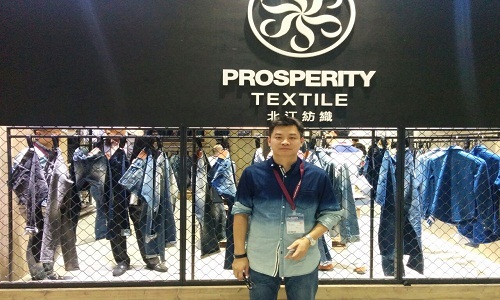

"A global leader in denim fabric Prosperity Textile has introduced multi fiber types. These are different fibers like cotton, Tencel, polyester rayon, etc, blended together to improve performance and the features. The company, founded in 1999 in China, will also start operating its Vietnam unit from next month. The unit has one roller dyeing for the denim. “We have around 120 looms and one full set for finishing. So our first phase capacity is 1.2 million yards per month,” explains Andy Zhong, Managing Director. The second phase of production will start in 2019 and by 2020 the aim is to reach five million yards. In China the capacity of Prosperity Textile for denim is about 80 million yards per year. “And by next year we will be close to about 100 million yards a year. Finally it will be more than 120 million. That’s the total capacity because we have 80 million in China, about 40-50 million in Vietnam.”

A global leader in denim fabric Prosperity Textile has introduced multi fiber types. These are different fibers like cotton, Tencel, polyester rayon, etc, blended together to improve performance and the features. The company, founded in 1999 in China, will also start operating its Vietnam unit from next month. The unit has one roller dyeing for the denim. “We have around 120 looms and one full set for finishing. So our first phase capacity is 1.2 million yards per month,” explains Andy Zhong, Managing Director. The second phase of production will start in 2019 and by 2020 the aim is to reach five million yards. In China the capacity of Prosperity Textile for denim is about 80 million yards per year. “And by next year we will be close to about 100 million yards a year. Finally it will be more than 120 million. That’s the total capacity because we have 80 million in China, about 40-50 million in Vietnam.”

A global leader in denim fabric Prosperity Textile has introduced multi fiber types. These are different fibers like cotton, Tencel, polyester rayon, etc, blended together to improve performance and the features. The company, founded in 1999 in China, will also start operating its Vietnam unit from next month. The unit has one roller dyeing for the denim. “We have around 120 looms and one full set for finishing. So our first phase capacity is 1.2 million yards per month,” explains Andy Zhong, Managing Director. The second phase of production will start in 2019 and by 2020 the aim is to reach five million yards. In China the capacity of Prosperity Textile for denim is about 80 million yards per year. “And by next year we will be close to about 100 million yards a year. Finally it will be more than 120 million. That’s the total capacity because we have 80 million in China, about 40-50 million in Vietnam.”

Multiple blends within single fabrics

Prosperity Textile offers multiple blends within single fabrics. “Some fabrics have three to five blends,” Andy says. “You can see more colors like the indigo for winter. Every shade of this color has a different dyeing process, with different dyeing stuff, material etc. The dark blue shade is in demand as it is easily washable and easy to maintain,” he adds.

see more colors like the indigo for winter. Every shade of this color has a different dyeing process, with different dyeing stuff, material etc. The dark blue shade is in demand as it is easily washable and easy to maintain,” he adds.

The company’s products are exported worldwide. “Our major markets are: Bangladesh and Vietnam followed by Cambodia, Indonesia and other Asian countries,” Andy informs. “We sell around 50 to 60 per cent to China and export around 20 per cent to Bangladesh. Exports to Vietnam, Cambodia and Indonesia is about 5 per cent each,” he adds.

Business under pressure from rising prices

Talking about business Andy says, “Business this year is challenging. Demand is good but costs of material, dyeing ingredients, chemicals etc, have increased.” The reason for price increase is rising costs in China. “Also, there was a lot of focus on compliance during the first half of the year though it did not affect us; it affected others like the chemical supply chain etc, price of dye stuff increased 30 to 40 per cent during the first half of the year. And supplies were tight,” he adds. Prosperity Textile believes in fast delivery and therefore, keeps fresh inventory in large numbers. “We want to maintain prices of raw material, which puts a lot of pressure on us. But after the first six months, things have become easier now. Normally, second half of the year has a larger market share than the first half. This year, we have seen a modest increase compared to last year,” he adds.

Growing demand for denim

Andy points out, in the last few years, demand for denim has increased exponentially. “Brands and retailers have increased their denim portfolio, which makes us more confident of growth in the next few years,” he states. “Pressure from the other segments provides a lot of useful information, as we get better reference about denim requirements. In the past few years, denim has seen a lot of changes,” he adds.

Elaborating on upcoming denim trends, Andy says, “About 70 to 80 per cent of the denim fabric today is stretch. It is the current market trend. So, we work on four ways stretch or a comfort stretch. We also use sustainable materials, like sustainable cotton, sustainable recycled cotton, polyester etc. Ideally, this would offer more comfort and style,” he concludes.