FW

Centro Seta has introduced a collection of sustainable silk fabrics for autumn/winter 2015-2016. The collection, called Bacx, was developed through extensive technological research to ensure high quality silk fabrics were also sustainable and responsible, and the new range offers complete transparency across all production processes.

Bacx is a complete collection of new generation silks characterized by innovative styles and compositions born of innovative sustainable research, processes and solutions. Centro Seta is an Italian textile company. The transparent traceability of Bacx begins at the source – the raw materials – and crosses the production process all the way to the finished product.

Centro Seta’s new eco-friendly silks are offered in two ranges: GreenFiber and Newlife. GreenFiber range fabrics are created using a new silk yarn derived from recycled production wastes. The Newlife range of high-tech, eco-silk fabrics combines traditional silk with Newlife threads, which are made from recycled bottles. The bottles are transformed into a polymer and then worked into a thread through a mechanical process.

The result is a range of refined, unique and fully sustainable silk fabrics, 100 per cent made in Italy, produced using special, exclusive dyestuffs that ensure good wash fastness properties. The Bacx collection is certified by the Global Organic Textile Standard and is available in a wide variety of colors. For 30 years Centro Seta has been known for style, creativity and production excellence.

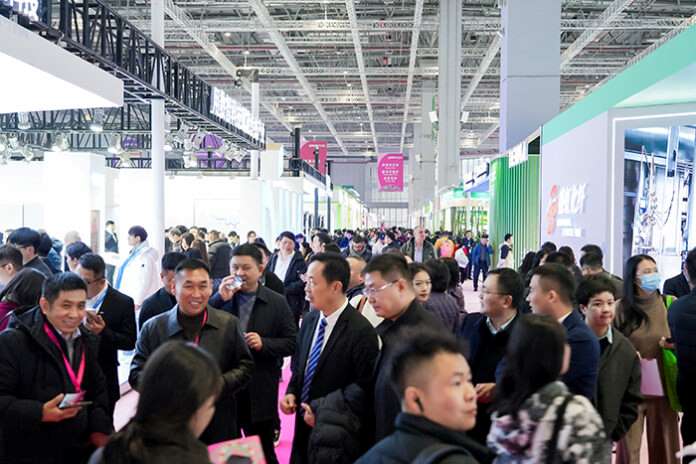

Shanghai will host the 25th edition of Spinexpo from March 9 to 11, 2015. This is a yarn, knitwear and knitted fabric trade fair. It will feature Spring/Summer 2016 trends and products. The S/S 2016 color preview can be seen in an animated mood-board with beautiful visuals overlaying one another, providing direction for colors and surfaces. Focusing on four color palettes, they are divided into warm jewel tones for friendships, cool blues and greens for conscience, neutrals with warm accents of red for senses and a whitened and icy palette for experiences.

The fair has become an international meeting place for manufacturers of ready-to-wear. Among the exhibits are flat-bed and circular knits, wovens, hosiery and new warp seamless knits, fibers and yarns for knitwear, weaving and hosiery, as well as knitwear collections from leading international manufacturers.

Spinexpo takes place twice a year in Shanghai and once a year in New York. It also features seminars and covers creative machinery for knitwear and circular knits. The event presents international top level offer in the field of fibers, yarns for knitting, circular knit and weaving (fabrics and upholstery), socks, laces, labels and technical textiles.

www.spinexpo.com/

For the January to September period, Lenzing saw a 16 per cent drop in profits. Sales were down 6.2 per cent. Lenzing is a specialist in cellulose fibers. The company has to deal with increasingly dropping prices of materials. The drop in prices is not entirely compensated for by the increase in the production of fibers and the volumes sold.

The Lenzing group is based in Austria. It supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to engineering services. With 75 years of experience in fiber production, Lenzing is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell fibers.

As a fiber producer, Lenzing is at the beginning of a long value creation chain in the textile industry. Although this chain is substantially shorter in the nonwovens segment there are still multiple stages between fiber production and the end consumer. The Lenzing business model involves push and pull marketing, where different links in the value chain become involved up to the retail level.

www.lenzing.com/

Peru has emerged as a sourcing center, as a quick-turn, high-quality manufacturing locale with model compliance standards and workmanship unmatched among many of its regional competitors. Other advantages are its homegrown pima cotton, its proximity to and duty-free trade privileges with the US.

The country produces high-end and mid-tier blends, most often using modal, micro modal, tri-blends, polyester, cotton, pima and Supima. Knits are a key specialty in Peru. Owing to its high-quality manufacturing, Peru has lured major brands like Polo Ralph Lauren, Marc Jacobs, Hugo Boss, John Varvatos and Lacoste.

Many factories in Peru are equipped for advanced processes and finishes like mercerization and techniques to minimize fabric shrinkage, and the care with which factories handle the product has been key for these high-quality brands. For brands doing cotton and cotton blend knits, control of shrinkage is very important. Peruvian factories can panel wash the fabric, then leave it to relax before they cut, therefore controlling the shrinkage much better than just fabric roll washing. The country also enjoys free trade with Canada, Europe, China and Japan, among others.

The country’s duty free status is a big plus, especially if the brand is making rayon-rich products. Mills in Peru are starting to develop more and more rayon-rich blend knits in an effort to capture this business, which is still largely Asia based.

Major cotton producers like China, India and Pakistan are taking measures to help cotton growers. They are reacting to falling cotton prices by market intervention or insulating farmers by offering subsidies.

Cotton prices have fallen 25 to 30 per cent across markets. Cotton-2 contract, which is traded on global exchanges and is a benchmark for global prices, peaked around May 5th this year, and has fallen 30 per cent since then. India, China and Pakistan together produce 60 per cent of the world’s cotton.

China has cut cotton purchases significantly. The Cotton Corporation of India has been actively buying under a market intervention scheme and has also beefed up storage for which the government has arranged a line of credit. The Trading Corporation of Pakistan, which has not purchased cotton since 2005-06, will buy about one million bales of lint this month at the announced minimum support price.

Cotton consumption, especially by mills, is projected to go up this season. However, in most places, mills are waiting for prices either to fall or stabilize. The situation is the same in India as cotton will be available cheap for some more time and mills are in no hurry to buy now.

Exports of apparel products from Bangladesh are losing out to competition from Vietnam, Cambodia, India and Indonesia. The declining trend is expected to continue in the months to come unless measures are taken to bring back buyers’ confidence. Already some American retailers are relocating orders elsewhere. Buyers are continuing to wait for the inspection report of Alliance, hitting exports to the US market. They want a certificate issued by Alliance that the relevant factories in Bangladesh are free from fault.

Alliance has already completed safety assessment of garment factories in Bangladesh. For the seventh month running, the country’s readymade garment exports to the US have slipped while those of other four countries saw strong double-digit growth. The two largest apparel suppliers to the US continue to be Vietnam and China. Readymade garments make up around 80 per cent of the total merchandise exports from Bangladesh.

Vietnam continues to benefit as both producers and buyers diversify their supply chains. Its apparel business is also being buoyed by the expected benefits of the proposed Trans-Pacific Partnership trade treaty with countries including Canada and the US. Like Vietnam, India may also have benefited from orders diverted from China and Bangladesh.

Private jute mills in Bangladesh are likely to get the same facilities the government gives state-owned jute mills. Jute mills are going through an acute financial crisis mainly due to a decline in exports of jute goods.

An advisory committee meeting of the Ministry of Textiles and Jute last year decided on sanctioning of fresh working capital for private jute millers, keeping their outstanding loans along with five years’ interest in a blocked account. The interest of five year loans up to June 30, 2014, will be deposited to the blocked account with two years’ moratorium. The advisory committee also urged banks to implement the decisions to keep the sector alive.

Millers also want use of the export development fund in case of import of capital machinery and spare parts and 30 per cent grant to purchase machinery from abroad. Export of jute and jute goods witnessed a 20 per cent drop while raw jute export experienced a decline of 45 per cent. At present, about 212 jute mills are in operation in the country. Of these, 21 are run by the government and the rest by private owners.

Private jute mills say they face a lot of difficulties in getting even simple loans, while state-run mills get various facilities including clearing bank debts, advance bank loan and incentives.

China’s imports of cotton in October were down 42 per cent on the same month last year, and the lowest level since January 2009. October imports fell after harvests in key exporting nations India and the United States were delayed, while importers also had fewer quotas this year to bring in cotton at a lower tariff.

China's cotton imports for the first 10 months of this year were down by 38 per cent. Imports are expected to remain weak in the coming months, with demand from textile mills sluggish and Chinese cotton prices under pressure from a local harvest. The country’s cotton imports in the 2014-15 crop year are expected to fall to a 10-year low, less than half the previous year's total.

China is the world's top consumer of cotton and has driven global demand and prices in recent years. But demand has been hit by an overhaul of Beijing's farmer support policy, which had artificially inflated local prices, making imports more attractive. For importers issued quotas based on a sliding tariff rate, the price differential between overseas and domestic cotton has narrowed to its lowest level since 2011. Full tariffs on non-quota cotton incur duties of 40 per cent.

Bangladesh needs to address the challenges of energy, skilled human resources and poor infrastructure promptly to reach its target of $50 billion apparel export by the end of 2021. Poor infrastructure is the main challenge to the growth of the country’s exports apart from a shortage of electricity and gas.

A high cost of production, high bank interest rates and lack of trained human resources are some other challenges to achieving the target for 2021. After the fires at Tazreen Fashions and Rana Plaza building collapse, the cost of production has increased significantly, but retailers still do not pay higher prices for apparel items. Although Accord and Alliance have inspected the factories, they did not approach any retailer to increase the volume of work orders from factories housed in shared buildings.

Both Accord and Alliance will continue inspecting factory buildings till June 2018, but it’s doubtful whether the workplace safety programs will continue after the departure of the agencies. After completing the inspection of more than 1,100 factories, Accord made a recommendation to close 25 factories. It’s felt a mechanism should be adopted by the government and the Bangladesh Knitwear Manufacturers and Exporters Association to take responsibility for monitoring the factory buildings after the departure of the agencies.

Kenya plans to set up special economic zones to woo global textile and apparel firms to look at the country as a manufacturing hub. Kenya wants to be the preferred gateway to Africa for foreign investors and home to a thriving army of local entrepreneurs. The country is now sub-Saharan Africa's largest apparel exporter to the US under the African Growth and Opportunity Act, having exported 83 million pieces.

Kenya Vision 2030 seeks to transform the country into an upper middle income economy driven by industrialization. To lower the cost of doing business, the government has put in place an elaborate program to make the business sector more productive and globally competitive. The textile and clothing sector, with a potential to create 2,00,000 jobs in the next two years, is a key priority area which the government has targeted for job creation.

Some of the initiatives include: 40-month program to inject over 5,000 mw electricity into the national grid, reducing the cost of power by over 40 per cent by end of this calendar year, fast tracking the Standard Gauge Railway project, and building the 10,000 km road infrastructure through an innovative financing model.