FW

"According to officials, India was hopeful of striking a tariff-cutting deal this year, in the clearest indication yet that India wants to accelerate progress on a bloc first launched in 2012. Ganeshan Wignaraja of the Asian Development Bank (ADB) feels a breakthrough on RCEP would help mitigate the competitive disadvantage of India being absent from the TPP. Concluding an RCEP agreement would mark a key milestone for the Modi government"

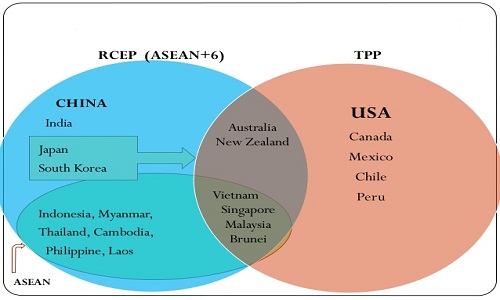

Concerned at being sidelined from the US-led Trans-Pacific Partnership (TPP), India is stepping up efforts to reach agreement with an alternative trade bloc centered around China, and hopes to reach a deal this year. India has long been seen by many countries as an intransigent player at the World Trade Organization (WTO), a multilateral forum that has struggled to find the consensus it needs to move forward. With 12 advanced economies accounting for 40 per cent of the global economy signed a TPP deal this month, India’s trade negotiators feel they need to get a move on, as Prime Minister Narendra Modi’s export-focused ‘Make in India’ drive as the path to prosperity for Asia’s third-largest economy, where per capita output is $1,688 a year, one fifth that in China.

Exploring access to Asian markets

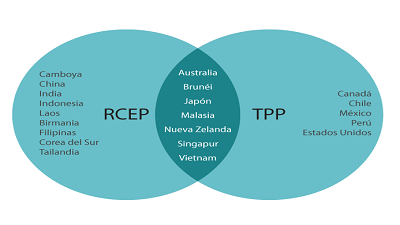

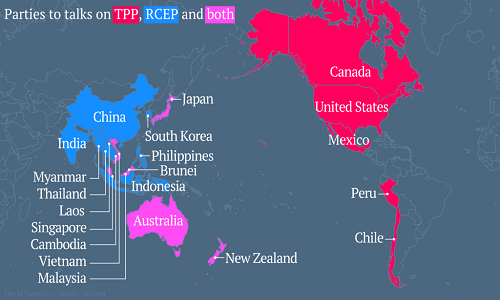

With TPP out of reach, India was not invited to join, India’s negotiators are focusing instead on a Chinese-led grouping called the Regional Comprehensive Economic Partnership (RCEP) that would improve its access to Asian markets. To iron out differences on tariffs, a trade representatives meet is scheduled in Brunei from February 15 to 19.

According to officials, India was hopeful of striking a tariff-cutting deal this year, in the clearest indication yet that India wants to accelerate progress on a bloc first launched in 2012. Ganeshan Wignaraja of the Asian Development Bank (ADB) feels a breakthrough on RCEP would help mitigate the competitive disadvantage of India being absent from the TPP. Concluding an RCEP agreement would mark a key milestone for the Modi government.

Experts caution that India has shown little appetite to open its market to imports, even as it seeks to ramp up exports, not least because of a gaping trade deficit with China. Some experts feel, India is worried about opening up to China and so there is cloud over whether RCEP deal would happen this year. With the TPP lacking votes in the US Congress and likely to be put on hold if a Republican is elected US president, any sign China is seizing the initiative in the trade arena could raise concerns over Washington’s declining clout in Asia. Meanwhile, with backing from close US allies like Britain, Beijing has already redrawn the financial map by launching the Asian Infrastructure Investment Bank (AIIB).

Fear of losing business

Even though TPP is years away from reality, New Delhi fears losing some textile and drugs exports to countries like Vietnam, which has embraced both the TPP and the RCEP. Officials point out, it could also raise barriers to entry on labour, environment and intellectual property when it comes to seeking access to other markets.

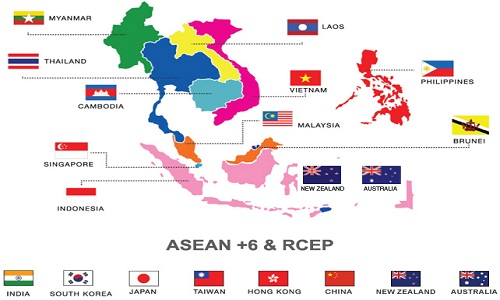

The TPP will certainly have an impact on India’s exports, believes commerce minister Nirmala Sitharaman said. It is most likely to affect sectors like leather goods, plastics, chemicals, textiles and clothing. Talks on creating the 16-member RCEP could be the last hope for some Indian companies to break into the global supply chain. The group comprises the 10 members of the Association of Southeast Asian Nations (ASEAN), China, Japan, South Korea, India, Australia and New Zealand. If signed, the regional free trade agreement would create an economic bloc with a population of 3.4 billion and trade volume of over $17 trillion.

Export industries, particularly garment and drug makers, are urging the Centre to speed up RCEP talks and wrap up trade deals with the European Union and Australia. But steel, tyre and chemical firms want the Centre to go slow, saying they have been undercut by free trade pacts already done with ASEAN, South Korea, Thailand and Japan.

Indian merchandise exports have fallen for 13 months in a row, depressed by weakening global demand and slumping commodity prices. To boost the country’s stagnant 1.7 per cent share of global exports, India needs to raise productivity and move up the value chain.

Despite a dispute over GSP facility, Bangladesh's apparel exports to the US booked double-digit growth both in terms of value and volume in 2015. The rise in garment export has been shown in US official data, in a comparative revelation of trade position with Bangladesh's competitors on the American market.

According to industry-insiders the prevailing stable political situation and ongoing safety drive helped in regaining the buyer confidence, resulting in such performance. In 2015, Vietnam, one of Bangladesh's main competitors, also registered a double-digit growth on the US market. According to Office of Textiles and Apparel (OTEXA) under the US Department of Commerce, shipment of local garment products to its single-largest destination reached $5.40 billion during 2015 calendar year, registering an 11.74 per cent growth over the previous year.

Bangladesh's apparel export to the United States fell to $4.83 billion in 2014 from $4.94 billion in 2013. The country exported 1.86 billion sq. mt. of apparel products, showing a 16.17 per cent growth, last year compared to that of 2014. Overall exports to the US, however, stood $5.60 billion in the last calendar year, up from $5.0 billion in 2014, reveals the OTEXA data.

Experts argue, though the garment-export earnings from the US market registered a double-digit growth, the price of locally-made apparels did not increase in line with the rising production cost. Meanwhile, India and Sri Lanka registered a growth of 7.78 per cent and 15.82 per cent with earnings worth $ 3.36 billion and $2.03 billion respectively in the past year, the OTEXA data showed.

Polyester manufacturer Indorama Synthetics has reported a standalone net profit of Rs 35 lakh for Q3 ended on December 31. The company had posted a net loss of Rs 58.40 crores in the corresponding period a year ago.

Net sales of the company on standalone basis during the quarter under review were Rs 585.10 crores, down 9.81 per cent, as against Rs 648.80 crores in the October-December period last fiscal. The company registered higher sales of 12 per cent in terms of volume at 83,175 tons as compared to 74,442 tons in the corresponding quarter of the previous year.

Domestic sales volume increased by 27 per cent during this period from 56,145 tons to 71,574 tons. The results for this quarter have started to fall in line with the company’s objective to make the company profitable. Cotton production is expected to remain low in this calendar year, which will help the company in improving margins. Indorama Synthetics is India’s largest dedicated polyester manufacturer. The company offers a wide range of polyester products which includes polyester staple fiber, partially oriented yarn, draw texturised yarn, fully drawn yarn and polyester chips.

www.indoramaindia.com/

Indonesia’s biggest producer of textile raw materials Indorama Synthetics opened a $40 million spinning mill facility in Purwakarta, West Java says the country’s Investment Coordinating Board (BKPM). According to Franky Sibarani, Chairman, BKPM, Indorama’s expansion can support the government’s plan to reduce unemployment and improve the locals’ income in Purwakarta district, while also improving foreign exchange earnings from exports.

Purwakarta mill is Indorama’s ninth plant in the archipelago nation. The plant, which has a capacity to produce 10,800 metric tons of textile raw materials per annum, is situated on a 50-hectare plot land that has been owned by Indorama since 1997. The plant will provide 270 new jobs.

Indorama Synthetics, controlled by Indian-born businessman Prakash Lohia, has been listed on the Indonesia Stock Exchange since 1990. New investment in the textile and textile products industry last year stood at Rp 8.3 trillion, up 35.7 per cent compared to a year earlier. New local investment in the sector was recorded at Rp 2.7 trillion while foreign investment contributed Rp 5.4 trillion, according to BKPM.

Egyptian textile industry has proven that it is more than up to the task, if only given the chance. According to the country’s central bank statistics, in the decade before Egypt’s 2011 uprising, cotton textile exports increased by about 19 per cent a year on average, having surged from US$108.9 million in 2001-02 to $628.0m by 2010-11.

Exports of ready-made clothes climbed almost as quickly, jumping 17.6 per cent a year, from $187.2m to $771.2m. Since the uprising this growth has come to halt, with exports of cotton textiles increasing by only 3.1 per cent annually in the four years to June 2015, and ready-made clothes by only 1.4 per cent. Textile exports actually contracted in the two years after July 2013, when Mohammed Morsi was removed from power and a degree of political stability was restored. Many smaller companies have shut down entirely.

To be sure, the overvalued pound has not caused all the problems, according to Mohamed Kassem, chairman of the Ready Made Garments Export Council of Egypt. The government raised the prices of electricity and natural gas in July 2014, with those paid by industry rising especially sharply. Labour and water bills also increased, and because of security concerns the government has made it harder to import many chemicals. All this has happened at a time when textile prices were falling around the world.

According to Kassem, the biggest problem remains that the strong pound is pricing Egyptian textiles out of the export market. The exchange rate is at the top of the list. Although the Egyptian pound was devalued against the dollar several times last year, since mid-2013 it has actually strengthened against the euro, the currency of one of Egypt’s main export markets. Meanwhile, the currencies of many of Egypt’s competitors have weakened, making their products more attractive.

Bangladesh and the European Union will form a joint business council soon to boost trade between the two partners. As per the plans, representatives from the private sector will be incorporated in the Bangladesh-EU council to take business ties between the two partners to a new height. Commerce minister Tofail Ahmed briefed a visiting EU delegation on the progress made by Bangladesh for safer working environment at the factory level under the Sustainability Compact.

After the collapse of Rana Plaza building, Bangladesh signed the International Labour Organisation-brokered Sustainability Compact with the EU in 2013, committing to responsible business behaviour. Later, the US and Canada joined the deal. Two follow-up meetings of the Sustainability Compact, so far were held to review the progresses of workplace safety and labour rights. According to Ahmed, Bangladesh has fulfilled almost all conditions put in the Compact and the EU delegation is also satisfied with the progresses.

Ahmed said that the three agencies - Accord, Alliance and the National Action Plan - have completed inspections of 3,800 factories for deficiencies in structural, electrical and fire safety.

China will cooperate with Azerbaijan in cotton production. A plant will be set up in Azerbaijan for production of seedless raw cotton and cotton seed, based on new technologies. Cooperation with China is of significant importance in terms of development of seed farming, cotton processing and seed cleaning in Azerbaijan.

Azerbaijan is keen to give new life to the cotton production industry. The country was famous for high production of cotton the last century and was a leading cotton producer in the Soviet Union. However, over the past 18 years, production dipped six fold. Areas under cotton reduced nine times. Despite the heavy demand, the decrease in interest in cotton resulted from the low profitability margins of cotton production. Azerbaijan collected 35,000 tons of cotton in 2015, which is 14.6 per cent less than in 2014. This was the lowest indicator of cotton production in Azerbaijan since 2010.

The target for 2016 is to plant cotton on 30,000 hectares of land (80 per cent more than the previous year), and to supply 70,000 tons of raw cotton. China is the largest cotton producing country in the world. Some 300 million people are involved in cotton production in the country’s 24 provinces.

Argar Technology’s trump card while the ideating the production of HV (high visibility) fabrics was to manufacture new knitted fabrics to substitute 100 per cent polyester regularly used to achieve the chromatic specification fixed by EN20471 rules. Argar, double knitting technology was innovatively applied in the production of its high visibility HVis-Tes® Knitted Fabrics. In its new HVis-Tes® range of products the external face of fabric is now 100 per cent polyester, while the internal face is 100 per cent pure cotton.

According to the company, this peculiar interlacement guarantees at the same time the extraordinary features of durability and endurance of a polyester fabric and the comfort that only a cotton fabric is able to provide in touch with the skin. On customer’s request they are also available with antibacterial and UV-protection treatment (complying respectively with EN20645:2005 + EN20743:2007 and AS/NZS 4399:1996 norms).

The range of HVis-Tes® ESD Knitted Fabrics adds to the advantages of the high visibility items with the antistatic function given by conductive fibers. The features of HVis-Tes® ESD Knitted Fabrics fully comply with the specifications of EN20471, EN1149 and Oeko-Tex ® Standard 100 Class II Certifications rules.

Similarly, the features of Noflam®-HV Knitted Fabrics fully comply with the specifications of EN11612, EN20471 and Oeko-Tex ® Standard 100 Class II Certifications rules. The company guarantees knitted fabrics, which are fully manufactured and ennobled in Italy and mostly have European Preferential Origin. The few items of the standard collection which have no Preferential Origin Status can be manufactured with Preferential Origin upon Customer’s request.

Klopman has developed a new range of products made with recycled polyester. Europe’s leading brand in work wear has been involved in the production and marketing of blended fabrics in 65 per cent polyester and 35 per cent cotton since 1968.

Today, the basic yarn utilized for the making up of work wear garments can be replaced by similar materials aimed at reducing the environmental footprint, conservation of resources and to support developing countries. Recycled polyester is made from PET plastic bottles, a resource that would otherwise end up in landfills. The challenge for the company was to develop a sustainable product capable of maintaining the features and fabric standards in terms of comfort and durability.

The company also constantly applies its commitment to innovation in accordance with ethical and environmental considerations. From the selection of raw materials through weaving, dyeing and finishing, the company is constantly working to minimise the use of toxic substances, reduce waste, reduce energy consumption and to sustain the development of renewable energies.

The company is also equipped with advanced air extraction systems, which are installed throughout the factory, filter and purify the air by minimising the impact of harmful substances into the outside environment.

www.klopman.com/

Karl Mayer has developed new machines and applications for warp knitting, weaving warp preparation and composite fabrics. The company innovates in functional sportswear up to the use of carbon fiber in cars.

It offers high performance warp knitting machines, producing new and sophisticated fabrics for automotive applications, and for sportswear, including seamless garments. For the weaving industry, Karl Mayer has an automatic sectional warper for the flexible production of high-precision warp beams. For sizing the company offers a VSB size box, a revolutionary new development that will generate significant savings. Another key area is for the composites industry, and an innovative carbon fiber spreading unit.

The Karl Mayer Academy holds fabric forming familiarisation courses, providing more insight in the application possibilities of the presented technologies.

Germany. The company offers raschel machines, lace machines, warping machines, tricot machines. Specialist machines are also available for producing stretch and non-stretch fabrics. India is an important market for Karl Mayer, as its the second most important sales region for its warp preparation business unit. In some sectors, such as direct beaming and sizing machines, Karl Mayer has a market share of more than 90 per cent.

www.karlmayer.com/