products and NIRVIK for extending competitive credit facilities and higher insurance coverage with lesser premium and also simplified procedure for claim settlements. “Happy to note that FM announced again that Refund of Taxes scheme (RODTEP) will be soon implemented for exporters. As exporters of cotton textiles products are suffering due to a sharp decline in exports of yarn, and retrospective removal of MEIS, it is important to get this scheme implemented for exports all textile products at the earliest,” says Lahoti

SIMA also welcomed the announcement of addressing inverted duty structure in GST as textile industry has been suffering with huge accumulation of inverted duty of capital goods and certain services. Prem Mallik, a veteran in textile industry and past president CITI, states, “The announcement on refund of taxes including electric duty, mission on technical textiles and intent to incorporate rules of origin in FTA,S are welcome steps. I request the government to implement these positive steps, immediately.”

However not all are happy with the Budget proposals as R D Udeshi, President Polyester Chain, Reliance Industries opines “Disappointing Budget, as very little has been done for textile industry. More concrete steps were required for growth of the industry. Vision of $400 bn will remain only on paper,” he summed up.

Apparel Sourcing and Texworld were held in the US, January 19 to 21, 2020. The shows made news because of a greater focus on sustainable practices. They are seen as the premiere platform for sourcing and product discovery in the marketplace. Attendance increased eight per cent. Exhibitors were from Canada, the United States, Colombia, India, China, Hong Kong, Japan, Thailand and Ukraine. Country pavilions were organized to represent the offerings of Mauritius, Korea, Nepal and Taiwan. Lenzing showcased products using Tencel and Lenzing Modal. The show floor equipped retailers, designers and apparel buyers with knowledge about new materials, technology and trends to grow their businesses. Industry leaders discussed trends and advancements, including blockchain technology, circular tracing and biosynthetic materials.

As sustainability continues to reflect an expanding umbrella of progressive initiatives such as ecologically sound manufacturing, closed-loop apparel manufacturing, ethical sourcing and empowerment of developing communities, this edition provided the needed clarity to help attendees make decisions regarding their next steps. The push toward sustainability in the garment industry is growing with rising concerns about environmental impacts and social awareness.

For the third quarter Trident’s net profit fell 27.7 per cent. Consolidated profit before tax slumped 74.1 per cent. Tax expense dropped 70.1 per cent. Net debt jumped 10.42 per cent. This year Trident saw growth in the first two quarters. However, the third quarter brought some headwinds due to which overall revenue declined as compared to the previous quarter as well as compared to the corresponding period of last year. Lower traction in the home textile segment along with reduced realizations in the yarn and paper segments impacted revenue as well as profitability for the quarter. The company is expecting an improvement in capacity utilization in the bath linen segment in the next quarter and is looking at the order book for the sheeting segment for the next quarter.

Trident is a vertically integrated textile and paper manufacturer. Trident believes in offering innovative solutions and delivering high-quality value-added products to customers. Trident is expanding spinning capacity at its Madhya Pradesh plant. The project, expected to begin commercial production by January 2021, will help strengthen Trident’s existing home textile business and further expand its market presence. Trident’s existing capacity is 5,43,744 spindles and 6,464 rotors, and the current capacity utilisation is 99 per cent. Trident has planned for maintenance capex at Rs 100 crores for fiscal ’20 and the same will be utilized toward small maintenance capex in the form of de-bottlenecking and upgradation of capacities.

Myanmar has begun investing in environmental sustainability. Till now, only one garment manufacturer in the nation has been certified Leadership in Energy and Environmental Design platinum. Two other facilities, both operated by garment manufacturer Guston Amava, comprise 34 per cent recycled building materials, such as reclaimed steel, in their construction, along with rooftop solar panels, an evaporative cooling system and water-reduction features.

However, Myanmar has a long way to go. Factories are missing cost-saving benefits of making their operations greener and securing higher investments as buyers pay closer attention to sustainable production. Myanmar is one of the world’s fastest growing garment, footwear and travel goods suppliers. But this growth also results in increased environmental impact, which requires best-practice solutions for improved production efficiency, energy, water and waste management.

At a time when retailers and consumers are paying close attention to the conditions under which their garments are produced, ethical and sustainable production is a big deal. Making their operations more environmentally friendly will help factory owners compete with other sourcing markets and give them a better chance of retaining existing orders and securing new business. Else they face the danger of ceding business to competitor countries.

Asics has bought a stake in No New Folk Studio. Asics jointly with No New Folk Studio is developing smart running shoes that give runners real time feedbacks on the changes in their foot movement. Foot movement data, including number of steps /distance, cadence, and angle of ground contact, are collected and together with biomechanics expertise are analyzed to provide runners feedbacks on gait analysis, including step length and foot strike pattern.

Asics is a footwear and sports equipment group from Japan. No New Folk specializes in the design of artificial intelligence applied to sports shoes. No New Folk Studio develops IoT interface that seamlessly integrates movement, light, and sound to facilitate new forms of art and performance. No New Folk was founded in 2014 and has previously worked with Asics on different projects. The companies have developed smart shoes to measure the shape of the footprint and the movement of the foot while exercising or walking. One of the core strategies of Asics is enriching sports lives through the use of digital technology, and the company is focusing on improving the sense of fulfillment customers get from sports by using digital power. The investment in No New Folk Studio is part of that strategy.

Helena Helmersson is CEO of H&M, a veteran of the same company she started in 1997 as an economist at the buying department and held various roles within buying and production. She was sustainability manager for five years, and after that production manager based in Hong Kong.

H&M with nine labels is one of the biggest fashion retailers globally. It has gradually improved profits and has a strong position with many well-established brands, millions of customers worldwide and good financial strength. For the fourth quarter net sales rose nine percent. The online and physical stores are being increasingly integrated with continued optimisation of the store portfolio. Developments this year will include both physical spaces and web stores. Around 200 new stores are planned to open in 2020, mainly in growth markets, but there are also around 175 planned store closures, mainly in established markets. Australia is scheduled to become a new H&M online market in the second half of 2020 and H&M will be launched on an e-commerce platform in South Korea this year. In a challenging context, and while the industry is facing a radical transformation, the Swedish group has been experimenting with new store concepts and chains for the past years in a trial and error strategy.

As part of its restructuring process Gap closed 40 stores across the world. The US retailer plans to close a total of 230 stores over the next two years.

The closings come as part of Gap’s restructuring plan, which includes withdrawing Old Navy from China this year and focusing on its North America market to boost sales. The apparel retailer is focused on aggressively addressing the operational issues that are hindering the performance of its brands. The company’s management structure will be slimmed down in order to speed up decision making as well as a refreshed senior compensation plan, based around performance and accountability. Meanwhile Gap and Arvind have embarked on a water-saving project. This is at Arvind’s denim manufacturing facility in Ahmedabad. The project will save eight million liters of fresh water a day or 2.5 billion liters of freshwater on an annual basis. The first mill in India to manufacture denim, this will now operate entirely with reclaimed water using Membrane Bio Reactor technology, which will treat domestic wastewater drawn from the surrounding community and avoid the use of chemicals in the process. A newly constructed pipeline will draw wastewater from the local municipal line. In the face of local water scarcity challenges, the facility will also reduce business risk for Arvind, Gap and other brands that source from the facility.

Pakistan’s fashion industry has come a long way, and it is only expected to flourish in the coming years. The fashion industry, though quite small, has kept growing over the years. There are award programs such as the Lux Style Awards and Hum Awards, fashion shows like the PFDC Fashion Walk held by the Pakistan Fashion and Design Council, and model-hunt shows like Veet Miss Super Model, among other things.

An important addition to Pakistan’s fashion industry besides clothes, jewelry ad makeup is fragrances. Ayesha Ziya is known for her luxury perfume brand. Television host and anchor Waseem Badami also has a perfume collection, as does retired cricket player Wasim Akram as well as the late musician turned religious scholar Junaid Jamshed.

The country’s fashion industry got international attention and is viewed as a promising market. Being able to design outfits in a range of categories is a skill among the country’s fashion designers. The Annus Abrar studio is known for its luxury pret, festive and bridal collections. Modeling is an important aspect of the fashion industry. Model Aneesa Sharif has a clothing brand named Niya. Models use their star status to raise awareness regarding different social causes.

Challenges confront the global apparel industry in 2020. Polarisation of manufacturers is continuing, with top class of large, well equipped manufacturers growing their market share at the expense of smaller suppliers. Domestic production in the US and in Europe is growing, but its market share is still very small. All of these trends are expected to continue in 2020.

The supply chain needs to accelerate the transformation to a more demand driven model. That’s a prerequisite for improving the bottom line. The challenge is for buyers and manufacturers and their suppliers to build responsive, flexible and sustainable value chains that are able to deliver the right product in the right amount at the right time. This requires collaboration which in turn requires from buyers to look beyond cost, to be prepared to share part of the investment burden by forfeiting short term lower buyer prices for long term gains and to engage suppliers as strategic partners. It also requires an acceleration of implementation of the ample technology available to move the industry into the digital age.

Another challenge is to reduce the environmental impact of clothing. Once improvements are made they must be communicated in the right way to consumers.

The National Cotton Council (NCC) applauded President Trump’s signing of the Congressionally-approved U.S.-Mexico-Canada Agreement (USMCA).

NCC Chairman Mike Tate said this trade agreement will provide a boost in trade certainty for U.S. cotton and cotton textile products in the North American market. He noted that Mexico is the second largest export market for U.S. cotton textile/apparel products and Canada is the fourth largest for these goods. Mexico also is a top market for U.S. raw cotton.

The Alabama cotton producer said the USMCA, which updates and modifies the North American Free Trade Agreement, includes a textile chapter that offers significant improvements for domestic textile manufacturers and workers. Among those provisions are: a stronger rule of origin for certain regional textile products; strong customs enforcement language; and ensuring that a significant amount that the Department of Homeland Security spends annually on clothing and textiles is on domestically-produced products.