FW

Riri Group, a leading brand in the zip and button manufacturing sector for high couture and outdoor apparel, will launch its new Fall/Winter 2020-21 collection at the Première Vision Paris from September 07 – 19, 2019.

The new collection is inspired by winter landscapes and polar tones. It features shades of grey, azure and white that remind of the typical tones of ice. Its dominant presence of the blue color is in contrast to its attractive green inserts; while black interventions have been harmoniously inserted as part of the color palette and create an appealing interplay of color references.

Tapes, pullers and chains provide new unexpected visual inputs to the collection. The garments reproduce an iceberg effect with a laser system, their texture reminiscent of the snake skin. Among the new innovations include the Metal 3H zip which is the smallest and most innovative in the collection, lightweight and with a streamlined design. The collection also features a zip made of synthetic fur and incorporated buttons, whose cover can be removed and then reapplied, to face polar temperatures with a touch of glamour.

Luxury apparel retailer Olivela has raised $35 million in a Series A funding round, led by Morgan Stanley & Co. International. The retailer plans to use the new funds to expand its business both digitally and physically. This expansion will help Olivela find and partner with more charitable organisations in the U.S. and around the world.

The new funding will be used to fuel Olivela’s new campaign for the quarter called ‘Women’s Empowerment.’ The campaign includes a trip to Jordan where Boyd will meet with 30 young women who were sent to school from Olivela’s donations last year, as well as 100 more who will go to school next year thanks to purchases on Olivela.com and in store.

Olivela plans to open additional boutiques this year with the funding, but it is ramping up its focus on the holidays. The merchant did 90 times the number of transactions in December 2018 than in January 2019. It now looks forward to expanded offerings and brands this season.

Denim mills are tapping into social media influencers’ vast and information-seeking audiences through collaborations, special products and as a vehicle to share their messages about sustainability and innovation. Mills are recognising the power and the influence of the social media and the people who manage accounts. By partnering with an influencer, the supply chain is able to reach more people and tap into specific areas of expertise, knowledge and interest. Influencers have become a go-between from the mill and the producer to the consumer.

Mills are representing themselves more as a brand. And as a result, they’re looking for ways to reach the end consumer to feed them with information about the ingredients and processes that go into the jeans they purchase. The new way of advertising is through influencers.

Kelly Harrington, a textile consultant and social media influencer, teamed with Ukraine-based denim label Ksenia Schnaider to help promote the sustainable story behind its avant-garde denim designs, such as its signature asymmetrical jean. In her Instagram post, Harrington showcases the brand’s cropped jean jacket and frayed shorts with a caption that describes Ksenia Schnaider’s experimental designs. For Harrington, promoting Ksenia Schnaider’s collection on Instagram was an authentic choice. It’s a brand she wears and loves.

M&J Group’s leading facility Genesis aims to explore new business possibilities in China through innovative and sustainable developments, showing the interconnections between quality production and a truly responsible approach, one that must also become socially conscious.

The main long-term goal of the company remains to reach a “near zero” input of fresh water in the process, contributing to manage this precious resource at its best.

It has also decided to set up a Mini Fire Brigade Station in its campus in Bangladesh in collaboration with the Fire Service and Civil Defence of Bangladesh.

The company recently obtained two prestigious LEED Platinum certifications and was granted the LEED Earth certificate for its washing facility in June 2019. This washing facility recycles 50 per cent of treated effluent from WWTP/ETP (Wastewater Treatment Plant). The treated effluent is recycled directly in the garment washing process, thereby reducing fresh water requirement by 50 per cent. This improvement is important because it allows reductions in costs while keeping the garment price the same, saving lots of water as well.

Gap Inc's Old Navy brand plans to double its store count in North America as the apparel retailer readies itself to split from the parent company next year. The brand, which offers more affordable clothing and accessories, plans to open 860 stores in North America and focus on opening outlets in smaller markets and off-mall locations.

Old Navy, which recorded net sales of about $8 billion in 2018 and ended the year with 1,140 locations, said plans to reach more than $10 billion in annual sales by opening new stores. The brand’s plans to open these stores is a result of Gap and other brick-and-mortar players shutting underperforming locations bowing to pressure from online sellers, fast-fashion retailers and ever-changing consumer trends.

The brand also plans to focus on the denim category besides improving its margins. It expects $400 million to $450 million in one-time separation expenses and $300 million to $350 million in capital-related costs between 2019 and 2021.

To be held in Germany from January 7 to 10, 2020, Heimtextil will attract new participants from Europe and overseas. .

Overall, some 3,000 exhibitors are expected to take part in this exhibition. International manufacturers rely on Heimtextil as an attractive platform for export business and as a trendsetting launch event where they can present their new season products at the start of the year.

The exhibition will exhibit products by around 250 international textile designers. Manufacturers of machines for digital printing and textile processing will present their innovations. The trade fair will also present furnishing solutions and specialist offers specifically aimed at contract furnishing. It offers interior designers, architects and hospitality experts a business and networking forum. The exhibition has a lot to offer for interior designers and international furnishers. There will be curtains, decorative fabrics, carpets, interior sun protection and decorative systems, as well as new collections.

Around 140 companies, including start-ups and top international players, will present textile innovations for the bedroom. The section on fashion and home sectors will also see illustrious names from the Netherlands, Austria and Sweden. The exhibition will also see high-end home textiles producers from Asia.

Cotton made in Africa (CmiA) is expanding its network of cooperation partners and brands to include Hugo Boss. This partnership will enable the premium-segment fashion brand to develop a series of new products that will hit the shelves next spring.

Comprising around half of all material used by Hugo Boss, cotton plays a significant role for the German fashion company, which has committed to source 50 percent of its cotton from sustainable production by 2020 and 90 percent by 2025.

Cotton made in Africa operates on the principle that partnering retailers and brands pay a licence fee for every product bearing the CmiA label. Income from these licensing fees is reinvested in its African project which is used to train cotton farmers in sustainable cultivation methods and basic business administration. This enables farmers to improve their water and soil management. At the same time, the use of genetically-modified seeds and the deforestation of primary forests are prohibited.

Around one million smallholder farmers in eleven countries are currently participating in the initiative, through which their cotton is sold to more than 40 international textile companies and brands, including Cortefiel, OTTO, or Asos.

The brand has launched the first release from its new eco tights collection featuring its classic Polka Dot Tight and the bestselling Over-the-Knee Tight. It’s an important initiative, for which the brand chose the cutting-edge recycled yarn by Fulgar.

Canadian brand Rachel is known for its tights collection featuring printed tights and colorful tights. The brand makes apparels for women who want to feel beautiful, comfortable and feminine every day, with an accessible and essential wardrobe accessory. Based in Italy, the brand produces innovative, sustainable manmade fibers. Its green portfolio is growing all the time, and the Q-Nova fiber is the first specialty developed by the company in this field. This eco-sustainable fiber makes a company’s production processes more sustainable, leading to a reduction in CO2 emissions and water use. Q-Nova is made exclusively from raw materials regenerated through a mechanical process that takes place without the use of chemicals that could compromise the sustainability of the end product. More and more international brands are choosing Fulgar fibers to make eco-sustainable products.

Rachel’s partnership with Fulgar has resulted in two eco-friendly tights styles. Rachel is the only Canadian company to offer the option of sustainable tights.

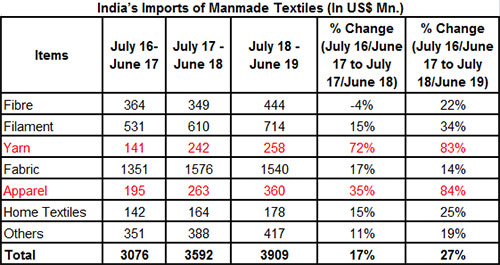

"According to Jain, the implementation of GST has led to an increase in import of all MMF products. Particularly, the imports of MMF yarn and apparels have increased by 83 per cent and 84 per cent respectively. The main reason for this increase is the removal of CVD post GST, which made imports cheaper by over 12 per cent."

Sanjay Jain, Chairman CITI recently requested the Government to extend a uniform GST rate of 5 per cent on MMF products including fibre, yarn and fabric. According to him, this would eliminate the accumulation of ITC. Jain also requested the Government to increase the import duty on MMF based Spun Yarn to 10 per cent as there is huge surge of imports in these categories post GST.

Jain further called for a higher drawback for value added industry to maintain a level playing field with global competitors. Further, all FTAs, need to take into account the size, importance and competitiveness of both the domestic and partner country industry before giving duty free access to the Indian market.

According to Jain, the implementation of GST has led to an increase in import of all MMF products. Particularly, the imports of MMF yarn and apparels have increased by 83 per cent and 84 per cent respectively. The main reason for this increase is the removal of CVD post GST, which made imports cheaper by over 12 per cent. Though the Government had increased the import duty on fabrics and garments to control this rise, it could not control the import of garments due to the FTAs.

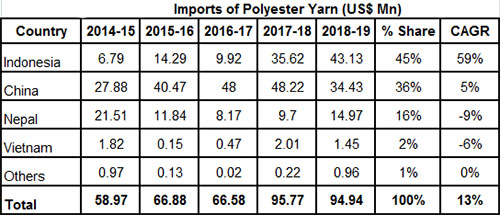

From April-July 2019, the imports of polyester and viscose spun yarn increased by about 71 per cent and 78 per cent respectively as compared to the corresponding period last year. In the month of July alone, imports of both products increased exorbitantly by 193 per cent and 342 per cent, respectively as compared to the corresponding period of the last year. These rising imports are impacting the domestic MMF yarn and garments manufacturers and preventing the upstream industry from investing.

Jain also pointed out that MMF textile products suffer from an inverted duty structure as they attract GST at the rate of 18 per cent, 12 per cent and 5 per cent respectively. This blocks the working capital. The GST on capital goods, services and certain inputs further add to the cost in the hands of the MMF Textile buyer. These taxes are not considered for calculation of refund of input tax credits. This makes the MMF Textiles costlier to the extent of such un-refunded taxes.

Prabhu Dhamodharan, Convenor of Indian Texpreneurs Federation (ITF) met Union finance minister Nirmala Sitharaman to discuss measures needed to revive the sector. He said, one of the common demands of the industry was structural changes for man-made fibre (MMF) sector. There was a need to remove the anti-dumping duty on MMF and rationalise GST for this segment. While India is competitive in the international market for several cotton products, it is not so for MMF products.

The industry should be able to tap opportunities in the global market in synthetic products. Another demand placed by the industry is extension of Rebate of State and Central Taxes and Levies (ROSCTL) schemes, now available to garments and made-ups, for yarn and fabric too.

The ITF also suggested that the government comes out with a system to bring the MNC brands to the manufacturing clusters and engage them directly with the suppliers. This will help reduce imports, he said. The industry also demanded multi-skilling facilities in Tirupur.