FW

After the signing of nuclear agreement between Tehran and US and its allies, the world is looking to do business with Iran. In fact, every industry would be affected after the rollback of sanctions, certainly the textile and garment sector is no exception.

Import of fabrics set to soar

Iran had recently announced it would be importing fabrics from Italy and other countries that had earlier announced they would do business after the sanctions are lifted. For India its good news as Iran imported $1.29 billion of textiles and clothing from the world in 2014 of which textiles was $1,292 million and clothing was only $4 million. India’s share in the Iranian textile and clothing market was 11 per cent. Iran’s total import of cotton yarn from the world in 2014 was $51.63 million. And India was the largest supplier of all types of yarns to Iran with approx $35.35 million worth of exports. India ranked 2nd in supply of made ups which was around $2 million and 5th in cotton fabrics at $3.19 million.

Experts believe that the entry of foreign producers will benefit the domestic industry by creating a competitive textile market. Companies set to benefit most immediately from the rollback of sanctions are those that are already present in Iran believes Ramin Rabii, Head of Turquoise Partners Group, an investment firm in Tehran. Germany's BDI industry federation believes exports to Iran could rise four-fold to more than $10.9 billion in the medium-term, up from 2.4 billion in 2014, thanks to the need to modernise industry.

Iran, though does have a long history of producing fabrics, however, the quality has declined in the absence of foreign competition. The feeling is that boosting of trade ties with textile producers will improve the quality of domestic products. Indeed competition is important to encourage domestic textile producers to improve their quality to attract more customers and increase their market share.

Expert’s feel boosting trade ties with foreign textile producers is vital to enhance the quality of domestic products. Italy-based fashion and cloth designer Behnoud Javaherpour, and Majid Mozaffari, a producer of traditional embroidery cloth from Yazd reiterate that Iranians have been producing fabric for the last 6,500 years. Weaving and embroidery have also been a big part of ancient Iranian textile sector. However, the use of use of new designs will help revive the industry and introduce Iranian textiles to the world.

Once the industry gathers steam, Iran has great potential to become the fashion centre of the world as the country’s textile manufacturers are capable of producing unique apparels with traditional and attractive designs. Moreover, some countries are fascinated with Iran’s culture. Iranian designers need to learn sewing techniques, painting, and fashion designing simultaneously, to lead in the global market.

Mozaffari feels that Iran should participate in international festivals and exhibitions and hold training courses to update the knowledge of weavers and improve fields such as printing, fashion designing and textile weaving, to be a part of the global fashion industry.

Meanwhile, Iran is organising Irantex in Tehran from September 4 to 7, 2015. The three day fair will be held at Tehran International Permanent Fair Ground with the active support of Association Industries, Iran Textile Exporters & Manufacturers Association, and Textile Machinery Association of Iran. IRANTEX is a comprehensive international trade fair for textile machinery and textile products. It showcases latest range of textile products, and is a networking place for leading buyers. Manufacturers of knitting, sewing, embroidery, apparel and accessories machines will be present. Also on the list are men women and kids apparel makers, home textile makers, yarn, fiber, dyestuff manufacturers among others. India’s Texprocil too will put up a India Pavilion at IRANTEX.

Dohler is one of Brazil’s leading home textile producers. It has ambitious plans to double production within five years and is constantly seeking new technologies and solutions to further improve its production techniques. Döhler was founded in 1881. It’s a family concern. It produces curtains, upholstery, table cloths, bed linen, terry towels, kitchen towels, vertical blinds and mattress covers. It has fully integrated vertical operations.

The company has recently introduced Montex stenter which has increased production speeds and significantly reduced energy costs with wider fabric widths. It has made possible finishing on a wide range of fabrics including 100 per cent cotton, cotton/polyester, cotton/viscose, viscose/polyester blends, linen, plus aramide and polyamide for military uniforms and raincoats.

The Montex has introduced wider fabric working at faster speeds. It has already provided energy saving of around 18 per cent and increased production by as much as 30 per cent with fabric widths of up to 3.20 meters. While older stenters are virtually able to finish only one particular product, the Montex can carry out virtually every application required.

www.dohler.com.br/

Official sources say, Pakistani’s raw cotton at present is being traded at an average discount of 13 cents per pound in the international market, due to lack of quality-based pricing system and non-practising of the cotton standardisation system. Analysis of the current price differential with reference to international market (Cotlook index A), and Karachi Cotton Association (KCA) shows that it is over 16 cents per pound for 13 million bales, total $780 million. Thus, this price loss would be manifold in value added textile goods.

The New York Cotton Market price was 72.50 cents per pound, on July 14, this year at China Cotton Index it was 91.25 cents per pound and Indian Cotton Index was 72.40 cents per pound. In comparison, in Pakistan it was 56.16 cents per pound, which is equivalent to Rs 5,017 per 40-kg. This price, though may touch Rs 6,000 per maund if the quality is improved.

Pakistani cotton is considered as one of the most contaminated crop in the world. It is the fourth largest cotton producing country. Cotton from the country is hand-picked with good colour, however, the weather conditions which is dry and hot is a bane. Therefore, it is traded at lower prices and considered most contaminated cotton. APTMA estimated over $1.4 billion loss due to the quality of cotton, whereas National Textile University in a study estimated over $4 billion loss because of cotton contamination.

Cotton from Pakistan is basically of good quality, and according to a six-year survey, only 8-10 per cent cotton falls in grade IV or below and over 90 per cent in Grade III (Base grade) or better. Over 45 per cent of Pakistani cotton would be traded at premium, if there’s proper standardisation.

Australian Wool Network (AWN) has launched a Direct Network Advantage (DNA) wool supply program, linking garment brands to woolgrowers on South Australia’s Kangaroo Island. Kangaroo Island is the first district to join the DNA scheme, to supply wool for KI-branded garments that will be available at 230 retail outlets around Australia, including international airports.

The DNA concept enables retail consumers to follow the journey of wool from bale to garment and allows woolgrowers to potentially have their own district knitwear brand. A key feature of the DNA program is a QRC tag (Quick Response Code) on each garment that can be scanned by a smart phone to show a video of how Kangaroo Island wool is produced. AWN is now inviting wool growers around Australia to submit wool that meets specifications suitable for the DNA program and the end product.

AWN’s DNA wool supply program was developed as a result of their purchase of knitwear manufacturer Hysport. One of the products to be available under this scheme is the luxury knitwear label MerinoSnug, one of Hysport’s premier clothing brands which is made from Australian Merino wool and New Zealand possum fur. According to Australian Wool Network Managing Director, John Colley, by controlling wool processing from bale to retail, AWN is in charge of some of the associated costs, which enables them to offer a better price for specific wool types.

www.woolnetwork.com.au

Pashmina, one of Kashmir's oldest handicraft legends and legacy is under threat from imitations as this expensive handmade fabric is slowly being overthrown by cheap, machine-made namesake. The laws in Jammu & Kashmir to protect genuine pashmina are observed more in their breach as the machine-made rival is giving the original a hard time.

According to local artisans, many influential traders have introduced spinning machines and power looms despite a ban on their use. Local artisan say wealthy traders with strong connections manufacture machine-made pashmina but the authorities are not bothered and the laws and bans are merely on paper. Also, imitation gives a bad name to the original product.

Union commerce ministry at the Crafts Development Institute (CDI) at the Baghi Ali Mardan Khan had set up a testing centre to test the purity and genuineness of handmade pashmina. Created by the central and state governments to promote handicrafts in the state, the CDI is an autonomous body, but local artisans allege that the centre exists only in name. Rouf Ahmad Qureshi, President of the Kashmir Pashmina Karigar Union (KPKU) stated that the forming of a testing centre was pointless as it never became operational. And as Gazanfar Ali, Director (Handicrafts) points out that their effort was to promote genuine handicrafts and get rid of all fakes sold in the state.

Locals lament that using spinning looms to produce machine-made pashmina is threatening their livelihood and giving the Kashmiri pashmina a bad name.

As per latest US Department of Agriculture (USDA) projections, global cotton mill usage is expected to expand for the fourth consecutive season. World 2015-16 cotton consumption is forecast at 114.4 million bales, 3 per cent (3.6 million bales) is above a year ago. China remains the leading user of raw cotton, accounting for 30 per cent of the total.

However, China’s share of the global market has declined for several years, as its cotton spinning costs have increased relative to costs in other countries. As a result, cotton mill use growth has recently shifted among countries. Using 2012-13 as the base year, global cotton mill use is projected 6 per cent higher in 2015-16, a two per cent annual growth that is near the long-term average. Although growth has not occurred in China, mill use has expanded in countries such as India, Bangladesh, and Vietnam.

In 2015-16, mill use in India and Bangladesh is expected to be about 20 per cent above 2012-13. The most impressive growth among all these neighbouring countries is being seen in Vietnam. In 2015-16, mill use in Vietnam is expected to more than double the 2012-13 level.

www.usda.gov

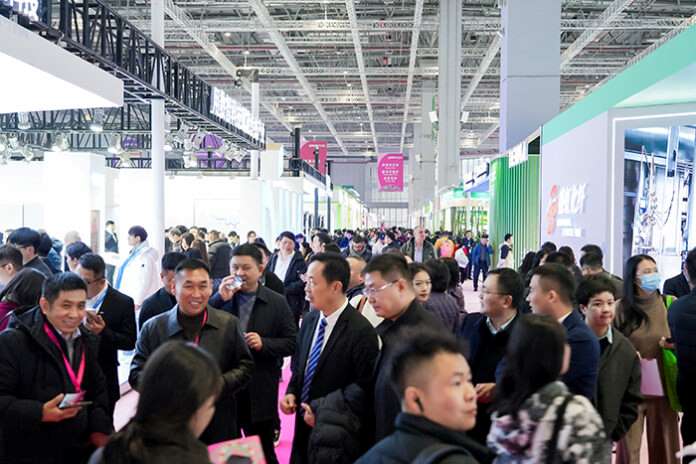

The 11th edition of Interfilière Shanghai will be back from October 12 to 13, 2015 at the Shanghai Exhibition Center with a complete offer of intimates and swimwear.Over the past 10 years, Interfilière Shanghai has grown progressively, increasing the number of exhibitors. In 2014, there were 275 exhibitors, a rise of over 11 per cent coming from 16 countries. Nearly 7,300 visitors from 53 countries visited last year, 76 per cent of them from Mainland China.

Following the success of the new layout in Paris in July 2015, Interfilière Shanghai too will follow a new layout. Exhibitors will be clearly spread across seven product-based sectors but not only in the west and east wings, but also in the central hall. In addition, seven sectors will be renamed in order to be identical to its sister show, Interfilière Paris. New sectors will now be called Lace It, Brod’Cust, Neoskin, Access’Folies, Creative, OEM /ODM and Hi’Tech.

For the second time, Interfilière Shanghai will organise the Interfeel Awards, wherein a selection globally recognised professionals of the intimates and swimwear industry will reward the knowhow and collections of exhibitors under different categories. Following the success of the workshop program on trends and brand building in 2014, Interfilière Shanghai is back with a new workshop program. Also, the exhibition will bring the industry visitors and exhibitors the most forward-looking information on trends and consumers’ insights. The program will be conducted by Edith Keller, CEO of Carlin International Group.

In July 2015, Interfilière Paris and Paris Capitale de la Création rewarded Italian company Eurojersey, leader of the textile industry for the production of patented warp knit, the Sensitive Fabrics. Developed in 1989, Sensitive Fabrics are lightweight, breathable and versatile with unique technical features and functionality and meet the most modern solid and printed trends. They are used for ready to wear, lingerie, beachwear and sportswear collections.

In January 2015, Piave Maitex has earned the prestigious title of Designer of the Year. Established in 1908 this Italian company with a long tradition in stretch fabrics relies on considerable experience and know-how to meet today’s technological challenges. Having established Piave Maitex as one of Europe’s leading stretch fabrics specialists, the collections feature nearly 200 references, which are updated each season. The Italian company was a pioneer in the shapewear sector with its Oversexy line. Its latest key innovation is Body One: a bodysuit with a non-slip quality and guaranteed comfort. Piave Maitex also promotes eco-compatible production techniques via its ‘Green Line’.

www.interfiliere.com

A $15 minimum wage slated to be implemented by 2020 may force US companies to outsource services, says a Wall Street Journal report. Los Angeles in particular, which has factories producing jeans, jackets and other apparel items employs most of the workers in the country. Manufacturers and designers feel that ‘Made in LA’ may suffer due to the impending new wage law, which would increase city’s minimum wage to $15 an hour by 2020.

Los Angeles sees more people working in garment factories than traditional business towns such as Chicago, Detroit or Philadelphia. While the number of manufacturing workers in Los Angeles and nationwide has plummeted from 25 years ago, the community has maintained its leadership position. There are about 524,000 manufacturing workers in the region, well above 409,000 in Chicago and 368,000 in New York, according to the U. S. Department of Labor figures.

The city’s wage law, which will raise the base pay by 50 per cent over five years, will surely help the working families in raising their living standards but would put a pressure on manufacturers and they may have to move out of L. A. to reduce cost burden. With manufacturers in L. A. fearing the worst, around eight cities, including St. Louis, New York and Washington, are now evaluating their proposals to raise the minimum wage to $15 an hour.

www.dol.gov

Led by the International Labour Organisation (ILO) and the government, RMG factory assessment, involving structural integrity and electrical safety inspection, may take more time to complete. Reason: RMG manufacturers have been given a couple of months more to pull up their socks. The step taken though, has not gone down well with the Inspector General of Department of Inspection for Factories and Establishments (DIFE), Syed Ahmed. Questions have been raised on the relevance of extending the deadline in a meeting held recently.

The meeting saw the presence of ambassadors from the five countries, including EU, US, Canada and the Netherlands. They too were in favour of extending the deadline. The ILO, designated to oversee the RMG factory assessment affairs, is expected to inform the BGMEA authorities soon.

The BGMEA had earlier asked for time extension from ILO on the pretext that owners will not be able to meet the deadline on account of Eid. The ILO has done this several times before. The purpose of this exercise is to implement the Sustainability Compact and progress in the RMG sector. The safety measures are the direct fallout of the collapse of Rana Plaza factory in 2013.

The Zero Discharge of Hazardous Chemicals (ZDHC) group has released a new Chemical Management System (CMS) guidance manual aimed at helping textile factories, brands, retailers and suppliers develop an in-house CMS. ZDHC feels a sound chemical management system is not only important for worker safety and to reduce environmental impacts on the community and broader environment but is a cornerstone for ensuring continuous improvement and harmonisation towards the group's zero discharge goal.

The guidance manual creates a comprehensive and pragmatic process for managing hazardous chemicals that allows an entry point for different roles in the supply chain. The manual is structured into various sections. The ‘planning’ stage involves committing to CMS as well as assessment and prioritisation. This includes an environmental audit. The ‘do’ phase involves chemicals management, the ‘check’ phase involves monitoring and the ‘final act’ stage entails management review.

In 2011, a group of major apparel and footwear brands and retailers made a shared commitment to help lead the industry towards zero discharge of hazardous chemicals by 2020. Members of the ZDHC group include Adidas, Benetton, Burberry, Esprit, Gap, H&M, Inditex, Levi Strauss, Nike and Puma and a diverse group of stakeholders.

www.roadmaptozero.com/