FW

From operating a mill 24x7, textile mills of the Northern India Textile Mills’ Association (NITMA) may keep their units shut once a week and cut back production. Excess spinning capacity in the country and poor demand for yarn from overseas markets has led to the accumulation of stocks and poor liquidity. This is the reason for the weekly shutdown by textile mills.

President of NITMA, Sharad Jaipuria said that new investments in spinning were happening in states such as Madhya Pradesh, Gujarat, Maharashtra, Rajasthan, Andhra Pradesh and Telengana. This was because of their new Textile Policy, which offered loads of incentives and sops thus adding more than required capacity in the country. He added that Tamil Nadu too would be announcing a new Textile Policy soon.

Meanwhile, China, had cut-down imports in the past few months, so the situation had worsened, which in turn led to an accumulation of yarn stocks in Indian spinning mills. Senior Vice President, NITMA, H S Cheema also felt that the spinning industry was in a crisis and the situation was worsening and spinners were incurring losses. Thus, they were looking at several options to reduce their daily production.

Moreover, the TUFS reimbursements were pending for cleared cases from the July-September 2014 quarter. This only added to the woes of the industry.

More than 250 textile and garment factories in Bangladesh have not been in operation for the last few years. They want to relocate to places that meet workplace and other safety requirements but have not been allowed to shift their existing gas connection to new destinations. The reason: the government does not allow a shift of gas connections is unknown.

After the Rana Plaza building collapse, many manufacturers frantically tried to relocate their units from shared or rented buildings to more sustainable locations. While they could shift machines and workers, they were forced to leave their boilers and generators and washing and dyeing units behind, since they were not assured of power in the new locations. Some 30 spinning mills are waiting for gas connections though they have invested a huge amount of money.

Leaders of garment factories have demanded gas connections for the country’s largest foreign currency earner on a priority basis. Investment in 30 spinning mills has remained unused while many more units could not go in for expansion due to gas scarcity for some years. On the other hand it is not possible for garment owners to continue operating from where they have been. If they do that they risk losing orders because buyers insist the units meet safety requirements.

China is helping Texas, US, to improve cotton production. Reason: Many of the challenges Texas faces are similar to those encountered in cotton-producing areas of China. One of the critical issues facing Texas is water-use efficiency of major agronomic crops and how to adopt better irrigation management strategies. To accomplish this, there has to be a better understanding of soil-crop water relations and the physiological processes and crop traits that regulate crop water use.

The Chinese are interested in studying the response of cotton plants to limited water use and drought stress. They have been investigating water use and root development in cotton crops. The data will be important toward developing models to determine crop water use over the entire growing season of cotton crops.

There is a lot of clay soil in areas of Texas, which is also characteristic of soils in many of China’s cotton-producing areas. So it’s important to understand soil differences and how the water gets to the plant roots. That way it’s possible to determine if there are better ways to plant crops and to direct the flow to maximize the amount of water getting to the roots.

Adding the soil dimension to the crop-water-soil dynamic will allow researchers to have a more complete picture of how cotton yield might be improved and how the amount of irrigation needed can be reduced.

In March this year, Birla Cellulose launched 'Liva', as an independent property. Liva is expected to play a key role in producing excellent fabrics in line with consumer tastes and demands. During S/S15, Liva tagged garments were available with major retail brands, across 84 cities. Recently Liva hosted the Liva Partner Conclave 2015 in Jaipur in collaboration with the Garment Exporters Association of Rajasthan.

The focus of the event was on Liva S/S16 collection specially highlighting Indo-western and ethnic garments. Liva has been a vital ingredient in the entire gamut of fashion wear from skirts, kurtis to palazzos.

Manohar Samuel, President, Marketing & Business Development, Birla Cellulose addressed the audience and stressed on the importance of the event as he said “Our vision of taking brand Liva to the consumer along with our brand associates and the Liva Accredited Partner Forum Members has now reached greater heights with the inclusion of leading garment makers under the Garment Exporters Association of Rajasthan”.

Birla Cellulose also launched a unique concept called ‘Liva Accredited Partner Forum’ (LAPF), of aggregated partners in March 2015 which saw a continuation in this meet. LAPF is a community of spinners, fabricators and processors, who work closely with Birla Cellulose on innovation, quality and technology to deliver Liva fabrics to consumers.

Terming the garment industry as the mainstay of manufacturing sector, Fiji Export Council CEO, Jone Cavubati, said the sector has registered a healthy growth over the year and has become more organised and consistent in approach with time. He further said, the sector was strengthened by the fact that the garment industry is one of the biggest contributors in generating employment in the country. Referring to the factories, established with an investment of $10 million in Lautoka, Cavubati said, such heavy investments in the garment industry are clearly indicative of growth and the expansion the sector is witnessing across the country.

Bullish on exports, the CEO said, they are doing good in this area and can expand further since they have an advantage over other Asian countries. He further stated that big Asian players in the sector such as China are bulk manufacturers, while a country like Fiji can meet small requirements of other countries. He also asserted that it is true that Australia and New Zealand were Fiji’s competitors, but serve as its main markets too. He was apprehensive about the increase in cost of manufacturing that is a big hindrance in the way business is conducted.

Vietnam has overtaken Bangladesh, as the world's second largest apparel exporters, in exports of readymade garments (RMG) to the US. Though retailers had stocked up for higher sales in summer, Vietnam’s exports of RMG exceeded those of Bangladesh, said traders. Bangladesh exported 162 million SME (square metre) in June, while Vietnam exported 269 million SME. China, on the other hand, which is the largest supplier of apparels to the US, exported 996 million SME in the same month.

Vietnam was on the second place among the top-10 RMG exporters to the US, while Bangladesh was pushed to number three. China, though, remained at the top, with growth increasing in speed from the previous month. The volume of US apparel imports from all sources rose by 7.7 per cent year-on-year in June, up from 6.8 per cent rise in May, this was reported by the Department of Commerce's Office of Textiles and Apparel (OTEXA).

Imports in the US reached 2.33 billion square metre (SME), which is an increase from 2.17 billion SME in June 2014. China’s shipment, was up by 6.4 per cent to 996 million SME followed by Vietnam, which grew to 269 million SME, compared to the same month a year ago.

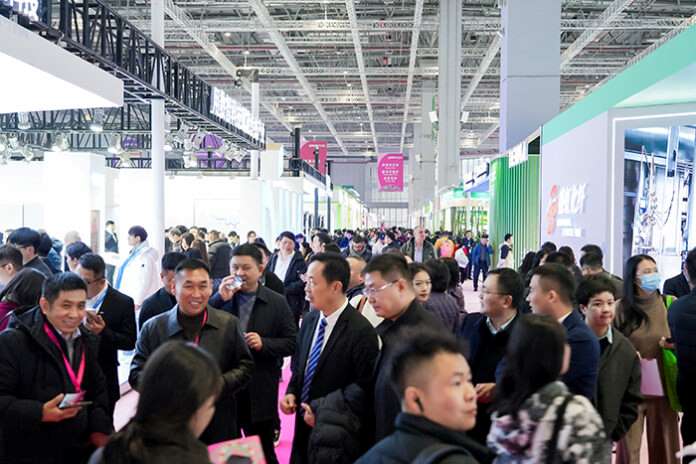

The largest Yarn Expo Autumn is will be held from October 13 - 15 in Shanghai. Both the gross area and number of exhibitors have seen an all-time-high. The fair will showcase a wide spectrum of natural and blended yarns including cotton, wool, flax, regenerated flax and man-made fibres and yarns as well as specialty products including elastic, and fancy and blended yarns.

To be held at the new National Exhibition and Convention Centre, Shanghai, the autumn fair will take up 8,500 sq. mt. gross area to house over 250 exhibitors, with both figures seeing an increase of over 70 per cent compared to last year. Among the exhibitors, almost 100 are from overseas such as Hong Kong, India, Indonesia, Korea, Pakistan, Singapore, Switzerland, Uzbekistan and Vietnam.

Three synthetic fibre zones from China

Meanwhile, over 150 domestic exhibitors brought by the China Cotton Textile Association and China Chemical Fibre Association will showcase sophisticated innovative fibres. Synthetic fibres from China continue to be featured in three zones. Three special zones will be featured to demonstrate synthetic fibres from Mainland China, including Advanced Cottony Polyester Fibre Zone featuring top imitation cotton suppliers in China, who will demonstrate how these fibres can be employed in sportswear, overalls and denim outfits. Renewable & Recycling Zone will bring all the country’s major renewable & recycling fibre suppliers under one roof, who will showcase a full range of products ranging from raw materials to finished goods. Functional Fibre Zone will be displaying mainly polyester, nylon, biochemical fibres, spandex, polypropylene fibres and acrylic fibres. More eco products, such as environmentally friendly dyed yarns, will also be another highlight of this zone.

Trend Forum

The most authoritative platform to learn about fibre trends ‘The Trend Forum’, is being organised by the Ministry of Industry and Information Technology of China, the China Chemical Fiber Association, Donghua University and the China Textile and Chemical Fiber Product Development Centre. Visitors can learn about upcoming fibre trends in China. With a theme of ‘Innovation & Integration’, next year’s trends will be elaborated in four sections: Fiber Technology, Fiber Life, Fiber Ecology and Fiber Defense.

Yarn Expo Autumn 2015 will be held concurrently with other three textile trade events, namely Intertextile Shanghai Apparel Fabrics 2015, China International Fashion Fair 2015 (CHIC) and PH Value.

Southern India Mills' Association (SIMA) has appealed to the Centre to take immediate steps to create a level-playing field for the sector. The industry is looking to the government for duty relief. In the absence of a level playing field due to higher duty rates of Indian textile products in various international markets, higher costs of raw materials, funding and high transaction etc, the industry is not in a position to achieve its potential growth rate.

Therefore, it wants raw materials of both cotton and synthetic fibers available at prices comparable to international prices; free trade agreements expedited with all major textile importing countries particularly China and EU; and tariff rates slightly lower than or at par with other competing nations’.

The Association has pitched for an early rollout of GST and prefers textile products to be brought under the lowest rate of GST as the textile industry is a low profit margin industry. Measures like these are expected to enable the industry to achieve a growth rate of 25 to 35 per cent in the short run and 20 per cent in the long run.

Spinning mills in the south want the 14 per cent import duty on cotton to be withdrawn. They are mulling suspending production for a day to draw the attention of the government to the industry's plight and impress the need for right policy initiatives.

A new organisation, Child Labor Free, is working with influential advertising agency Saatchi & Saatchi to tackle the problem of child labor in the textile industry. There is already growing consciousness about manufacturing practices in the textile industry.

If Child Labor Free does attain a position of influence customers will soon see garments on retail shelves with a little red heart symbol on the label. The red heart will indicate that the garment was produced without the involvement of child labor. The intent is that customers will shun garments not bearing the label.

This means that for brands not sourcing T-shirts and other garments with the little red heart symbol on the label may have an adverse impact on sales. Brands applying to use the Child Labor Free mark will have to provide manufacturing, component and sourcing information, along with evidence that child labor is absent in their supply chains. Child Labor Free will then evaluate the report, which may include recommendations for site inspections if deemed necessary.

Eliminating child labor in the textile industry is of course a noble cause, but success will ultimately depend upon the response of the average consumer.

A large number of world’s leading outdoor brands are now incorporating merino wool innovations into their collections, with wool becoming more prominent in outerwear apparel. As casual wear catches on across the world, major brands are increasingly interested in merino wool’s versatility.

Traditionally, wool was seen mainly as a fiber used in men’s suits. Yet, while it is still the premier fiber for high end woven wear, there is a lot of discussion about other uses for wool and the rise of the fiber in outdoor apparel. The Woolmark Company is highlighting Australian merino wool as the ultimate natural fiber and premier ingredient in luxury apparels. This is a reflection of trends. The world is experiencing a rise in sports luxe apparels, with consumers buying sportswear-turn-street wear, resulting in traditional fashion brands incorporating an element of active wear into their collections.

Merino is one of the world’s most ancient breeds of sheep. It makes its home in freezing conditions. The merino’s fleece is breathable in summer, insulating in winter, yet exceptionally soft and lightweight. Merino wool is a completely renewable fiber. When disposed of, the wool decomposes in soil in a matter of years, slowly releasing valuable nitrogen-based nutrients back into the earth, acting like a fertiliser. In contrast, synthetic fibers can be extremely slow to degrade.