FW

East Africa is seeking to galvanise synergies of textile industry players by linking the local cotton, textile and apparel industry to local suppliers and fashion designers in the region. Policies will be framed for promoting the sector’s performance, productivity and quality.

East African countries will embark on manufacturing apparels such as inner garments, ties and scarves that require low level technology and skills. The East African Community comprises Burundi, Kenya, Rwanda, South Sudan, Tanzania and Uganda. The region is trying to phase out imports of second hand clothes. Over the years, the clothing and shoe manufacturing industries in the EAC have collapsed due to the emergence of the informal sector.

Cotton production, processing and trade in East Africa is influenced by policies like price support, tariff protection, production subsidies and stock piling that destabilise cotton prices. The competitiveness of the cotton industry in the East African Community is faced with challenges such as low yields, ginning overcapacity, low ginning out-turn ratio and inefficient value addition. It’s felt that value addition in the cotton and textile industry in the form of innovative aesthetic accessories, interior designs and fashion can create more job opportunities.

Meanwhile the United States Agency for International Development has approved a grant to the East African Community. This will support the health, energy and environment sectors.

International Apparel and Textile Fair (IATF) will be held in Dubai from November 1 to 3, 2017. This is the UAE’s exclusive sourcing fair for textiles and clothing. More than 140 exhibitors from across the world will be participating. It provides manufacturers and their agents the opportunity to showcase their products to the most influential buyers and designers in the UAE fashion sphere. The event further offers buyers, distributors and designers the opportunity to view a wide range of textiles from the most prestigious global mills.

IATF attracts some of the world’s largest manufacturers of fabrics and clothing as well as some leading print design studios. Exhibitors are from Turkey, China, Italy, Spain, India, UK and many more. A show like IATF is much needed in the region as the UAE continues to see robust growth in the clothing and textile industry. The last few years have shown a remarkable increase in retail sales in apparel, making it as one of the most attractive sectors in the UAE.

The apparel industry in the region provides an opportunity for international retailers to expand in the UAE. The country is also the world’s eleventh biggest clothing importer. Next to London, Dubai is the second global city having the highest percentage of international retailers.

The garment industry in Cambodia expects orders to increase next year due to improved working conditions and the introduction of a higher minimum wage for the sector. The country expects purchasing orders in the garment sector in 2018 to be higher than in 2017.

There is a lot of room for progress in the garment sector and many opportunities for the government and buyer companies to work together towards a better future for the industry. After months of negotiations, the minimum wage for garment workers in Cambodia was recently raised to 170 dollars, with the new law coming into effect early next year.

Foreign purchasers appear to be satisfied with what Cambodia has achieved when it comes to worker welfare. Now, there is a stable environment, good relations between players in the industry. Cambodia has a great future for securing business and industry investment. The country works closely with national organisations and international partners like the ILO, the Global Deal Initiative, and GIZ to guarantee Cambodian garment and footwear products followed strict standards of quality and adhere to international good practice when it comes to workers’ rights. The country now wants GSP for its garment and footwear exports to the United States.

Brooks Brothers has evolved into an international apparel corporation, distinctive for its American style. Founded in 1818, Brooks Brothers was the first label to sell industrially manufactured garments, and in 1896 it invented the button down shirt.

The label currently operates 280 stores in the US and over 700 worldwide, featuring high-end, classic family fashion, well-suited to both men and women.

The brand will celebrate completion of 200 years next January at the Pitti Uomo menswear show in Florence. Brooks Brothers will feature as one of the event’s main highlights, notably with a catwalk show that promises to be a landmark moment. It will in fact be the very first catwalk show for the label, acquired from Marks & Spencer in 2001 by Italian businessman Claudio Del Vecchio, now the CEO. The show is scheduled for January 10 at the iconic Salone Cinquecento in Florence’s Palazzo Vecchio, home to the Florence mayor’s offices.

From January 11 to 14, Palazzo Vecchio will also host a Brooks Brothers retrospective, exhibiting several items coming from the US label’s archives. This anniversary is a significant, historic milestone not just for Brooks Brothers but for the fashion industry at large.

Pitti Uomo is an international benchmark for menswear.

Textile major Arvind will invest Rs 300 crores in setting up a mega apparel factory near Ahmedabad. It will produce 24 million garments a year. The plan is to commence commercial production in the fourth quarter of 2018 and create 10,000 jobs, mainly for women.

Arvind is one of India’s largest manufacturers and exporters of textile products with a turnover of nearly $1.5 billion in fiscal 2016-17. The company is also one of the largest producers of denim fabrics and is a supplier to a large number of fashion brands in the world. It does 60 exports and 40 domestic. It is focusing on consolidation and adding value to the supply chain.

Arvind’s textile business (denim and fabric) contributes 60 per cent to total revenue and the rest is by brands and retail business. The Ahmedabad-based company has a portfolio of owned and licensed brands. Its own brands include Flying Machine, among others, while its licensed product brands include Tommy Hilfiger, Calvin Klein, Arrow, Gant, Nautica, Gap, and Aeropostale.

Gujarat’s new Garments and Apparel Policy 2017 encourages employment in the garment sector and promotes garment production in the state. The policy is expected to help the state forward integrate into apparel manufacturing and develop vertical solutions for global brands.

Meanwhile leading textile company Grasim too has signed MoU with the Gujarat government to set up a production facility in the state. Grasim, a flagship company of the Aditya Birla Group, is planning to set up man-made fibre plants in Vilayat GIDC and Kharach-Kosamba in the state’s Bharuch district. The company signed an MoU with the Gujarat government to invest about Rs 4,100 crore. As per its MoU, Grasim will employ about 1,300 people directly and indirectly at the facilities which are likely to be commissioned in 2018 and 2020, respectively.

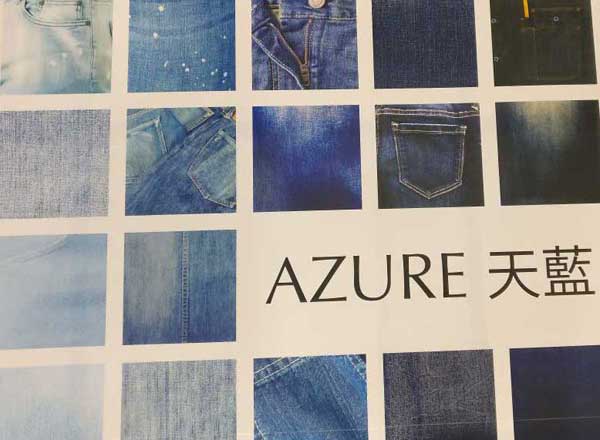

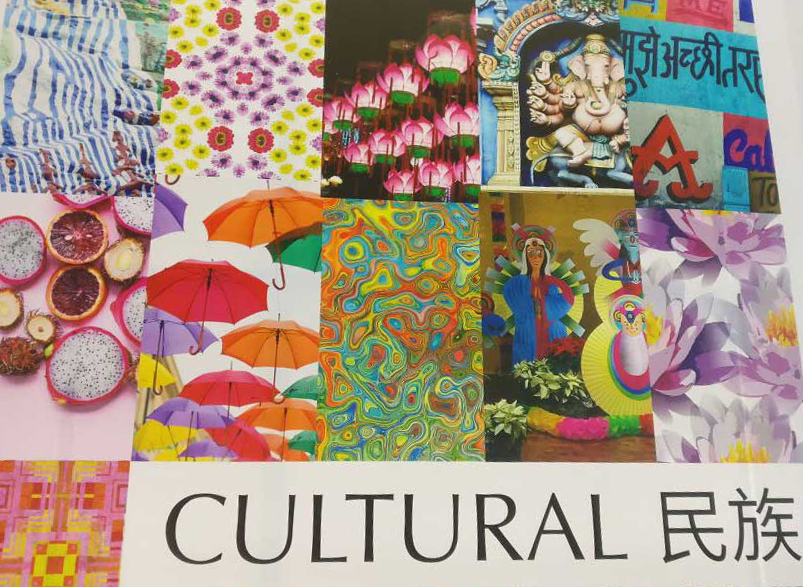

Beyond Denim, a part of Intertextile Shanghai Apparel Fabric had an elaborate display of trend forecast section for denims dedicated this time, for Autumn Winter 2018. The trends were divided into three broad themes of Azure-relating with genesis of indigo blue, New Age-a contemporary high tech interpretation of denim and Cultural-a mix of cultural lineage of past and present…

In today’s digital and tech-enhanced world we are searching for tactile and immersive discoveries in our day lives. The Autumn/Winter 2018 season engages the senses creating a 3-D experience through a unique cube design perspective. This season there is a spectrum of visual trends to explore. In Azure, Denim returns to its authentic roots while looking to new sustainable practices in the process. Innovation and technological advances are at the forefront in new age, set against a cityscape backdrop, and a colorful explosion of craftsmanship is displayed in cultural. Look up and look down in order to discover all of the sensorial details that denim has to offer

AZURE

Authentic + Sustainable

Authenticity is at the core of denim's rich hi story. A myriad of washes and dyes are being explored through tradition al techniques, showcasing a long history of established craftsmanship. State-of-the-art ecological and sustainable washes and technology in finishing are the focus of the season.

NEW AGE

Modern + Technical Innovation

A contemporary and chic city aesthetic define the new age look. For a lifestyle that is constantly on the go, function and comfort are important, with high-tech innovation in new fiber blends and performance capabilities. Protective elements with thermal properties and stretch enhancement give new life to denim.

CULTURAL

Culture + Craft

Hybrid collaboration’s and interconnectivity create a new cross pollination kaleidoscope of the past and the present. We are influenced by a patchwork of diversity that combine into a contemporary, multicultural lifestyle filled with color and wonder. Embroideries, appliques and innovative silhouettes and prints define this textured and layered style.

Driven by a quest for rare, invaluable fibres to manufacture the most magnificent fabrics in the world, the House of Dormeuil is celebrating the 175th anniversary of its foundation with an innovative creation. Known as ‘175 fabric’, this new cloth is masterfully woven with, the softest Vicuña and the finest Merino wool form an exquisite fabric. The fabric is a combination of two superlative wools from the Andes and Tasmania. Dominic Dormeuil, the 5th generation of the family, searched the Altiplano until he reached the Puno province, at 4800 meter mountaintop. From there, he selected the finest Vicuña, the fibre of the Gods.

Driven by a quest for rare, invaluable fibres to manufacture the most magnificent fabrics in the world, the House of Dormeuil is celebrating the 175th anniversary of its foundation with an innovative creation. Known as ‘175 fabric’, this new cloth is masterfully woven with, the softest Vicuña and the finest Merino wool form an exquisite fabric. The fabric is a combination of two superlative wools from the Andes and Tasmania. Dominic Dormeuil, the 5th generation of the family, searched the Altiplano until he reached the Puno province, at 4800 meter mountaintop. From there, he selected the finest Vicuña, the fibre of the Gods. Long reserved for the Inca emperors, it is today revered as a sacred gift of Pachamama, the Mother Earth goddess. Sheered only once every two years, a vicuña produces from 120 to 300 gm of fibre.

These animals demand specific attention to care and unpolluted fields for grazing. The Winton merinos produce a wool of unparalleled fineness, thanks to the quality of the land, 3,000 hectares of gently rolling hills, abundantly covered in lush vegetation and boasting a mild climate. When sheering season arrives during the Austral winter, the fleece bears witness to its extraordinary quality. Perfectly uniform and crimped, the long fibres are bewitchingly velvety and very resistant. Their ultra-soft feel, lightness and remarkable fineness (13.5 microns) offer a unique texture.

Weaving finesse

The Dormeuil Huddersfield workshops in Yorkshire have designed a specially adapted weave. Master weavers drew from 175 years of expertise combining ancestral weaving and finishing methods in the English fashion with innovative techniques. On state-of- the-art looms, each weaver ensures that the process runs smoothly and that the shuttles remain supplied with yarn. Fabric 175 has impeccable drape that recovers neatly when stretched, proof of its elasticity. The House has designed a straightforward, contemporary palette for 175 in tune with the Dormeuil tradition.

The USP

Dominic Dormeuil, President, says “Dormeuil is the first company in the world that has launched natural stretch in pure wool fabrics, without any use of spandex or elastane material.” He explains, wool as a fibre has natural elasticity up to 30 per cent, earlier as a process, elasticity is removed before processing the wool fibre in spinning, weaving and finishing because it is very difficult to process with elastic fibre. “But now, we have developed technology to process the natural elasticity through spinning, weaving and processing to have a finished product that has stretch up to 15-25 per cent, and please note this is not mechanical stretch. A part of our range has already been introduced in natural stretch. This adds approximately 10 per cent to the cost of fabrics. But this is being highly appreciated by luxury brands, as no one in luxury segment appreciates spandex/elstane based stretch,” informs Dominic Dormeuil. For Dormeuil, Asia is the biggest market especially Japan and China, followed by the US and then Europe.

Colours & trends

The luxurious fabric is available in tones of navy blue and anthracite grey, echoing the magnificent immensity of the Altiplano and Tasmania. Deploying the traditional dying processes, the discreet weave pattern underpins the remarkable fineness of the wool. For Dormeuil, all colors and shades of blue are in, the trend now as he says, “Blue is the new Black”. Speaking on trends, he remarks, that trend is towards more of casualwear and youth wear, jacketing and reversible products.

India’s annual rate of inflation, based on the monthly wholesale price index (WPI), declined to 2.60 per cent for September 2017 over the same month last year. The WPI for all commodities for the month of September 2017 declined by 0.4 per cent to 114.3 from 114.8 for the previous month.

The index for manufactured products for September 2017 rose by 0.4 per cent to 113.4 from 112.9 for the previous month. The index for the textiles sub-group rose by 0.6 per cent for the previous month due to higher price of texturised and twisted yarn and weaving and finishing of textiles, manufacture of cordage, rope, twine and netting and cotton yarn. However, the price of viscose yarn and manufacture of knitted and crocheted fabrics declined.

The index for primary articles declined by three per cent from the previous month. On the other hand, the index for fuel and power rose by 1.7 per cent from the previous month due to higher price of LPG, naptha, ATF, petrol, kerosene, HSD, furnace oil, and bitumen. However, the price of petroleum coke declined.

The index for Manufacture of Wearing Apparel sub-group rose by 0.1 per cent in September 2017 from the previous month due to higher price of trousers/pants made of cotton and/or manmade fiber.

"To attract consumers with its ethical practices, textile and apparel industry needs to look for sustainable alternatives. There are six interesting alternatives natural resources like bananas, coffee, pineapple, lotus, stinging nettles and hemp that can be used to turn into sustainable textiles. One of the most versatile natural fibers can be obtained from hemp (Cannabis Sativa plant) - hemp fibers, which are antibacterial, durable and resilient, work as a natural air-conditioning system. In addition, hemp is a fast-growing plant that consumes little water and does not require herbicides, pesticides, synthetic fertilizers or GMO seeds."

To attract consumers with its ethical practices, textile and apparel industry needs to look for sustainable alternatives. There are six interesting alternatives natural resources like bananas, coffee, pineapple, lotus, stinging nettles and hemp that can be used to turn into sustainable textiles. One of the most versatile natural fibers can be obtained from hemp (Cannabis Sativa plant) - hemp fibers, which are antibacterial, durable and resilient, work as a natural air-conditioning system. In addition, hemp is a fast-growing plant that consumes little water and does not require herbicides, pesticides, synthetic fertilizers or GMO seeds. China currently accounts for more than 50 per cent of the global hemp production and holds more than half of the more than 600 international patents on hemp fibers and textile production. This needs to change.

Hemp fibre

The common stinging nettle, Urtica dioica, is a widely used plant that is easy to grow. For the production of the fibers, the nettles are harvested in the summer and the stalks dried well. This removes the sting. After drying, the stalks are broken to separate the woody parts. Then, the plant is hackled to separate the fibers and to remove the leaf attachments. After that, the fibers are spun wet and then dried. Twisting them increases tear resistance.

Similar to hemp fibres, stinging nettle fibres are versatile, keep the wearer warm in winter and cool in summer, and can be grown with far less water and pesticides than cotton. Thanks to new spinning techniques and hybrid plant species, nettle plants with super high fiber content are obtained, which are strong and flexible and have a good spinning length.

Coffee ground fibre

To make coffee ground fibres, the most important raw material is coffee ground which most coffee drinkers simply throw away after making their coffee. Taiwanese textile company Singtex’s technology combines the post-patented processed coffee ground with polymer to create master batches before spinning it into yarn. The resulting coffee yarn is multi-functional and can be used in a variety of products, from outdoor and sports performance wear to household items used every day.

Fabrics made out of coffee ground fibres like S.Café by Singtex offers excellent natural anti-odour qualities, in addition to UV ray protection and a quick drying time. The coffee grounds used to create the yarn are taken and recycled from some of the world’s largest coffee vendors, like Starbucks. In this way, the company gives a second life to coffee grounds which would have otherwise ended up in the trash. Coffee ground fibres have many advantages but now, the challenge remains in taking the fibre global and ensuring more apparel brands incorporate it into their collections in lieu of conventional fabrics and that it extends its reach to outside of the fashion industry.

Pinatex

Pineapple fabric Piñatex, is a vegan alternative to leather, which is made from pineapple leaves. London-based Ananas Anam has developed a natural and non- woven textile out of pineapple leaves, known as Piñatex which is remarkably similar to leather. The revolutionare pineapple fabric is made from pineapple leaf fibres, a by-product from the pineapple harvest in the Philippines. During a process called decortication, the fibres are extracted from the leaves. The fibres then undergo an industrial process to become a nonwoven textile, which is the base of Piñatex. A by-product derived from the manufacturing process is biomass, which is converted into organic fertilizer or bio-gas and used by the farming communities, thereby closing the loop of the material's production.

Piñatex is the result of years of work and the search for an alternative to leather; a new type of natural tissue, which is 100 percent vegan and sustainable. In addition, it is also a strong, yet versatile, breathable, soft and flexible, material which can be easily printed on, stitched and cut, making it suitable for a number of fashion products. It has also won a number of awards. The next big step is to popularise Piñatex further and to continue developing and stabilizing its supply chain to meet the growing demand for its pineapple leaf, in a way that does not compromise its mission and fundamental values concerning environmental, ethical, social and economic sustainability.

Banana & lotus fibre

Banana fibre is another world’s strongest natural fibres made from the stem of the banana tree and is incredibly durable and biodegradable. The fibre consists of thick-walled cell tissue, bonded together by natural gums and is mainly composed of cellulose, hemicelluloses and lignin. Banana fibre is similar to natural bamboo fibre, but its spin ability, fineness and tensile strength are said to be better. Banana fibre can be used to make a number of different textiles with different weights and thicknesses, based on what part of the banana stem the fibre was extracted from. The material cycle is closed when producing banana fibres as they are made from waster products: from recycled banana stems, which the farmers would throw away otherwise.

Banana fibres can be used to make ropes, mats, woven fabrics as well as handmade papers. Green Banana Paper, a company based on the island of Kosrae in Micronesia, is using banana fibre to make vegan wallets, purses, beads and paper. However, extracting the banana fibre from the banana stems is not an easy, or simple, process but a labour intensive one. Banana yarn or cloth is made by boiling strips of the sheath in an alkaline solution to soften and separate them. Once this is done, the fibres are joined together to create long threads which are then spun wet, in order to prevent them from breaking. Afterwards, the threads can be dyed or weaved.

Lotus fibers have been used for special garments for centuries in Thailand and Myanmar. The manufacturing process produces a luxurious fabric that feels like a mixture of silk and raw linen that is also stain-resistant, light weight, soft, silky and extremely breathable. But in this case, the complicated and lengthy manufacturing process is the biggest hurdle when using lotus stems.

It remains to be seen how commercially viable and suitable each of the six sustainable fibres are for large scale production. Fabric made out of lotus and pineapple likely to interest the luxury market while hemp, nettles and coffee has huge potential in the mass market.

Bangladesh’s export earnings in the first quarter were 2.84 per cent less than the target set for the period. However, earnings for the readymade garment sector were 7.17 per cent higher compared to the same period a year ago. Earnings from knitwear products were 10.18 per cent up, and woven garments’ earnings were up 4.04 per cent compared to the corresponding period last year.

September earnings fell short of the monthly target. September exports were 10.18 per cent less from a year earlier and 44.23 per cent less from August. Lower shipments of garment products, which typically account for 80 per cent of the total export receipts, have been blamed for the slump in September’s export earnings. Another reason for the slowdown in garment exports in September is that it coincided with Eid-ul-Azha, so the factories remained shut for a long stretch.

Shipment of jute and jute goods grew 15.46 per cent, which is 5.87 per cent below the target for the July-September period. Home textile exports grew 23.81 per cent during July-September. Bangladesh targets reaching $50 billion in exports by 2021. It’s essential to take steps to reduce transport costs, ensure better infrastructural facilities and build deep-sea ports.