FW

Organized by the Office of the Development Commissioner for Handlooms Ministry of Textiles, Government of India, in Bharat Mandampam alongside Bharat Tex 2025, the fashion event, ‘Breathing Threads’ demonstrated the power of Indian heritage textiles on a global stage.

The event was organized at an amphitheatre in with Vaishali S Couture, Vaishali S Threadstories and in coordination with Handloom Export Promotion Council. It was a great success and hugely appreciated by buyers from overseas countries such as Australia, UK, France, Germany, Italy, Russia, Srilanka, Bangladesh, Kuwait, Chile, etc. Stakeholders from the Indian textile industry also appreciated gther show.

A 24-year old brand, Vaishali S Couture is dedicated to reviving old and dying hand weaving techniques and offers them to the top global luxury brands.

The show featured fabrics woven in the villages from five different states viz. West Bengal, Madhya Pradesh, Uttar Pradesh, Karnataka and Rajasthan. The weaves were showcased by 20 models in 30 looks, draped in seven different weaving techniques including Chanderi, Maheshwari, Jamdani, Khun, Benarasi, Kota Doria, Murshidabad. Each of these weaves was creatively embellished with unique textures and cording.

The show highlighted the importance of skill and hard work alongwith with creativity in making a hand-woven fabric.

Despite a 16.22 per cent decline in textile imports by the EU, Tunisia's textile exports increased from €1.96692 billion in 2019 to €2.35840 billion in 2023, according to official data.

From January-December 2023, Tunisia's clothing exports grew by 6.8 per cent to 8,178.68 million Tunisian dinars, while textile exports rose by 3.07 per cent. Overall textile and clothing exports by Tunisia grew by 5.61 per cent to nearly 9.7 billion dinars, with a 12.5-point improvement in the trade balance. Along with the support from public authorities and companies, the Tunisian textile industry is well-positioned for future challenges.

Tunisia has focused on product quality to differentiate itself in the European market. While competitors have lowered prices, Tunisian companies have maintained margins by offering high-end products. Tunisia ranks 10th globally as a clothing supplier to the EU, surpassing major players like the UK and Egypt.

An ambitious roadmap aiming to recycle 90 per cent of wastewater and reduce the carbon footprint by 30 per cent by 2030 is expected to further enhance Tunisia's competitiveness.

The Export Promotion Center (CEPEX) plans to organize professional and partnership meetings for the textile, clothing, leather and footwear sectors on April 21-22, 2025, in Algiers, during the 8th TexStyle Expo. This event will provide Tunisian companies with opportunities to establish business relationships and partnerships with economic operators in the clothing and footwear sectors.

The event will target sectors including materials and accessories for clothing, solutions for the textile and clothing industry, and leather, soles, and footwear components. This mission will be eligible for the Export Promotion Fund (FOPRODEX), a financial support mechanism for Tunisian exporters, notes CEPEX.

Parent company of Calvin Klein and Tommy Hilfiger, PVH has been added to the ‘unreliable entities’ list of China's Ministry of Commerce (MOFCOM). According to MOFCOM, PVH undermines market rules and violates Chinese laws.

This designation could potentially shut down all of PVH's business operations in China, although no specific sanctions have been announced yet, and PVH has a timeframe to present its defense.

PVH is the first fashion brand to receive this designation, typically reserved for companies in defense and biotech, such as Illumina, which was also recently added to the list. This move comes amidst escalating US-China trade tensions and follows the Trump administration's 10 per cent tariff on Chinese imports. MOFCOM has been investigating PVH's China operations since September.

In its 20 years of operating in China and serving customers, PVH has always maintained strict compliance with all relevant laws and regulations and operates in line with established industry standards and practices, a company’s spokersperson. It will continue engaging with relevant authorities and looks forward to a positive resolution, he adds.

The MOFCOM decision appears to stem from PVH's ban on the use of cotton from China's Xinjiang region, aligning with US government’s import restrictions imposed in 2020. Experts suggest that China is using PVH as an example in the ongoing trade dispute.

While Stefan Larsson, CEO, PVH emphasizes on the importance of the Chinese market for retail growth (the Asia-Pacific region accounted for approximately 20 per cent of PVH’s $9.2 billion in revenue in fiscal year 2023), the greater threat may be to PVH’s manufacturing capabilities.

The company operates 128 factories in China, producing approximately 20 per cent of its goods. Shifting manufacturing could be disruptive, impacting quality and production processes, according to analysts. PVH also has manufacturing facilities in Vietnam, Turkey, and other countries.

Experts speculate, PVH was targeted due to its size—large enough to make a statement, but not as large as other US brands like Nike or Gap, which also have policies against using Xinjiang cotton. Tommy Hilfiger and Calvin Klein have a significant retail presence in the Asia-Pacific region, with thousands of stores.

Neil Saunders, GlobalData, opines, China is using PVH as an example to say, look, if tariffs go ahead, if other restrictions are put in place on China, we can make life difficult for US companies in the country.

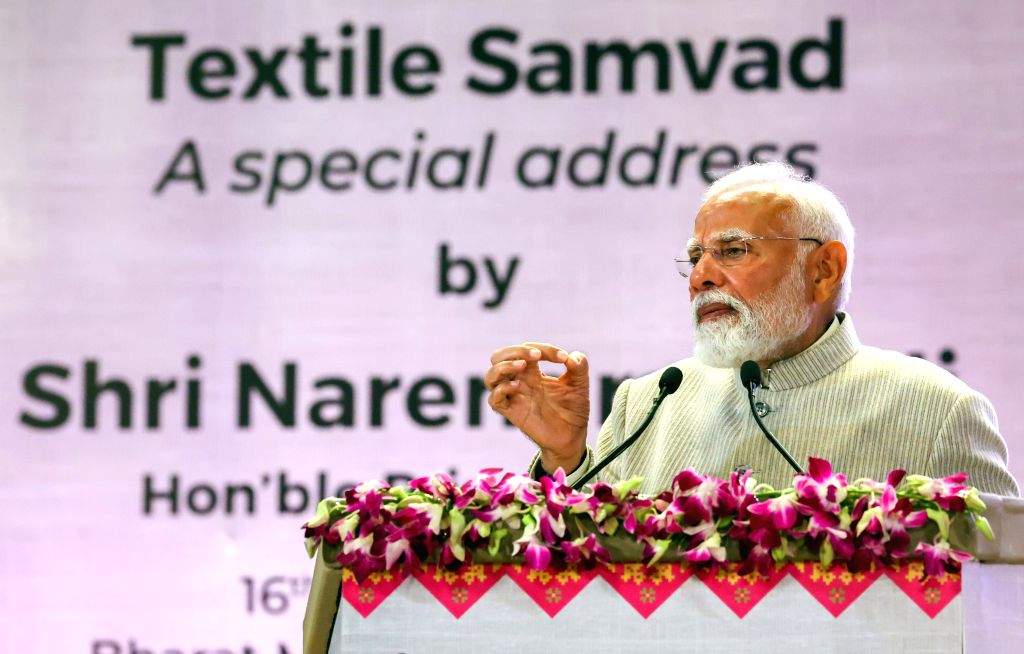

PM Narendra Modi inaugurated Bharat Tex 2025 at Bharat Mandapam, highlighting India’s textile heritage and expanding global reach. He toured the exhibition and praised Bharat Tex for evolving into a major international event. This edition featured exhibitors across the full textile value chain, from accessories to machinery, chemicals, and dyes.

Addressing industry leaders and stakeholders, Modi called Bharat Tex a vital platform for global collaboration among policymakers, CEOs, and entrepreneurs. He noted the participation of 120 countries, offering Indian businesses key exposure to international markets. Many exhibitors from last year reported securing new buyers and expanding their reach. The Prime Minister urged the banking sector to support textile entrepreneurs to drive further growth and employment.

Textile industry’s global expansion and economic contribution

Modi outlined India's textile sector growth, reporting a 7 per cent rise in exports last year, making India the sixth-largest textile exporter. He set an ambitious goal of tripling exports from Rs 3 lakh crore to Rs 9 lakh crore by 2030. Foreign investment in textiles has doubled in a decade, now contributing 11 per cent to India's manufacturing sector.

The Prime Minister highlighted the Mission for Cotton Productivity, aimed at making Indian cotton globally competitive and strengthening the entire value chain. He also pointed to initiatives in technical textiles, including the development of indigenous carbon fiber. With MSMEs contributing 80 per cent of textile production, expanded credit access and revised classifications in the latest budget will boost growth.

Modi emphasized the role of skill development, noting efforts by National Centres of Excellence and the Samarth scheme to upskill artisans and workers. Handloom promotion remains a priority, with 2,400+ marketing events in the past decade and the launch of the India-hand-made e-commerce platform. He also highlighted the benefits of GI tagging in promoting traditional crafts.

Sustainability, innovation, and the future of Indian textiles

Sustainability remains a key focus for the textile industry. Modi warned that global fashion waste could reach 148 million tons by 2030 and called on India's textile industry to lead in recycling and upcycling. He highlighted traditional practices like rug and quilt-making from old fabrics and announced a government-backed textile waste collection and recycling initiative. India’s textile recycling market is projected to reach $400 million soon.

The Prime Minister urged industry leaders to blend tradition with innovation, encouraging young entrepreneurs to create products inspired by Indian textiles. AI and technology, he noted, are reshaping fashion trends and textile design. He linked India’s sustainable fashion leadership to global discussions on climate change and responsible consumption. Modi expressed confidence that Bharat Tex would drive future industry growth, reiterating India's commitment to strengthening its textile sector. He emphasized its historic role in India's prosperity and its potential to drive economic growth.

Bharat Tex 2025 (Feb 14-17) is among the largest global textile events, drawing policymakers, industry leaders, and 5,000+ exhibitors. It features exhibitions, conferences, panel discussions, startup pitch fests, and innovation challenges to drive investment and technological advancement. More than 25 global textile organizations, including ITMF, ICAC, EURATEX, Textile Exchange, and USFIA, took part in Bharat Tex 2025.

Turkiye’s ready-to-wear clothing and apparel exports to Europe rise to $1.1 million in January: Data

Despite economic stagnation and recession concerns in the EU, Türkiye's ready-to-wear clothing and apparel exports to Europe increased to $1.1 million in January, as per data from the Turkish Exporters’ Assembly.

Compiled by the Anadolu Agency, the data shows, Turkey’s overall exports increased by 7.1 per cent Y-o-Y to $10.3 billion in January. This growth in Turkish exports to Europe was led by the automotive industry with exports worth $2.6 billion in January. Other significant export categories included chemicals and chemical products ($1.4 billion), electricity and electronics ($752.7 million), ferrous and non-ferrous metals ($767.1 million), and steel ($691.8 million).

Geopolitical tensions from the war in Ukraine and tight monetary policies to combat high inflation have created vulnerabilities in the European economy. Global tariff threats, including potential further tariffs, also impact the region.

Despite these challenges, Europe accounted for 48 per cent of Türkiye's total exports in January. Overall, Türkiye's exports grew by 5.8 per cent Y-o-Y last month, totaling $21.1 billion.

Germany was the top destination for Turkish exports, receiving $1.6 billion in January, followed by the UK ($1.1 billion), Italy ($910.5 million), France ($795.7 million), and Spain ($774 million).

Istanbul led Turkish exports to Europe, accounting for $2.9 billion in January. Other major exporting provinces included Kocaeli ($1.4 billion), Bursa ($948.8 million), Izmir ($625.1 million), Ankara ($419.2 million), and Sakarya ($385.7 million).

A global leader in developing innovative and sustainable fiber and technology solutions for the apparel industry, The Lycra Company unveiled its exclusive range of Coolmax Core fibers for the Indian market at Bharat Tex 2025.

Recognized worldwide for its permanent moisture management properties, the Coolmax Core fiber helps the wearer stay cool, dry, and comfortable. A special dyed version in filament form, the fiber is available in more than 25 shades as it provides a wide range of product development opportunities across the apparel industry’s value chain.

The fiber improves textile processing production efficiency by eliminating the fabric dyeing process, which also helps reduce the risk of effluents impacting the environment. It helps meet the increasing demand for dyed Coolmax brand yarn in India’s shirting, knitwear, and formalwear segments, says Alistair Williamson, Vice President-EMEA and South Asia, The Lycra Company. The solution enables brands to offer a cooling experience that responds to the wearer's needs, even in the most demanding climates, she adds.

British fashion brand Superdry has extended its licensing agreement with Brand Collective in Australia for a period of 12 years. The multi-million dollar royalty deal grants Brand Collective exclusive rights to the Superdry brand in the region.

This extended partnership aims to usher in a ‘new era’ of growth, with both companies targeting a doubling of revenue to AU$100 million within the next five years. The collaboration promises new collections, bold designs, and an enhanced retail experience tailored to the Australian consumer's demand for style and quality.

This extension illustrates the value Superdry places on the trust, longevity, and continuity of the relationship between the two companies, says Julian Dunkerton, Founder and CEO, Superdry. This ongoing partnership will continue to grow and strengthen the brand across Australia, he adds.

An operator of 300 stores in Australia, Brand Collective partners with 16 other retailers. Superdry joins a portfolio of fashion brands including Reebok, Review, Clarks, and Hush Puppies.

Dave Thomas, CEO, Brand Collective, states, it heartening to see Australians embracing Superdry, The partnership between these two companies will help Brand Collective create a positive future for the brand in Australia, he adds.

Bharat Tex 2025 will help strengthen India's position as a global textile leader, opines Bhadresh Dodhia, Chairman, Matexil and Co-Chairman-Core Committee, Bharat Tex 2025. The event will prove to be a game-changer for India's textile industry and a moment of national pride, he adds.

Spanning over 220,000 sq m, the exhibition showcases the entire textile value chain, from fiber and yarn to fabrics, garments, home textiles, made-ups, and technical textiles. It is being attended by exhibitors, buyers, policymakers and industry leaders from around the world.

Emphasizing on sustainability and innovation, Bharat highlights India's progress in eco-friendly textiles, digital manufacturing, and smart fabrics, notes Dodhia. The event features specialized sessions on the circular economy, digital transformation, and technical textiles, bringing together global experts.

The event has received an overwhelmingly positive response, with exhibitors and delegations from key global markets, including the US, EU, Middle East, Russia, Africa, and Southeast Asia participating in it, states Dodhia. It offers Indian manufacturers an unparalleled opportunity to showcase their capabilities, attract investment, and boost exports, he adds.

In 2024, China's polyester industrial yarn (PIY) exports soared to 559,600 tons, marking a notable 7.6 per cent year-on-year increase. This rise is due to rebounding global demand and reduced EU anti-dumping duties, has reshaped the dynamics of the global yarn market, presenting both challenges and opportunities for India's burgeoning yarn industry.

Impact on India's yarn trade

Imports from China: While specific data on the volume of Chinese PIY imported by India remains sparse India, as a significant consumer of polyester yarn, is inevitably influenced by China's export growth. The increased availability of Chinese PIY in the global market indirectly impacts India's domestic prices and availability, necessitating deeper analysis to quantify precise import volumes and their market implications.

Exports from India: Concurrently, India exported 30,145 tons of PIY in 2024, reflecting a modest increase from the previous year. However, amidst China's expanded global footprint, Indian exporters face heightened competition in international markets. Despite being among China's top 10 export destinations, India contends with challenges in maintaining competitive pricing and market share, particularly in regions where Chinese PIY is increasingly prevalent.

Table: China's top 10 PIY export markets (2023-2024)

Nation 2024 (tons) 2023 (tons) YoY change (tons) US 62,343 51,441 10,902 South Korea 55,948 49,493 6,455 Turkey 40,277 43,436 -3,159 Vietnam 37,186 27,878 9,308 Brazil 33,014 33,414 -400 India 30,145 28,616 1,529 Russia 24,286 33,493 -9,207 Belgium 20,998 15,102 5,896 Canada 19,364 18,543 821 Germany 17,818 17,174 644

The global impact of China's export growth

China's robust export performance in PIY is primarily driven by recovering demand from overseas markets, particularly in developed economies where polyester yarn is integral to sectors such as automotive, infrastructure, and transportation. The gradual relaxation of EU anti-dumping measures in 2023 further bolstered China's export capabilities, allowing its PIY exports to EU nations to rebound by 11.2 per cent year-on-year.

Moreover, China's strategic expansion in high-modulus low-shrinkage (HMLS) PIY production capacity in late 2024 has enhanced its export competitiveness, catering to diverse global markets with increased supply flexibility.

Impacts on global markets

Price fluctuations: The rise in demand and subsequent increase in both imports and exports can lead to price volatility in the PIY market. The increase in domestic supply in China could put downward pressure on global prices.

Competition: Growth of China as both a major importer (initially) and exporter intensifies competition in the global PIY market. Other producing countries need to adapt to this increased competition, potentially through innovation, cost optimization, or specialization in niche markets.

Supply chain disruptions: Trade policy changes, like anti-dumping duties, can create significant disruptions in the global PIY supply chain. Companies need to diversify their sourcing and markets to mitigate risks associated with such policies.

Technological advancements: The increasing demand for HMLS PIY highlights the importance of technological advancements in the textile industry. Manufacturers who invest in R&D and produce high-performance materials will likely have a competitive advantage.

Regional shifts in production: The data suggests potential regional shifts in PIY production. The increase in Vietnam's exports to China (before the increase in China's domestic capacity) illustrates how production can shift to take advantage of favorable conditions. The increase in China's domestic production suggests a potential move towards greater self-sufficiency.

Looking at China's PIY exports in 2025 suggests a potential moderation in growth rates following the substantial base set in 2024. For India, this means higher competitiveness through value-added products, targeted niche markets, and agile pricing strategies. Therefore, as China consolidates its position as a dominant player in the global PIY market, India's yarn industry faces a strong competition. Adapting to this growing competition requires proactive strategies that prioritize innovation, market diversification, and operational efficiency. By embracing these imperatives, India can not only safeguard its market position but also seize new opportunities amidst the evolving landscape of international trade in polyester industrial yarn.

In essence, while China's export surge poses challenges, it also beckons India to forge ahead with resilience and strategic foresight in the competitive global yarn market.

A recent report compiled by analyst Veronica Bates Kassatly and statistician. Terry Townsend, published by the Bremen Cotton Exchange, has brought to light a critical concern: the pervasive presence of microplastics in textile production, particularly within synthetic fibers, and its potential health and environmental consequences. This report expands the scope of concern beyond cotton production to include the significant contribution of synthetic fibers to the microplastic problem.

Concerning microplastics

The report emphasizes the ubiquitous nature of microplastics, tiny plastic particles less than 5 mm in size, and highlights mounting evidence of their harmful effects. It cites studies linking micro and nanoplastics to severe health issues, including myocardial infarction (heart attacks), stroke, and even death. Furthermore, the report points to research that has identified these particles in the bone marrow of leukemia patients and, alarmingly, in the brains of individuals with dementia, including Alzheimer’s disease, with concentrations in some brain samples up to ten times higher by weight than in healthy samples.

A key aspect of the concern surrounding synthetic fibers is the vast number of chemicals associated with them. The report notes that approximately 2,566 chemicals are either used in, present in, or released from PET (polyethylene terephthalate), a common synthetic fiber. Disturbingly, hazard data exists for only a small fraction of these chemicals. While 31 are known to be non-hazardous, 31 per cent are known to be hazardous, leaving the majority with unknown potential for harm. This lack of data underscores the urgent need for further research into the toxicity of these chemicals.

Micofiber hazard

The report stresses that plastic microfibers pose a distinctly different hazard compared to other microfibers and should be treated accordingly in Life Cycle Assessments (LCAs) and Product Environmental Footprints (PEFs). Recognizing this crucial distinction, the European Commission’s March 2024 resolution on the Green Claims Directive mandates that the PEF for Apparel and Footwear incorporate a microplastic assessment.

A significant challenge highlighted in the report is the influence of vested interests on the assessment of microfiber impact. The report points out that the sources used by both the French and EU PEFs to evaluate this impact are not independent scientific organizations but rather entities created and funded by stakeholders deeply involved in the production of plastic apparel. This conflict of interest undermines the scientific integrity of environmental legislation and hinders effective solutions to long-term environmental problems.

Bates Kassatly and Townsend recommend that fashion value chain LCAs/PEFs clearly state that plastic fibers contain hazardous chemicals and that these fibers can lead to exposure to various chemicals throughout the product's lifecycle. They go so far as to suggest that, similar to the health warnings on tobacco product packaging, a warning label should be mandatory on point-of-sale packaging for all products containing synthetic fibers. This recommendation underscores the seriousness of the issue and calls for greater transparency and consumer awareness.

In conclusion, the report by Bates Kassatly and Townsend provides compelling evidence of the potential dangers of microplastics, particularly from synthetic fibers, and their impact on human health and the environment. It calls for a shift towards greater scientific independence in environmental assessments, more comprehensive research into the toxicity of chemicals used in synthetic fiber production, and increased transparency in labeling to empower consumers to make informed choices.