FW

Lineapelle New York is back at the Metropolitan Pavilion in Manhattan on Wednesday 31 January and Thursday 1 February. ‘This is an ideal event for a market in search of materials and solutions of genuine excellence,’ the company says. Around 123 selected exhibitors, including tanneries, accessories, components and alternative materials will present their stylistic work-in-progress with samples for summer 2019, inspired by the trends developed by the Lineapelle Fashion Committee under their main theme of Empathy. The theme will be explored in depth during three seminars: Two on the first day and one on the second. The programmes will also features another workshop, Know Your Leather, a technical workshop for analysing “leather as a material”.

Lineapelle New York was launched in January 2001 with 25 exhibitors and has grown exponentially to the point where the July 2017 show hosted 120 exhibitors and welcomed over 1,300 visitors. These numbers confirm the show as a leading event for the US fashion industry, a client of historic and fundamental importance for the Italian leather industry, which has systematically increased its exports to the US from 2009 to 2016, tripling them in value. Trade remained stable in 2017, confirming the USAs position as the fifth biggest destination country for Italian finished leather products.

The New York preview introduces Lineapelle Milano (February 20 to 22 at Fieramilano Rho), the reference event for the global leather area for which a strong turnout of US buyers and brands is expected.

There are many novelties to be displayed by Metalbottoni at three of the most important events in the industry early in the new year. The company from Bergamo will is present at Munich Fabric being held from January 30 to February 1, and then at Milano Unica from February 6-8 and in Paris for the new edition of Première Vision Accessories from February 13 to 15.

For S/S 2019 season, Metalbottoni has implemented new sustainable processes. This production process has been implemented to obtain better results on products that reduce water consumption by half, reducing processing time and energy consumption. Metalbottoni has been able to introduce novel finishing with a polished and valuable look, perfect for the world of ready-to-wear. “Our Style Office daily activity” explains Maria Teresa Ricciardo, Creative Director at Metalbottoni, “is more and more oriented towards an approach that includes dedicated support to customers through all our technical and stylistic competences, in order to achieve a steadily improving level of personalization in our products.”

Among the novelties which will be presented during the three exhibitions, Monster SS 2019: the line dedicated to the most authentic denim is enriched by this new collection, restyled according to the most recent green technologies and the philosophy of sustainable denim, without neglecting intense and vibrant style touches. The line is increasingly enhanced by elements which address sportswear with strength, assertiveness and personality.

In this new collection, classic shapes are restyled in terms of proportions, from mini to oversize, deformed and renewed thanks to the choice of special paints combined with novel processing and finishing. The collection for the new season ranges from jeans buttons and rivets to chinos buttons, buckles and loops, rings, hooks and spring clips. Labora SS 2019: a range which includes buttons, buckles, plates and clips dedicated to pure fashion, for men and women: new proposal which remind us of earth, air and water elements with items in natural and earthy colours. Materials such as bronze and aged brass are matched with transparent and coloured polyester accessories, with pearly, polished and valuable finishing. For this season the collection shows a remarkable sportswear influence, with a range that goes beyond buttons, with hooks, spring clips, rings, loops and pulleys with bright and shiny colours, enhanced by the 3D-effect processing.

“Boosting research, innovation and offer in order to highlight our added value” says Gregorio Valli, CEO and President of Metalbottoni S.P.A, “along a path that leads us to be more and more of a branding ingredient for customers, who today see Metalbottoni not just as an outstanding manufacturer, but also as a consultant and strategic support partner.”

The Synthetic & Rayon Textile Export Promotion Council (SRTEPC), one of the oldest export promotion councils in India, has conferred Rajen Udeshi, President, Polyester Chain, Reliance Industries Ltd. (RIL) and President Association of Synthetics Fibre Industry, with SRTEPCs Life Time Achievement Award for his exceptional contribution to the development and growth of manmade fibre and fabric industry in India. The Council also awarded RIL with a series of awards for its exceptional performance in exports of fibres and yarns.

RIL has been honoured for its best export performance in the category of overall exports, polyester staple fibre, continuous yarn and fibre and yarn exports to Latin American and African countries. Udeshi, a member of RIL’s leadership management team for over three decades, has played a key role in the growth of RIL’s polyester chain business.

The list of awardees that SRTEPC honoured from RIL are: SRTEPC lifetime Achievement Award conferred to Rajen Udeshi. Award for Best Overall Export Performance in the category of SRTEPC Special Award (Gold Trophy). Award for Best Export Performance in the Category of Polyester Staple Fibre (Gold Trophy). Award for Best Export performance in the Category of Continuous Yarn (Gold Trophy). Award for Best Export Performance in the Category of Exports of fibre/yarn to ‘Focus LAC’ Countries (Gold Trophy). Award for Best Export Performance in the Category of Exports of fibre/yarn to ‘Focus Africa’ Countries (Gold Trophy)

Ready to source fabric and network with industry peers, buyers flooded into Texworld USA Winter 2018 edition in record numbers. Held January 22 to 24 at the Jacob K Javits Center in New York City and organised by Messe Frankfurt, the sourcing event for apparel fabric buyers, research and product development specialists, designers, merchandisers and overseas sourcing professionals takes place biannually in the US in January and July. Collocated Apparel Sourcing USA, Texworld USA hosted 4,500 attendees, 371 exhibitors in an area of 47,000 net square feet.

In its 10th year, the Winter edition is the smaller of the two Texworld shows, although both events sees huge crowds. Buyers visiting Texworld USA experienced an expanded exhibit hall and several new show-floor elements, including content features for start-ups and small designers. Jennifer Bacon, show director, fashion and apparel said, “We partnered with Startup Fashion to provide more information for startups. I truly believe today’s independent designers will be tomorrow’s big brands. We added a low minimum supplier list to the floor that features exhibitors who will sell at lower quantities and Resource Row that goes beyond textile sourcing to support other areas of the business.”

Bacon was quick to point out that the retail climate has been changing quickly and dramatically over the past 12-18 months and went on to explain, while how we shop is changing, we are still buying apparel and some companies are really thriving, particularly those with ethical, technical or sustainable features. Content on the show floor featured a wearable section and even covered trends in recycling leftover scraps and surplus fabrics.

Texworld USA also made enhancements to its educational offerings by adding a new element to its seminar series: Explore the Floor. During these sessions, a seminar presenter guided the group to areas on the showfloor where buyers could see and experience the topic first hand, ask questions and learn how to apply concepts. This year, the show’s art directors created a spotlight trend area on denim and artist Moon Heemin, who designed a fun art installation of dogs made out of denim that proved to be a powerful backdrop for social media sharing.

Show officials note that Texworld USA is anchored in New York City for several reasons, including the city’s status as one of the world’s four fashion capitals and a convenient destination for attendees to reach. In addition, the show itself has a reputation as a benchmark for colours and materials.

Swiss company HeiQ has launched HeiQ Fresh FFL (Fresh For Long), a 100 per cent bio-based odour control technology. The product targets the sportswear and intimate segment, with application suitable for seamless garments made of synthetics that are prone to permastink. Visitors at ISPO got a sneak peak of the technology at HeiQ’s booth at Hall C3 Booth 402.

Apart from its founding silver product that is today used worldwide in over 500 million garments by over 100 major active wear brands and the recently launched volatile odour source sequestering technologies HeiQ Fresh NKU and HeiQ Fresh AGOS.

HeiQ says it continues to redefine freshness for textiles by introducing the world’s first bio-based, non-antimicrobial, non-silver-based textile odour control technology – HeiQ Fresh FFL, which is based on a biopolymer derived from 100 per cent renewable source. The wash-resistant, biodegradable textile finishing is said to stop bad smell before they emerge on textiles.

HeiQ Fresh FFL is a non-antimicrobial alternative to traditional odour control in textiles. The sustainable, fully biomass-derived Amino-Sugar-Polymer functions by binding proteins and other sweat components that can cause odour. The HeiQ Fresh FFL biopolymer supports quick removal of these sweat secretion during home laundering. As a non-antimicrobial solution to odour control, the regulatory obligations normally associated with biocides are of no relevance when applying HeiQ Fresh FFL on garments and other textile products, the company reports.

Ralf Mundinger, HeiQ’s Head of Technology Application explains, “Odour control efficacy is maximised with the correct technology-fibre match, as well as the right application of the technology in the textile finishing process. While most odour-control textile finishing target polyester, the application is often limited to padding, which is not utilised for textiles that seamless garments are made from.

HeiQ Fresh FFL can be used on both cellulosic and synthetic fibres. The flexibility of application of HeiQ Fresh FFL – can be done through either exhaust or padding – means that brands can apply it freely on different fibre and product design, including seamless garments.”

A $23 million venture fund resolve the threat of forced labour in big businesses with the help of tech start-ups was launched, backed by brands from Disney to Walmart. Humanity United, a US-based foundation, has partnered major corporations and the British government to create Working Capital, a first-of-its-kind fund to invest in innovations to ensure that companies’ supply chains are free from slavery. Humanity United says the fund has received capital from the C&A Foundation, affiliated with fashion retailer C&A, the Walmart Foundation, and Walt Disney Co, among others.

Slavery has increasingly come under international spotlight, putting continuous regulatory and consumer pressure on companies to ensure their supply chains do not employ forced labour, child labour and other forms of slavery.

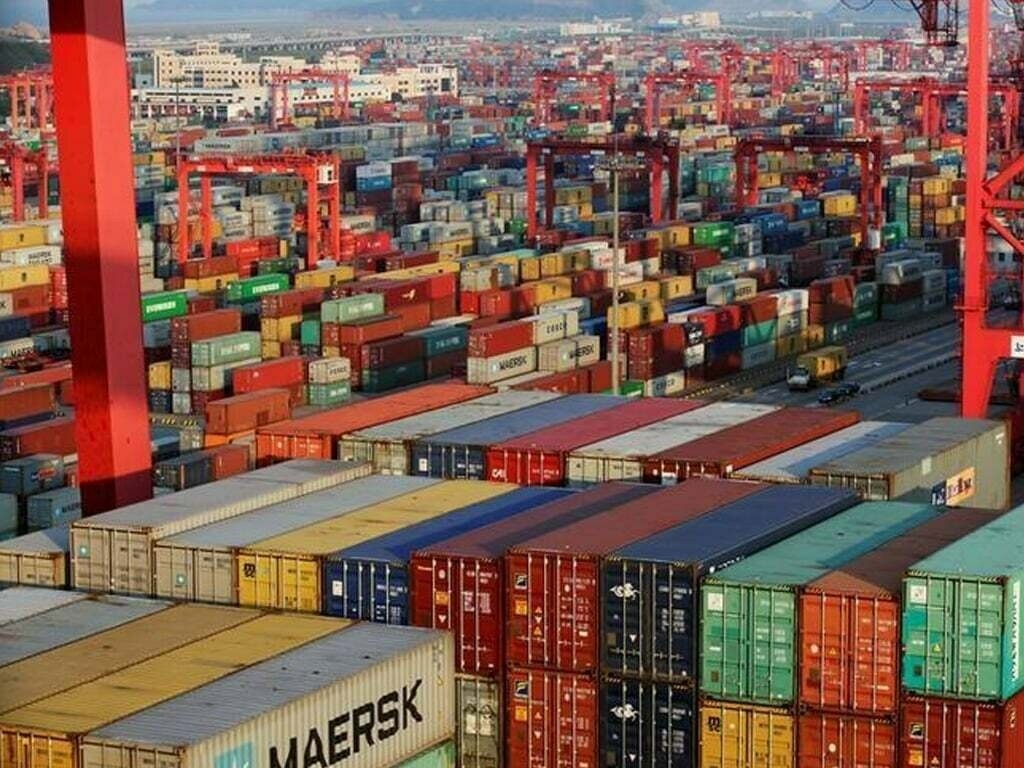

From cosmetics and clothes to shrimp and smartphones, complex supply chains have multiple layers across countries — whether in sourcing raw materials or creating the final product — making it extremely difficult to clearly identify exploitation/slave labour conditions.

Ed Marcum, MD at Working Capital says, “There is a growing market demand for more transparent and responsible corporate supply chains. We see an opportunity to invest in emerging solutions that will meet the demands of large multinational corporations while also benefiting millions of vulnerable workers,” he added.

The fund, which received $3.5 million from Britain’s foreign aid department (DFID), is investing in new technologies to map supply chains and help workers to raise grievances, find legitimate employers and understand their rights. Its portfolio includes Provenance, which uses blockchain to trace products from producer to consumer, and Ulula, a platform helping firms to measure risky practices in their supply chain.

Humanity United, established by eBay founder Pierre Omidyar and his wife Pam in 2005, was involved in founding The Freedom Fund, the world’s first private donor fund designed to raise and deploy at least $100 million to combat modern slavery worldwide.

China is once again going to organize the ‘13th Dhaka International Yarn & Fabric Show 2018 - Winter Edition’ from January 31 to February 3 at the International Convention City (ICCB), Dhaka. This expo is being organised post successful completion of previous editions, CEMS Global-Conference & Exhibition Management Services and the Sub-Council of Textile Industry (CCPIT).

This year’s show will be taking place along with two simultaneous exhibitions the ‘2nd Dhaka Int’l Denim Show 2018-Winter Edition’ and '30th Dye+Chem Bangladesh 2018 International Expo-Winter Edition’ After 12 highly successful editions in Bangladesh, the ‘13th Dhaka International Yarn & Fabric Show 2018-Winter Edition’ is expected to draw a large number of visitors from the Textile and Apparel industry of Bangladesh.

These three international exhibitions will accommodate 350 international exhibitors, from over 21 countries worldwide, who will showcase their up-to-date fabrics, which are ready-to-use for garment, accessories, industrial use and various other applications.

The expos will play an important role by displaying latest yarn and fibre, fleece, knitted fabrics, coated artificial fur, artificial leather, denim accessories, embroidery/digital printer, adhesives, dyestuff, catalysts, dyes and dye stuffs, dye and fine and specialty chemicals. The manufacturers will put on display all ranges of textile products enhanced with the latest technology, along with smart fabrics to satisfy the growing demand of various buyers. It will enable the textile/apparel industry buyers to meet local and overseas textile and yarn manufacturers face to face

IndustriALL Global Union records 60 global brands have already signed up to renew their commitment to bearing the costs of health and safety checks, including Adidas, Lidl and Primark. However, some top UK fashion and clothes retailers have not yet signed the deal to renew their commitment to factory safety in Bangladesh. John Lewis, M&S, Next, Debenhams and Sainsbury’s are yet to add their names to the list of brands committing themselves to Bangladesh’s latest laws on fire and building safety. The renewed agreement will see greater investment in health and safety checks come into effect this year as the original 2013 agreement is due to expire in May. A legally binding agreement was set up in 2013 where brands must share responsibility for the costs of improving health and safety in Bangladeshi factories. Bangladesh’s Accord on Fire and Building Safety was introduced after the devastating Rana Plaza factory fire which killed 1,135 workers and left over 2,500 people injured.

A spokesperson from John Lewis said the company is currently reviewing details of the new agreement before making a final decision ahead of the deadline. M&S reportedly said it is still “in discussion with stakeholders on Accord 2.0”, while Debenhams said it had “meetings in the diary” before May. A Next spokesperson said “If Next decides not to sign Accord 2 – it is confident that it already has a competent, directly employed code of practice team (and office) in place in Bangladesh, to manage safety in that region.” Sainsbury’s said it was actively involved in discussions and said it "applauded the progress that's been made by the Accord in Bangladesh.

Trade unions representing Bangladeshi textile workers reached a $2.3m (£1.6m) settlement earlier in January with an unnamed multinational fashion brand accused of delaying fixes to life-threatening hazards in factories. The UNI Global Union and IndustriALL Global Union took two leading fashion brands to court in 2016 following the introduction of Bangladesh’s Accord on Fire and Building Safety in 2013.

Lakshmi Machine Works’ revenue de-grew by 6.8 per cent yoy to Rs 542cr. EBITDA was Rs65 cr, down by 4.8 per cent yoy. EBITDA margin grew by 25 bps yoy to 11.95 per cent. Adjusted PAT grew by 4.7 per cent yoy to Rs 57 cr. Depreciation and amortization expenses de-grew by 9.6 per cent yoy to Rs 14.16 cr.

Revenue from textile machinery and machinery tool foundry segment contributed Rs 391.08 cr (down 23.1 per cent yoy) and Rs 98.80cr (up 44.9 per cent yoy) respectively.

Lakshmi Machine Works’ is India's largest textile machinery and CNC Machine Tool manufacturers, based in Coimbatore founded by Cavalier G K Devarajulu. It started operations in 1962 in Coimbatore with technical collaboration with Swiss-based textile machinery manufacturer Rieter for textile machines and German based Steel and Ammunition major Krupp. In mid 1980s the company bought over its Coimbatore based longtime rival and much older Textile and engineering giant Textool. The company is promoted and owned by the Lakshmi Mills family. LMW has 60 per cent market share in domestic textile spinning machinery industry.LMW diversified into CNC Machine Tools and is a brand leader in manufacturing customized products.

Trident’s revenue or Q3FY18, grew by 0.3 per cent yoy to Rs 1,137cr. EBITDA came in at Rs 200cr, down by 11.2 per cent yoy. EBITDA margin contracted 227 bps yoy to 17.59 per cent. Adjusted PAT de-grew by 7.1 per cent yoy to Rs 73cr. The Board has declared 2nd interim dividend of Rs 0.6 per fully paid up equity share of Rs10 each. Record date is February 6, 2018. Finance cost de-grew by 16.3 per cent yoy to Rs 25.2cr. Depreciation and amortisation expenses de-grew by 2.1 per cent yoy to Rs 101.3cr. Employee benefit expenses de-grew by 24.9 per cent yoy to Rs 108.3cr due to rationalisation of manpower cost including structuring of salary and manpower.

Revenue from textile and paper and chemicals segment contributed Rs 913.23cr (up 0.2 per cent yoy) and Rs 224.06cr (up 0.7 per cent yoy) respectively.

Trident Limited (Trident) is the flagship company of TridentGroup, a $1 billion Indian business conglomerate. The group operates in five business segments: Yarn, Bed Linen, Paper, Chemicals and Captive Power. Trident Limited, the flagship company of the group has its customer base in more than 100 countries across six continents. Trident is one of the largest yarn spinners in India, one of the world's largest terry towel manufacturers and the world's largest wheat straw based paper manufacturer.