FW

Coteminas, the biggest vertically integrated textile group in Brazil, Latin America plans to explore Turkey as its next ideal location for investment due to its large domestic market and export potential. Coteminas, with a cutting edge technology in each of its 22 factories, produces threads, fabrics, knits, bed linen towels, T-shirts, socks, and bathrobes. It is also responsible for approximately 20 per cent of Brazil’s cotton consumption.

Brazilian companies are increasingly finding that Turkey’s business and investment environment is suitable location in Europe due to its geography and growing economy. Also, Turkey is located close to the EU, which is already showing signs of recovery after the eurozone crisis.

Also the textile major feel Turkey would be its first choice given the growth potential and central status providing easy access to the European, Middle Eastern and African markets and make the country the ideal choice for an investment. Coteminas President recently met with the head of Turkish Textile Employers' Association (TTSIS). According to him, Turkey and Brazil could do more to improve their business and trade relations. The two countries have a combined population of 300 million people and a $3 trillion GDP. Both countries have the advantage of having large domestic markets.

Turkey is fast becoming recognized as a fashion center and top clothing supplier. The country has over 35,000 textile and clothing companies and is the fourth largest supplier of clothing in the world and ranks among the top ten exporters in the textile industry. Turkey has also been able to maintain its edge in the industry by investing early in cutting-edge technologies.

www.coteminas.com.br

After two decades of lull in the Australian wool industry due to collapse of the reserve price scheme, it is suddenly witnessing an upturn as global fashion companies are focusing their attention to natural fibre- wool. For instance, recently internationally renowned L'Uomo Vogue from Italy teamed with The Woolmark Company to display Australian wool and fashion during a week-long celebration.

As a part of the celebration, Sydney's CBD shopping zone will pay homage to wool and fashion, with store windows including David Jones displaying photographs from L’Uomo Vogue archives. And the exclusive photographic exhibition ‘An Artful Thread between Fashion and Style’ will show at the Museum of Contemporary Art.

The Italian men’s magazine has also dedicated its entire March edition to Australia featuring its heritage, including woolgrowers with award-winning actor Cate Blanchett on the cover. Bugaboo, the Dutch baby brand has also started marketing 100 per cent Australian wool accessories, including pram linings and baby blankets made of wool.

Other initiatives like different marketing campaigns including the HRH The Prince of Wales Campaign for Wool and International Woolmark Prize have been promoting wool bringing it back into the spotlight. In fact over the past six months at least 10 countries including Russia, Japan, India and China visited Australia to see the wool growing process. Vietnamese manufacturers and processors would now be visiting Australia as a part of their wool-buying mission.

www.woolmark.com

As a part of its restructuring process, Bombay Rayon Fashions has declared a lock-out at its mill division located at Dodaballapur, Bangalore. The company had also announced that pursuant to the Clause V of the company's code of conduct for prevention of Insider Trading, the trading window of the company would remain closed up to March 20, 2014.

Net loss of Bombay Rayon Fashions stood at Rs 21.47 crores in the quarter ended December 2013 as against net profit of Rs 47.20 crores during the previous quarter ended December 2012. Sales rose 0.51 per cent to Rs 822.92 crores in the quarter as against Rs 818.74 crores during the previous quarter ended December 2012.

In the second quarter, company reported a net loss of Rs 104.85 crores against the net profit of Rs 43.58 crores in the corresponding quarter of previous fiscal. The loss, however, narrowed significantly from Rs 411.75 crores reported in the preceding quarter ended June 30, 2013.

Losses at the company's wholly owned subsidiary BRFL Italia Srl, Italy, had also hit the bottom-line of the company. Due to economic slowdown in Europe and rising costs, BRFL Italia has been shutting down its loss making stores and is in the process of rationalizing the business.

www.bombayrayon.com

Rana Plaza workers, will get Tk 50,000 each as compensation, to be disbursed by the Rana Plaza Donor's Trust Fund by mid-April. The UK-based retailers have now agreed to compensate the tragedy victims through the Rana Plaza Compensation Coordination Committee.

The coordination committee includes representatives of the Bangladesh government, local industry, global brands and retailers, and Bangladeshi and international trade unions and non-governmental organisations (NGOs). The UN agency - International Labour Organisation (ILO) - acts as a neutral chair of the body. The Trust Fund was formed to compensate the victims of the building collapse that killed more than 1,100 workers in April last year.

Recently, UK-based retailer Primark announced its plans to contribute and compensate the 580 workers of New Wave Bottoms during April-May through the coordination committee, which was housed in the Rana Plaza building. Among the 580 workers, 200 are deceased workers' families or their dependents, including the 47 missing, while 227 are injured. They will get compensation according to the ILO convention.

Primark will distribute $9 million among the 580 workers of New Wave, apart from contributing $1 million to the Trust Fund for workers, who worked in four other garment factories. Processing of compensation claims for the Rana Plaza victims will start from March 24.

www.ranaplaza-arrangement.org

The 2014 winners for the FabricLink Network's top 10 innovation awards include: CRAiLAR, Edema Stocking, ELUTE, EQ-Top Seismic Wallpaper, Geckskin, GeoDetect, Mushroom Materials, PurThread, and QMilk, and RamTect.

The award recognises outstanding new developments in textile fabrics across a variety of industries, including technical sports textiles, industrial, medical, safety/protective and home furnishings. The selection is made by the FabricLink Network based on a review of new products currently in the marketplace.

The products under the winning category include: CRAiLAR Flax, a new, high-quality, sustainable natural fibre, which surpasses the comfort of cotton, but exhibits performance characteristics similar to a synthetic. It is said to reduce chemical and water usage and is designated as a 100 per cent biopreferred product by the USDA. </br>

The Edema Stocking, on the other hand, developed by Ohmatex, is a smart electronic textile device that monitors and measures changes in leg volume for patients suffering from edema of the lower limbs. ELUTE is a biodegradable, drug-loaded fibre delivery system, developed by TissueGen, which can be used in implantable medical devices.

EQ-Top Seismic Wallpaper, developed by the Karlsruhe Institute of Technology and Bayer’s Material Science division, is a composite of strong, stiff glass fibres, crisscrossed in various directions to distribute energy evenly when the walls of a building shake during an earthquake. Geckskin, developed by scientists at the University of Massachusetts Amherst, is a new attach-and-release material that replicates the feet of the gecko. The material peels away easily on any surface, leaving no residue, and can hold up to 700 lbs, the company reports. GeoDetect, developed by TenCate, is a combination of geotextile performance and fibre optic sensing technology to provide actionable information related to soil strain and temperature changes of geo-structures.

Mushroom Materials, developed by Ecovative, are a new class of home-compostable bio-plastics with a mycelium base, which are said to be a high-performance and an environmentally responsible alternative to traditional polystyrene plastic foam packaging material, insulation, and other synthetic materials. PurThread Technologies' high-performance fabrics are embedded with an EPA-registered antimicrobial agent developed by Eastman Kodak. The antimicrobial agent, a form of silver salt, works to keep fabrics fresh by inhibiting the growth of odour-causing bacteria, mould, mildew, and fungus.

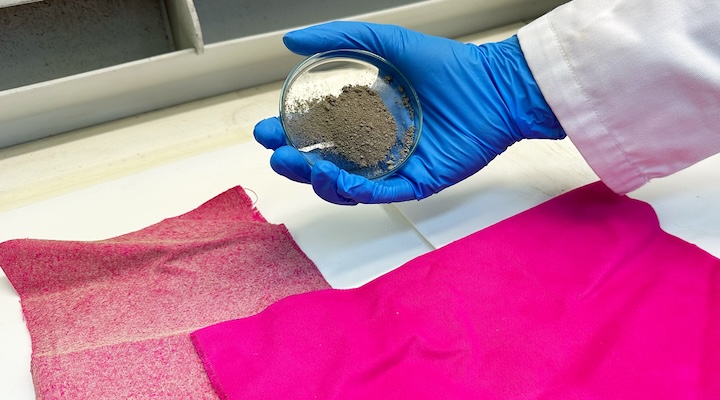

Qmilk, a biopolymer fibre manufactured by Qmilch, is a compostable fibre based on casein milk protein. It can be obtained both as a staple fibre and filament. And RamTect is a 100 per cent American wool insulation product, developed by Hobbs Bonded Fibres, to serve as insulation for outdoor garments.

www.fabriclink.com

As per Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), though demand for knitwear products made in Bangladesh is on the rise, the segment has failed to get fresh investments in the last three years. The segment is in need of funds to become competitive to be able to cater to the export demand. However, recent incidences of fire and other calamities that brought to light the poor working conditions in factories are also one of the reasons why investors are staying away.

The industry body said that the sector is bogged down with issues like power crisis, labour unrest and a new wage structure, which further is causing a roadblock to fresh investments. According to BKMEA data, over the last three years, fewer than 30 new small-scale factories were established in manufacturing knitwear fabrics. In 2011 there were more than 1,500 factories but now only 800 factories are regular members of the BKMEA. The data also reveals that the sector has not only failed to attract new investments but also many existing owners are shutting down their factories.

The segment is waiting to get impending issues resolved so that investors start looking at it once again. There is also fear of rising unemployment due to shutting down of existing factories. The organization is seeking government assistance to establish a planned industrial estate, which could bring in fresh investments.

www.bkmea.com

BIFF&BIL 2014, ASEAN's biggest trade forum for fashion and leather products was held from March 12 to 16, 2014 at Challenger Hall 1-2, Impact Muangthong Thani. The fair had an international feel as 700 booths put up by manufacturers.

BIFF&BIL 2014, ASEAN's biggest trade forum for fashion and leather products was held from March 12 to 16, 2014 at Challenger Hall 1-2, Impact Muangthong Thani. The fair had an international feel as 700 booths put up by manufacturers.

Visitor turnout cascade

Thailand’s political unrest took a toll on the number of visitors to the event this time as BIFF & BIL 2014 saw a 15 per cent fall in the number of visitors this year. Yuttna Silpsarnvith from TGMA (Thai Garment Manufacturers Association) revealed that political problems and demonstrations were the main reasons for low turnout. “This is better than what we forecasted at 20 to 30 per cent less,” said Silpsarnvith. In fact, Hong Kong government issued a notification saying it is critical and hence did not want their people to visit the fair. “It was a difficult situation to deal with,” Silpsarnvith pointed out.

Locals were lesser in numbers however, there was an increase in foreign visitors  especially suppliers. Japanese customers came in large numbers and 12 Japanese brands put up booths for the first time. These brands came with an intention to expand to Thailand and Asia so they scored really well. This is the first time they were looking at a change in their consumer bases. “They intend to come back with more than 20 booths next time. Korea has also expressed its desire to increase its presence. This year they had eight booths but next year they will come with more textiles and want to expand here,” added Silpsarnvith.

especially suppliers. Japanese customers came in large numbers and 12 Japanese brands put up booths for the first time. These brands came with an intention to expand to Thailand and Asia so they scored really well. This is the first time they were looking at a change in their consumer bases. “They intend to come back with more than 20 booths next time. Korea has also expressed its desire to increase its presence. This year they had eight booths but next year they will come with more textiles and want to expand here,” added Silpsarnvith.

Emerging talent at BIFF & BIL

Designers’ Room project dominated the event. As a part of this project, new designers showcased their talent. It supports emerging talents whose ambition is to become accomplished fashion designers and build global fashion brands. The project aims at offering a new generation of Thai fashion designers to develop their capabilities and have trade opportunities as well as acquire experience in marketing. Members of Designers’ Room are recognized by their creativity, strong design aesthetic and distinctive character.

AFF promotes Asian lifestyle

The AFF conference was another major highlight of the event where six countries viz. China, Japan, Korea, Singapore, Thailand and Vietnam were invited to hold fashion shows. David Wang, Chairman, Asia Fashion Federation Singapore Committee explains, “The main objective of AFF (Asian Fashion Federation) is to promote Asian style and that is not just fashion but lifestyle. The West has been influencers of fashion for a long time but Asia would be next. And we are trying to make Asia the next powerhouse. This will take time because you can’t change perceptions overnight.” Wang further added, “We feel that even though western fashion is looking to East, they are looking away from traditional fashion sources like New York, Paris, Milan. We are trying to promote Asian styles here.”

AFF started with China, Japan and Korea and Singapore followed by Thailand and Vietnam. Wang says they would like to have India on board as well as it has a rich culture and a variety in textiles. “Indian designers do a fantastic job however, we have had no Indian association or designers approach us as yet. We have designers from Indonesia and Philippines, so we are considering those countries next,” added Wang.

Apart from the annual fashion showcase, AFF also organizes seminars which usually revolve around the fashion industry and latest techniques. It tries to analyze what customers want. The fair also held an ‘Elderly Fashion Exhibition’ featuring clothes, footwear, bags and other products, Hotel Lifestyle Exhibition featuring items such as uniforms, footwear and beddings, and a seminar on 2014-’15 trends for leather products by experts from Italy. Additionally, there was business-matching to help manufacturers discover partners and build networks with potential buyers from ASEAN and other countries. More than 31 companies indicated their readiness to take the ‘Small Lot Orders’ to accommodate buyers making orders with small quantity yet with wide variety of product designs and custom-made quality. Manufacturers participating in this program had booths bearing the ‘SOOK (Small Order OK)’ logo.

Cotton grown in five continents will now be listed on a new futures market as the US loses its central role as a source of the commodity. World cotton futures will be listed on Intercontinental Exchange (ICE), in the second half of 2014. ICE’s existing benchmark cotton futures, which dates back to 1870, is priced exclusively against US-grown crops.

Members of two industry groups, the American Cotton Shippers Association and the Liverpool-based International Cotton Association, have also reached a consensus on the origins and delivery points of the new market. In early 2011, prices reached record above 2 dollars per pound amid a perceived cotton shortage, leading to losses, defaults and lawsuits that continue to have an impact over the industry. ICE May cotton was 91.98 cents/lb early this week.

By accepting delivery of cotton cultivated in more places, traders hope to avoid squeezes and better track prices in the global marketplace. Futures are contracts that require delivery of a commodity by a certain date. Cotton from Australia, Brazil, India, the US and, West Africa, Benin, Burkina Faso, Cameroon, Ivory Coast and Mali will now be eligible for deliveries against the new world contract. All these countries are net cotton exporters.

The new world contract will showcase delivery points in the US, Australia and Malaysia, since it is close to yarn mills in China and Vietnam. The international cotton market is led by commodities trading houses such as Louis Dreyfus Commodities, Cargill, Glencore Xstrata, Noble Group and Olam. ICE will continue to list its benchmark US contract alongside the world contract.

www.theice.com

The lifetime achievement AATTC (Association of Textile, Apparel and Materials Professionals), world’s leading non-profit association serving textile professionals since 1921) Award for outstanding achievement has been bestowed to John Richard ‘Dick’ Aspland in the field of textile chemistry.

Aspland’s research included a wide range of textile chemistry interests, including fluorescence of dyeing and laundered fabrics (bi-spectral-spectrometry) ; fastness properties of dyeing on novel polymers; implementation of novel shade sorting software for colour users from colour instrument manufacturers to apparel cutters; the influence of fibre, yarn and fabric parameters on the physical properties of coated fabrics; synthesis of isotopic tracers for studying diffusion in nylon dyeing; the effect of colour distribution on the colour appearance of yarns, fibres, and fabrics (mirco-spectrometry); and the interactions between pigment particles and polymers.

Aspland has been active in textile chemistry for more than 50 years as a, researcher, and educator in academia and industry. His book ‘Textile Dyeing and Colouration’ published by AATCC in 1997, has been used as a premier literature on dyeing. Aspland and his former student, Ann Laidlaw, together published the AATCC ‘Colour Guidebook’ in 2011. He has published more than 145 articles in journals and in conference proceedings, three peer-reviewed book chapters, and holds two patents.

He is an AATCC member since 1971, and has received the AATCC Harold C. Chapin Award for services to AATCC in 1999. In 2005, he was bestowed with the AATCC William J Weaver Paer of the Year Award for his contributions to textile science literature. He also received the Award for Faculty Excellence in 2000 and 2002 from the Clemson University Board of Trustees. He is also a member of the Inter-Society Colour Council and the Fibre Society.

www.aatcc.org

Garment exporters in Pakistan are opposing the demand by spinners to re-impose 5per cent duty on yarn imports from India. The demand for withdrawal of the duty exemption on India’s yarn was made by Aptma to restrict its imports after New Delhi announced a 4per cent rebate on its exports after the EU granted GSP+ status to Pakistan.

While Aptma is of the opinion that the duty rebate would make Indian yarns much cheaper compared to domestic products, Prgmea on the other hand is in favour of the rebate, since it would assist the export community in increasing exports of quality products to the EU. Aptma argues that Indian textile industry is already enjoying several incentives in the form of low energy prices, almost free credit and export rebates, which are causing dumping of cheap yarn in Pakistan, affecting the domestic production. And to control yarn imports from India, it has demanded re-imposing of five per cent duty to protect the domestic industry.

Prgmea, however, feels that at a time when small garment exporters have been hit hard by abrupt appreciation of the rupee, imposition of duty on Indian yarn would further lead to a rise in domestic prices at the cost of value-added exports. The imposition of duty, will increase domestic yarn prices putting pressure on domestic production cost. And if there are no value added textiles to exports then the GSP+ concessions would not mean anything.

The ministry has called for a meeting with stakeholders belonging to both sides to take a decision on the issue.

www.prgmea.org