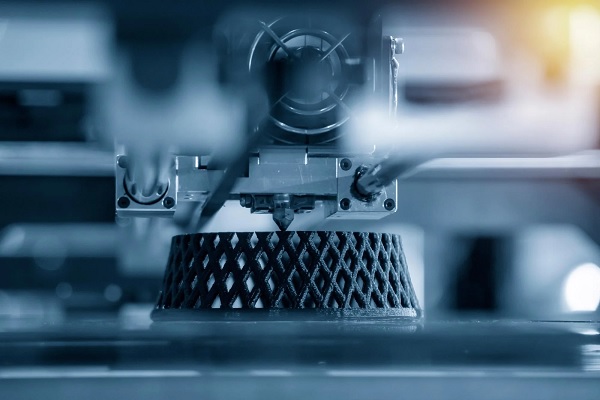

It was just a matter of time that the fashion sector would embrace 3D printing technology as the way forward with textiles, samples, embellishments and accessories. The advancement in 3D printing and 3D scanning are set to usher in huge changes in the production process of the fashion and textile industry. These sectors have quickly noticed the advantages and fashion designers and textile manufacturers are on an experimental run. 3D printing technology has opened up endless possibilities hitherto unexplored by both, designers and textile manufacturers - different shapes and geometries that can generate amazing outfits and prints.

Sustainability is a driver

As consumer trends indicate their preference for sustainable clothing and accessories, the efficiency and wastage-saving features of 3D printing are winners. Whether it is creating prototypes and samples to bespoke haute couture, 3D printing technology cuts down on fabric wastage enormously. This is a badge fashion labels can proudly proclaim – from runway to store with minimum wastage. Look at it this way – water usage in the manufacturing of textiles and fabrics has become a worldwide debate, wasted fabric from creating outfits is another topic fashion brands are grappling with and emissions from textile plants is also on the hit list of unsustainable production processes as are dyes used as colorants that are chocking vast numbers of water bodies. Enter 3D printing and it seems poised to drive fashion and textile industries towards a greener methodology. Additionally, 3D printing technology has another clear advantage – speed to market with garment lines being printed within 24 hours and ready for shipping.

Designers’ dream

3D printing has enhanced the limitless possibilities in terms of not only designing patterns for textiles but also for garments. Fusion of legacy and contemporary design elements can be achieved in minutes and embellishments added to textiles in a matter of hours. This is a great advantage for creating unique rolls of fabrics and outfits, making the art of bespoke much less time consuming and drawing board nightmares.

Is 3D knitwear the most environment- friendly?

Whilst 3D printing does impact on wastage, can it be said to be truly environment-friendly? 3D printing mostly uses plastic and metal and therefore is not the best green solution. Moreover, plastic and metal are not flexible enough. 3D knitwear is something that may provide a better solution for not only the textile manufacturing sector but also for fashion designers. Researchers are looking into viable options as knitwear machines can produce a 3 dimensional garment in a single pass by uniting threads one after another. It eliminates the usage of plastic and metal filaments by staying on course with natural fibres.

From concept to commercial

The concept of 3D printing to revolutionise the manufacturing of textiles is still at a very inchoate stage with commercial mass production in the distant future. Many R&D wings of major companies such a Teflon, 3M and Dupont are working below the radar at the moment to find out cost-efficient and greener filaments that can actually live up to the sustainability element of 3D printing of textiles. One emerging process that has proven to be successful in this regard is the 3D panel printing on textiles. It well may be that collaborations between textile manufacturers and innovation companies will speed up the process for mass production soon.