FW

Pakistan has introduced some measures for improving the textile industry. These include: imposition of 10 per cent regulatory duty on the import of yarn and fabric, especially from India, provision of long term financing to the ginning and spinning sectors and a reduction in long term financing and export financing by one per cent.

Yarn rates have risen only slightly in the domestic market but the off take remains mostly low. Thus only moderate enquiries for yarns are being received by mills. There are reports that considerable quantities of seed cotton from Sindh are being sold in Punjab due to the higher rates there.

Though yarn prices have increased moderately, cotton prices have risen further this week. Cotton rates have gone up because mills desire to produce a higher quality of yarns and textile products for the export market.

In Karachi nearly 1.4 million bales during the current season have been booked for imports till now and may total about 2.5 million bales during the current season. Quality damage has also been reported in the current domestic crop leading mills to go for imported cottons.

Domestic mills have also reportedly covered more cotton recently due to problems of lower quality of lint which may persist in the local cotton for the remainder of the season.

Messe Frankfurt (HK)’s Senior General Manager, Wendy Wen, said, “While this has been our biggest autumn edition to date in terms of the number of exhibitors, what has been more pleasing is the success, fair participants have had over the three days. The increase in internationalism of exhibitors and buyers has benefited both groups, while the country pavilions and product zones, most of which grew in size this year, have proved a great success in terms of facilitating business, and have also helped to provide a focus to the fair as it grows bigger.”

Specialised country pavilions and product zones

A lot of efforts were taken by the organisers to ensure that, as the fair expands in size, exhibitors and buyers can still do business effectively and efficiently. “This year the fair featured 11 country and region pavilions, 11 group pavilions and six product zones which created an impression of having smaller, specialised fairs under one roof, which really benefited both exhibitors and buyers,” Wen explained.

Exhibitors such as Lanificio F.lli Cerruti in Italy’s Milano Unica Pavilion were just one of those to profit from this. “It’s important to have the Milano Unica Pavilion as being here is really good for our brand image,” Daniele Sanzeni, CEO and Managing Director explained, adding, “The buyers coming here already know our brand and know that we provide top quality products, and are more willing to purchase here. The visitor flow of the first two days was incredible, and we met a lot of customers not only from China, but also from overseas including Japan, Korea, Thailand and the Middle East.”

The advantages of these areas got extended to buyers too. As Domenic Colaianni, Product Developer at Berkeley Apparel from Australia said, “The pavilions and product zones benefit us as instead of going to Europe we come here to select our fabrics, either at the European pavilions or from Chinese mills, so we can do both here. It gives us a variety of styles, products and fabric choices to choose from.”

Global touch attracts exhibitors and buyers

As the fair has developed over the years, it has increasingly become a meeting point for the global industry, rather than just the Chinese market, this was felt strongly by many of this year’s participants. “I found many good international and local brands that I might consider working with. It is just the first day, but I have already placed orders with Korean and Chinese companies,” Michel Baron, from Kazar Trade Co, Brazil said.

Taiwanese exhibitor Far Eastern New Century Corp’s Eric Hu, President, Textile Industry said, “Intertextile is an international fair for sure. The visitor flow has been fantastic, and on the second day we met customers from Switzerland, India, the UK and the US, just from half an hour of my observation.”

Intertextile Shanghai Apparel Fabrics – Autumn Edition 2015 was co-organised by Messe Frankfurt (HK); the Sub-Council of Textile Industry, CCPIT; and the China Textile Information Centre.

Milano Unica World concluded its cycle for 2015 following the success of the Shanghai VIII edition. Numerous projects for New Year are already in the making, increasing the spotlight on Milano Unica exhibitors. New textile/accessories trends will provide inspiration and substance to the production and serve as guidelines for designers regarding fabric choices. Meanwhile, the organisers say that a sort of synergy has developed between supply and demand, transforming matter and then consolidating it into shape.

“It is the law of elective visions that links the northern and southern parts of the world, making up the DNA of the S/S ‘17 trends” explains Stefano Fadda, Art Director of Milano Unica.

Trend research remains fundamental for Ercole Botto Poala, new President of Milano Unica, who says, “Despite social influence that winks to seasonless and genderless, colour and fabric trends, blend and research inspiration and important events that inspire collections, have always and will always exist.”

Firms are often influenced by the rapid and superficial rhythm of production, while the concept that only a profound creative process can invent solid and long-lasting ideas for the future remains constant. “Ideas are consolidated in the Trend Area of Milano Unica, an essential section in the heart of the tradeshow, where economic and creative efforts are formulated to provide clients with optimum service,” asserts Massimo Mosiello, General Manager of Milano Unica.

Four themes are proposed which can either coexist in one unique, intricate interpretation or evolve separately with the aim of satisfying creative and business demands for all sector operators. They are - Abyss - Depth as an inspiration, Nature and Artifice - A mosaic of real and artificial geometric landscapes, Africa Punk - Primitive and natural urban fabric and Pycho Bit - A hallucinatory trip into arithmetic progression.

www.milanounica.it

Mimaki a leading manufacturer of wide-format inkjet printers and cutting machines for the graphics, textile, apparel and industrial markets has come out with a new direct-to-textile inkjet printer, the TX 300P-1800. Mimaki offers wide format printers, large format printers, cutting plotters.

The latest printer is designed to meet the demand for smaller lot sizes, faster delivery times and the ability to quickly produce samples. It is available with a variety of ink types.

The eight-color inkjet printer features a new print head that ejects ink droplets at high speed to ensure accurate ink droplet placement with a high head gap. This makes the printer ideal for printing high quality images on all types of fabrics, including thicker and textured materials. It has been made to suit the distributed model of textile printing.

Other features include print speeds that are more than twice as fast as those of a conventional printer; stable textile transport that maintains optimum tension; a choice of sublimation dye, disperse dye, pigment, reactive dye and acid dye inks to meet a wide range of application needs; uninterrupted printing with automatic detection and cleaning of clogged nozzles; and the production of large, seamless patterns from a single image.

eng.mimaki.co.jp/

Vietnam will increase its capacity to produce cotton in order to satisfy the rising demand from garment exporters. Vietnam needs about 8.5 billion sq. mt. of fabric. The capacity to produce domestic fabric is about three billion sq. mt.

Local garment exporters need to use locally made cotton, or cotton produced by other member countries of the Trans Pacific Partnership free trade agreement, to be entitled to tax cuts when shipping products to other TPP markets. Countries have to abide by the yarn forward rule of origin, which means all items in a garment from the yarn stage onward must be made in one of the nations that are party to the TPP accord.

The TPP deal, which aims to liberalise commerce in 40 per cent of the world’s economy, was reached earlier this month. Vietnam last year produced over 9,00,000 metric tons of fiber types, but two-thirds were shipped overseas. In order to fully meet the demand for fabric, and comply with the requirements of the TPP and Vietnam-EU deals, there needs to be more incentive for business in the form of infrastructure and land use in industrial parks, improvement in sewage, and environmental management capacity.

After three days of intense activity at CNR Expo, Première Vision Istanbul closed its doors on the third edition. The event attracted 8,407 visitors, a 1.3 per cent rise over the October 2014 edition, including a 10 per cent increase in 1,530 international visitors.

“Premiere Vision Istanbul demonstrated its full power of attraction by welcoming 18 per cent foreign visitors. Our international professionals included, in particular, 24 per cent of visitors from CIS and Ukraine ; 11.5 per cent from Greece; and 10 per cent from Iran. The show's exhibitors also signalled a very positive development in terms of visitor profiles. In three editions, Première Vision Istanbul has confirmed its position as the premium hub for Middle East & Eastern Europe Fashion,” said Guglielmo Olearo, Première Vision International Show Director.

Around 161 exhibitors presented their collections for autumn/winter 2016-’17. Up by 5 per cent against the October show and comprised of Turkish companies (69 per cent) and international ones (31 per cent) from 15 countries including Italy, Germany, Portugal, France, Austria, Bulgaria, United Kingdom, Romania, the Netherlands (first participation), Lithuania, Morocco, China, India and Pakistan.

The event benefited from the active support of country's main professional associations: ITHIB (Istanbul Textile and Raw Material Exporters’ Association), UTIB (Uludag Textile Exporters' Association), Athib (Mediterranean Textile and Raw Materials Exporters Association), Eib (Egean Exporters Association) and the Turkish Ministry of Economy. The next edition of Première Vision Istanbul will be running from March 23 to 25, 2016.

“We will be rounding out the offer at the show and, starting with the March 2016 edition, proposing a manufacturing sector welcoming companies specialised in CMT (cut, make, trim) fashion manufacturing based in Turkey, Morocco and neighbouring countries. Our goal is to offer the show's visitors proximity, full-package offer,” said Guglielmo Olearo. Additionally, for the show's campaign, Première Vision Istanbul is continuing its story of iconic stars. After Arzu Kaprol for its Istanbul October 2015 edition, Première Vision has selected the globally recognised and talented Turkish designer Bora Aksu.

www.premierevision-istanbul.com

Nandan Denim Limited (NDL), India’s second largest integrated denim fabric company has one of the largest manufacturing capacities in the world. NDL is a part of leading conglomerate, Chiripal Group, established in 1972 and is currently diversified across several businesses like textiles, petrochemicals, chemicals, packaging, infrastructure, and education.

Deepak Chiripal, CEO, NDL, says that the company continued to increase its penetration of international markets to drive its exports business as revenues from exports grew 75 per cent –yo-y to reach Rs 1,36.3 crores in fiscal year 2015, from Rs 77.7 crores in fiscal year 2014.

Speaking about the evolution of denim, Chiripal believes that denim has evolved from humble casual wear to haute couture today. It is a universal fabric and not just a commodity, but the lifeline of fashion. In this context, Chiripal states that NDL is optimistic about the prospects of the domestic denim industry. Today’s youth is increasingly turning towards denim, and the company wants to capitalise on this opportunity promising to give the youth an international fabric at a local price. Chiripal says India has one of the lowest per capita consumption of 0.3 pairs in the world, with far more opportunities in the offing.

Thus, with rising denim demand, the company is well-placed to meet it and has spearheaded a capacity expansion programme at a project cost of Rs 612 crores for which the debt tie-up is completed. The installed capacity will stand at 110 million metres per annum (MMPA) of denim fabric, 124 tonnes per day (TPD) of spinning facility and 10 MMPA of Yarn Dyed Shirting facility, after the commissioning of the expansion project. Chiripal says that the project will be completed on time by the first quarter of 2017.

Shares of the textile firm Trident surged nearly nine per cent after the company reported a two-fold increase in standalone net profit for the second quarter ended September 30, 2015. The increase in net profit was mainly because of reduced expenses.

Trident had posted a net profit of Rs 20.98 crores for the corresponding period of the previous fiscal. However standalone total income of the company stood at Rs 960.99 crores for the quarter under consideration as against Rs 965.70 crores for the same period a year ago.

Trident is the flagship of the Trident Group, a billion dollar Indian business conglomerate and global player. It has state-of-the-art manufacturing processes and systems coupled with appropriate human capital and credentials. The company was incorporated in 1990. The group today exports to over 75 countries. It is one of the largest integrated home textile manufacturers in the world. With a CAGR of over 30 per cent it is the world's largest manufacturer of terry towels and one of the top 10 yarn manufacturers in India.

The company’s board has declared a second interim dividend of Rs 0.30 per fully paid up equity share of Rs 10 each for the financial year 2015-16.

www.tridentindia.com/

Novibra is introducing high speed spindles. Its new low energy consumption and noise absorption high-speed spindles are designed for tube lengths of 200 mm to 210 mm.

Its clamping and cutting crown is operated by the spindle speed and allows an automatic doffing. The improved design of the teeth guarantees a reliable clamping and cutting of the yarn. The crown is designed to reduce the risk of yarn breakage during start-up, increase energy consumption, minimise material loss and reduce maintenance. The crown is suitable for use with new machines as well as an upgrade for some old machines.

Spindles in modern ring spinning machines reach speeds of up to 25,000 rpm. In these high-speed applications energy consumption is an important issue. The company’s Noise Absorbing System Assembly ensures minimum neck bearing load, vibration and noise level at high speed. This leads to lower energy consumption.

Novibra is based in the Czech Republic. It is a leading company in spindle technology and the only 100 per cent in-house spindle maker constantly bringing innovation to the world of spinning. The leading position of Novibra spindles is based on patented design of spindle insert and the highest quality of production. Beside complete spindles, Novibra supplies also individual inserts and thus other spindle brands are also equipped with Novibra technology.

www.novibra.com

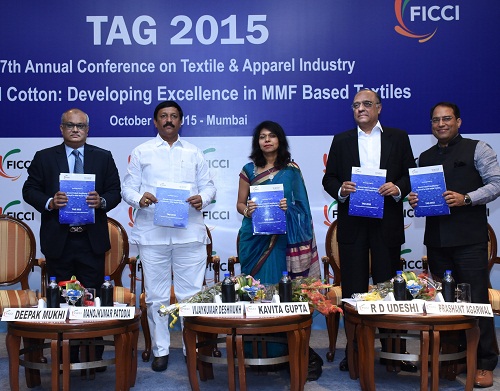

Textile ministry chalks out development plans

“For the development of textile industry in Maharashtra government is working on a new textile policy and developing and promoting various textiles park to strengthen textile clusters,” pointed out Deshmukh. Kavita Gupta, the Textile Commissioner, stressed upon the need of R&D in the textile and apparel industry, which needs to be addressed collectively and in time bound manner. She also said that the government is focusing on skills development and industry should come forward to work hand in hand with government in this area. Gupta also informed that the government will open textile commissioner’s office in every state, which will help industry to interact with the ministry on a regular basis.

In his welcome speech Manoj Patodia, Member, Ficci said that the share of polyester fibre in textile and apparel industry has gradually increased in recent years, from 34 per cent in 2000 to 38 per cent in 2014. “This pattern is expected to remain in growth phase as an alternate to cotton. Ficci has already sent its representation to the government for promoting consumption of man-made fibres to reduce the huge gap between man-made fibres and cotton,” he added.

Various experts speaking at the event were also of the opinion that the gap between natural and man-made fibres must be bridged. As Rakesh Gaur, Sector Head (Polyester), Reliance Industries pointed out, “There is no country where fiscal policies discipline the consumption of a particular fiber except in India. Excise duty was lowered but the gap between manmade fibers and natural fibers has widened, while in other fiber producing countries like China, Japan and US, there is absolutely no difference between the two. Growth in textiles has to come from growth in manmade fibers.

Man-made textiles to boost industry’s growth

R D Udeshi, President (Polyester Chain), Reliance Industries, in his address said that the growth of man-made textiles is playing an important role in textile industry. He said, since the government is aiming to increase the size of textile and apparel industry from $110 billion to $400 billion, inputs from man-made fibre segment will also multiply. Hence, man made fiber will need immediate attention on its development as cotton may not be able to fulfil that demand.

“The incremental growth in cotton will be 1.3 per cent. We are living in a multi-fibre society. So there is room for every fibre to grow. Our per capita consumption is 5 kgs, which is low. The world average is 11 kg. We have to grow and we can. We have a growing middle class, a young population, which is ready to spend 16 per cent on clothing. But policies should not be skewed or disruptive,” said Anil Biyani, Executive Director, Damodar Industries.

Prashant Agarwal, Jt MD, Wazir Advisors believes, investment in man-made fibre based textile value chain will help in successful implementation of the ‘Make in India’ initiative for textile sector. “This will help in reducing dependability on MMF based fabric imports worth $1.2 billion and make India a self-sufficient in MMF based textiles. Out of total global trade of MMF based apparel, which is currently pegged at $170 billion, India has a low share of 2.2 per cent.

Reiterating similar sentiment, Manohar Samuel, President-Birla Cellulose, Grasim Industries said, “We have some big manufacturers in India involved in man-made fibres. Birla Cellulose is one of the largest manufacturers in the world for viscose, Reliance is the largest player in rayon, polyester and polyester and rayon are the major man-made fibres in the world, so we are already quite strong in fibres. We also have a value chain which is clearly segmented into textile hubs such as Erode, Pallipaliyam which are fantastic in viscose, while Bhilwara belt has done good progress in polyester. Another aspect is, consumer demand can be best aligned in India and international markets because of the advantages India has, such as good fibre and manufacturing base.”

www.ficci.com