FW

As the 40th edition of IHGF Delhi fair organised at the India Expo Mart in Greater Noida, by Export Promotion Council for Handicrafts (EPCH), the nodal agency for promotion and development of handicrafts in the country, drew to a close, business enquiries worth Rs 2,700 crores were generated.

Rakesh Kumar, ED EPCH, mentioned that over 7,300 trade visitors interacted with India’s handicraft sector making it the world’s largest fair of Indian handicrafts, home, lifestyles and fashion products. The visitors included international buyers, buying agents and domestic volume retailers.

The IHGF Delhi fair played host to over 2,750 exhibitors spread over 1,90,000 sq mts area, this year, with more than 1,600 product lines and styles at state-of-the art India Expo Centre & Mart, Greater Noida.

Over 110 countries and Indian volume retail visitors mesmerised overseas volume buyers with their spectacular display of traditional Indian art and craft. Products on display included house ware, tableware, kitchenware, hotel ware, home furnishing, home textiles, linens, festive decor, Christmas, Halloween, birthdays, anniversaries, celebrations, fashion jewellery, bags, scarves, ties, fashion compliments, luggage, leather bags, furniture, hardware and accessories, carpets, rugs and floorings, bathroom accessories, candles, incense, potpourri and aromatics, stationery, lamps and lighting, chandeliers, lanterns, decorative articles & giftware, garden ornaments, lawn accessories, sustainable products, jute, cane, bamboos, natural fibres, educational games, etc.

Moreover, various knowledge seminars were held along with cultural programmes and fashion shows. Besides, Bhagwat Saran Gangwar, Honble Minister of State for SSI & EP, government of Uttar Pradesh presented the prestigious Ajay Shankar Memorial Awards for best display and design in 10 product categories.

www.epch.in

The oldest registered textile association in Tirupur knitwear cluster, South India Hosiery Manufacturers Association (SIHMA), celebrated its 60th founding day.

S A Khader of Travancore Knitting Company, was the President, when the journey started with 106 member textile units in 1956. Since then, the membership rose to over 1,500 at a point and presently stands at 555 units.

A C Eswaran, SIHMA President said that earlier units that constitute entire apparel production chain such as knitting, dyeing, compacting and garment-making were members of the SIHMA. However, he said, the membership dipped once the segment specific-Associations for different stages of production such as exports, dyeing, compacting, fabrication and knitting, etc., started coming up. A majestic diamond jubilee building has been constructed by the SIHMA at an outlay of Rs 1.1 crore.

The rapid strides in the growth of the region as a knitwear cluster apparently happened after the formation of SIHMA, although Tirupur had gradually started becoming the investment destination for apparel production from a single textile unit that functioned in 1928.

Eswaran stated that the formation of SIHMA had facilitated arrangement of institutional loans for the hosiery industry and import of high quality machines for apparel production in the 1960s. Besides, during the mid-70s, SIHMA initiated the first modernisation drive in the cluster, after which it started gaining its prominence as an export hub, he added.

Moreover, SIHMA initiated the periodic wage pacts since early 1970s. This was non-existent in majority of the industrial clusters across the country at that period, say the workers.

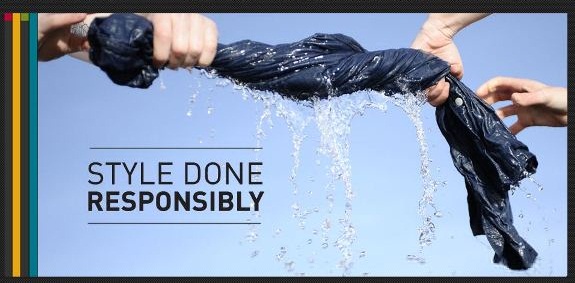

With sustainable buying making huge strides among consumers, there’s still a huge disconnect between consumer demand for more ethical products and a lack of awareness of how and where the clothes are made. Lee said that this is because the complexity of the apparel chain and also the trend of ‘fast fashion’ augmenting the issue.

Since ‘fast fashion’ is frowned upon, as it moves quickly from production to retail to offer the latest trends, Lee believes we need a cultural shift towards endurance of apparel products to address this.

He said that durability and quality have to be the value proposition for our clothing, instead of the thrill of buying the next new thing. He also predicted that the industry has almost reached a tipping point with consumers, however, the industry is still struggling with how to make those consumer connections.

‘Remake’, a start-up seeded by the Levi Strauss Foundation, Lee said, is working to engage consumers in a fresh way to learn about the people behind the products they buy. The organisation’s vision is to create a community of conscious shoppers through films, visual story-telling and immersive journeys.

Ayesha Barenblat, Remake’s founder said that they aim to move away from the pain narrative that has for long paralyzed consumers into inaction. They instead, build human connections between shoppers and makers, she added. By pain narrative, Barenblat refers to changing the conversation from scare tactics, shaming or short-lived calls, to boycott after a factory disaster, toward more meaningful engagement.

Other stakeholder groups such as labour/human rights advocates and shareholders are increasing their expectations of transparency from apparel brands, while consumers are demanding more responsible products. Companies though, feel the pressure to do more than just follow the law; they feel the need to demonstrate actual social impact within their supply chains.

Penetration in the supply chain

One company to put efforts and resources into moving from compliance to deeper engagement with its supply chain and saw results, is Levi Strauss & Co. Lee told the SXSW Eco audience how the company has put millions of dollars in supply chain worker programmes to address issues such as health and financial security.

In 1991, the early days of apparel outsourcing of labour, Levi Strauss adopted a code of conduct called its ‘Terms of Engagement’ (TOE), or as Lee put it—‘the code that launched a thousand codes’. In 2011, Lee partnered with the business side to establish the ‘Improving Worker Well-Being’ initiative for apparel workers in communities where Levi Strauss’s products were manufactured. From just a compliance-focused ‘do no harm’ labour policy, the idea was to move and truly collaborate with suppliers on the ground to make a tangible impact on workers’ lives.

Recently, the finished pilots of the ‘Worker Well-Being’ initiative in Bangladesh, Cambodia, Egypt, Haiti, and Pakistan. Here, it provides support, surveys and curricula to suppliers on topics such as financial security and women’s health, connecting suppliers with local partners to help them meet the TOE.

Looking into workers’ well-being has resulted in Levi Strauss witnessing a return of up to $3 for every $1 invested in ‘Worker Well-Being’ initiatives, across the supply chain.

Finding the right partners is one of the biggest obstacles in implementing these programmes. To build capacity in developing nations to better serve workers, the NGO sector serving supply chains needs help. Thus, the company focuses its programmes in nations with the most marginalised communities. Lee said that they look at who is the most impacted, and invest in nimble organisations to build bridges with suppliers.

Standing up marginalised people isn’t really reinventing the wheel for Levi Strauss, Lee mentioned. It, in fact, builds on a 163-year history of being a values-driven company.

www.levistrauss.com

Switzerland’s Bluesign Technologies has selected Archroma’s One Way calculation tool as the engine behind its resource tool that is due to be launched in 2016. Archroma is a global leader in colour and specialty chemicals. It was the first to introduce a tool that would help its textile customers make the best choices in favor of resource optimisation.

The new tool BlueXpert represents a milestone in resource-efficient textile production, as it enables manufacturers to immediately save 50 per cent water, 30 per cent energy and 15 per cent chemicals during the production process.

Via this initiative, Archroma is joining with other textile chemical leaders to help textile brands, retailers and manufacturers to make the best choices for more sustainable processing of textiles.

One Way was designed to demonstrate it is possible to bring together the dual objectives of ecology and economy. The tool provides a fast, measurable and reliable approach to selecting chemical product and resource-saving process solutions.

BlueXpert operates within the high-security IT environment of Bluesign technologies, as it is hosted in the firm’s state-of-the-art data center in Switzerland. BlueXpert also includes proprietary algorithms specific to Bluesign criteria, such as the air emission factor. This tool is exclusively available to Bluesign partners only.

www.bluesign.com

The European Union (EU) will give the GSP plus trade concession to Sri Lanka next year, says the country’s government.

Harsha de Silva, Deputy Foreign Minister said that the EU and the Sri Lankan Government are working together to regain the key trade concession. While speaking at an event attended by several garment factory workers and officials of the garment industry, he stated that they were working together with mutual respect to get it done by mid 2016 since they had established a government of good governance with respect for human rights.

A recent technical paper on the ‘World Economy’ showed that the loss of the trade concession had a negative impact, with the worst affected being the low-income workers in the cities, de Silva said.

When the former Government was in power after it failed to meet the criteria to continue as a beneficiary, Sri Lanka had lost the GSP plus trade concession from the EU. The new Government, however, had reapplied for the concession and had made commitments to meet the required criteria.

Philippines has begun preliminary negotiations to join the Trans Pacific Partnership (TPP) countries. But there is a possibility that joining the TPP might result in the Philippines’ getting flooded with duty-free American products.

The major textile and apparel countries – China, Bangladesh, Cambodia – are not going to join the TPP. This presents a golden opportunity for the Philippines to revive its textile and apparel industries.

Since China is organizing its own common market, the manufacturing hub of the TPP will be Vietnam and, hopefully, the Philippines. The Trans Pacific Partnership is envisioned to be similar to the European common market. The goal is to eliminate trade barriers, especially tariffs and quotas, among countries in the Asia Pacific region.

Joining the TPP will mean more jobs, faster economic growth and reduction in poverty. The biggest beneficiary of the TPP would be Vietnam. This country has the lowest wages compared to the other TPP members.

The United States is interested in joining because the TPP will open up new markets for its service industries. This will present potential competition for local companies in the financial and professional services.

The TPP will create the most powerful and wealthiest economic region in the world. The 12 countries now in the TPP account for 40 per cent of the world economy.

After three intense days at the Milano Unica Pavilion, the 8th edition of Milano Unica China ended on a positive note.

“I conclude my term today, at a tradeshow that once again has confirmed its appeal to the top-end Chinese market. The positive outcome of Milano Unica China VIII demonstrates that even a more demanding market can find answers among the textile-accessories proposals of our exhibitors,” confirms Silvio Albini, President of Milano Unica for eight seasons, who officially handed over the leadership of Milano Unica World to Ercole Botto Poala.

Satisfaction reigned among the 94 exhibitors who presented their F/W 2017 collections to a market which is always open to innovation and research by the Italian textile-accessories industry. Guided by a stunning and highly acclaimed trend area, guests were able to visit stands with clear ideas about the type of product they were looking for, geared to top-end Chinese fashion.

Attendance rose three per cent over the previous October 2014 figures. The women's wear market is growing and has become part of Chinese high society, and the classic menswear market is also on the rise, together with a new sector dedicated to leisurewear which is beginning to take hold. Even though it does not directly affect the number of visitors, the new image of a united Made in Italy, that promotes its production chain with elegance and style, has certainly had an impact on a population which is already fascinated by the glamour of the Italian lifestyle.

“The presence of Filo together with Milano Unica, featuring seven ‘pioneer’ spinners in China, and at the same time ‘La Moda Italiana’ in the enormous fair headquarters in Shanghai, demonstrates that things have changed and much more can also happen”, emphasizes Massimo Mosiello, General Manager

www.milanounica.it

Bringing together the world’s most influential textile business leaders to debate issues of strategic importance to the global industry, the World Textile Summit is perhaps one of the most unique one-day events.

To be held on November 1, 2015, the summit will address what really matters to strategic decision makers such as what returns can be expected from capital investment in clean technologies, and what do investors think about sustainability issues.

Aloe Group’s co-founder, Vivek Tandon will set off as to why strong sustainability credentials can help a business to attract investment from capital markets. The mission of the company, it states is to develop hard-asset based companies, which provide proven technological solutions to environmental and social challenges, especially those experienced by the high growth markets of Asia. The company will base its approach on the UN Global Compact.

Paula Oliveira, Director, Interbrand will explore, through their commitment to sustainability, how companies can differentiate themselves from their competitors and further build a unique identity that will attract customers.

A recent survey of CEOs by the United Nations Global Compact on sustainability, revealed that 'brand trust and reputation' were their top reasons for taking action on sustainability. This is what Oliveira’s advice was based on. Others, though, stress that sustainability must be about driving substantial and authentic change and warn regarding the temptation of 'green-washing', which can undermine trust.

www.worldtextilesummit.com

India’s share in the global apparel trade has remained modest, with a share of just four per cent last year. The country’s market share in world trade has not significantly changed despite the depreciation of the Indian rupee during the last three years.

While China, Bangladesh and Vietnam have increased their share in the global apparel trade substantially, India's share has remained modest despite the fact that India is among the largest producers of cotton and man-made fiber and has the second largest capacity for spinning and weaving.

China is the largest apparel exporter on account of the largest global capacities across the textile value chain. The fragmented nature of the weaving, processing and garmenting industries, the low levels of modernisation, high costs of production, the modest share of non-cotton apparel and a reliance on imported machinery across the textile chain have been the key factors which have constrained growth in India's apparel exports.

It is the spinning sector that has mainly availed of the benefits of the flagship program for textile sector upgradation, the Technology Upgradation Fund Scheme. The downstream sectors (weaving, processing and garmenting) have witnessed limited participation. The domestic apparel market has grown at a mean annual growth rate of 10 per cent over the last five years.

Recently, at HCM City's War Remnants Museum, a collection of Vietnamese ao dai and Indian saris was showcased at a fashion show held there.

Organised by the Indian Consulate General of HCM City and the Ao Dai Museum, Ao Dai and Sari—An Ever Unbreakable Friendship was held to celebrate Vietnam Women's Day.

Over 50 designs made with high-quality materials were featured on the catwalk. Women of the Indian community presented nearly 20 elegant and charming designs of saris in bright colours.

Designers, at the Ao Dai Museum offered Vietnamese models ao dai, which they wore. The outfits were made of silk and voile decorated with printed images of flowers and sparkling details.

Pham Huong, Vietnam Miss Universe 2015 was invited to perform on the catwalk in both, the sari and ao dai. Duc Hai, Vietnamese supermodel was also paired with Huong in the ao dai catwalk. Indian artists performed at the event as also Vietnamese war veterans and the famous singer, Nguyen Phi Hung.

Consul General of India in HCM City, Smita Pant said that the show was expected to encourage the young generations of India and Vietnam to learn more about their traditional costumes, and to preserve and promote them. Also, the collections would open for another fashion show in December. This show, organised by famous ao dai designer Si Hoang, present Vietnamese costumes made in Indian traditional fabrics.