FW

Textile companies are working toward eradicating harmful chemical substances from their clothing supply chain. They are creating an auditing protocol, tracking progresses, publishing case studies and showing transparency through the publication of testing results. Some have chosen the chemical management gold standard by which all other fashion brands and sectoral hazardous chemical initiatives will be measured. Now that their own suppliers are committing to eliminate hazardous chemicals, these brands have no excuse but to follow suit.

Hazardous chemical groups that need to be removed include perfluorinated compounds, brominated and chlorinated flame retardants, organotins compounds and amines associated with azo dyes that can have negative effects on human reproductive systems and cause cancer.

Other areas where hazardous chemicals need to be eliminated include yarn production, fabric production, textile raw material production, yarn dyed and fabric dyed. Some 35 international fashion and textile brands and retailers—representing more than 15 per cent of global textile production in terms of sales—have already committed to a toxic-free future. Among the participating companies are Miroglio and Inditex, as well as Valentino, Adidas, H&M and Burberry.

Greenpeace’s Detox campaign aims to lead the industry toward eradicating all harmful chemical substances from the clothing supply chain by 2020.

Advanced flat knitting technology is now poised to revolutionize the sport of lacrosse. Lacrosse is a contact team sport played between two teams using a small rubber ball and a long-handled stick sometimes called a ‘crosse’. The head of the lacrosse stick is normally strung with loose mesh designed to catch and hold the lacrosse ball and it is this mesh which is being replaced with the engineered flat knit.

Sportswear and sports equipment giant New Balance has launched The Warp, a lacrosse stick incorporating an engineered flat net knitted on a Stoll CMS flat knitting machine, which is designed to catch and hold the lacrosse ball.

Each knitted pocket consists of 2,536 knitted rows, takes 1,604 machine carriage strokes with 513 stitch transfers, and is knitted in one piece with every single stitch engineered to specification. So there is no need to adjust strings before the game, between whistles, or on the sidelines. In fact, there are no more strings.

The pocket comes game ready. Unlike mesh that comes flat and hasn’t been created specifically for the head, the warp’s pocket shape is engineered with a three-dimensional knitting process, molded directly into the head. This means the pocket works in perfect unison with the entire head.

India has made changes in the duty drawback scheme to help boost exports. These industry rates of duty drawback will be effective immediately. New entries in the drawback schedule have been created for cotton yarns mixed with manmade fiber - both grey and dyed. It has also increased the drawback caps in the case of certain manmade fabrics. There is a separate entry for cotton yarn mixed with manmade fibers.

However, in product coverage some clarifications are needed with regard to the classification of some high-valued items like boiler suits and protective wear made of blends containing cotton and man-made fibers.

Duty drawback is a refund of duties on imported inputs for export items. Drawback caps are imposed on several export products with an aim to obviate the possibility of misuse by over invoicing of the export value. Steps have been taken for the smooth implementation of the three per cent interest equalisation scheme. Problems faced initially by some exporters in getting the benefit from their banks have been largely resolved.

Even though Indian cotton textiles products are competitive in world markets, preferential access being given to some of the competing nations like Bangladesh, Cambodia, by major importing countries like the EU, are affecting exports.

Pakistan’s low cotton output may hurt millions of families in the farming communities, which would ultimately affect exports and the gross domestic product. The country would miss the target of cotton production by 4.6 million bales, necessitating imports worth four billion dollars to keep the textile industry running which would hit the balance of payment situation and forex reserves.

Cotton is the backbone of Pakistan’s economy. It holds a 8.5 per cent share in the GDP, fetched 12 billion dollars through exports and provides jobs to 40 per cent of the labor. The reasons behind the low cotton output include sudden and unpredictable rains, drought in some areas, low cotton prices and a hike in prices of inputs by 15 to 20 per cent and the use of substandard seed and fake pesticides, which discouraged farmers.

The sowing target of cotton was also missed, with potentially disastrous consequences. Genetically modified seeds were introduced in the hope they would be pest resistant. But the imported seeds failed to withstand pink bollworm and whitefly attacks while sprays and medicine to tackle the pests were not available in the market. So the pests played havoc with the crop.

Cotton producers in the United States could plant up to 9.1 acres of cotton this coming spring, up 6.2 per cent from 2015. In the mid-south, growers intend to plant 1.2 million acres, which is a 24.9 per cent increase from last year. Growers in the southwest are eyeing 5.3 million cotton acres, which indicates a 6.1 per cent leap.

Elsewhere in the US, far west cotton producers expect to plant 2,13,000 acres, totaling 24.4 per cent more than what was recorded in 2015. The southeast is the only region with an expected decrease of 5.1 per cent, reducing its total to 2.1 million acres.

Planted acreage is just one of the factors that will determine supplies of cotton and cotton seed. Ultimately, weather, insect pressures and agronomic conditions play a significant role in determining crop size. Upland cotton intentions are 8.9 million acres, which is a 5.7 per cent jump from 2015. Extra-long staple intentions of 2,08,000 acres make up a 31.2 per cent increase.

History has shown that US farmers respond to relative prices when making planting decisions. Cotton is grown in 17 states stretching across the southern half of the United States. Cotton is produced on about 18,600 farms in the US.

The latest edition of Milano Unica was held in Italy, February 9 to 11, 2016. It was dedicated to fabrics and accessories and showcased collections for the spring/summer 2017 season. It had 371 exhibitors, 72 from outside Italy, as opposed to 361, 64 from abroad. Added to these, 40 Japanese companies and 13 Korean fabric manufacturers were featured in the Japan and South Korean observatories. Altogether the show hosted 424 exhibitors compared to 399 in February 2015, an increase of six per cent.

In the next September edition, the show will relocate and enjoy a complete makeover of its facilities. The reason for relocation is that the event wants to occupy a bigger space. Italy’s benchmark textile show will adopt for the occasion a new floor plan, built around a central square, a reference to a typical Italian piazza. The idea is to become an event open to international excellence, in order to create synergies with Italian know-how.

The underlying project appears to be that of bringing together several events linked to the fashion world in one place at the same time. Stress has been laid on the importance of team-work and of pooling energies together around a single, coherent project.

www.milanounica.it/

Cotton farmers in Andhra Pradesh are getting remunerative prices. They are probably benefiting from the crop damage in Pakistan, Bangladesh and China. The remunerative price has crossed Rs 4,600 per quintal, which is almost Rs 500 higher than the minimum support price. The average price in the last three years was hovering between Rs 2,500 to Rs 3,000 per quintal. Prices have jumped nearly 100 per cent from the previous season. In anticipation of a further price rise, farmers have, so far, sold just around 8 to 9 lakh bales against the total production of around 22 lakh bales.

Spinning mills who are the main buyers say farmers are refusing to part with their stocks even at prices of Rs 4,500 per quintal. So these mills fear coming under pressure in the coming weeks as the global markets are also indicating low production. The crop damage in Pakistan, Bangladesh and China has triggered a demand in global markets. Pakistan has, so far, imported nearly 30 lakh bales from the total exports of 45 lakh bales from India. India's exports too are expected to go beyond the normal 80 to 90 lakh bales.

On the whole the scenario has come as a relief for Andhra Pradesh’s cotton farmers who had witnessed huge losses in the last three seasons.

"According to officials, India was hopeful of striking a tariff-cutting deal this year, in the clearest indication yet that India wants to accelerate progress on a bloc first launched in 2012. Ganeshan Wignaraja of the Asian Development Bank (ADB) feels a breakthrough on RCEP would help mitigate the competitive disadvantage of India being absent from the TPP. Concluding an RCEP agreement would mark a key milestone for the Modi government"

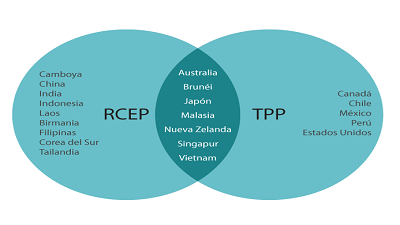

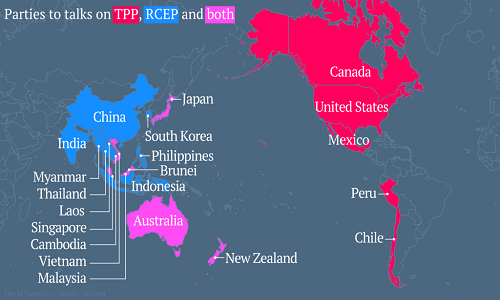

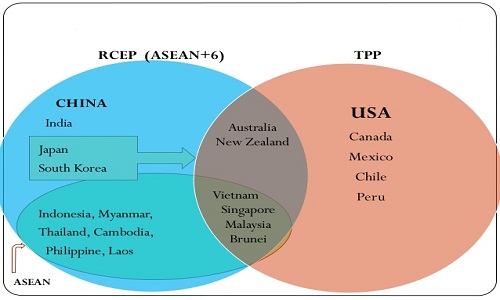

Concerned at being sidelined from the US-led Trans-Pacific Partnership (TPP), India is stepping up efforts to reach agreement with an alternative trade bloc centered around China, and hopes to reach a deal this year. India has long been seen by many countries as an intransigent player at the World Trade Organization (WTO), a multilateral forum that has struggled to find the consensus it needs to move forward. With 12 advanced economies accounting for 40 per cent of the global economy signed a TPP deal this month, India’s trade negotiators feel they need to get a move on, as Prime Minister Narendra Modi’s export-focused ‘Make in India’ drive as the path to prosperity for Asia’s third-largest economy, where per capita output is $1,688 a year, one fifth that in China.

Exploring access to Asian markets

With TPP out of reach, India was not invited to join, India’s negotiators are focusing instead on a Chinese-led grouping called the Regional Comprehensive Economic Partnership (RCEP) that would improve its access to Asian markets. To iron out differences on tariffs, a trade representatives meet is scheduled in Brunei from February 15 to 19.

According to officials, India was hopeful of striking a tariff-cutting deal this year, in the clearest indication yet that India wants to accelerate progress on a bloc first launched in 2012. Ganeshan Wignaraja of the Asian Development Bank (ADB) feels a breakthrough on RCEP would help mitigate the competitive disadvantage of India being absent from the TPP. Concluding an RCEP agreement would mark a key milestone for the Modi government.

Experts caution that India has shown little appetite to open its market to imports, even as it seeks to ramp up exports, not least because of a gaping trade deficit with China. Some experts feel, India is worried about opening up to China and so there is cloud over whether RCEP deal would happen this year. With the TPP lacking votes in the US Congress and likely to be put on hold if a Republican is elected US president, any sign China is seizing the initiative in the trade arena could raise concerns over Washington’s declining clout in Asia. Meanwhile, with backing from close US allies like Britain, Beijing has already redrawn the financial map by launching the Asian Infrastructure Investment Bank (AIIB).

Fear of losing business

Even though TPP is years away from reality, New Delhi fears losing some textile and drugs exports to countries like Vietnam, which has embraced both the TPP and the RCEP. Officials point out, it could also raise barriers to entry on labour, environment and intellectual property when it comes to seeking access to other markets.

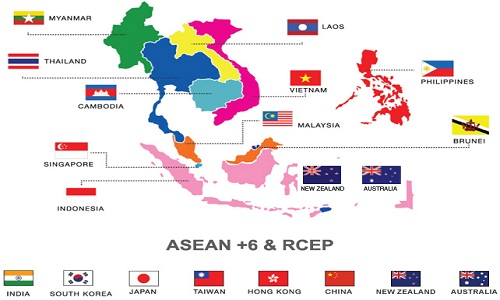

The TPP will certainly have an impact on India’s exports, believes commerce minister Nirmala Sitharaman said. It is most likely to affect sectors like leather goods, plastics, chemicals, textiles and clothing. Talks on creating the 16-member RCEP could be the last hope for some Indian companies to break into the global supply chain. The group comprises the 10 members of the Association of Southeast Asian Nations (ASEAN), China, Japan, South Korea, India, Australia and New Zealand. If signed, the regional free trade agreement would create an economic bloc with a population of 3.4 billion and trade volume of over $17 trillion.

Export industries, particularly garment and drug makers, are urging the Centre to speed up RCEP talks and wrap up trade deals with the European Union and Australia. But steel, tyre and chemical firms want the Centre to go slow, saying they have been undercut by free trade pacts already done with ASEAN, South Korea, Thailand and Japan.

Indian merchandise exports have fallen for 13 months in a row, depressed by weakening global demand and slumping commodity prices. To boost the country’s stagnant 1.7 per cent share of global exports, India needs to raise productivity and move up the value chain.

Despite a dispute over GSP facility, Bangladesh's apparel exports to the US booked double-digit growth both in terms of value and volume in 2015. The rise in garment export has been shown in US official data, in a comparative revelation of trade position with Bangladesh's competitors on the American market.

According to industry-insiders the prevailing stable political situation and ongoing safety drive helped in regaining the buyer confidence, resulting in such performance. In 2015, Vietnam, one of Bangladesh's main competitors, also registered a double-digit growth on the US market. According to Office of Textiles and Apparel (OTEXA) under the US Department of Commerce, shipment of local garment products to its single-largest destination reached $5.40 billion during 2015 calendar year, registering an 11.74 per cent growth over the previous year.

Bangladesh's apparel export to the United States fell to $4.83 billion in 2014 from $4.94 billion in 2013. The country exported 1.86 billion sq. mt. of apparel products, showing a 16.17 per cent growth, last year compared to that of 2014. Overall exports to the US, however, stood $5.60 billion in the last calendar year, up from $5.0 billion in 2014, reveals the OTEXA data.

Experts argue, though the garment-export earnings from the US market registered a double-digit growth, the price of locally-made apparels did not increase in line with the rising production cost. Meanwhile, India and Sri Lanka registered a growth of 7.78 per cent and 15.82 per cent with earnings worth $ 3.36 billion and $2.03 billion respectively in the past year, the OTEXA data showed.

Polyester manufacturer Indorama Synthetics has reported a standalone net profit of Rs 35 lakh for Q3 ended on December 31. The company had posted a net loss of Rs 58.40 crores in the corresponding period a year ago.

Net sales of the company on standalone basis during the quarter under review were Rs 585.10 crores, down 9.81 per cent, as against Rs 648.80 crores in the October-December period last fiscal. The company registered higher sales of 12 per cent in terms of volume at 83,175 tons as compared to 74,442 tons in the corresponding quarter of the previous year.

Domestic sales volume increased by 27 per cent during this period from 56,145 tons to 71,574 tons. The results for this quarter have started to fall in line with the company’s objective to make the company profitable. Cotton production is expected to remain low in this calendar year, which will help the company in improving margins. Indorama Synthetics is India’s largest dedicated polyester manufacturer. The company offers a wide range of polyester products which includes polyester staple fiber, partially oriented yarn, draw texturised yarn, fully drawn yarn and polyester chips.

www.indoramaindia.com/