FW

Vardhman Textiles has reported a 37.27 per cent increase in consolidated net profit for the first quarter ended June 30, 2015, helped by lower expenses. Net sales in the quarter under review were down 2.26 per cent compared with the same quarter last year. Total income decreased 3.5 per cent.

Overall expenses were down 6.95 percent compared to the corresponding quarter a year ago while production improved 8 to 10 per cent. The rise in cotton prices last year impacted the June quarter top line growth. Other expenses like depreciation remained high. The company expects sales to remain flat and an EBITDA of 18 to 22 per cent in financial year ’16.

Vardhman is a major integrated textile producer in India. The group was set up in 1965 at Ludhiana. Since then, it has expanded manifold and is today one of the largest textile conglomerates in India. The portfolio includes manufacturing and marketing of yarns, fabrics, sewing threads, fiber and alloy steel. The group has also diversified into yarn processing, weaving, sewing thread, fabric processing, acrylic fiber manufacturing and into special alloy steels. Over the years, the group has expanded its spinning capacities besides adding new businesses.

www.vardhman.com/

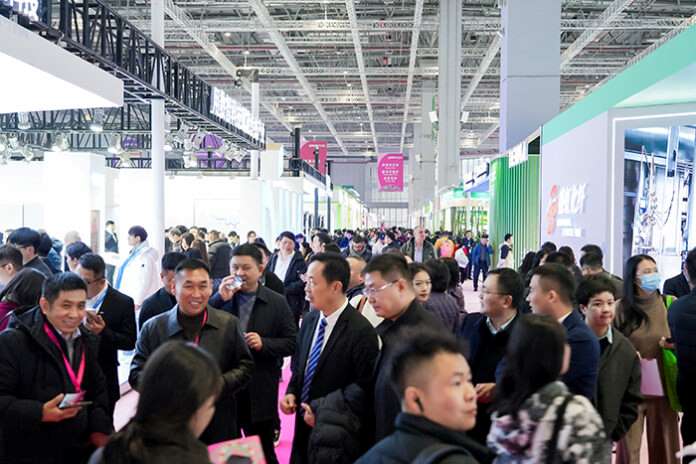

After holding successful conferences in the past including the 1st Asian Textile Conference in 1991, the 7th Asian Textile Conference in 2003, et al, The Textile Association (India)- Delhi Unit is organising National Textile Conference 2015. The conference to be held on October 26 and 27, 2015 in New Delhi will be on the theme: ‘Make in India: Destination Textiles’.

Textile industry plays an important role in Indian economy as domestic consumption and exports of textile and clothing amounts to approximately 6 per cent of the GDP. This sector contributes to almost 12 per cent of the total export earnings of the country and employs more than 100 million people, directly or indirectly. The textile and clothing market size has grown at a compounded rate of 12 per cent per annum from $66 billion in 2009 to $115 billion in 2014. The industry is projected to remain on a high growth path and reach $535 billion by 2024-2025. The conference will focus on the importance of implementing the national program in Indian textile industry.

The two day conference will see a mix of presentations and panel discussions involving renowned textile sector stakeholders of the country. The key topics include facilitating investment, fostering innovation, enhancing skill development, protecting intellectual property and building best-in-class manufacturing infrastructure which is the underlying aim of ‘Make in India’ campaign. The discussions will present India's manufacturing competitiveness in terms of raw material availability, manpower resources, technology and infrastructure and delve on key growth constraints.

Facilitation of investment in India is one of the key objectives of the conference. The focus will be on ways to foster investment in the sector and importance of partnership to bring investment as well as technical know-how. The conference will also witness a cultural program and fashion show by students of fashion institutes in the region.

www.textileassociationindia.org

Focus on denim as active wear

First used as a fabric for workwear, denim is now facing a threat from new-found ‘Athleisure’ trend. But denim has survived and triumphed many such challenges over decades and the challenge has continuously raised the bar of this versatile fabric pushing denim players to continuously experiment and innovate. The more they stretched their imagination, the fabric evolved.

The fourth edition of Denimsandjeans.com Bangladesh to be held at Radisson Dhaka derives its inspiration from ‘Denim Players’. The theme is aptly selected as ‘Denim Playground Dhaka’, where exhibitors from around the world will showcase their sporty innovations to visitors. It will emerge as a playground for denim lovers.

Elaborating on the theme Sandeep Agarwal, Organiser, Denim Playground said, “Bangladesh today is the most important destination for denim sourcing and it is our endeavour to bring the world industry together on this platform to further develop business from this region. Our next show in October shall have the 'Playground’ theme emphasising the active wear aspect of the product and constant innovation inspired by the athleisure trend. Our exhibitors will bring their high-tech products in the supply chain to cater to this growing trend and enable the retailers and brands to source fabrics and garments from this region.”

Prime global event for the denim industry

Last edition saw over 400 companies attending the show including most reputed retailers, factories, buying houses and, brands such as: Tesco, Tom Tailor, C&A, Carrefour, Coolcat, Celio, Charles Voegele, Cortefiel, Uniqlo, S.Oliver, Walmart, Debenhams, Dewhirst, El Corte Ingles, Esprit, Grouppo Coin, H&M, HEMA, Hermes, OTTO, O’stin, Inditex, Kappahl, Kmart, LCWaikiki(Tema), Levi Strauss & Co, Li & Fung, Lindex, Marks & Spencer, Mondial, New Times, Next, Perry Ellis, PVH, Redpoint, S. Oliver, Sainsbury’s, Target and VF Corp.

The event also witnessed ‘The Godfather of Denim’ – Adriano Goldschmied and renowned denim consultant, Piero Turk, whose views about the show were very encouraging for the industry. Sustained focus on eco sustainability has always been the mantra of Denimsandjeans.com website as well as its shows. In the last show, GIZ -Deutsche Gesellschaft für Internationale Zusammenarbeit Gmb was the technical partner, who organised the panel discussion ‘Development Prospects in Denim Production – the Way Forward’ with a focus on eco sustainability. The fair also had fashion in denim event called ‘FASHIONIM’ sponsored by three exhibitors.

The long list of exhibitors included Artistic Fabric Mills Garment Industries, Artistic Milliners, Arvind, Bhaskar Denim, Denim International, DeriDesenetiket, Envoy Textiles, Foison Textile, Ginni International, Ha-Meem Denim, Indigo Textile, Litun Fabrics, Mafatlal, NDL, ORTA, Nahar, Pacific Denims, among others.

Japan's Toray Industries recorded high sales in its Czech subsidiary, Toray Textiles Central Europe (TTCE). With a boost in textile sales, the company is strengthening its position in Central-Eastern Europe’s textile market. TTCE’s sales went up by 72 per cent to about €51 million, last year. This was due to a higher demand for its products and relatively weak Czech krona. The company expanded its net profit by about €5.8 million, which is in line with its rise in sales in 2014.

Due to the facility’s increasing sales, which is located in Prostejov, in the Czech Republic’s south-eastern part, the group is now the largest foreign investor in the country’s Olomouc region. The company plans to expand its output capacity further and create 30 new jobs at the Czech plant this year.

Toray Industries’ products are 100 per cent polyester filament fabrics, plain taffeta, textured taffeta and pongee. Besides, TTCE is the first Czech-based firm to make textiles for automotive air bags, besides, lining cloth, sportswear, furnishing materials, outer-wear, and base fabric for industrial use.

Shozo Sugaya, chief executive of TTCE said that increased share of higher added-value products resulted in improved sales and subsequently, improved financial results for the firm. TTCE increased its sales of polyester lining fabric by 27 per cent, and sales of fabrics used in the manufacturing of airbags by 22 per cent, last year compared to the sales of the same in 2013. According to Sugaya, this was because of increased sales to automotive parts maker Autolive, which is the largest supplier of airbag components in the world.

Hugely popular apparel brand, Executive Order Clothing (EOC), has announced that it would be moving its production from Pakistan to Waterloo, Canada. Apparel brands that have high standards for their clothing and for ethically sourced and manufactured materials, are in great demand. The young, yet promising brand, Executive Order Clothing covers all these aspects well.

Michael J Young Jr, EOC’s founder stated that apart from the brand making remarkable progress even though relatively new, it was also making positive changes to ensure longevity. ‘Cut and Sew’ designs for ladies will be the first step in expansion for the brand on September 11. V-Necks, T-shirts with alligator skin and genuine leather, Polos and sweaters, etc, will be included in the range. Most of these would be handmade, and look and feel stylish.

EOC’s new collection is for both men and women. Men’s shirts will display stunning art and design, crafted by the staff that include experience with some major players such as Akademiks, Ralph Lauran and Enyce. While its women’s wear range spells ‘elegance’ according to young.

Besides, an ‘Executive Exchange’ insurance policy on items priced $35 and above will be offered to customers, where they can exchange any clothing item for a brand new one, no matter in what condition the garment is in.

The predominantly cotton based textile industry in India has been facing several challenges in recent times owing to higher tariffs imposed on Indian textile products in all major international markets compared to competing nations. Undue delay in disbursing Technology Upgradation Fund Scheme subsidies, volatility and uncertainty in cotton prices, sudden glut in the synthetic yarn market, closure of dyeing units in northern states resulting in accumulation of fabric stock in different power loom clusters have added to the crisis of the sector.

At present, the spinning sector has 10 per cent excess capacity, due to poor demand for yarn exports though there have been improvements in recent months resulting in accumulation of yarn stock and liquidity problems. To discuss various problems being faced by the spinning sector, and to decide on the future course of action to mitigate the crisis, the Southern India Mills Association has convened a meeting of its member mills today.

Spinning in India can be classified into two categories: medium and long staple. Development of new varieties of seeds and adopting advanced procedures of cultivation will add to the profit in the cotton textile sector of the spinning industry.

Growth to continue upward ride

The report anticipates the industry to continue on a growth path both in terms of sales and profits even in the near future. Growth in sales will be backed by a continuation in demand for apparels from both the domestic and the overseas markets. Going forward, increase in urbanization, rapid changes in fashion and lifestyle patterns, rise in consumer spending would propel the domestic demand for apparels, it said. On the other hand, improved prospects of global economies will fuel the overseas demand. Furthermore, lower operating and non-operating expenses would result in a healthy growth in the industry’s profits.

During 2015-16, the industry’s sales are expected to grow by 13.3 per cent. Revenues of Page Industries, the largest listed company in the industry, are expected to grow by 26.6 per cent, in both - volumes and realizations. The company is into manufacturing innerwear and primarily caters to the domestic market. Similarly, sales of Rupa & Co, another leading manufacturer of innerwear is likely to grow by 13.5 per cent during the year.

Gokaldas Exports, one of the top apparel exporting companies in the industry, is expected to report a 10.3 per cent increase in sales in the current fiscal. Among the other major apparel companies, sales of Orient Craft, Lux Industries, Pearl Global Industries, Dollar Industries, Sudar Industries and Raymond Apparel are expected to grow in the range of 10-15 per cent.

In the ongoing fiscal, prices of raw materials such as cotton yarn and synthetic yarn are expected to be lower as compared to the preceding year. Prices of cotton yarn are expected to decline by about five per cent and that of polyester by around eight per cent. Consequently, raw material expenses of the industry are likely to grow by 11.5 per cent, slower than the growth in sales. Other expenses viz. power & fuel, wage bills and other operating expenses are expected to increase in the range of 12-14 per cent. Consequently, the industry’s operating profit is projected to rise by 15.5 per cent. Operating margin is likely to expand by 40 basis points to 12.5 per cent.

In 2016-17, the industry’s sales growth is likely to improve to 14.1 per cent. Operating profit is expected to grow by 17.8 per cent and net profit by 24.5 per cent. Operating margin and net margin are likely to expand by 40 basis points and 50 basis points to 12.9 per cent and 6.3 per cent, respectively.

Industryoutlook.cmie.com

Nandan Denim (NDL) has reported a net profit of Rs 15.50 crores for the first quarter of 2015-16 as against Rs 11.47 crores in the corresponding period in 2014-15, a rise of 35 per cent. Net sales for the quarter at Rs 280.50 crores were higher by 6 per cent over previous fiscal’s same quarter net sales of Rs 263.68 crores. NDL reported healthy EBITDA and PAT margin at 16.5 percent and 5.5 per cent respectively.

The company reported EBITDA of Rs 46.23 crores during the quarter compared to Rs 41.13 crores in the corresponding period last year, an increase of 12 per cent. EPS stood at Rs 3.40. During the quarter, the company reported 14 per cent of revenues from export markets. It exports to 28 countries.

Commenting on the performance, Deepak Chiripal, CEO, Nandan Denim said, “The company is following its well defined charter of growth and we are pleased with the performance so far. A disciplined approach in line with the long term strategy would enable us to further cement our position in the industry.”

NDL, a part of Chiripal Group, is second largest integrated denim fabric company and has one of the largest manufacturing capacities in the world. The company commenced its operations in 1994 with textile trading business and forayed into textile manufacturing in 2004. It currently manufactures denims, cotton fabrics and khakis.

www.chiripalgroup.com

The recent free trade deal between the EU and Vietnam may prove a challenge to Vietnam’s neighbour, Cambodia. The agreement offers Vietnam duty-free exports to the EU and may not have an immediate impact, but would eat into similar advantages the region enjoys in the long-term, in the near future. The pact between the two economies, would, do away with 99 per cent of tariffs for selected Vietnamese sectors. This includes, garment and rice industries, which are the mainstays of Cambodia’s economy.

Ken Loo, Secretary General of Garment Manufacturer Association of Cambodia (GMAC), says the new agreement FTA would certainly affect Cambodia’s garment sector, though it would take time. Vietnam will enjoy duty-free exports only in seven years (after sanctioned). The Vietnamese agreement stipulates that garment exports to the EU should only use Vietnam-made fabric, while Cambodian garment exporters can source fabric from anywhere, Loo added. He feels that the impact will be good for Vietnamese items that can make use of the domestic fabric.

Vietnam also enjoys the advantage of locally made raw materials, which would be augmented considering the dearth of local supply in Cambodia, feels Piet Holten, President of Pactics Cambodia, a manufacturer of fabric cases for sunglasses in Siem Reap.

The process of twisting fibres together to make yarn is making a comeback these days. Sarah Anderson of Snohomish, Washington, author of ‘The Spinner's Book of Yarn Designs’ (Storey Publishing, 2012) says that now, textile artists want to control the front end of their yarn. They can pick the wool and silk together and blend the two to make the yarn they want. Anderson adds that there was a renaissance in knitting around 15 years ago and now many of those knitters have started to spin. One can control the weight, texture and colour, by spinning yarn yourself. Besides, today’s fibres are made from plant stock as well, such as wood pulp, and synthetic fibers, such as nylon.

Rachel Romine, a longtime spinner and knitter who works at her family's shop Paradise Fibers, in Spokane, Washington says that many spinners like to try out every fibre available. She’s seen artists spin feathers, shredded newspaper or pet hair into yarn. Anderson argues knitting and crochet, spun yarn can be used in weaving, rug hooking, needlepoint, crewel embroidery and tatting, among other textile crafts.

Natural fibres such as wool, cotton, silk and linen, were spun into yarn during ancient times, with a winding stick, and later with a hand spindle. In the 11th century, with the invention of the spinning wheel in Asia and its entry in Europe around 200 years later, spinning experienced its first renaissance, and the Western textile industry was born.