FW

Panipat will have a common training facility center for textile machinery. This will help manufacturers in the area known for textile products and textile machinery to get training, about manufacturing of textile machinery and would help them upgrade skills with advanced technologies.

The center would be set up at a cost of around Rs 19 crores. The union government would provide Rs 12 crores while the state government would contribute Rs 6 crores and rest of the amount would be paid by manufacturers of textile machinery. Manufacturers of textile machinery and parts would so be able to export their products to Middle East. At present, its exported to Sri Lanka, Bangladesh, Nepal and some other countries. There are around 200 manufacturers of textile machinery and parts besides thousands of textile units in Panipat.

Panipat is about 100 km from Delhi and is at the junction between Punjab and Gangetic plains. It is known for its cottage and handloom industries. Panipat is famous for its durries, produced by a number of weaving units within the city. It also makes large sized handloom durries, rugs and carpets, blankets and a vast variety of furnishing fabrics.

Invista's Cordura brand has announced its second designer collaboration with Struktur Studio’s Michelle Rose to showcase the softer side of Cordura lifestyle apparel fabrics. The collaboration will also highlight the new Sewfree bonding technologies from Bemis Associates and garment production innovations from Youngone.

The Cordura-Struktur studio collection will include an outdoor anorak jacket, top and pants. The collection not only highlights Invista’s soft comfort Cordura apparel fabrics but also allows Invista to work with companies to support the growing demand for stylish yet performance inspired apparel for women.

Sewfree’s bonding products and design expertise provided advanced construction techniques, helping to make the collection aesthetically modern. The first Cordura collaborative collection featured a lifestyle and urban fashion capsule with Alex Valdman and his multi-purpose jacket and pant that showcased the brand’s debut of Cordura Combat Wool.

Known for its resistance to abrasions, tears and scuffs, Cordura is used in many of the world’s leading high-performance gear and apparel products. These include luggage, upholstery and backpacks to footwear, military equipment, tactical wear, work wear and performance apparel. Michelle Rose felt it was meaningful to partner with a brand that is as dedicated to being a part of the design community as Cordura fabric.

www.cordura.com/

India is again headed for a bumper cotton crop on the back of record sowing operations completed on around 110 hectares so far this year. So there is a possibility of weakening of cotton prices in the coming season owing to a huge carry over stock of around 138 lakh bales. The highest ever cotton crop was in 2007, when the country produced some 567 lakh bales. In 2013-14, cotton production touched some 401 lakh bales.

Cotton sowing still continues in Andhra Pradesh and the southern parts of the country and there has been rapid progress in southern Telangana. Among the 84-odd cotton growing nations, Indian productivity is at 32nd rank. This has been the case for the last 10 years. But India is still the world’s highest cotton producer. China comes second, having reduced its cotton acreage to some 38 lakh hectares from 54 lakh hectares last year, and US ranks third in cotton acreage with 33 lakh hectares under cotton.

This year, after China stopped imports, there has been a glut of cotton in the Indian market with a carry forward stock of some 138 to 148 lakh bales. In the last four to five years, this has been the best sowing India has ever had.

About half of the fibre procured in the crop year 2014-15 under the minimum support price (MSP) operation was sold off, by government-based Cotton Corporation of India (CCI). Since October last year, the CCI has acquired 8.6 million bales (a bale is 170 kg), totally. This it started offloading in the domestic and international markets through daily and weekly tenders. This included export of 80,000-100,000 bales to Bangladesh.

The price of cotton at Rs 33,000 a candy (356 kg) is at a four-year low. Domestic textile mills complain that CCI has not been releasing enough, though, the quantity of sale is quite considerable, which has resulted in a rise in prices. B K Mishra, Chairman and Managing Director states they had kept more than 100,000 bales on a daily basis for sale and the daily average they estimated from mills was at 80,000-90,000 bales. He added for August and September, they have kept 1.5 to two million bales to sell to the domestic textile mills.

The CCI entered into MSP operations after many years of regular purchases on behalf of customers, only on direction from the government and acquired 8.6 million bales out of its target of nine million. The problem of liquidation started with slow pick-up from China, due to slowing in the country's economy, China is one of the world's largest consumers.

In the crop year 2014-15 (October-September), the Cotton Advisory Board estimates output at 40 million bales, against 39.8 million of the previous season. The US department of agriculture estimates output at 37.5 millon bales in the harvesting season 2015-16, starting this October. Besides, CCI is looking at sales opportunities in other Asian markets such as Thailand.

Vardhman Textiles has reported a 37.27 per cent increase in consolidated net profit for the first quarter ended June 30, 2015, helped by lower expenses. Net sales in the quarter under review were down 2.26 per cent compared with the same quarter last year. Total income decreased 3.5 per cent.

Overall expenses were down 6.95 percent compared to the corresponding quarter a year ago while production improved 8 to 10 per cent. The rise in cotton prices last year impacted the June quarter top line growth. Other expenses like depreciation remained high. The company expects sales to remain flat and an EBITDA of 18 to 22 per cent in financial year ’16.

Vardhman is a major integrated textile producer in India. The group was set up in 1965 at Ludhiana. Since then, it has expanded manifold and is today one of the largest textile conglomerates in India. The portfolio includes manufacturing and marketing of yarns, fabrics, sewing threads, fiber and alloy steel. The group has also diversified into yarn processing, weaving, sewing thread, fabric processing, acrylic fiber manufacturing and into special alloy steels. Over the years, the group has expanded its spinning capacities besides adding new businesses.

www.vardhman.com/

After holding successful conferences in the past including the 1st Asian Textile Conference in 1991, the 7th Asian Textile Conference in 2003, et al, The Textile Association (India)- Delhi Unit is organising National Textile Conference 2015. The conference to be held on October 26 and 27, 2015 in New Delhi will be on the theme: ‘Make in India: Destination Textiles’.

Textile industry plays an important role in Indian economy as domestic consumption and exports of textile and clothing amounts to approximately 6 per cent of the GDP. This sector contributes to almost 12 per cent of the total export earnings of the country and employs more than 100 million people, directly or indirectly. The textile and clothing market size has grown at a compounded rate of 12 per cent per annum from $66 billion in 2009 to $115 billion in 2014. The industry is projected to remain on a high growth path and reach $535 billion by 2024-2025. The conference will focus on the importance of implementing the national program in Indian textile industry.

The two day conference will see a mix of presentations and panel discussions involving renowned textile sector stakeholders of the country. The key topics include facilitating investment, fostering innovation, enhancing skill development, protecting intellectual property and building best-in-class manufacturing infrastructure which is the underlying aim of ‘Make in India’ campaign. The discussions will present India's manufacturing competitiveness in terms of raw material availability, manpower resources, technology and infrastructure and delve on key growth constraints.

Facilitation of investment in India is one of the key objectives of the conference. The focus will be on ways to foster investment in the sector and importance of partnership to bring investment as well as technical know-how. The conference will also witness a cultural program and fashion show by students of fashion institutes in the region.

www.textileassociationindia.org

Focus on denim as active wear

First used as a fabric for workwear, denim is now facing a threat from new-found ‘Athleisure’ trend. But denim has survived and triumphed many such challenges over decades and the challenge has continuously raised the bar of this versatile fabric pushing denim players to continuously experiment and innovate. The more they stretched their imagination, the fabric evolved.

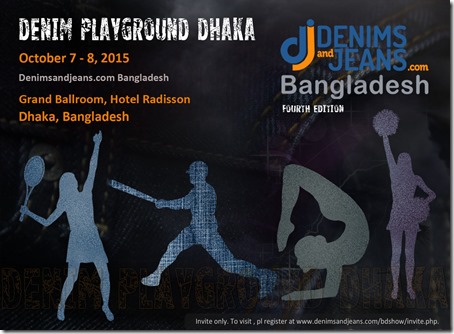

The fourth edition of Denimsandjeans.com Bangladesh to be held at Radisson Dhaka derives its inspiration from ‘Denim Players’. The theme is aptly selected as ‘Denim Playground Dhaka’, where exhibitors from around the world will showcase their sporty innovations to visitors. It will emerge as a playground for denim lovers.

Elaborating on the theme Sandeep Agarwal, Organiser, Denim Playground said, “Bangladesh today is the most important destination for denim sourcing and it is our endeavour to bring the world industry together on this platform to further develop business from this region. Our next show in October shall have the 'Playground’ theme emphasising the active wear aspect of the product and constant innovation inspired by the athleisure trend. Our exhibitors will bring their high-tech products in the supply chain to cater to this growing trend and enable the retailers and brands to source fabrics and garments from this region.”

Prime global event for the denim industry

Last edition saw over 400 companies attending the show including most reputed retailers, factories, buying houses and, brands such as: Tesco, Tom Tailor, C&A, Carrefour, Coolcat, Celio, Charles Voegele, Cortefiel, Uniqlo, S.Oliver, Walmart, Debenhams, Dewhirst, El Corte Ingles, Esprit, Grouppo Coin, H&M, HEMA, Hermes, OTTO, O’stin, Inditex, Kappahl, Kmart, LCWaikiki(Tema), Levi Strauss & Co, Li & Fung, Lindex, Marks & Spencer, Mondial, New Times, Next, Perry Ellis, PVH, Redpoint, S. Oliver, Sainsbury’s, Target and VF Corp.

The event also witnessed ‘The Godfather of Denim’ – Adriano Goldschmied and renowned denim consultant, Piero Turk, whose views about the show were very encouraging for the industry. Sustained focus on eco sustainability has always been the mantra of Denimsandjeans.com website as well as its shows. In the last show, GIZ -Deutsche Gesellschaft für Internationale Zusammenarbeit Gmb was the technical partner, who organised the panel discussion ‘Development Prospects in Denim Production – the Way Forward’ with a focus on eco sustainability. The fair also had fashion in denim event called ‘FASHIONIM’ sponsored by three exhibitors.

The long list of exhibitors included Artistic Fabric Mills Garment Industries, Artistic Milliners, Arvind, Bhaskar Denim, Denim International, DeriDesenetiket, Envoy Textiles, Foison Textile, Ginni International, Ha-Meem Denim, Indigo Textile, Litun Fabrics, Mafatlal, NDL, ORTA, Nahar, Pacific Denims, among others.

Japan's Toray Industries recorded high sales in its Czech subsidiary, Toray Textiles Central Europe (TTCE). With a boost in textile sales, the company is strengthening its position in Central-Eastern Europe’s textile market. TTCE’s sales went up by 72 per cent to about €51 million, last year. This was due to a higher demand for its products and relatively weak Czech krona. The company expanded its net profit by about €5.8 million, which is in line with its rise in sales in 2014.

Due to the facility’s increasing sales, which is located in Prostejov, in the Czech Republic’s south-eastern part, the group is now the largest foreign investor in the country’s Olomouc region. The company plans to expand its output capacity further and create 30 new jobs at the Czech plant this year.

Toray Industries’ products are 100 per cent polyester filament fabrics, plain taffeta, textured taffeta and pongee. Besides, TTCE is the first Czech-based firm to make textiles for automotive air bags, besides, lining cloth, sportswear, furnishing materials, outer-wear, and base fabric for industrial use.

Shozo Sugaya, chief executive of TTCE said that increased share of higher added-value products resulted in improved sales and subsequently, improved financial results for the firm. TTCE increased its sales of polyester lining fabric by 27 per cent, and sales of fabrics used in the manufacturing of airbags by 22 per cent, last year compared to the sales of the same in 2013. According to Sugaya, this was because of increased sales to automotive parts maker Autolive, which is the largest supplier of airbag components in the world.

Hugely popular apparel brand, Executive Order Clothing (EOC), has announced that it would be moving its production from Pakistan to Waterloo, Canada. Apparel brands that have high standards for their clothing and for ethically sourced and manufactured materials, are in great demand. The young, yet promising brand, Executive Order Clothing covers all these aspects well.

Michael J Young Jr, EOC’s founder stated that apart from the brand making remarkable progress even though relatively new, it was also making positive changes to ensure longevity. ‘Cut and Sew’ designs for ladies will be the first step in expansion for the brand on September 11. V-Necks, T-shirts with alligator skin and genuine leather, Polos and sweaters, etc, will be included in the range. Most of these would be handmade, and look and feel stylish.

EOC’s new collection is for both men and women. Men’s shirts will display stunning art and design, crafted by the staff that include experience with some major players such as Akademiks, Ralph Lauran and Enyce. While its women’s wear range spells ‘elegance’ according to young.

Besides, an ‘Executive Exchange’ insurance policy on items priced $35 and above will be offered to customers, where they can exchange any clothing item for a brand new one, no matter in what condition the garment is in.

The predominantly cotton based textile industry in India has been facing several challenges in recent times owing to higher tariffs imposed on Indian textile products in all major international markets compared to competing nations. Undue delay in disbursing Technology Upgradation Fund Scheme subsidies, volatility and uncertainty in cotton prices, sudden glut in the synthetic yarn market, closure of dyeing units in northern states resulting in accumulation of fabric stock in different power loom clusters have added to the crisis of the sector.

At present, the spinning sector has 10 per cent excess capacity, due to poor demand for yarn exports though there have been improvements in recent months resulting in accumulation of yarn stock and liquidity problems. To discuss various problems being faced by the spinning sector, and to decide on the future course of action to mitigate the crisis, the Southern India Mills Association has convened a meeting of its member mills today.

Spinning in India can be classified into two categories: medium and long staple. Development of new varieties of seeds and adopting advanced procedures of cultivation will add to the profit in the cotton textile sector of the spinning industry.